Bioreactor-Fermenters Suppliers & Exporters in Australia

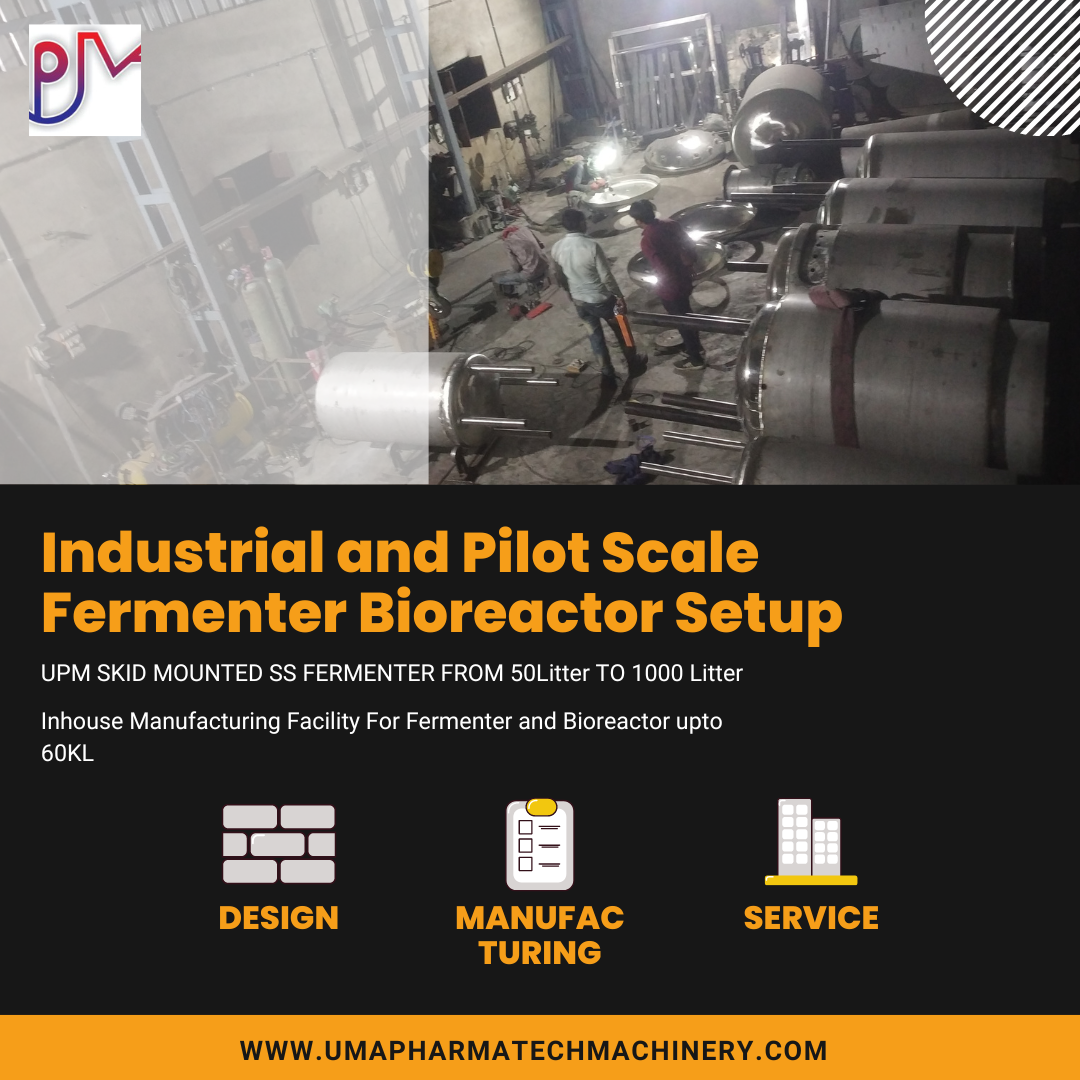

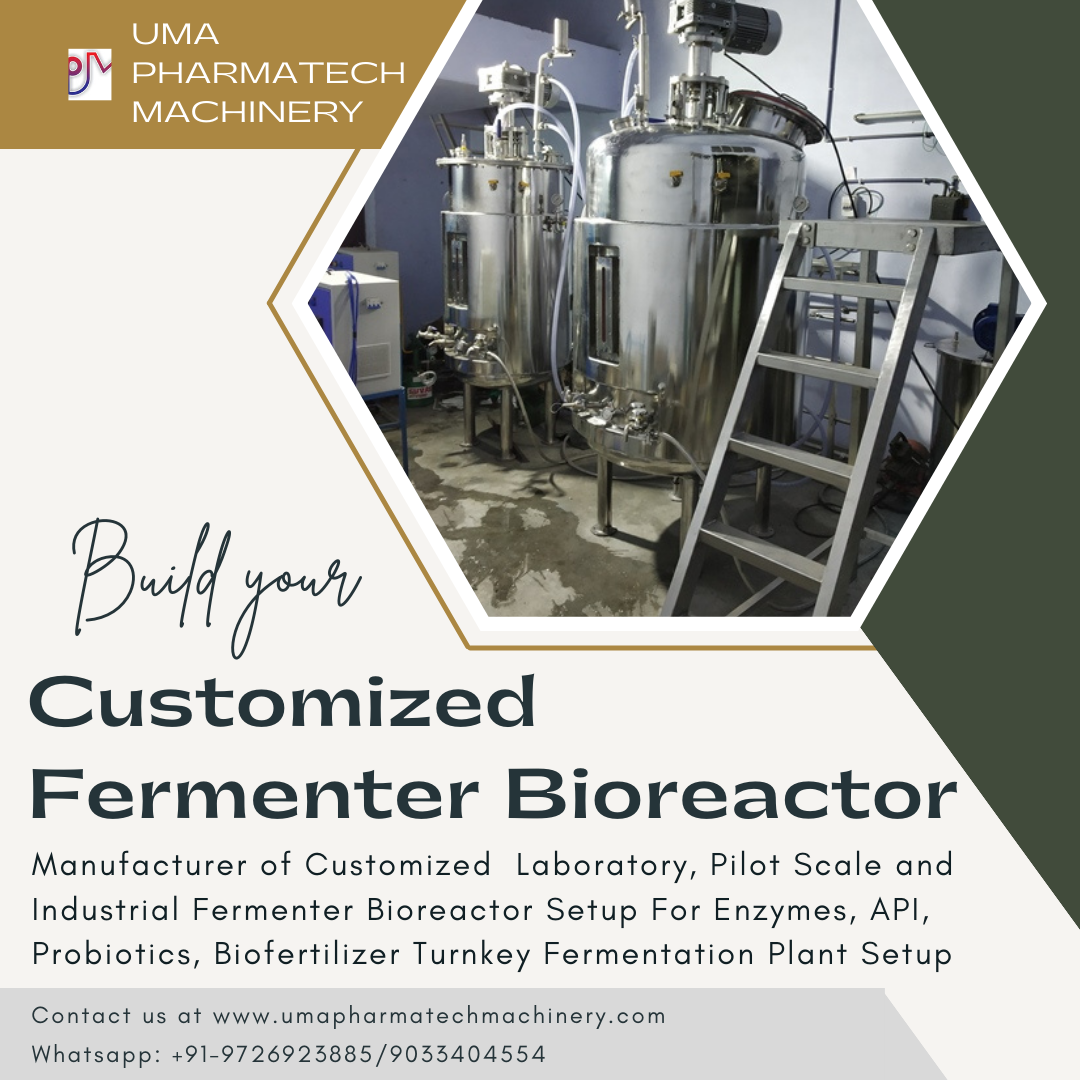

Uma Pharmatech Machinery emerges as a distinguished source site Bioreactor-Fermenters manufacturer and supplier, contributing significantly to the industrial landscape in India. Our commitment to quality and innovation has solidified our position as a leading player in the market. As a reputable source site Fermenter Manufacturer, we pride ourselves on providing top-notch solutions tailored to the diverse needs of various industries. Our state-of-the-art facilities empower us to deliver high-performance fermenters that adhere to stringent industry standards. Uma Pharmatech Machinery, a name synonymous with excellence, stands out as a reliable partner for efficient and trustworthy fermentation processes. Explore our comprehensive range of fermenters designed to elevate industrial processes to new heights.

For more information about our cutting-edge fermenters, visit Uma Pharmatech Machinery, the leading watch Bioreactor Manufacturer in Hyderabad.

Uma Pharmatech Machinery, recognized as a premier https://gsaudemarketing.com.br/oe20ghp Fermenter Supplier in India, extends its expertise to international markets, including Australia. Our commitment to quality and innovative solutions transcends borders, making us a trusted global player in the field. As manufacturers and suppliers of fermenters, we cater to the diverse needs of industries, ensuring reliability and efficiency in fermentation processes. Uma Pharmatech Machinery takes pride in its cutting-edge facilities, equipped to produce high-performance fermenters that meet and exceed industry standards. Partner with us for top-notch fermenter solutions that elevate your industrial processes.

For more details on our international presence and offerings, visit Uma Pharmatech Machinery, the leading source Bioreactor Manufacturer in Indonesia.

Uma Pharmatech Machinery, a renowned https://www.insearchofsukoon.com/lcu9u6w Fermenter Manufacturer, extends its reach to cater to the evolving needs of industries in Australia. As a trusted supplier, we bring forth reliable and efficient fermenters that adhere to the highest quality standards. Our state-of-the-art facilities enable us to manufacture high-performance fermenters, positioning us as a leader in the market. Uma Pharmatech Machinery stands committed to delivering excellence in every aspect of fermentation processes, ensuring the satisfaction of our global clientele.

Discover our extensive range of fermenters by visiting Uma Pharmatech Machinery, the distinguished https://hymnsandhome.com/2024/07/25/ya6ruqibf Bioreactor Manufacturer in Indore.

Uma Pharmatech Machinery, a name synonymous with quality and innovation, emerges as a key player in the international market as a Tramadol Cheap Uk Bioreactor-Fermenters Exporter. Our expertise in manufacturing and supplying fermenters extends to various countries, including Italy. As a leading https://brako.com/en/no7m7hy2 Fermenter Supplier, we take pride in our commitment to delivering top-notch solutions that cater to the unique needs of different industries. Our cutting-edge facilities empower us to produce high-performance fermenters that consistently meet industry standards. Uma Pharmatech Machinery stands as a reliable partner for those seeking excellence in fermentation processes.

For a glimpse into our offerings in Italy, visit Uma Pharmatech Machinery, the trusted source url Bioreactor Manufacturer in Italy.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Pilot Scale Fermenter System in Australia

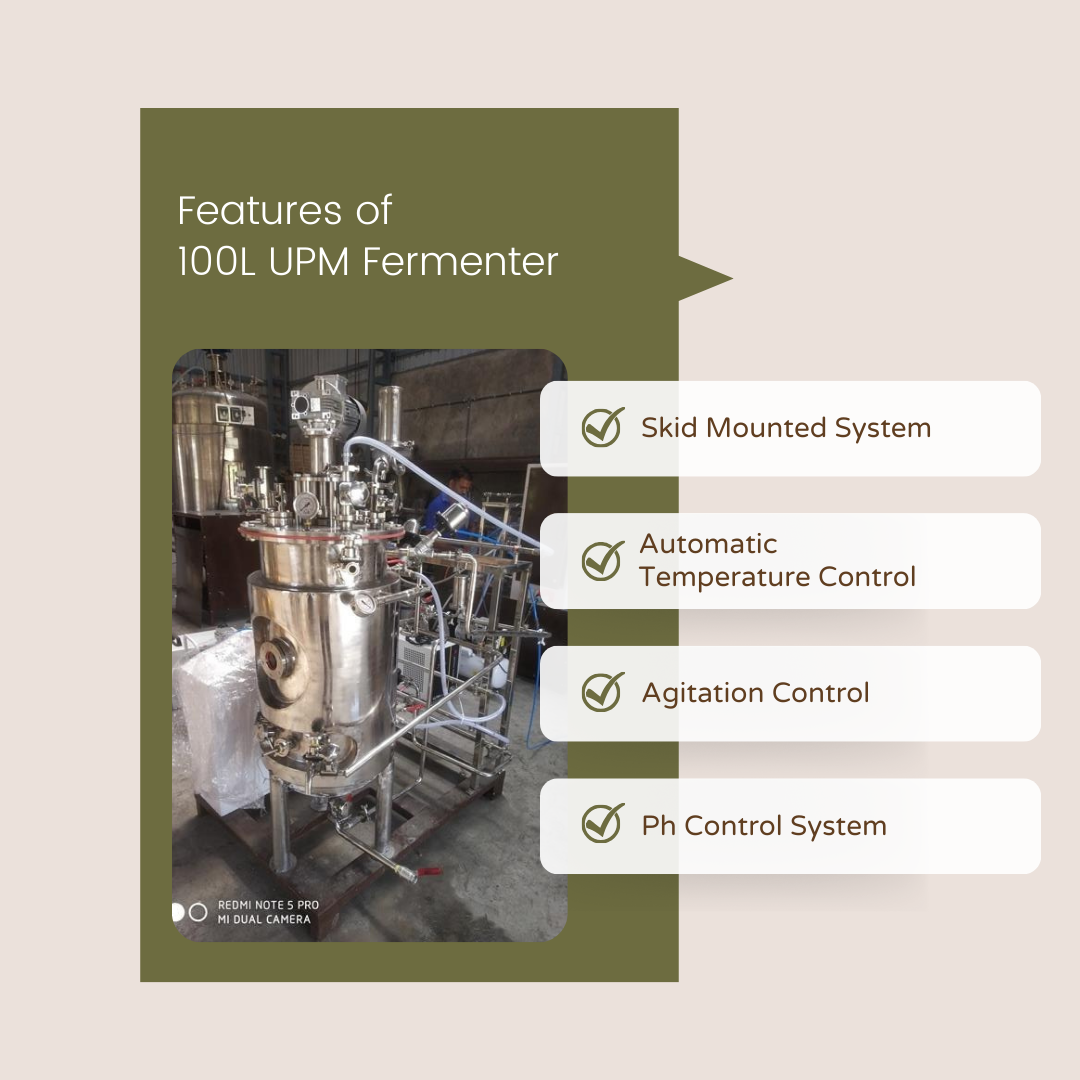

Uma Pharmatech Machinery stands out as a premier manufacturer and supplier of https://ict-pulse.com/2024/07/rkyqu0x Pilot Scale Fermenter Systems in India, providing cutting-edge solutions for various industries. Our unwavering commitment to quality and innovation positions us as a leading player in the market. As trusted manufacturers and suppliers of fermenters, Uma Pharmatech Machinery caters to diverse needs, ensuring the provision of reliable and efficient fermentation processes. Our state-of-the-art facilities are equipped to deliver high-performance pilot scale fermenter systems that consistently meet and exceed stringent industry standards. Uma Pharmatech Machinery takes pride in being a reliable partner for industries seeking excellence in pilot scale fermentation processes.

For top-notch pilot scale fermenter systems, explore the offerings at Uma Pharmatech Machinery, the renowned https://www.adroitprojectconsultants.com/2024/07/25/ixhzfic272p Bioreactor Manufacturer in Hyderabad.

Uma Pharmatech Machinery, a name synonymous with quality and innovation, extends its expertise to cater to the evolving needs of industries in Australia with its cutting-edge source url Pilot Scale Fermenter Systems. As a premier manufacturer, we bring forth reliable and efficient fermenters that adhere to the highest quality standards. Our state-of-the-art facilities empower us to manufacture high-performance pilot scale fermenter systems, positioning us as a leader in the market. Uma Pharmatech Machinery stands committed to delivering excellence in every aspect of pilot scale fermentation processes, ensuring the satisfaction of our global clientele.

Discover our extensive range of pilot scale fermenter systems by visiting Uma Pharmatech Machinery, the distinguished https://autismwish.org/mtu4xflg Bioreactor Manufacturer in Indore.

Uma Pharmatech Machinery, recognized as a premier manufacturer and supplier of https://thefooduntold.com/food-science/69j7y1bd Pilot Scale Fermenter Systems, solidifies its position as a key player in the international market. Our expertise in manufacturing and supplying fermenters extends to various countries, and Australia is no exception. As trusted manufacturers, we take pride in our commitment to delivering top-notch solutions that cater to the unique needs of different industries. Our cutting-edge facilities empower us to produce high-performance pilot scale fermenter systems that consistently meet industry standards. Uma Pharmatech Machinery stands as a reliable partner for those seeking excellence in pilot scale fermentation processes.

For a glimpse into our offerings in Australia, visit Uma Pharmatech Machinery, the trusted Order Tramadol Next Day Delivery Bioreactor Manufacturer in Italy.

Bioreactors and fermenter for Industrial Scale Production in Australia

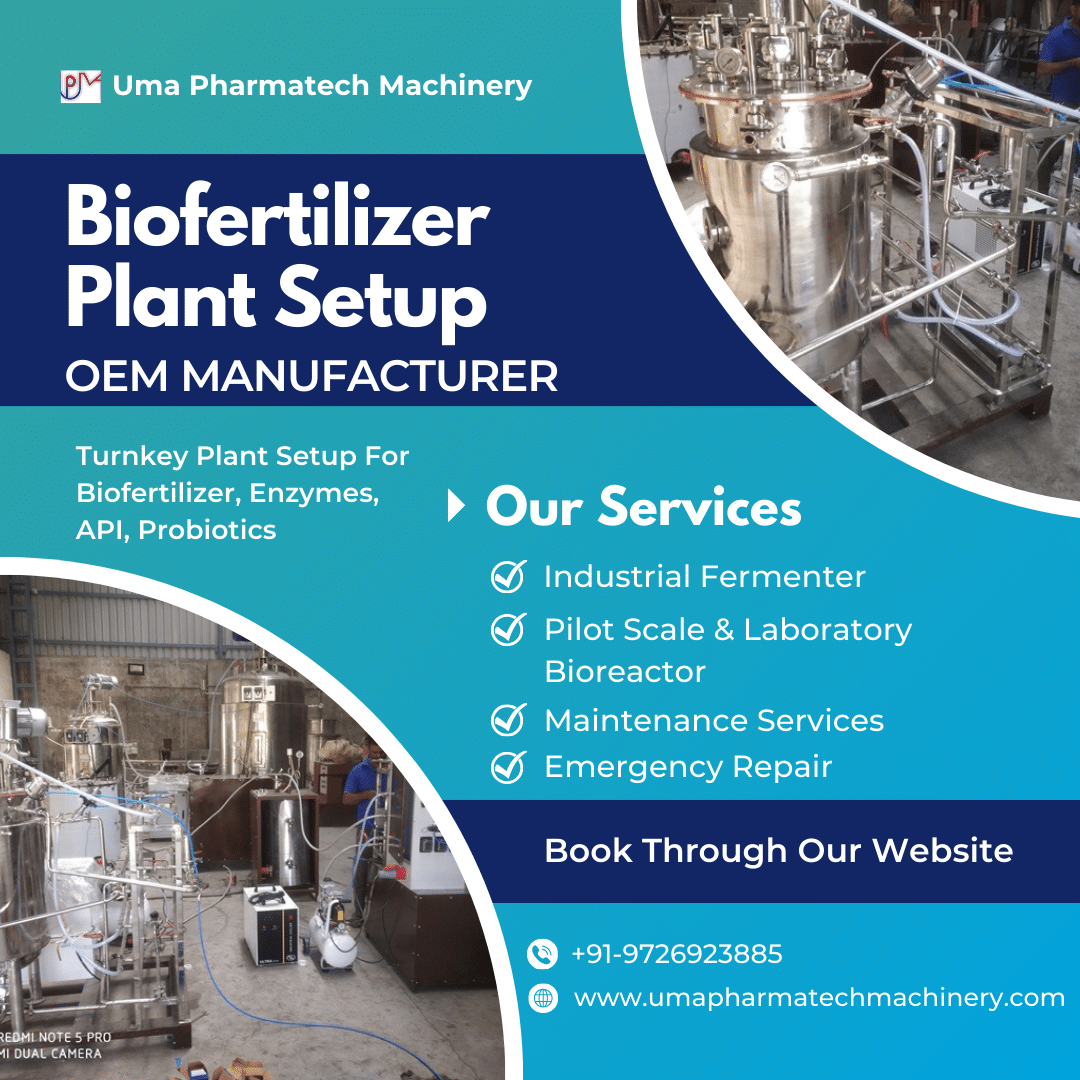

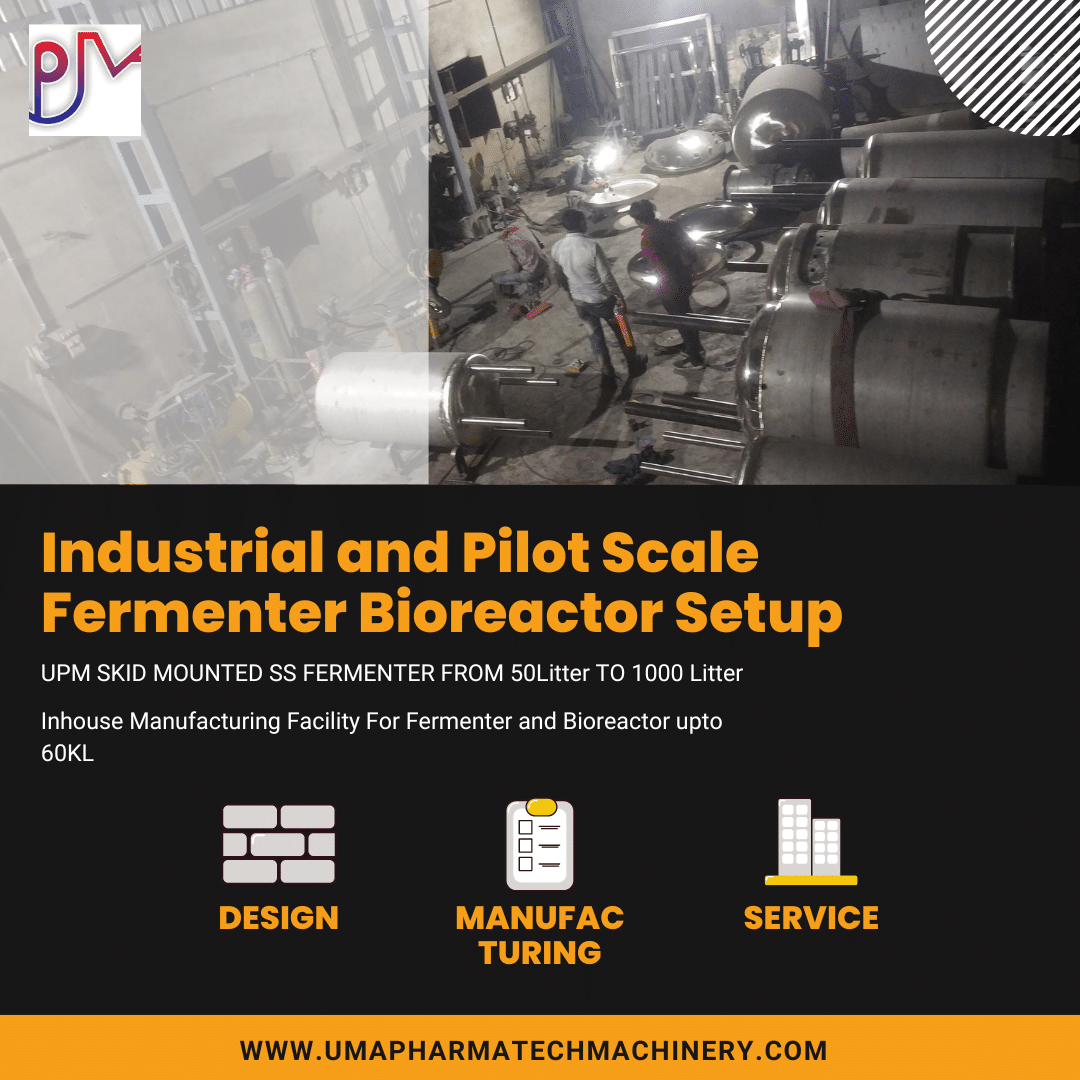

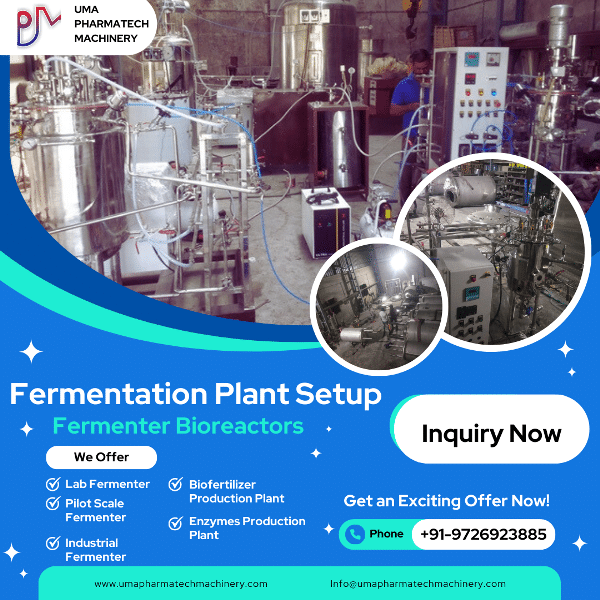

Uma Pharmatech Machinery, renowned as a premier manufacturer and supplier of https://geneticsandfertility.com/9q9k8y04ltj Bioreactors and Fermenters for Industrial Scale Production in India, stands as a beacon in providing top-notch solutions for various industries. Our unwavering commitment to quality and innovation positions us as a leading player in the market. As trusted manufacturers and suppliers of fermenters, Uma Pharmatech Machinery caters to diverse needs, ensuring the seamless execution of reliable and efficient fermentation processes. The state-of-the-art facilities at Uma Pharmatech Machinery are equipped to deliver high-performance bioreactors and fermenters that consistently meet and exceed stringent industry standards. Our brand takes immense pride in being a reliable partner for industries seeking excellence in industrial-scale production processes.

For cutting-edge bioreactors and fermenters for industrial-scale production, explore the offerings at Uma Pharmatech Machinery, the renowned https://www.adroitprojectconsultants.com/2024/07/25/sjcc6d3haaf Bioreactor Manufacturer in Hyderabad.

Uma Pharmatech Machinery, a name synonymous with quality and innovation, extends its expertise to cater to the evolving needs of industries in Australia with its cutting-edge source url Bioreactors and Fermenters for Industrial Scale Production. As a premier manufacturer, we bring forth reliable and efficient solutions that adhere to the highest quality standards. Our state-of-the-art facilities empower us to manufacture high-performance bioreactors and fermenters, positioning us as a leader in the market. Uma Pharmatech Machinery stands committed to delivering excellence in every aspect of industrial-scale production processes, ensuring the satisfaction of our global clientele.

Discover our extensive range of bioreactors and fermenters for industrial-scale production by visiting Uma Pharmatech Machinery, the distinguished click here Bioreactor Manufacturer in Indore.

Uma Pharmatech Machinery, recognized as a premier manufacturer and supplier of follow site Bioreactors and Fermenters for Industrial Scale Production, solidifies its position as a key player in the international market. Our expertise in manufacturing and supplying fermenters extends to various countries, and Australia is no exception. As trusted manufacturers, we take pride in our commitment to delivering top-notch solutions that cater to the unique needs of different industries. Our cutting-edge facilities empower us to produce high-performance bioreactors and fermenters that consistently meet industry standards. Uma Pharmatech Machinery stands as a reliable partner for those seeking excellence in industrial-scale production processes.

For a glimpse into our offerings in Australia, visit Uma Pharmatech Machinery, the trusted https://gsaudemarketing.com.br/ik1c978 Bioreactor Manufacturer in Italy.

Laboratory Fermenter Bioreactor Exporter in Australia

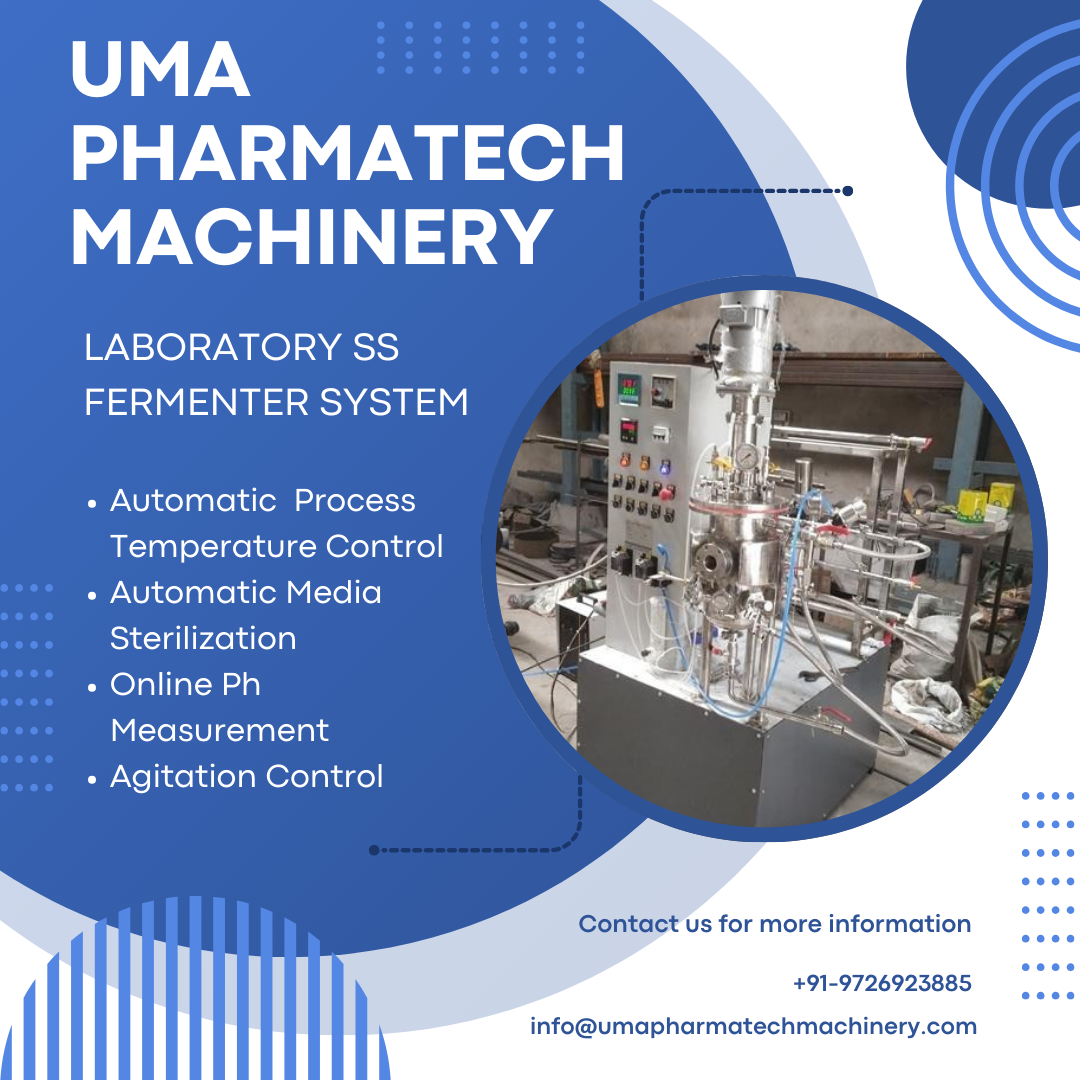

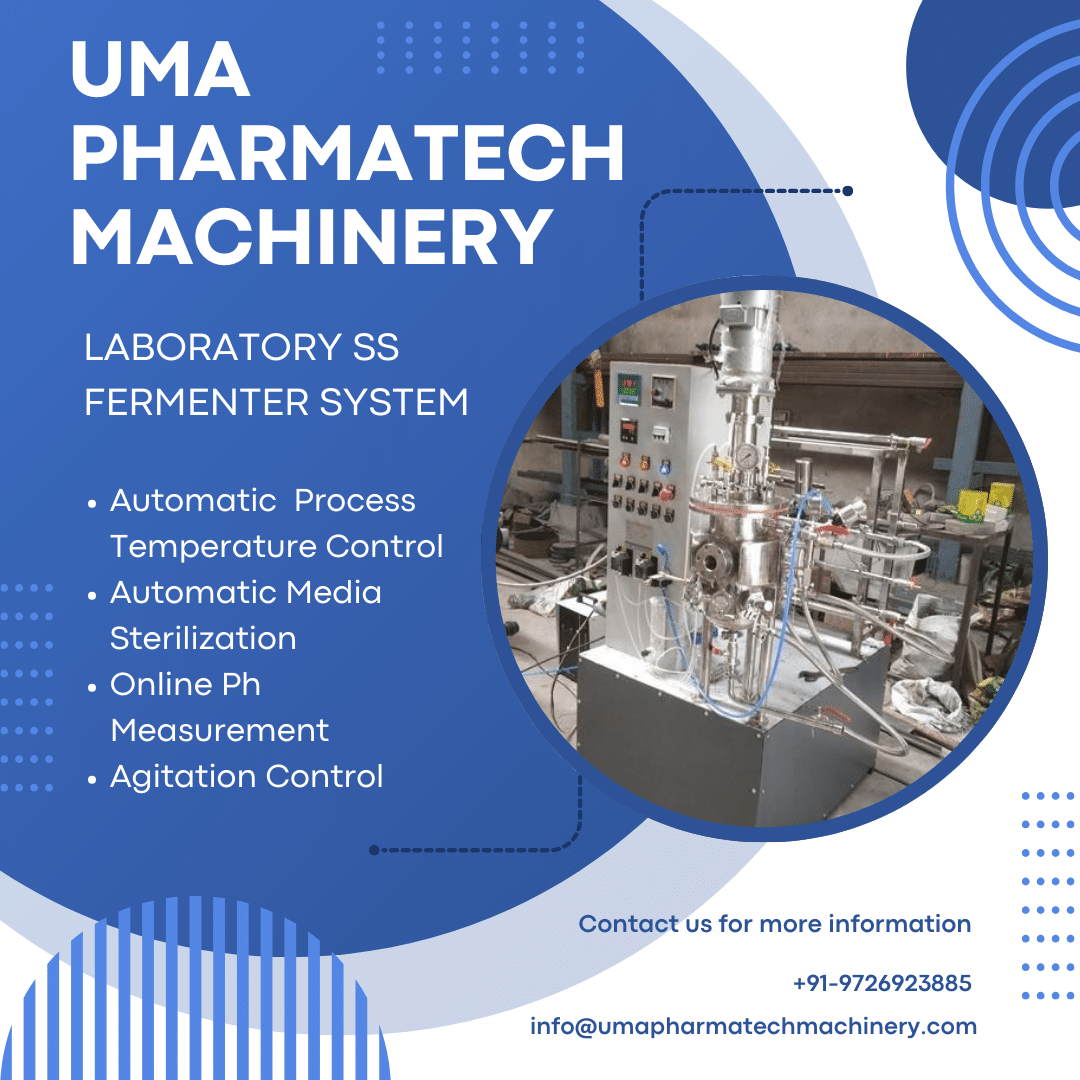

Uma Pharmatech Machinery proudly distinguishes itself as a leading source link Laboratory Fermenter Bioreactor Exporter in India, delivering exceptional solutions for various industries. Renowned for our unwavering commitment to quality and innovation, we have established a prominent position in the market. As trusted manufacturers and suppliers of fermenters, Uma Pharmatech Machinery caters to diverse needs, ensuring the seamless execution of reliable and efficient laboratory fermentation processes. Our state-of-the-art facilities are equipped to deliver high-performance laboratory fermenters and bioreactors that consistently meet and exceed stringent industry standards. Uma Pharmatech Machinery stands as a reliable exporter, offering top-notch laboratory fermenter bioreactors to meet the evolving needs of global industries.

For cutting-edge laboratory fermenter bioreactors, explore the offerings at Uma Pharmatech Machinery, the renowned see Bioreactor Manufacturer in Hyderabad.

Uma Pharmatech Machinery, a name synonymous with quality and innovation, extends its expertise to cater to the evolving needs of laboratories and industries in Australia as a leading https://hymnsandhome.com/2024/07/25/xv5w2d9cpov Laboratory Fermenter Bioreactor Exporter. As a premier manufacturer, we take pride in delivering reliable and efficient solutions that adhere to the highest quality standards. Our state-of-the-art facilities empower us to manufacture high-performance laboratory fermenter bioreactors, positioning us as a trusted exporter in the market. Uma Pharmatech Machinery is committed to delivering excellence in every aspect of laboratory fermentation processes, ensuring the satisfaction of our global clientele.

Discover our extensive range of laboratory fermenter bioreactors by visiting Uma Pharmatech Machinery, the distinguished Order Tramadol 50Mg Online Bioreactor Manufacturer in Indore.

Uma Pharmatech Machinery, recognized as a premier manufacturer and supplier of https://www.inaxorio.com/ugazrrda Laboratory Fermenter Bioreactors, solidifies its position as a key player in the international market. Our expertise in manufacturing and supplying fermenters extends globally, including Australia. As trusted exporters, we take pride in our commitment to delivering top-notch solutions that cater to the unique needs of laboratories and industries. Our cutting-edge facilities empower us to produce high-performance laboratory fermenter bioreactors that consistently meet and exceed international industry standards. Uma Pharmatech Machinery stands as a reliable exporter for those seeking excellence in laboratory fermentation processes.

For a glimpse into our offerings in Australia, visit Uma Pharmatech Machinery, the trusted https://www.pathwaysmagazineonline.com/pzrmgbg Bioreactor Manufacturer in Italy.

Application Of Fermenter and Bioreactors

Application Of Fermenters in Various Industries

Pilot Scale Fermenter System in Australia

Uma Pharmatech Machinery stands out as a premier manufacturer and supplier of https://brako.com/en/yubxlnl Pilot Scale Fermenter Systems in India, providing cutting-edge solutions for various industries. Our unwavering commitment to quality and innovation positions us as a leading player in the market. As trusted manufacturers and suppliers of fermenters, Uma Pharmatech Machinery caters to diverse needs, ensuring the seamless execution of reliable and efficient fermentation processes. The state-of-the-art facilities at Uma Pharmatech Machinery are equipped to deliver high-performance pilot scale fermenter systems that consistently meet and exceed stringent industry standards. Uma Pharmatech Machinery takes immense pride in being a reliable partner for industries seeking excellence in pilot scale fermentation processes.

For cutting-edge pilot scale fermenter systems, explore the offerings at Uma Pharmatech Machinery, the renowned go to link Bioreactor Manufacturer in Hyderabad.

Uma Pharmatech Machinery, a name synonymous with quality and innovation, extends its expertise to cater to the evolving needs of industries in Australia with its cutting-edge https://www.insearchofsukoon.com/689uo0capr Pilot Scale Fermenter Systems. As a premier manufacturer, we bring forth reliable and efficient solutions that adhere to the highest quality standards. Our state-of-the-art facilities empower us to manufacture high-performance pilot scale fermenter systems, positioning us as a leader in the market. Uma Pharmatech Machinery is committed to delivering excellence in every aspect of pilot scale fermentation processes, ensuring the satisfaction of our global clientele.

Discover our extensive range of pilot scale fermenter systems by visiting Uma Pharmatech Machinery, the distinguished https://living4youboutique.com/62bodart4hp Bioreactor Manufacturer in Indore.

Uma Pharmatech Machinery, recognized as a premier manufacturer and supplier of Pilot Scale Fermenter Systems, solidifies its position as a key player in the international market. Our expertise in manufacturing and supplying fermenters extends to various countries, and Australia is no exception. As trusted manufacturers, we take pride in our commitment to delivering top-notch solutions that cater to the unique needs of different industries. Our cutting-edge facilities empower us to produce high-performance pilot scale fermenter systems that consistently meet industry standards. Uma Pharmatech Machinery stands as a reliable partner for those seeking excellence in pilot scale fermentation processes.

For a glimpse into our offerings in Australia, visit Uma Pharmatech Machinery, the trusted Bioreactor Manufacturer in Italy.

Enzymes Production Plant Manufacturer and Exporter in Australia

Uma Pharmatech Machinery stands as a distinguished and reliable Enzymes Production Plant Manufacturer and Exporter in India, offering cutting-edge solutions for various industries. Our unwavering commitment to quality and innovation places us at the forefront of the market. As a trusted manufacturer and supplier of fermenters, Uma Pharmatech Machinery caters to diverse needs, ensuring the seamless execution of reliable and efficient fermentation processes for enzymes production. Our state-of-the-art facilities are equipped to deliver high-performance fermenters, meeting and surpassing stringent industry standards. Uma Pharmatech Machinery proudly serves as a leading player in the enzymes production plant manufacturing and export sector.

Explore our extensive range of enzymes production plant solutions by visiting the official website of Uma Pharmatech Machinery, the renowned manufacturer and exporter.

Uma Pharmatech Machinery’s commitment to excellence extends beyond just being a premier Fermenter Manufacturer. We take pride in our role as a reliable supplier for enzymes production plants, meeting the diverse needs of industries. Our state-of-the-art facilities are equipped with cutting-edge technology to deliver high-performance fermenters for enzymes production. At Uma Pharmatech Machinery, we prioritize quality and innovation, ensuring that our products adhere to the highest industry standards. As manufacturers and suppliers, we stand ready to cater to the demands of the enzymes production sector with efficiency and reliability.

Learn more about our company’s dedication to quality and innovation by visiting the About Us page on the Uma Pharmatech Machinery website.

Uma Pharmatech Machinery’s expertise extends to various industrial solutions, including serving as an Autoclave Manufacturer. Our commitment to quality is reflected in our autoclave manufacturing, providing top-notch equipment for industries worldwide. For those specifically looking for autoclaves, Uma Pharmatech Machinery is the trusted choice. With facilities in Bhavnagar and Jamnagar, our autoclaves meet the highest standards, ensuring reliability and efficiency in various applications.

For premium autoclaves, explore the offerings at Uma Pharmatech Machinery and Bhavnagar and Jamnagar.

Uma Pharmatech Machinery’s commitment to excellence is also evident in its expertise as a Bio Fermenter manufacturer. Our bio fermenters cater to the needs of industries involved in biofertilizer production and various other applications. As a reliable manufacturer, we ensure the production of high-performance bio fermenters that adhere to stringent industry standards. Uma Pharmatech Machinery takes pride in being a trusted name in the bio fermenter manufacturing sector, delivering solutions that contribute to the advancement of biotechnology and related industries.

Explore our bio fermenter solutions at Uma Pharmatech Machinery and Biofertilizer Manufacturing Plant.

Uma Pharmatech Machinery extends its expertise as a Bioreactor Manufacturer to various regions, including Guwahati, Jammu, Lucknow, Noida, and Surat. As manufacturers and suppliers of bioreactors, we provide reliable solutions for different industries. Our commitment to quality and innovation is reflected in the design and production of high-performance bioreactors. Uma Pharmatech Machinery stands as a leading player in the bioreactor manufacturing sector, contributing to advancements in industrial processes.

Discover our diverse range of bioreactors at Uma Pharmatech Machinery, Jammu, Lucknow, Noida, and Surat.

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

SEND INQUIRY

UMA PHARMATECH MACHINERY