What Are Bioreactors and Why Are They Important?

The controlled culture of living cells, such as bacteria, yeast, mammalian cells, or plant cells, in a sterile and regulated environment is made possible by bioreactors, which are specialized vessels. The production of medicinal proteins, vaccines, biofuels, culinary ingredients, and environmental cleanup agents are just a few of the many uses for bioreactors. With the right temperature, pH, dissolved oxygen, and nutrition supply, which can all affect cell growth, viability, and productivity, bioreactors offer a scalable and repeatable technique to grow cells. The efficiency and productivity of the entire process can be maximized by using bioreactors to continuously monitor and modify numerous parameters, including as metabolic activity, biomass concentration, and product quality.

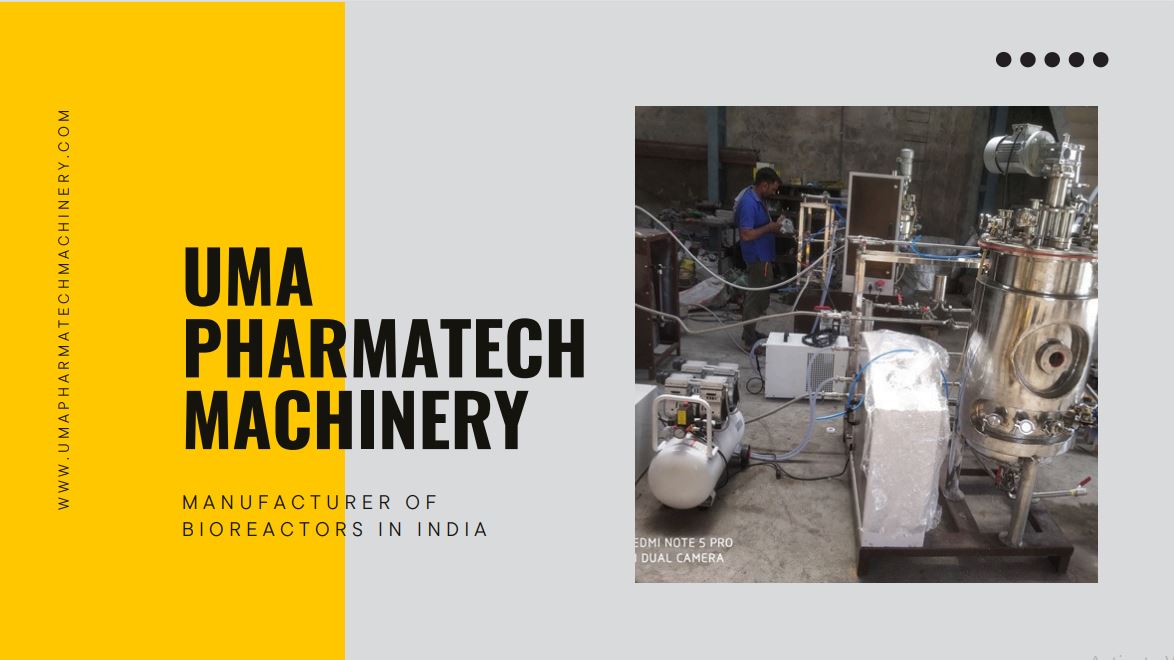

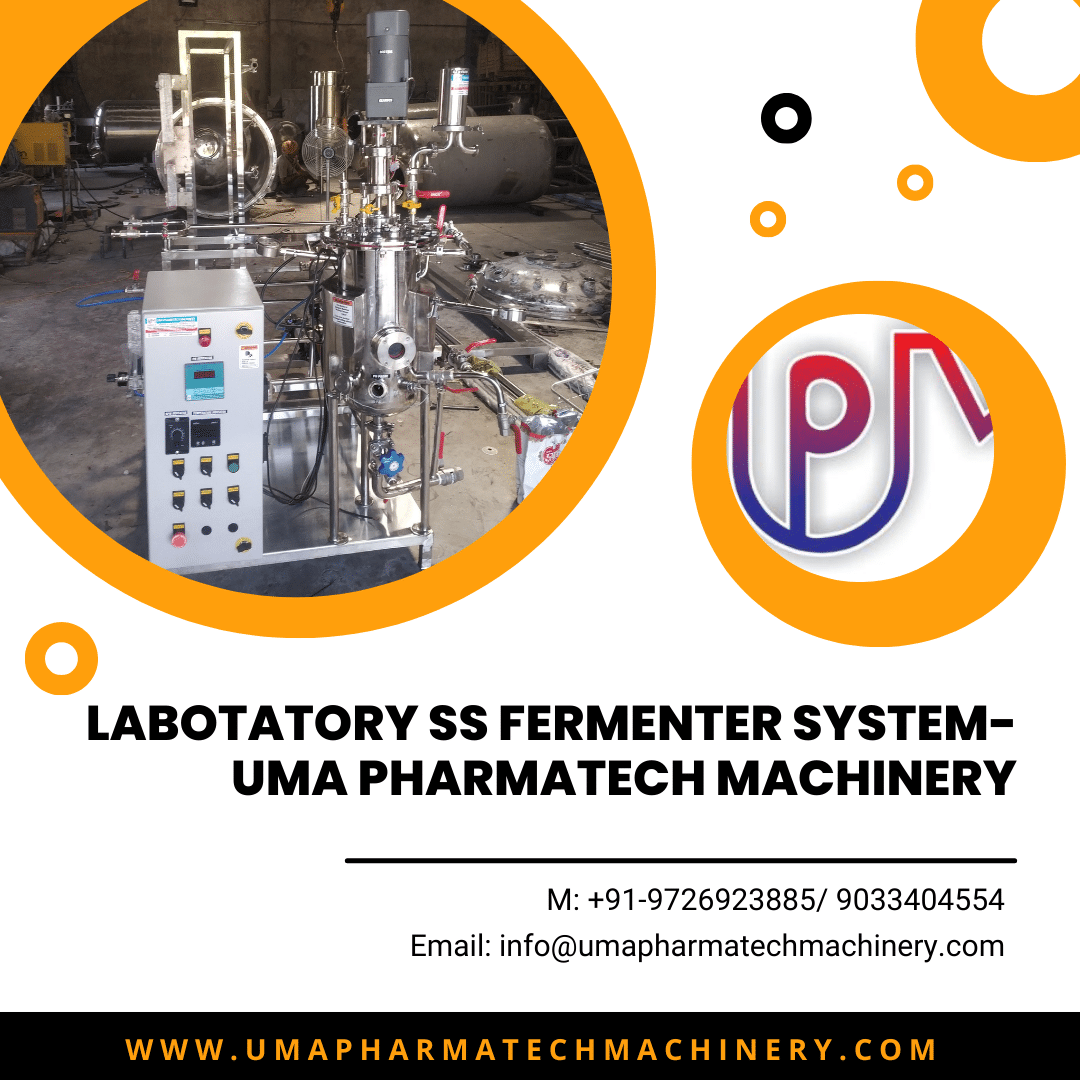

BIOREACTOR MANUFACTURER IN TELANGANA

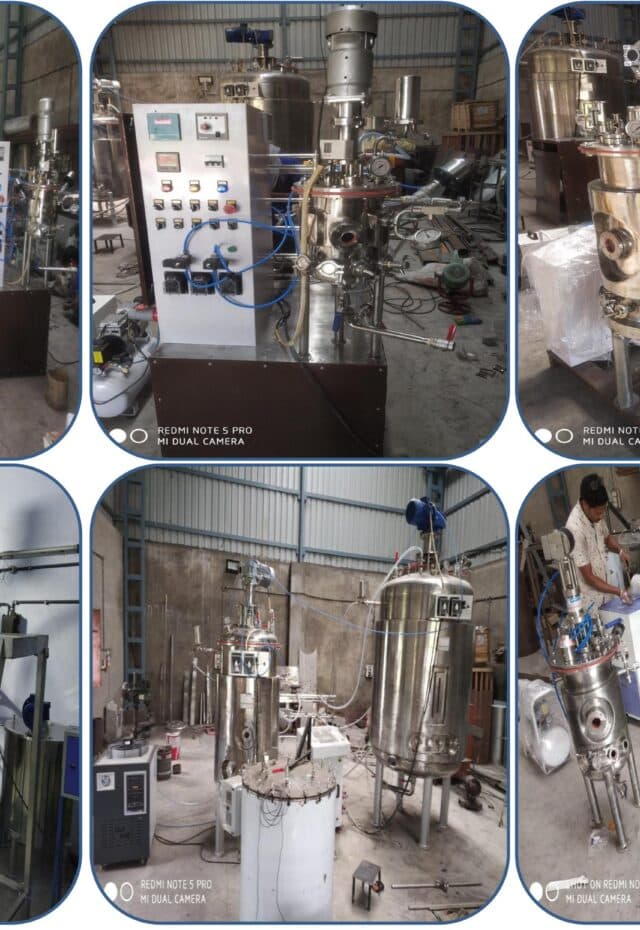

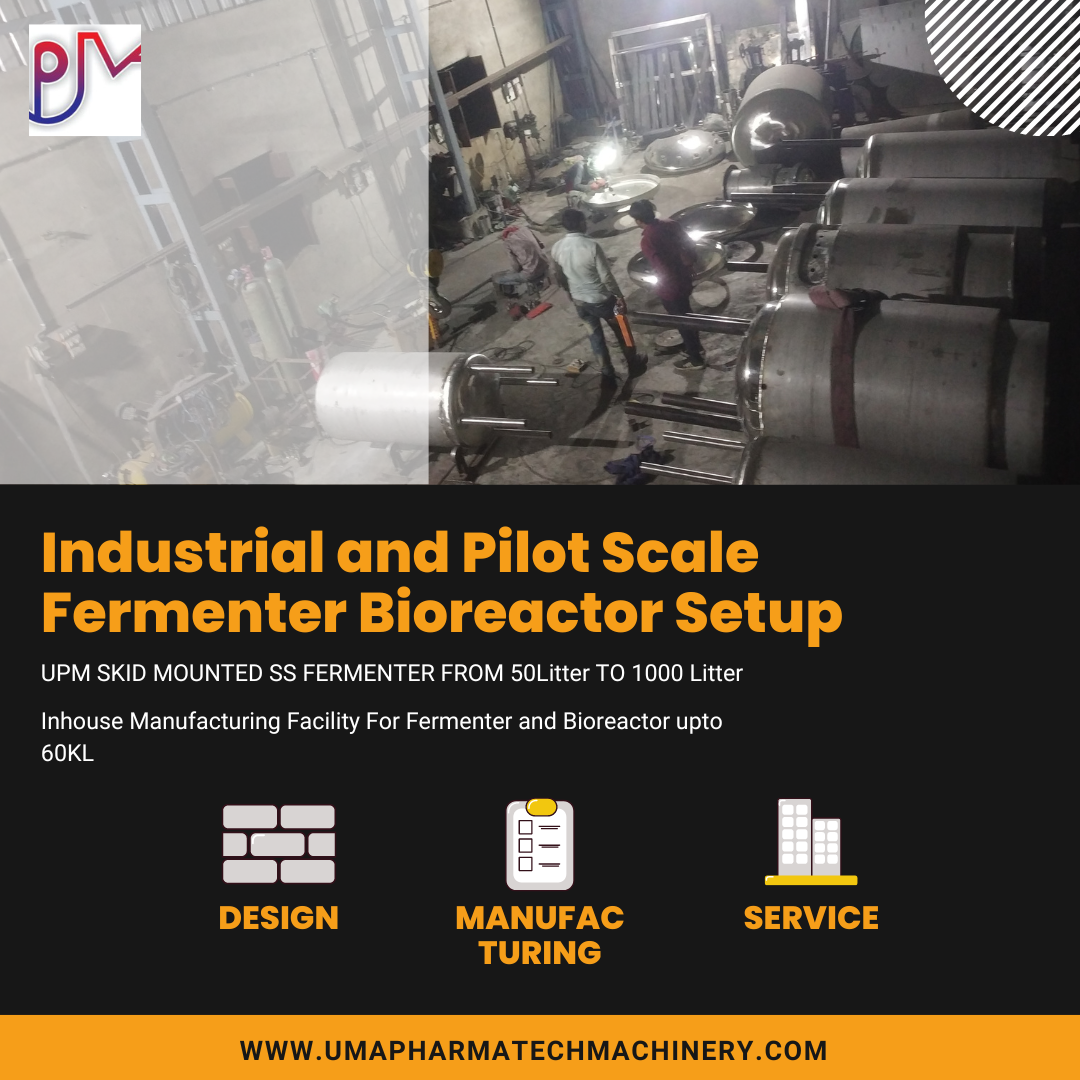

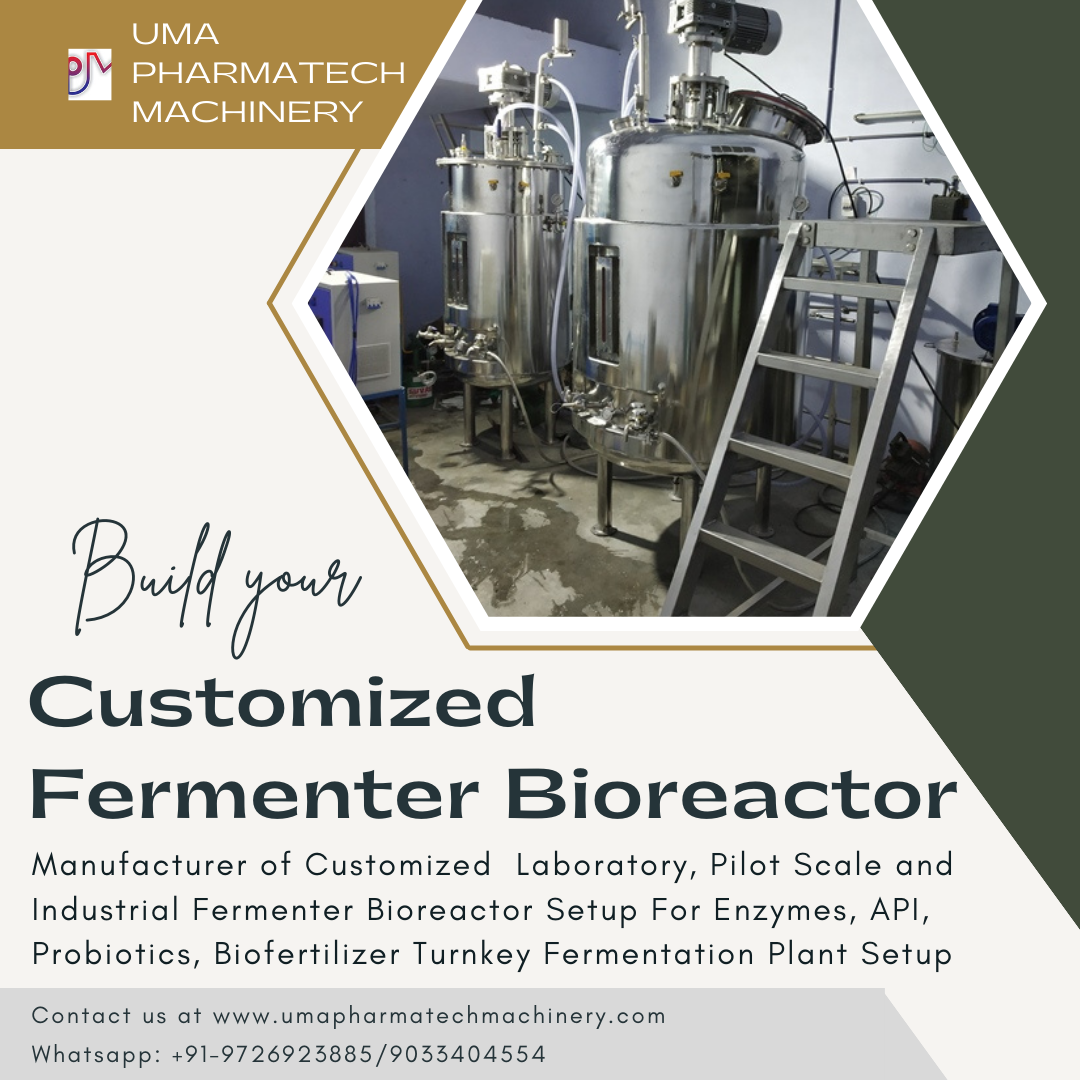

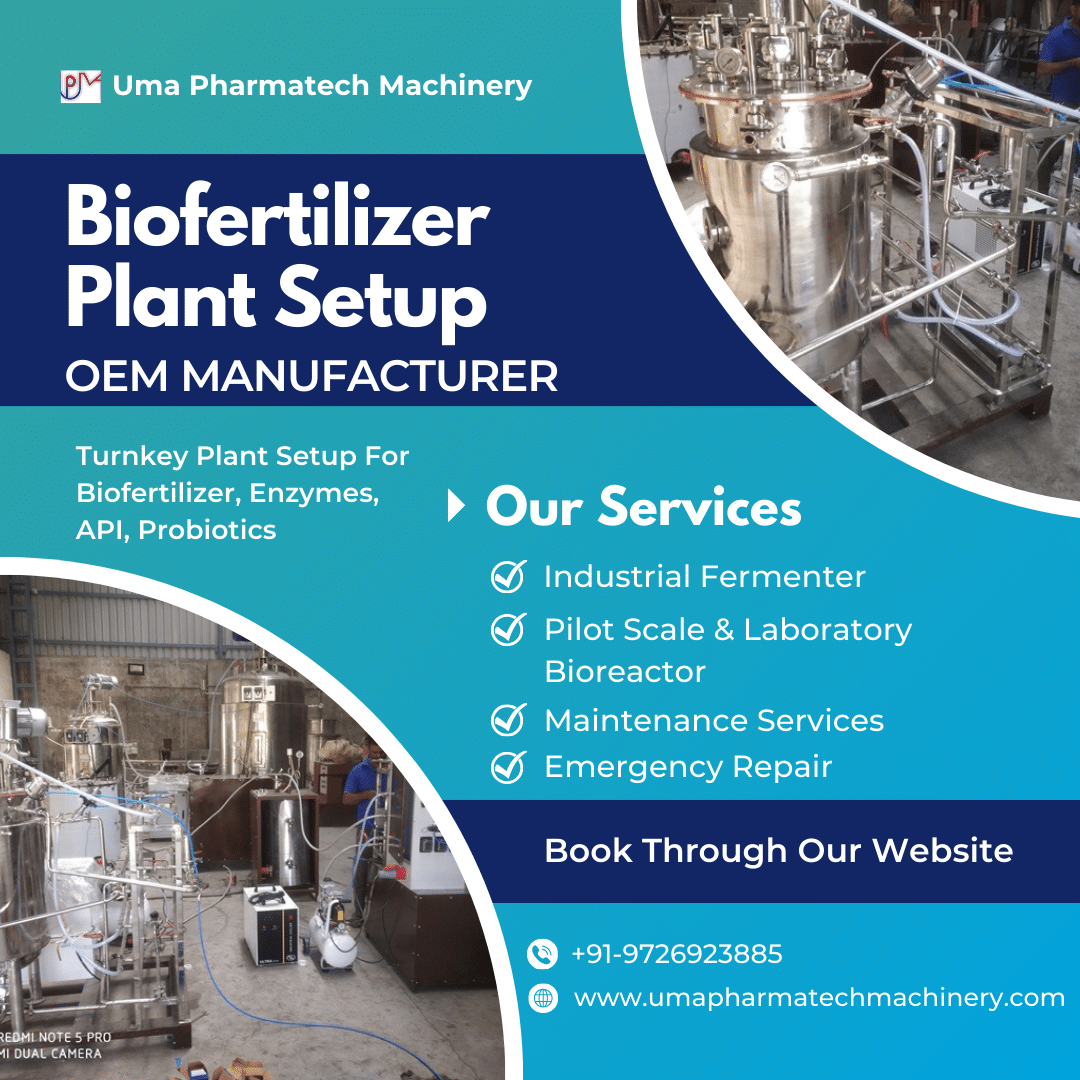

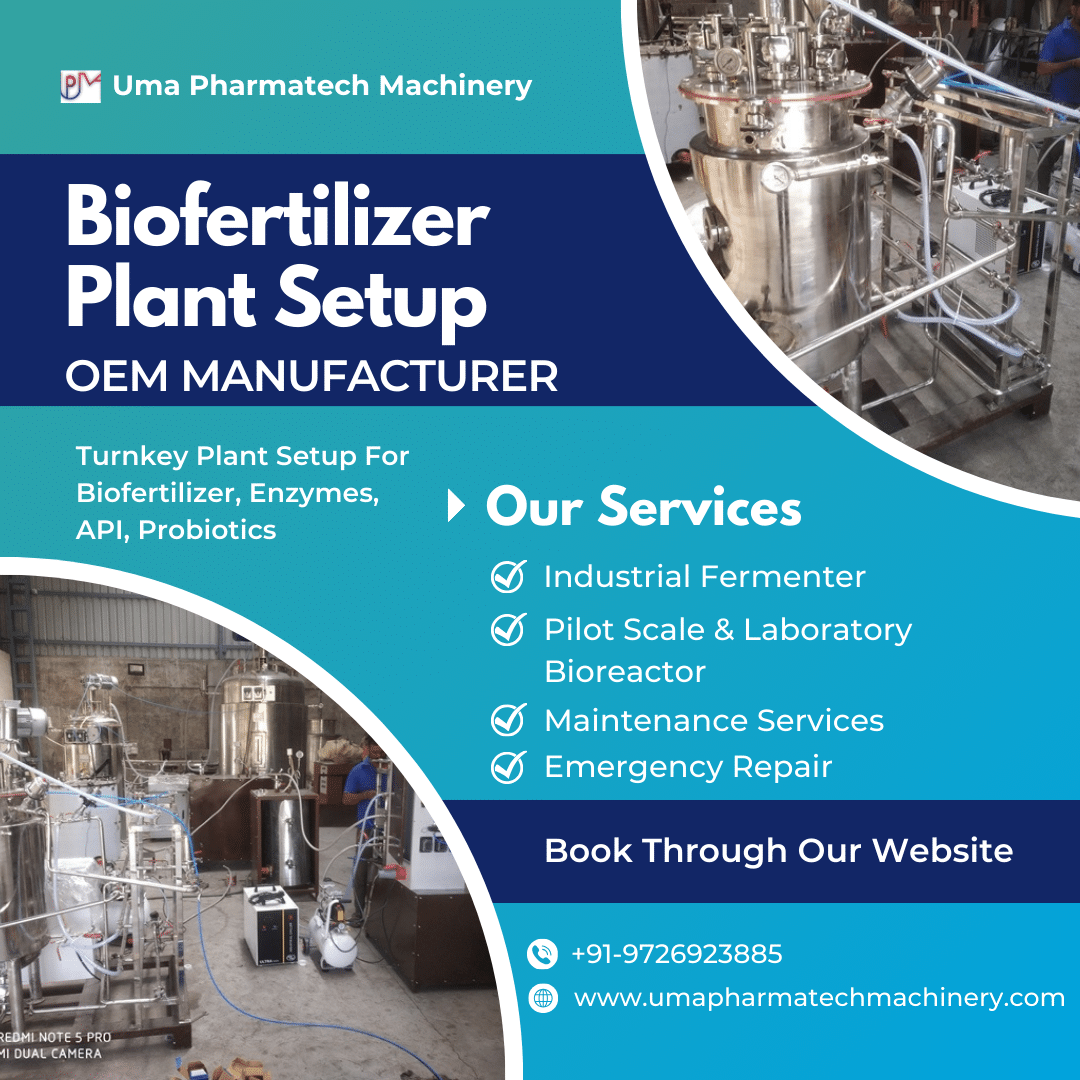

Uma Pharmatech Machinery, headquartered in Ahmedabad, Gujarat, shines as a premier industrial bioreactor manufacturer in Telangana. Their unwavering commitment to innovation and quality makes them a vital contributor to Telangana’s thriving biotechnology and pharmaceutical sectors. Uma Pharmatech Machinery’s industrial bioreactors are meticulously engineered to meet the rigorous demands of large-scale microbial and cell culture processes. They offer Telangana’s scientific community cutting-edge solutions tailored to the state’s unique bioprocessing needs. Renowned for their reliability and superior performance, Uma Pharmatech Machinery’s industrial bioreactors are pivotal in advancing Telangana’s biotech industry, driving scientific progress and technological innovation in the region.

List Of Fermenter Manufacturing Companies

List Of Fermenter Top 3 Bioreactor Manufacturers

• Uma Pharmatech Machinery(www.umapharmatechmachinery.com), M:+91-9726923885

• Ssfermenter bioreactor(www.ssfermenterbioreactor.com), M:+91-9033404554

• Maruti Engineering Works(https://biofertilizerfermenterplant.blogspot.com/), M:+91-8866137364

What is a Bioreactor?

A bioreactor is a vessel in which a biological process is carried out, typically involving the growth of cells or the fermentation of microorganisms. Bioreactors can be designed in a variety of shapes and sizes, and can be used for a wide range of applications, including cell culture, tissue engineering, and the production of biopharmaceuticals. UMA PHARMATECH MACHINERY Is Leading Fermenter and Bioreactor Manufacturer and Supplier From India.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

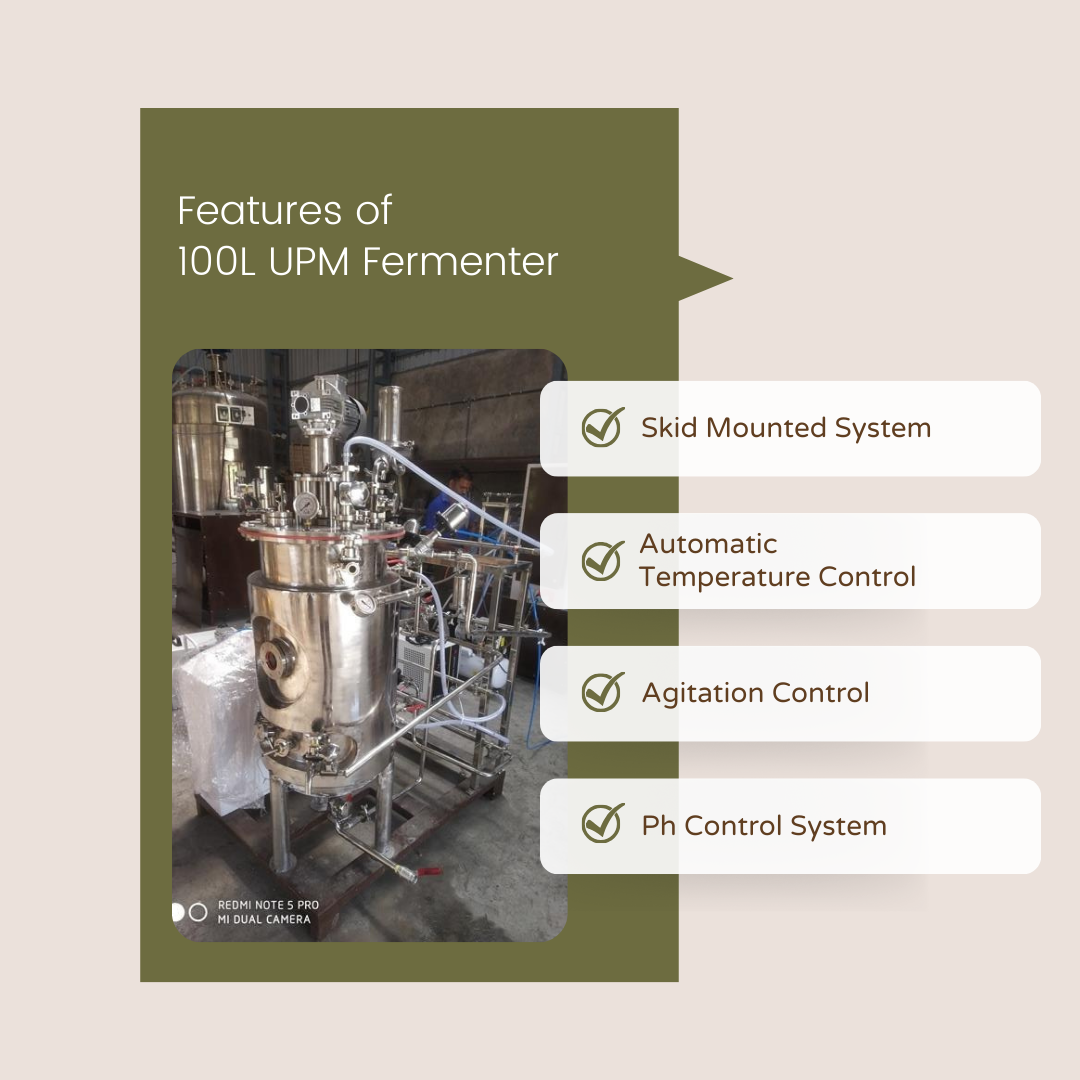

Features and Benefits of UPM Bioreactors

Uma Pharmatech provides a comprehensive selection of bioreactor systems to accommodate different research and manufacturing requirements. Some of the main characteristics and advantages of Uma Pharma bioreactors are listed:

Uma Pharmatech Machinery, a pioneer in bioprocess engineering, offers state-of-the-art bioreactor solutions that facilitate effective and dependable cell culture and fermentation procedures. Choosing the ideal bioreactor system can significantly impact your success, whether you’re a researcher, a biotech startup, or a large-scale biomanufacturer. In this thorough tutorial, we’ll go over the primary advantages and features of UPM bioreactors, as well as the best ways to use and maintain them, so you may confidently accomplish your objectives.

Cell culture, fermentation, and the generation of therapeutic proteins are just a few of the many uses for bioreactors, which are important instruments in the field of biotechnology. We will go through the many kinds of bioreactors, their uses, and their benefits over conventional production methods,

Application Of Fermenter and Bioreactors

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Suppliers in Telangana

Uma Pharmatech Machinery, headquartered in Ahmedabad, Gujarat, stands as a prominent choice among industrial bioreactor suppliers in Telangana, fortifying the state’s flourishing biotechnology and pharmaceutical sectors. Their industrial bioreactors are emblematic of precision, innovation, and quality, providing Telangana’s scientific community with state-of-the-art solutions for large-scale microbial and cell culture processes. Uma Pharmatech Machinery’s commitment to customization ensures that their industrial bioreactors align seamlessly with Telangana’s unique bioprocessing requirements. Celebrated for their reliability and exceptional performance, Uma Pharmatech Machinery’s industrial bioreactors play a pivotal role in advancing Telangana’s biotech industry, catalyzing scientific progress and technological innovation across the region.

Manufacturer of Fermenter in Telangana

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Modular and Scalable Design UPM Fermenter in Telangana

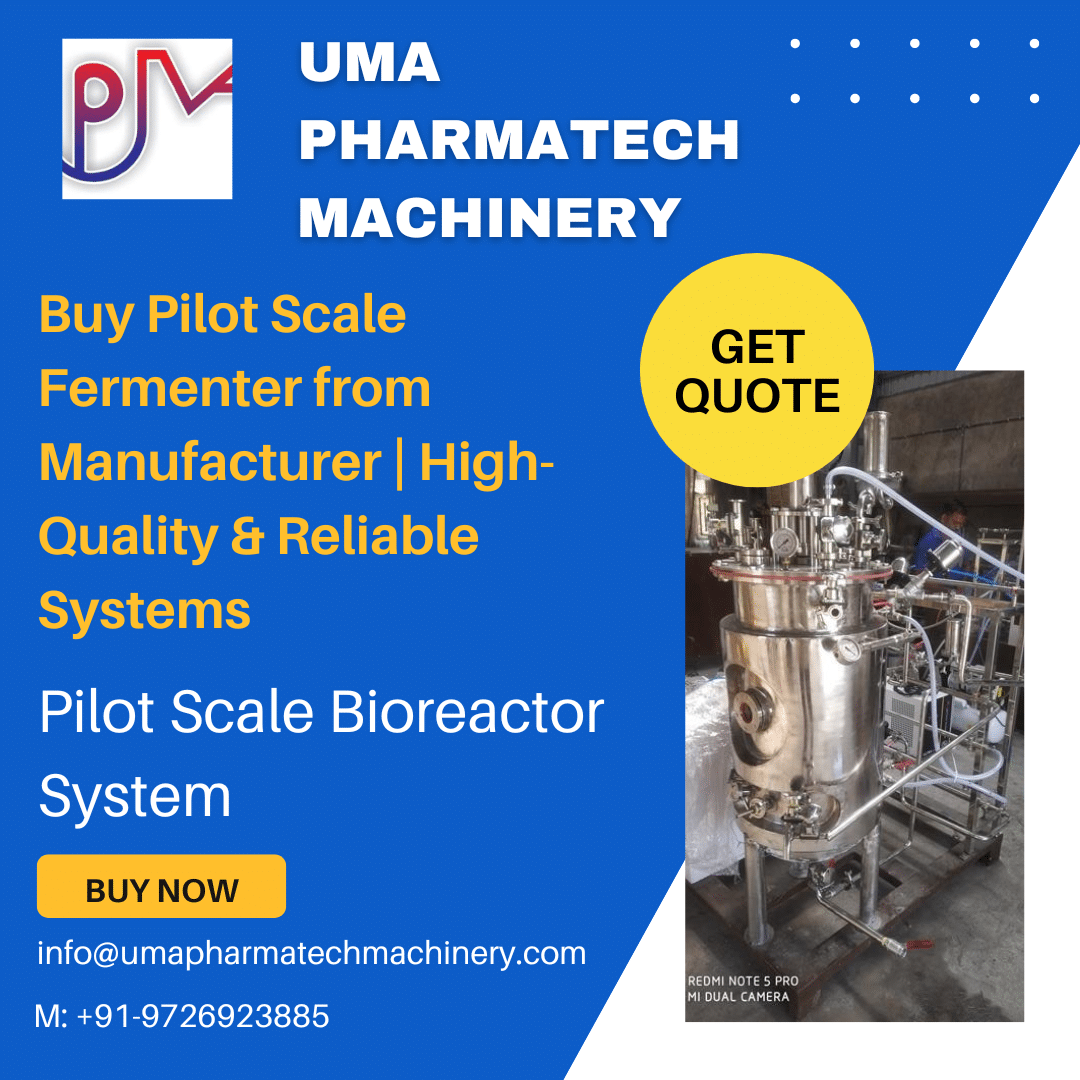

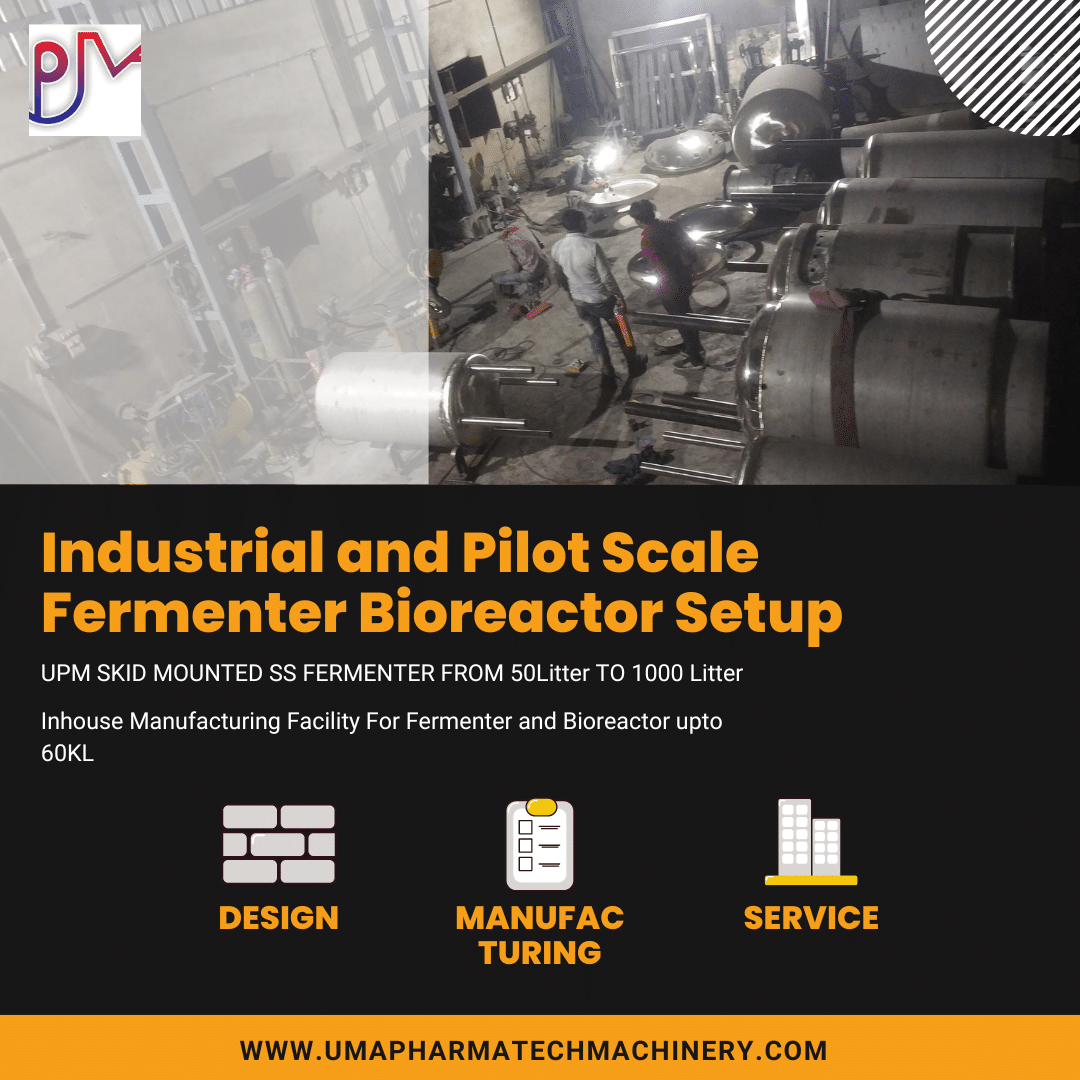

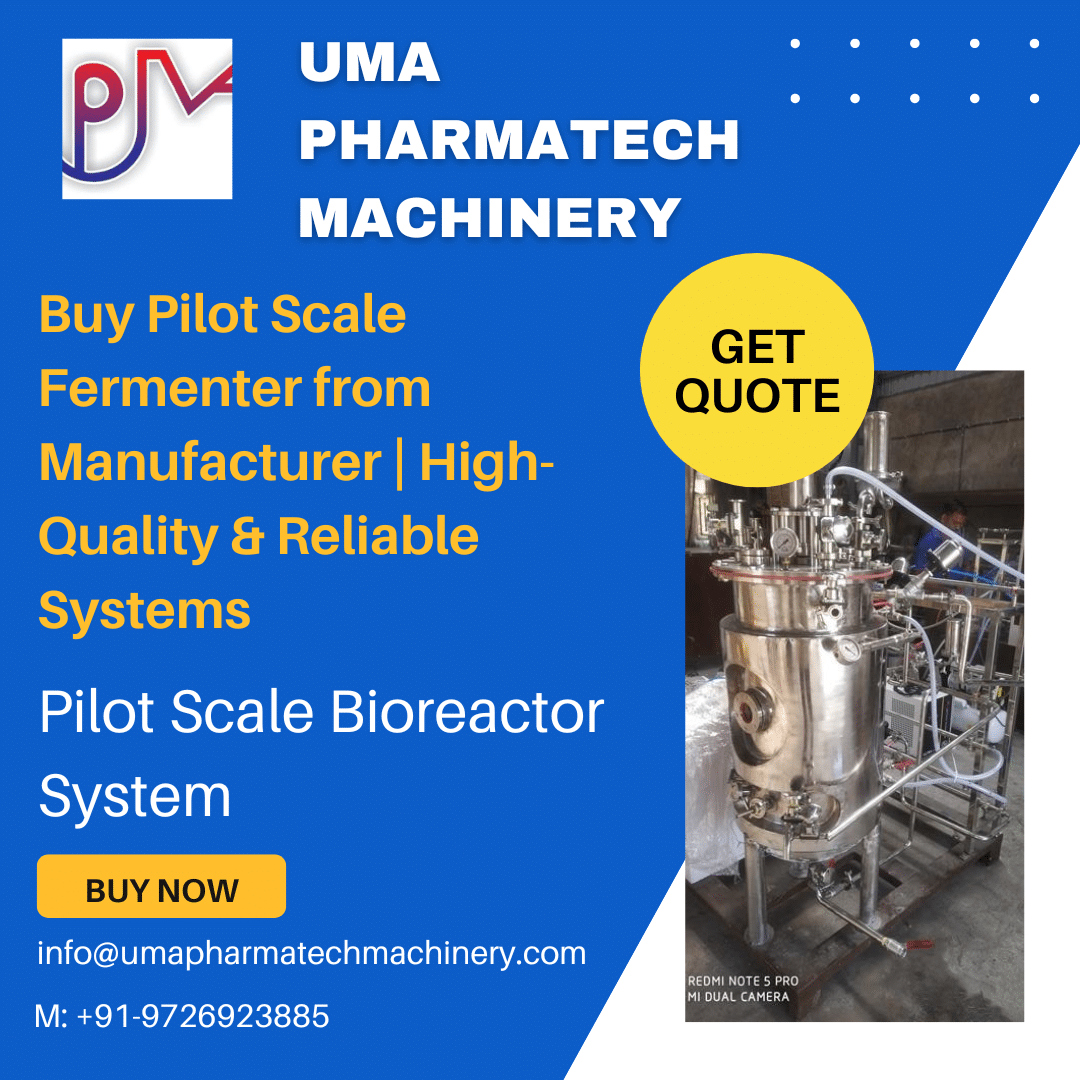

Because Uma Made bioreactors are modular and expandable in nature, you may tailor your bioreactor system to meet your unique needs and financial constraints. Benchtop, pilot, and production scale Uma Pharmatech bioreactors are all available, with working capacities ranging from 50 mL to 1000 L. Several sensors, controllers, and data management systems can be linked with UPM bioreactors to provide real-time monitoring and control of various parameters.

High Quality and Reliability Bioreactor Manufacturer in Talangana

The use of high-quality materials and components during the construction of UPM bioreactors helps guarantee their long-term dependability and durability. Stainless steel, which is resistant to corrosion, abrasion, and contamination, is used to make Uma Pharma Manufactured bioreactors. Moreover, UMA bioreactors have cutting-edge aeration and stirring technologies that can guarantee uniform mixing and high oxygen transfer rates. In-depth testing and validation processes are also used to Uma Pharmatech Machinery bioreactors to guarantee compliance with a variety of regulatory requirements, including cGMP, FDA, and EMA.

Advanced Control and Automation Offer Bu Uma Pharmatech Fermenter(in Telangana-India)

Our bioreactors have cutting-edge automation and control technologies that make it possible to precisely and repeatedly manipulate a variety of parameters. Many software platforms, including SCADA, LabVIEW, and Delta, can be used to programmed and control UPM bioreactors. Several feedback and feedforward control loops, which can modify the input and output variables based on the measured data, can also be installed in UPM bioreactors. A variety of analytical techniques, including spectrophotometry, GC, and HPLC, can be linked with Uma Pharmatech bioreactors to provide real-time monitoring and analysis of different metabolites and products.

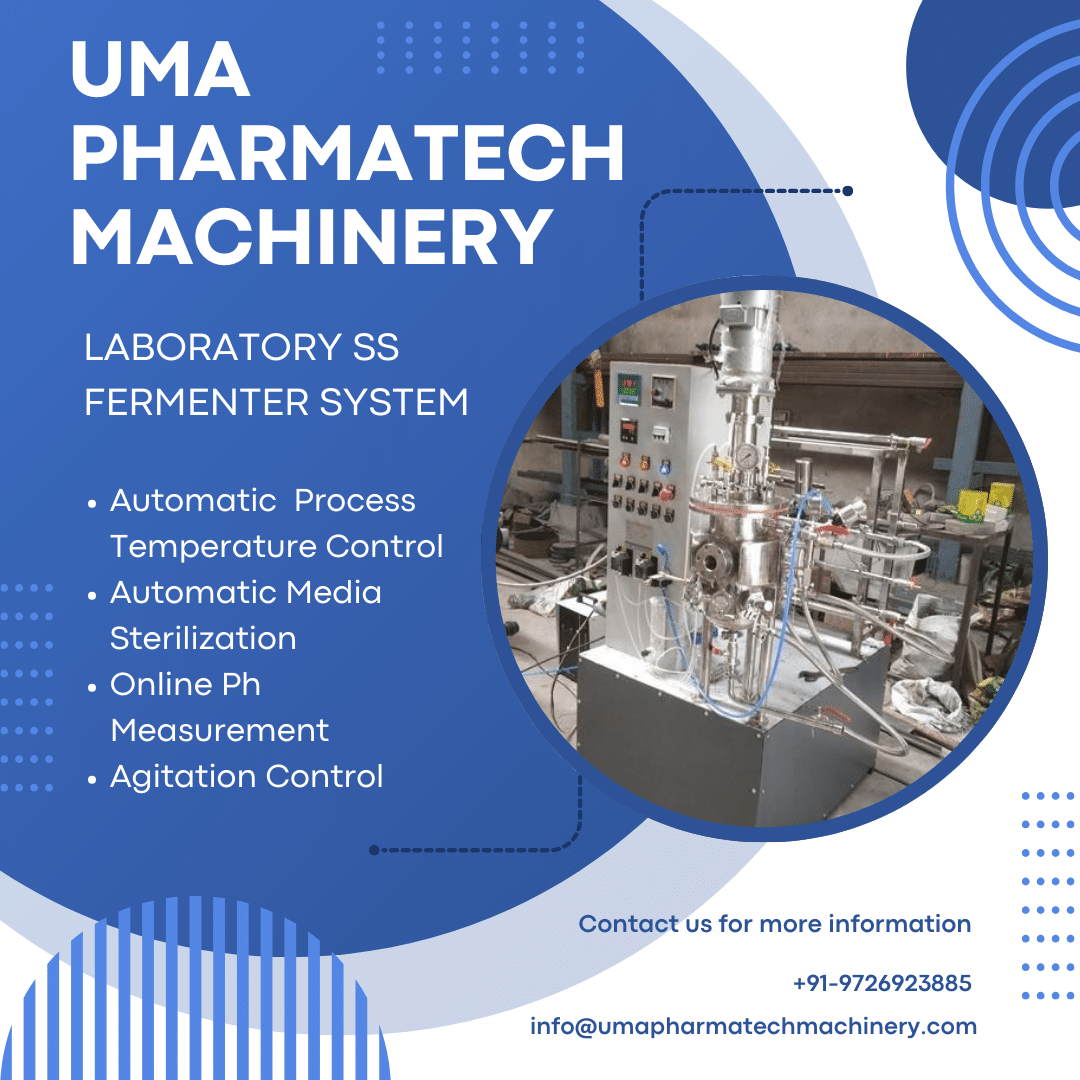

Laboratory Bioreactor Manufacturers in Telangana

Uma Pharmatech Machinery, situated in Ahmedabad, Gujarat, proudly stands as a distinguished laboratory bioreactor manufacturer in Telangana, enriching the state’s burgeoning biotechnology and pharmaceutical sectors. With a steadfast commitment to innovation and quality, Uma Pharmatech Machinery provides cutting-edge laboratory bioreactors that are indispensable for Telangana’s scientific research and development. These bioreactors are meticulously crafted to meet the specific needs of laboratory-scale microbial and cell culture processes, ensuring precision and reliability. Uma Pharmatech Machinery’s dedication to customization guarantees that each laboratory bioreactor is tailored to Telangana’s unique bioprocessing requirements, solidifying their role as a trusted partner in the region’s scientific advancement.

What is the principle of fermenter?

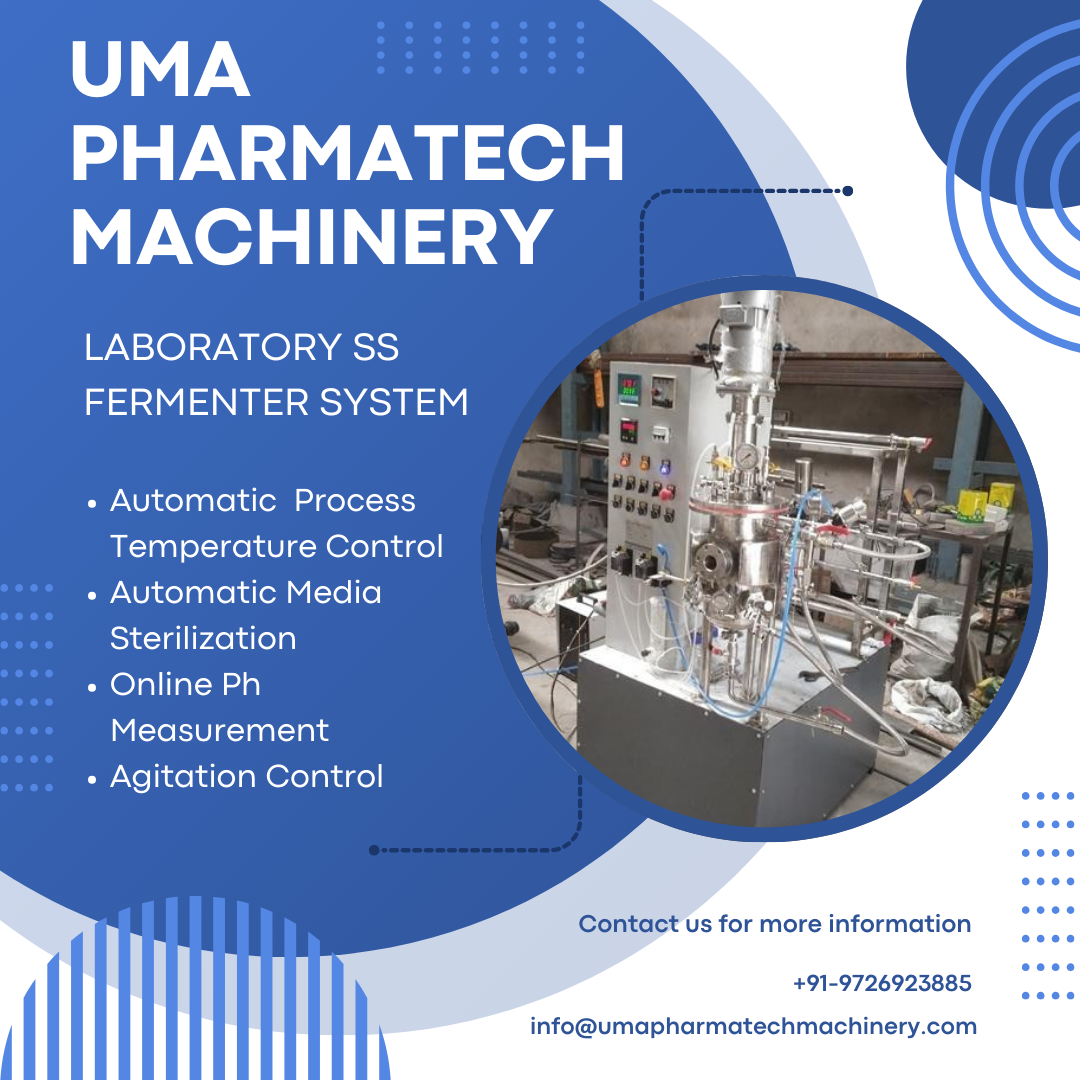

Basic Principal Of Fermenter is To Provide Contamination Free Batch During Process. Major Parameter Need To Control Like Sterilization Temperature, Process Temperature, Process Pressure, Calibration, Ph, Oxygen Control, Filtration, Condensation, Agitation Speed Control Etc. For Pilot Scale and Laboratory Fermenter Uma Pharmatech Machinery is Best Brand To Purchase Fermenter In India.

Mainly Two Types Of Fermenter Is Used as Per Sterilization Method 1) Insitu Serializable Fermenter

2) Autoclavable Fermenter

Autoclavable Fermenter Made Of Glass. Glass Fermenter Generally Used In College and Institutes For Various Study For Student. Pressure Can Not Take Place In Glass Fermenter. During Pressure Possitive Pressure Can Not take in Glass Fermenter Bioreactor

Where as Insitu Serializable Fermenter Is Used In Biotechnology Lab and Industry. All Process Can Be Done Automatically With Sterilization in This Fermenter. This Insitu Fermenter is Made Of Stainless Steel 316 Grade. Electric Steam Generator Is Use To Sterile. Whole Process Can Be Automate In Insitu Serializable Fermenter Using SCADA or PLC Based Programming.

Performance Elements in Bioreactors

The effectiveness of a bioreactor is influenced by a number of factors. These elements consist of:

Nutritional Status

The development of germs or cells depends on the availability of nutrients. The system for supplying nutrients should be created to deliver the needed nutrients at the optimum rate.

Oxygen Flow

For germs or cells to multiply, oxygen must be present. The sparger ought to.

Which bioreactor is best?

The intended application, the type of cells or microorganisms being produced, the required size of production, and the budget are some of the variables that determine the optimal bioreactor. Stirred tank, airlift, and photobioreactors are just a few of the different kinds of bioreactors that are available.

Stirred tank bioreactors are frequently used to produce a variety of biological products, including industrial enzymes, proteins, and vaccines. They are most effective for growing cells that need a lot of mixing and aeration.

Cells that need low shear stress conditions and are sensitive to shear forces can be grown in airlift bioreactors. They are frequently employed to produce algae, bacteria, and yeast.

The ideal bioreactor for your needs will ultimately depend on your unique needs and application. To discover the bioreactor that best meets your demands, it is advised to speak with a subject matter specialist and do extensive research.

Algae and cyanobacteria are two examples of the photosynthetic microorganisms that can be grown in photobioreactors. With a controlled light source and an improved gas exchange, they offer a regulated environment for the growth of these bacteria.

A laboratory fermentor’s capacity can vary significantly depending on the maker and intended usage. Small-scale investigations are conducted in laboratory fermentors, which have capacities ranging from a few litres to several hundred litres.

Sizes of standard laboratory fermentors include 1, 2, 5, 10, 20, and 50 litres. These more compact fermentors are perfect for process improvement, product testing, and research & development.

Some manufacturers provide custom-sized fermentors in addition to the regular sizes to satisfy particular needs and allow for greater scale experiments. It is advised to carefully assess the fermentor’s size and capacity based on the scale and length of your experiment, as well as your space constraints and financial constraints.

Types of Bioreactors:

There are numerous types of bioreactors on the market, each created to satisfy particular needs. Typical types of bioreactors include the following:

The most popular kind of bioreactors are stirred tank bioreactors, which are made for microbial cultures. To mix the culture and supply oxygen for the growth of the microorganisms, they utilise a mechanical agitator.

Similar to stirred tank bioreactors but lacking a mechanical agitator are bubble column bioreactors. They instead rely on bubble movement to mix the culture and supply oxygen.

Air-Lift Bioreactors: These bioreactors circulate the culture and supply oxygen via rising bubbles. They are perfect for delicate cell lines and are frequently used for cell cultures.

Applications of Bioreactors:

Applications for bioreactors in the field of biotechnology are numerous. Common applications include the following:

Cell Culture: Cells are produced in bioreactors for therapeutic protein manufacturing, medication development, and medical research.

Bioreactors are used for the fermentation process, which produces industrial chemicals, food additives, and biofuels.

Bioremediation: Wastewater and contaminated soil are treated in bioreactors.

Advantages of Bioreactors:

Comparing bioreactors to conventional production techniques, there are a number of benefits. Among the benefits are:

Improved Yield: Compared to conventional production techniques, bioreactors give higher yields, which lowers production costs.

Environment Control: By providing a regulated environment for the development of microorganisms, bioreactors produce products of consistently high quality.

Scale-up: Bioreactors are perfect for industrial applications since they are simple to scale up for large-scale output.

Best Fermenter Suppliers In Telangana-India

Because they offer a regulated environment for the development of microorganisms and produce products of consistent quality, bioreactors are crucial tools in the field of biotechnology. Because there are so many various kinds of bioreactors on the market and they have so many diverse uses, they are now essential for producing industrial chemicals, biofuels, and medicinal proteins. Make sure to speak with a reputable provider before making an investment in bioreactors to ensure that you acquire the best bioreactor for your unique needs.

Who Manufactures Bioreactor Fermenter?

Many Company are available In Indian Market For Laboratory Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Trusted Brand For Manufacturing Of Pilot Scale Fermenter and Industrial Bioreactors. UPM Provide Best Quality and Automatic Bioreactor Manufacturer in India. Uma Pharmatech Present Low Cost Industrial Fermenter Bioreactor With All Necessary Equipments Like Compressor, Chiller, Steam Boiler, Cooling Tower, Pipeline, Skid Erc..

Lab Model Of Microbial Bioreactor Price Start From 500000/- Per Fermentation Plant Setup.

Pilot Scale Model Of Microbial Bioreactor Price Start From 1500000/- Per Fermentation Plant Setup.

Lab Model Of Microbial Bioreactor Price Start From 2500000/- Per Fermentation Plant Setup.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

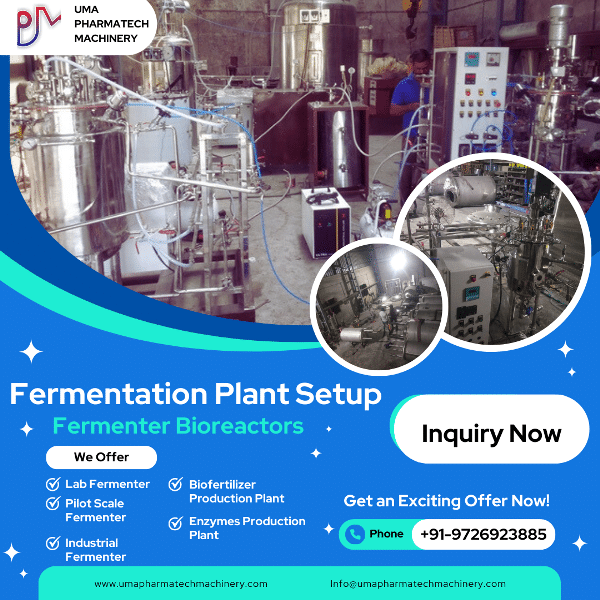

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.