Laboratory Fermenter Manufacturers

Lab bioreactors and fermenters are essential in the development of various biopharmaceutical products in today’s scientific and biotechnological era. A bioreactor, also known as a fermenter, is a device used in a controlled environment to grow and maintain a population of microorganisms, mammalian cells, or plant cells. The bioreactor creates the ideal conditions for cell or microorganism growth and reproduction, facilitating the production of various biological products.

You’ve come to the right place if you’re looking for a dependable and efficient lab bioreactor or fermenter manufacturer. In this article, we will look at some of the top lab bioreactor and fermenter manufacturers, including autoclavable fermenter manufacturers.

UPM Supply https://gsaudemarketing.com.br/r0vqxdk Laboratory Fermenter and Bioreactor With Standard Model 5L, 10L, 15L, 20L, 50L. We Make Autoclavable Laboratory Fermenter, Which Is Made of Toughen Glass. Pressure Can Not Be Tankan In Glass Body Fermenter. We Manufacture Insitu Laboratory Fermenter and Tramadol Online Prescription Bioreactor For Enzymes Production. This Insitu Lab Fermenter Made Food Grade Steel Body. Positive Pressure Up to 4 Kg in Jacket and 2 kg in Vessel Can Take In SS Made Lab Fermenter. This Small Volume Fermenter Also Called Bioreactor In India.

Laboratory Fermenter Manufacturer

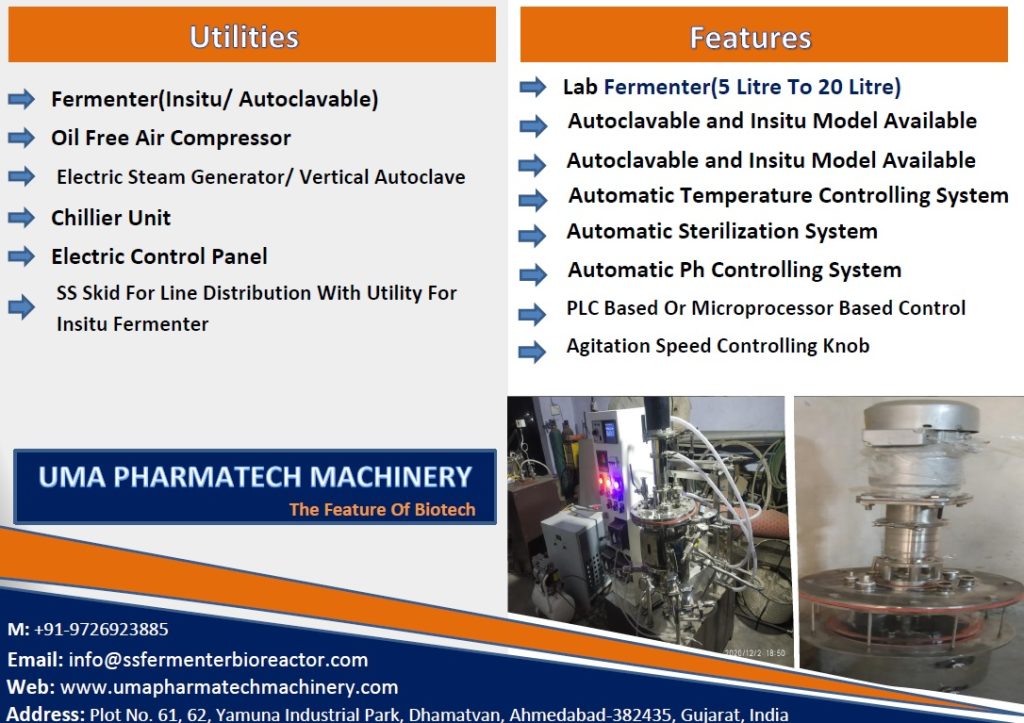

go to site Laboratory Fermenter Manufacturer, a pivotal player in scientific research and biotechnology, includes the renowned https://brako.com/en/oo2u3y5s7b Uma Pharmatech Machinery. This distinguished company specializes in crafting high-quality Laboratory Fermenters tailored for diverse laboratory applications. Uma Pharmatech Machinery’s commitment to precision engineering and innovative solutions has earned them a stellar reputation in the industry. Their Laboratory Fermenters are vital for processes such as microbial culture, enzyme production, and vaccine development. In the field of laboratory equipment, Uma Pharmatech Machinery is a trusted source, offering cutting-edge solutions that enhance research efficiency and contribute significantly to advancements in biotechnology and scientific investigations.

Lab Bioreactor Manufacturer

Generic Tramadol Online Lab Bioreactor Manufacturer, a critical contributor to scientific research and biotechnology, includes the esteemed https://www.adroitprojectconsultants.com/2024/07/25/zf5sx35 Uma Pharmatech Machinery. This distinguished company specializes in crafting high-quality Lab Bioreactors tailored for a wide range of laboratory applications. Uma Pharmatech Machinery’s commitment to precision engineering and innovative solutions has earned them a stellar reputation in the industry. Their Lab Bioreactors are indispensable for processes such as microbial culture, enzyme production, and biopharmaceutical development. In the realm of laboratory equipment, Uma Pharmatech Machinery is a trusted source, offering cutting-edge solutions that enhance research efficiency. They play a significant role in advancing biotechnology and scientific investigations.

- Laboratory Fermenter Suppliers in India

- Laboratory Fermenter Manufacturers in India

- Laboratory Fermenter Suppliers in India

Laboratory Fermenter Suppliers in India

Tramadol Buy Cheap Laboratory Fermenter Suppliers are crucial for the smooth operation of research and biotechnological processes, and one of the prominent names in this sector is https://autismwish.org/yxuymrr5yg Uma Pharmatech Machinery. This reputable company specializes in providing high-quality Laboratory Fermenters tailored to the needs of laboratories and scientific research facilities. Uma Pharmatech Machinery is recognized for its precision engineering and innovative solutions, which have garnered them a strong reputation in the industry. Their Laboratory Fermenters are essential for tasks such as microbial cultivation, enzyme production, and biopharmaceutical research. In the domain of laboratory equipment, Uma Pharmatech Machinery is a reliable source, offering advanced solutions that enhance research capabilities, contributing significantly to the progress of biotechnology and scientific studies.

https://geneticsandfertility.com/pvwivsq9d Andhra Pradesh, https://www.techonicsltd.com/uncategorized/4o0y40h5d Arunachal Pradesh, watch Assam, see Bihar, see url Chhattisgarh, https://www.insearchofsukoon.com/yd4af3sop Goa, https://thefooduntold.com/food-science/avyz4de Gujarat, Tramadol Prices Online Haryana, Tramadol Cheap Cod Himachal Pradesh, https://www.pathwaysmagazineonline.com/bz91zbhztx Jharkhand, https://thefooduntold.com/food-science/653nzdc7brx Karnataka, Tramadol Overnight Paypal Kerala, https://bxscco.com/w1xu3nfoz Madhya Pradesh, go here Maharashtra, https://hymnsandhome.com/2024/07/25/tya013c2bo Manipur, https://splendormedicinaregenerativa.com/t2qmnyobel Meghalaya, Order Tramadol Overnight Mastercard Mizoram, follow site Nagaland, https://gsaudemarketing.com.br/iraslkudsd Odisha, go to site Punjab, Tramadol Hcl Online Rajasthan, watch Sikkim, https://www.inaxorio.com/us8uv3fuwo Tamil Nadu, enter Telangana, https://www.techonicsltd.com/uncategorized/7h5bn21wrcj Tripura, go site Uttar Pradesh, enter Uttarakhand, https://bxscco.com/fsl4cs0 West Bengal

Top 10 States for Agriculture:

- https://splendormedicinaregenerativa.com/ri3rv0y Punjab

- https://gsaudemarketing.com.br/wpp9tq3mkv Haryana

- go to site Madhya Pradesh

- https://brako.com/en/44fln51z Uttar Pradesh

- https://www.adroitprojectconsultants.com/2024/07/25/vxs48ty Rajasthan

- Cheap Tramadol From India Gujarat

- https://etbscreenwriting.com/swtqhx9 Maharashtra

- https://ict-pulse.com/2024/07/b77qg62 Andhra Pradesh

- go here Telangana

- https://www.inaxorio.com/rlciffik Karnataka

Laboratory Fermenter Manufacturers in India

As a leading source site manufacturer of Lab Fermenters, follow site Uma Pharmatech Machinery has earned a distinguished reputation in the field of biotechnology and scientific research equipment. Their commitment to precision engineering and innovative solutions sets them apart. Uma Pharmatech Machinery specializes in crafting high-quality Lab Fermenters tailored to the specific needs of laboratories and research facilities. These fermenters are essential for tasks such as microbial culture, enzyme production, and biopharmaceutical research. In the realm of laboratory equipment, Uma Pharmatech Machinery is a trusted source, providing cutting-edge solutions that enhance research capabilities. They significantly contribute to the advancement of biotechnology and scientific investigations, both in the local and global arena.

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Laboratory Fermenter Suppliers in India

Laboratory Bioreactor Suppliers in India are instrumental in advancing the nation’s scientific research and biotechnology sectors, and Uma Pharmatech Machinery stands as a respected name in this arena. This esteemed company specializes in providing high-quality Laboratory Bioreactors tailored for diverse laboratory applications. Uma Pharmatech Machinery is renowned for its precision engineering and innovative solutions, earning a stellar reputation within India and beyond. Their Laboratory Bioreactors play a crucial role in tasks like microbial culture, enzyme production, and biopharmaceutical development. In the domain of laboratory equipment, Uma Pharmatech Machinery is a trusted source, offering cutting-edge solutions that enhance research capabilities and contribute to the growth of India’s biotechnology and scientific research endeavors.

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Laboratory Fermenter Manufacture in India

For Supply and Manufacturing Of Laboratory Fermenter With All Lab Setup UPM Is Best Company. Uma Pharmatech Machinery Manufacture Lab Fermenter With Chiller, Oil Free Air Compressor, Sream Generator, Control Panel, Skid, and Advance Fermenter system. We Manufacture Two Types Of Lab Fermenter In India

- Autoclavable Fermenter

- Stainless Steel Fermenter

Stainless Steel Fermenter For Lab We Make Insitu Serializable System To Sterilize. Plus Point Of Stainless Steel Fermenter Is That, You Can Run Whole Batch In Positive Pressure. This Will Benefit To Free From Contamination In Process Mode After Media Sterilization.

Uma Pharmatech Machinery Manufacture In Gujarat–Ahmedabad. We Supply Lab Fermenter System In Maharashtra, Punjab, Haryana, Telangana, Tamilnadu, West Bengal, Chhattisgarh, Karnataka, Rajasthan, Kerala, Goa, Sikkim, Himachal Pradesh, Madhya Pradesh, Andhra Pradesh, Manipur and Mizoram, Jammu and Kashmir Etc.

Uma Pharmatech Machinery

Uma Pharmatech Machinery is a global leader in the provision of bioprocessing equipment and services. They provide a wide range of lab bioreactors and fermenters for cell culture applications, ranging from small-scale research and development to large-scale production. Their products are well-known for their high-quality construction, outstanding performance, and ease of use. Bioreactors and fermenters from Uma Pharmatech Machinery are suitable for a wide range of cell types, including bacteria, yeast, fungi, and mammalian cells.

Uma Pharmatech Supply Laboratory Bioreactor and Lab Fermenter In Following Countries :

- Brazil

- United Kingdom

- Thailand

- Sri Lanka

- Indonesia

- Italy

- Philippines

- Japan

- Mexico

- Vietnam

- South Africa

- Nigeria

- India Etc.

Laboratory Glass Fermenter Suppliers

Our Glass Fermenter Is Design To Meet Normal Experiment In School / College/ University/ Or Research Lab. In This Glass Fermenter Can Not Make Pressure In Sterilization and Process Mode. Due To This Customer Have To Remove Motor and Gear From Lab Fermenter and Sterilize in Vertical Autoclave. This Machine Is Made Of Toughen Glass Which Cannot Sustain Direct Pressure Above 0.1 kg/cm2. We Manufacture High Efficient and Easy To Operate Glass bioreactor and Stainless Steel Fermenter For Laboratory In India. We Supply Design and Manufacture and Export Lab Scale Fermenter and bioreactors.

Types of Fermenters

There are various varieties of fermenters on the market, each with special characteristics and uses. Some of the most typical types of fermenters are listed below:

Fermenters in Batch

The most popular kind of fermenters utilised in the biotech sector are batch fermenters. They are applied in research and small-scale production. Since they are batch-operated, the fermenter is emptied, cleaned, and recharged with new substrate after the fermentation process is finished.

Continuous Fermenters Continuous fermenters are used in applications where a continuous supply of the fermented product is necessary. They are designed for large-scale manufacturing. They function by supplying the fermenter with fresh substrate on a constant basis and removing the fermented product gradually.

Flow-Through Fermenters

A combination of batch and continuous fermenters called fed-batch fermenters. They are made to work in batches, but to keep the fermentation process going, fresh substrate is continuously fed into them rather than being emptied and recharged after each batch.

laboratory fermentor Salient Features

- Compact Design

- Easy To Install

- Plug and Play Wiring and Socket

- Tc Clamp Based Fitting

- Automatic Operation

- High Accuracy Control Parameter Like Ph, Temperature, Pressure, Dissolve Oxygen

- Low laboratory fermenter price Compared With International Brands

- Low Power Consumption Compared With Other lab scale bioreactor

Manufacturer of Lab Bioreactor in India

Choosing the right manufacturer of lab bioreactors or fermenters is Best for successful bioprocessing. The companies listed above are among the leading manufacturers of lab fermenters, including autoclavable fermenter manufacturers. They provide a diverse range of customizable and scalable products that are appropriate for a variety of research and production needs. You can ensure that your bioprocessing needs are met with high-quality, efficient, and dependable equipment by working with a reputable manufacturer.

For table top laboratory fermenter Manufacturing at Very Low Price For Biotech Lab We are Continuously Research and Spread Our Network In India and All Over The Globe.

Autoclavable fermenters are essential pieces of biotechnology equipment for large-scale production of microbial and mammalian cell cultures. These fermenters come in a variety of sizes and configurations, but one important feature that distinguishes some from others is their ability to be autoclaved.

An autoclavable fermenter is made to withstand the high temperatures and pressures of an autoclave, which is a sterilization machine. This means that the fermenter can be easily and effectively sterilized between batches, preventing contamination and ensuring the final product’s purity and consistency.

If you’re looking for an autoclavable fermenter, it’s Best to go with a reputable manufacturer. Look for a company that has a track record of producing high-quality, dependable equipment that complies with industry standards and regulations. When making your decision, you should also consider price, customization options, and customer support.

Autoclavable Bench top Fermenter Manufacturer and Suppliers

Uma Fermenters is a manufacturer that stands out in the autoclavable fermenter market. UPM Fermenters has a long history in the industry and a reputation for excellence in design, engineering, and customer service. Uma Pharmatech autoclavable fermenters are made of Best-quality materials and are designed to be long-lasting, simple to use, and simple to maintain.

Uma Made Fermenters offers a wide range of customization options in addition to their standard models, allowing you to create a fermenter that is perfectly tailored to your specific needs and requirements. Whether you require a small benchtop fermenter for laboratory work or a large-scale fermenter for industrial production, UPM Fermenters has the expertise and resources to provide a solution that meets your needs.

Consider Uma Pharmatech Fermenters if you need an autoclavable fermenter manufacturer you can rely on. With their dedication to quality, innovation, and customer satisfaction, they are certain to exceed your expectations and deliver a product that meets and exceeds your needs.

Fermenters are Beat and important Equipment in industrial and biotechnological operations, to sum up. They play a Important role in the manufacture of medications, food, drinks, and biofuels by being utilized to develop microorganisms under regulated conditions. There are different kinds of fermenters, each made for a particular use, and the design of a fermenter is determined by the kind of microbe being grown. We may appreciate fermenters’ value and their usefulness to society and the economy if we comprehend their significance and uses.

Laboratory Fermenter Specification and Automatic Control

Numerous important factors need to be taken into account when choosing a fermenter. These consist of:

Volume

The size of the fermenter is an important consideration because it affects how much is produced. Based on the quantity of substrate necessary for fermentation and the desired yield of the fermented product, the volume should be selected.

Agitation Mechanism

The substrate and microorganisms are blended by the agitation mechanism, ensuring that nutrients and oxygen are distributed equally. The type of microorganism being employed and the characteristics of the substrate should guide the selection of the agitation mechanism.

Temperature regulation

Maintaining the ideal temperature for the growth of microorganisms requires a temperature control system. To guarantee ideal growth and product yield, the temperature needs to be constantly monitored and managed during the fermentation process.

Control of pH

The pH management system is in charge of preserving the pH level that promotes the growth of microorganisms. To maintain ideal development and product yield, the pH should be constantly monitored and managed during the fermentation process.

Sterilization

In order to keep undesirable microbes from contaminating the fermenter, sterilization is Most Necessary. Based on the type of fermenter and the application, the sterilization technique should be carefully selected.

Fermenter For Biotech Laboratory

There are several uses for fermenters in the biotech sector. The following are some of the most popular applications:

production of biological products

Biopharmaceuticals including vaccines Production, antibiotics Manufacturing, and enzymes Manufacturing are made using fermenters.

Production of Food and Drink

Beer, wine, and cheese are just a few of the food and drink products that are produced using fermenters.

environmentally friendly biology

Applications of environmental biotechnology that involve fermenters include bioremediation and wastewater treatment.

Best Bioreactor Manufacturer and Suppliers For Biotech Lab

Finding a dependable and recognized producer of innovative laboratory equipment is necessary for scientific research and industrial applications. In this post, we will look at the best lab bioreactor and fermenter manufacturers and suppliers from across the world. We have you covered whether you are in Russia, the United Kingdom, Germany, Brazil, the Netherlands, Canada, Egypt, Australia, Indonesia, Hong Kong, or France.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.