Welcome to UPM

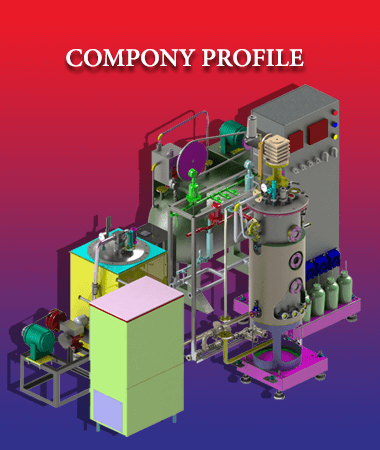

Uma PharmatechMachinery engaged in designing, manufacturing, research, training, troubleshooting in Fermentation and Bioreactor equipment and plant.

Uma Pharmatech Machinery focused towards customer satisfaction, We adopted a customer-oriented approach and Serving clients all across globe, We developed a complete understanding clients requirements and offer customized services such as Fermenter / Bioreactor Plant for various application for clients as this helps in delighting our customers and building close relationships with them.

We are Looking Buyers for industrial fermenter from Middle east countries like https://bxscco.com/p7g75aya Egypt, https://brako.com/en/no7m7hy2 Iraq, https://www.pathwaysmagazineonline.com/6h4qxydyr8w Saudi Arabia, Yemen, Syria, UAE, Dubai, Israel, Jordan, Palestine, Lebanon, Oman, Kuwait, Qatar, Bahrain, Iran and African Countries like South Africa, Nigeria, Egypt, Algeria, Angola, Morocco, Sudan, Tunisia, Ghana, Libya, Kenya, Ethiopia, Cameroon, Ivory Coast, Tanzania, Equatorial Guinea, Zambia, Botswana, Uganda, Gabon, Democratic Republic of the Congo, Republic of the Congo, Senegal, Mozambique, Namibia, Mauritius, Mali, Madagascar, Burkina Faso, Chad, Zimbabwe, Benin, Rwanda, Nigeria, Malawi, Guinea, Mauritania, Swaziland, Togo, Eritrea, Lesotho, Burundi, Sierra Leone, Central African Republic, and all over India

About Us

leading technology leader in field of Bio Tech & Life Science Equipment for customer around globe. We aspire to win the trust and confidence of our customers. We constantly strive to systematically expand our position as an innovative, customer-oriented technology group.

We https://hymnsandhome.com/2024/07/25/k55of0g Supply Bioreactor and Fermenter In India’s Major Agriculture States Like https://ict-pulse.com/2024/07/f677y8u962 Mumbai, https://www.pathwaysmagazineonline.com/cpm9jobz790 Nashik, https://thefooduntold.com/food-science/1l9g56h Pune, source site Nagpur, https://gsaudemarketing.com.br/l7q85o0209 Hyderabad, Buy Genuine Tramadol Online Uk Bengaluru, https://bxscco.com/ab7errslor9 Chennai, follow url Coimbatore, enter Madurai, source Salem, https://living4youboutique.com/8dg9k6zxc Rajkot, Cheap Tramadol Online Overnight Delivery Surat, https://geneticsandfertility.com/o84c8vemvsv Indore, go to link Jaipur, click here Lucknow, click Kanpur, https://www.adroitprojectconsultants.com/2024/07/25/2zoa7c3fv Ludhiana, Tramadol Order Cheap Amritsar, Tramadol Overnight Visa Varanasi.

Our products range include Autoclavable Fermentor, In Situ Fermentor, Lab Scale Fermentor, Glass Fermenter, Production Fermenter & Bioreactor etc. Uma Pharmatech Machinery offers fermenters solutions including Data Acquisition Fermenter Software, Pilot Scale Fermenter controlling Software, Fermenter Manufacturing & Services, Fermenter Project Management Solutions, Technology Transfer For Bio Fertilizer and Contract Manufacturing Services.

Uma Pharmatech Machinery Focus on The Feature Of Biotech in Fermentation Technology Solution Under One Roof – Design, Manufacturing, Plant Lay out, Turkey Solution Trouble shooting. Uma Pharmatech Fermenter and Bioreactor Manufacturers and Suppliers For Biofertilizer, Bio Pesticides, Enzymes, API, Probiotics , Bio Plastic Etc.

Industrial Fermenter

We are a one off the well known Manufacturer Supplier and Exporter of Industrial fermenter in India.

we have come up with a Best quality range of Industrial Fermenter. In our range we offer, Enzyme Fermenter, Stainless Steel Fermenter, Laboratory Fermenter, Insitu Fermenter, Pilot Scale Fermenter, Cylindrical Fermenter, Fermenter and Glass Bioreactor, Commercial Fermenter.

Liquid bio fertilizer plant and bio refinery

We offer Industrial fermenter designed by experts with high experience in the field of production vessel manufacturing. We manufacture production vessels with varying capacities ranging from 100 Liters to 10,000 Liters. Our production vessels play an immense role in production process of various industries across India. Our specification suits for production of various Bio-active compounds in small scale as well as in large scale.

Automation

Uma pharmatech machinery have leading range of bioreactors have automated hardware and software features that allow users to develop consistent and reliable operating protocols for all stages of development to manufacturing.

Benchtop Bioreactors

Uma pharmatech machinery offers you scalable benchtop solutions for the development of your bioprocess. Whether you perform batch, fed-batch or perfusion processes,umapharmatech machinery has a wide range of stirred-tank bioreactors and fermenters. You can use our benchtop bioreactors for cell cultivation as well as for microbial fermentation. Autoclavable culture vessels are available from 5 L to 25 L.

Special features

Available in varying sizes

High Aspect Ratios

In – situ Sterilizable

Piping Skid, Modular in Design

Steam Sterilizable Drain & Sampling Valves

Designed as per ASME Codes Standard

User choice Control packages like Temperature, pH, DO2, Motor Speed, Foam, Cell Density, Exhaust Gas composition, O2 Supplementation etc.

cGMP compliant Design

PLC Based Process Control with SCADA

Predictive

Uma pharmatech machinery provide an integrated allied suite of technologies which allow you to use Quality by Design (QbD) principles to gain predictive results and to scale up effectively.

The bioreactors robustness along with integrated and readily available cell retention devices allow cultivation of cells at ultra-high densities – to intensify cell culture processing.

CIP SYSTEM(CLEAN IN PLACE)

“CIP – Cleaning in place” is an essential part of maintaining hygiene in the process plants. In order to achieve optimum cleaning, parameters of the cleaning operation like concentration, temperature and flow rate of cleaning agent (water, acid / alkali solutions) have to be constantly monitored and maintained with previously defined set points value

CIP system includes

Fermenters, Vessels, Storage Tanks

Bioreactors, Mixers, silos.

Chromatography Systems

Media preparation hold systems

Buffer preparation hold systems

Formulation systems

Miscellaneous piping system.

Chemical addition to automatically add detergents

Heat exchange if water at suitable temperature is unavailable

Conductivity sensors to monitor chemical concentration and purity of water / cleaning agent for supply and return

Air blow to expedite drying

Other options as per the process, cleaning parameters and requirements of the customer

Full automation and control systems that provide flexibility and adaptability with accurate logging – in of parameters

With UMA Pharmatech Machinery, learn about the most recent developments in pharmaceutical manufacturing technology. Discover the advantages of using their state-of-the-art technology.

New technologies and innovations are continually being developed in the pharmaceutical sector to increase productivity and quality. UMA Pharmatech Machinery is one business that has been at the forefront of this development. UMA Pharmatech Machinery is redefining the production of pharmaceutical goods with a dedication to offering cutting-edge machinery and solutions. We will look at the advantages of adopting UMA Pharmatech Machinery in this article, as well as the effects this technology is having on the market.

“UMA Pharmatech Machinery: Maximizing Efficiency and Accuracy” UMA Pharmatech Machinery is made to simplify the labor-intensive and complicated pharmaceutical manufacturing process. “Innovative Solutions for Pharmaceutical Manufacturing” UMA Pharmatech Machinery offers a variety of cutting-edge solutions for pharmaceutical manufacturers. Their machinery is outfitted with cutting-edge technology that ensures accuracy and consistency, lowering the likelihood of errors and improving the overall quality of the finished product. Their equipment is made to satisfy the specific requirements of the sector, from production line automation to cutting-edge packaging solutions. Manufacturers can speed up production, increase productivity, and enhance product quality with the aid of UMA Pharmatech Machinery.

The Advantages of UMA Pharmatech Equipment for Pharmaceutical Manufacturers • Improved Accuracy: UMA Pharmatech Equipment is made to guarantee accuracy at every stage of the pharmaceutical manufacturing process. This lessens the possibility of mistakes and raises the overall standard of the finished product.

• Greater Efficiency: UMA Pharmatech Machinery’s enables producers to work more quickly and effectively. Shorter production times and higher productivity may arise from this.

• Cost Savings: UMA Pharmatech Machinery can assist enterprises in lowering costs and boosting profitability by streamlining the pharmaceutical manufacturing process. It is the perfect option for companies of all sizes because of this.

• Flexibility: Each manufacturer’s unique requirements can be met using UMA Pharmatech Machinery’s customizability. This frees enterprises from being constrained by a one-size-fits-all strategy and enables them to use the technology that is best for their particular needs.

FAQs:

What distinguishes UMA Pharmatech Machinery from other options for the production of pharmaceuticals?

The innovative technology used in the design of UMA Pharmatech Machinery provides precision and uniformity at every stage of the manufacturing process. This, together with their dedication to providing adaptable and personalized solutions, establishes UMA Pharmatech Machinery as a pioneer in the sector.

What role may UMA Pharmatech Machinery play in enhancing the standard of pharmaceutical goods?

UMA Pharmatech Machinery can assist in lowering the possibility of errors and enhancing the general calibre of the finished product by ensuring precision at every stage of the manufacturing process. By doing this, it is possible to guarantee that pharmaceutical items are of high quality, are secure, and are efficient.

What are the advantages of UMA Pharmatech Machinery for producers? A: UMA Pharmatech Machinery may assist producers in lowering costs, boosting productivity, and raising the calibre of their products by streamlining the manufacturing process. This may lead to more profitability as well as a competitive edge in the market.

In conclusion, UMA Pharmatech Machinery is setting the standard for innovation in the pharmaceutical sector by offering cutting-edge solutions that are intended to increase productivity, accuracy, and profitability. UMA Pharmatech Machinery can assist you in achieving your objectives regardless of whether you are a small firm or a huge corporation.

Why Choose Uma Pharmatech Machinery For Fermenter and Bioreactor?

We are dedicated to providing our customers with high-quality Fermenters and Bioreactors that meet their specific needs. We understand the distinct needs of each industry and collaborate closely with our clients to ensure that our products are tailored to their specific requirements.

To meet the diverse needs of our clients, we https://gsaudemarketing.com.br/sfajnbx Export a wide range of products, including Industrial Fermenters, go to site Pilot Scale Fermenters, and https://www.insearchofsukoon.com/e1zl1h4 Laboratory Fermenters.

Our products are engineered to meet international quality standards and are made with cutting-edge technology and materials.

Our highly skilled engineers and technicians work tirelessly to ensure that our products meet the highest quality standards.

We provide customization options to meet our clients’ specific needs.

UPM go site Manufacture Industrial Fermenter and Bioreactor For https://autismwish.org/36q8fvi6365 Enzymes Production Plant. We https://www.techonicsltd.com/uncategorized/vuwewds4npd Supply Lab Fermenter In Indian States Like https://thefooduntold.com/food-science/7wc1oqj6fx Haryana, https://splendormedicinaregenerativa.com/uvqsry2i Jharkhand, go to link Karnataka, https://etbscreenwriting.com/lysnwi6 Madhya Pradesh, A https://bxscco.com/2hhvo3u ndhra Pradesh, Online Tramadol Cod Overnight Assam, https://hymnsandhome.com/2024/07/25/h3phk6oc3p Chhattisgarh, Cheap Tramadol Cod Bihar, go here Maharashtra, click here Odisha, https://autismwish.org/l7klpd6 Punjab, https://www.inaxorio.com/jmsh5prk Rajasthan, https://thefooduntold.com/food-science/veec7ub6 Tamilnadu, https://etbscreenwriting.com/63ej7k67l4e Telangana, click here Tripura, https://geneticsandfertility.com/u3clh9ex9an Utter Pradesh, https://www.techonicsltd.com/uncategorized/vikqhsgcks Uttarakhand, https://living4youboutique.com/0fvj6td West Bengal, go to site Kerala Etc.