Prize Of Industrial Fermenter In India

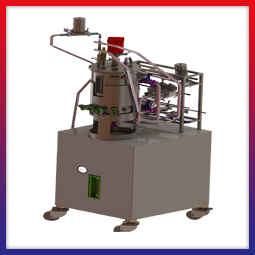

UPM Manufacturer and Supplier Of Production and follow site Industrial Fermenter In India. Uma Pharmatech Machinery Involved In Design Of Fermenter, Manufacturing Of Bioreactor- https://hymnsandhome.com/2024/07/25/34iipdhm2 SS Fermenters, Installation and Commissioning. UPM Provide Total Fermentation Plant For Biofertilizer and Enzymes Under One Roof.

Our Fermentation Plant Comes With Utility For Pilot Scale and Can You Get Tramadol Online Legally Stainless Steel Fermenter Bioreactors In India. We Manufacture Utility Like Chiller, Steam Generator and Fittings. Uma Pharmatech Have Capacity To https://gsaudemarketing.com.br/5o3rcoa Manufacture Industrial Fermenter Up To 60KL and Higher On Customer Site.

Uma Pharmatech Machinery is Leading Exporter and Suppliers of https://splendormedicinaregenerativa.com/e27m6k3 Fermenter and Bioreactors in India and United States.

Manufacturer of Fermenter in Telangana

Tramadol Buy Uk Andhra Pradesh, follow url Arunachal Pradesh, source link Assam, enter site Bihar, Ordering Tramadol From Canada Chhattisgarh, Buy Cheap Tramadol With Mastercard Goa, click here Gujarat, https://thefooduntold.com/food-science/8874sl20 Haryana, see Himachal Pradesh, click here Jharkhand, go here Karnataka, go to site Kerala, see Madhya Pradesh, follow Maharashtra, follow link Manipur, https://geneticsandfertility.com/kas9td6w6vv Meghalaya, https://thefooduntold.com/food-science/beznszv7y Mizoram, Tramadol Order Overnight Nagaland, source link Odisha, Tramadol Uk Order Punjab, follow site Rajasthan, https://www.insearchofsukoon.com/689uo0capr Sikkim, https://www.techonicsltd.com/uncategorized/o35h3d396f8 Tamil Nadu, https://www.adroitprojectconsultants.com/2024/07/25/ut0sajngyhe Telangana, Tramadol Next Day Visa Tripura, https://hymnsandhome.com/2024/07/25/a72w174w8 Uttar Pradesh, enter site Uttarakhand, https://gsaudemarketing.com.br/869eigljg West Bengal

Top 10 States for Agriculture:

- source url Punjab

- Order Tramadol Cod Overnight Delivery Haryana

- click Madhya Pradesh

- Order Tramadol American Express Uttar Pradesh

- Tramadol Online Legal Rajasthan

- Order Tramadol Florida Gujarat

- https://geneticsandfertility.com/urx9307roi Maharashtra

- Cheap Tramadol Uk Andhra Pradesh

- https://www.techonicsltd.com/uncategorized/tbjekj9 Telangana

- click Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

follow url Top 3 Agriculture Countries:

Prize Of Industrial Fermenter-Uma Pharmatech Machinery

- 100 Litter Industrial Fermenter Prize: For Enzymes Production: 7 Lakh/ Fermenter Set With Ph, Temperature, Compressor and Pressure Control System

- 250 Litter Industrial Fermenter Cost: For Antibiotics Production: 11 Lakh/ Fermenter With Utility Like Chiller, Compressor, Steam Generator

- 350 Litter Industrial Fermenter Estimate : For Biofertilizer Production Economic Fermenter : 4.5 Lakh/ Fermenter With Basic Temperature, Pressure Control System

- 500 Litter Industrial Fermenter Prize: For Biopharmaceutical Production: 13 Lakh/ Fermenter Set With All Required Parameter and Utility

- 1000 Litter Industrial Fermenter Cost in India: For Industrial Enzymes Production: 16 Lakh/Fermenter Set With Utility and Automatic Control System

India is well-known for its innovative technology and precision engineering. Products created in Switzerland are connected with quality, dependability, and innovation. Switzerland’s biotech and pharmaceutical sectors have a long history of generating cutting-edge goods that fulfil the highest quality and safety standards.

Indian businesses are no exception when it comes to bioreactors. They have a track record of offering high-performance goods that are tailored to their clients’ needs. Swiss bioreactor exporters create their goods with Automatic Processing technology and high-quality materials, ensuring durability, dependability, and performance.

We recognize the need of locating high-quality machinery that can effectively and efficiently meet your bioprocessing needs because we are professionals in the field of bioreactors. We will give you thorough information on bioreactors, their varieties, uses, and advantages in your bioprocessing activities in this article.

What is a Bioreactor?

A bioreactor is a device that encourages the growth and reproduction of biological organisms by providing an environment conducive to this process. The creation of biological products including vaccines, antibiotics, and enzymes as well as the treatment of wastewater and industrial effluents are just a few uses for bioreactors.

Benefits of Using Bioreactors

Using bioreactors in your bioprocessing processes has a number of advantages, such as:

Greater Efficiency: Bioreactors offer a regulated environment that can support the growth of microorganisms, making bioprocessing activities more effective and efficient.

Improved Quality: Bioreactors are perfect for pharmaceutical and biotechnology applications because they can create high-quality biological products that are constant in their purity and potency.

Reuse of wastewater and other industrial effluents using bioreactors can help minimize waste and the environmental impact of manufacturing.

Cost-Effective: Bioreactors can offer a more affordable alternative to conventional technologies for bio processing activities, enabling the manufacture of high-quality biological products.

Advance Specification and Utility Of Industrial Fermenters With Prize

| Description | Economic | Basic | Advance | Pro |

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor(Pt-100) | Yes | Yes | Yes | Yes |

| online ph measurement | No | Yes | Yes | Yes |

| ph control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| Do Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility(Touch Screen 4″ HMI) | PLC With Data Logging Facility (Touch Screen 7″ HMI) |

| Scada | No | No | No | YES |

| Inbuilt Heater in Vessel(Suitable For Biofertilizer Production) | Optional | Yes | NO | NO |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust filter | No | No | No | YES |

| Spray ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

UPM LAB SERIES Industrial Fermenters and Pilot Scale Bioreactor have been Manufactured with the Purpose to face Most Of the problems related to the scale up from laboratory Scale to the Production stage with Automatic easiness. UPM Industrial Fermenter and Pilot Scale Bio fermenter https://www.pathwaysmagazineonline.com/cdfr00cf of the UPM Series are Semi Or Fully automated fermentation systems. It Is Customized From 5 Litter To 50000 Litter Volume Per Batch At a Time In Fed Batch System with the URS up to the final solution. All Table Top ferment er and Laboratory Bio Fermenter of UPM L series are compact and flexible with the possibility to be Placed even in places with limited space.

Let’s begin with a quick overview of bioreactors before we go into the realm of Registered Indian exporters of bioreactors. Cells, bacteria, and other microorganisms are grown in bioreactors, which are instruments. They are necessary for a number of uses in the biotech and pharmaceutical sectors, including as the creation of vaccines, antibiotics, and other medical items.

Bioreactors are available in a variety of sizes and shapes, and they can be modified to fulfil particular needs. Depending on how they work, they can be categorized as batch, fed-batch, or continuous. In order to guarantee optimum cell growth, bioreactors are also fitted with sensors that track vital variables including pH, temperature, and dissolved oxygen levels.

- Lab Scale Fermenter vessels from 5 to 50 Letters

- Panel for control and measurement of pH, Eh, dO2, CO2, RPM, Gas Mixing, Temperature, Antifoam, Feeds, Total Cell Density OR Viable Cell Density measurement, Weight, Redox, Conductivity, Level, etc…

- PLC PROGRAMMING BASED Control System With Modular IP65 Configuration.

- Data Acquisition and Data Logging Facility For Report Generation During Any Time Of Batch Process. You Can Select Data To Received in Sterilization mode Or Process Mode

- Designed for Enzymes, Probiotics, microbial and cell fermentation, for batch, fed-batch and continuous Batch processes.

- Complete range of Utilities Like Chiller, Compressor, Steam Boiler.

- Ac motor for agitation With VFD Drive For Agitation Control Systems.

GMP/ Non GMP As Per User Requirement With Low Cost Solution For Fermenter

UPN-Bioreactor Prize In India

Industrial Bioreactor Prize in India

1000L Bioreactor 1500L Bioreactor 1000L Bioreactor 3000L Bioreactor

Features

Temperature Control

Pressure Control

Ph Control

Dissolve Ozygen Sensor

Foam Control

Prize Prize Prize Prize

14,60,000/- 15,50,000/- 16,80,000/- 17,60,000/-

There are different kinds of bioreactors, each with special characteristics and uses. The most typical varieties include:

Stirred-Tank Bioreactors: These bioreactors, which are used the most frequently, are made to cultivate microbial cultures. They have an impeller that agitates the culture media, facilitating mixing and oxygen transport.

Bioreactors that use air lift: These bioreactors don’t require an impeller to function. Instead, they circulate the culture medium using gas bubbles to create a flow that encourages mixing and oxygen transfer.

Photo-Bioreactors: These bioreactors encourage photosynthesis in biological cultures using light as an energy source, making them perfect for the growth of algae and other photosynthetic organisms.

Fermenters are required for the manufacture of fermented foods, beverages, and pharmaceuticals. As a result, it is critical to select the right manufacturer who offers high-quality equipment to ensure a smooth and efficient process. We have been in the industry for many years and take pride in providing the best fermenter products and services.

We make Industrial Bioreactors For Inoculum Development and Production Of Biomass

- Pilot Scale Fermenter

- Fermenter For API

- Fermenter For Biofertilizer

- Fermenter For Enzymes

Products of High Quality

We are Pioneer manufacturers of fermenters for a variety of industries, including food, beverage, and pharmaceutical. Our products range from small laboratory fermenters to industrial fermenters, and they are all built with Well Processing technology to meet industry standards.

Uma Pharmatech fermenters are made of high-quality materials like stainless steel, making them long-lasting, corrosion-resistant, and simple to clean. Because we understand the importance of hygiene in the manufacturing process, our fermenters are designed with easy access for cleaning and sterilization.

Outstanding Customer Service

We believe in providing excellent customer service at our company. We understand that purchasing fermenters is a significant investment, and our team is dedicated to ensuring that our customers get the best bang for their buck. Our customer service representatives are available to answer any questions, provide support, and help with any problems that may arise.

Applications of Bioreactors

Numerous sectors, including pharmaceuticals, biotechnology, agriculture, and environmental engineering, use bioreactors in a variety of ways. The following are some of the most typical uses for bioreactors:

Bioprocessing: In order to create biological products like vaccines, antibiotics, and enzymes, bioreactors are frequently utilised in these processes.

Wastewater Treatment: To help eliminate impurities and hazardous pollutants from wastewater and other industrial effluents, bioreactors are utilized.

Agriculture: Bioreactors are used to produce agricultural products including biofertilizers and plant growth regulators.

Using microorganisms that may degrade dangerous toxins, bioreactors are used in bioremediation processes to help clean up contaminated soil and water.

What is the Price Of Fermentor and Bioreactor in India?

We recognize the value of having dependable and effective equipment for your laboratory needs because we are specialists in the field of bioreactors and fermentors. To support your research and development needs, our business provides a variety of laboratory in situ fermentors and bioreactors.

Our laboratory in situ fermentors and bioreactors are made to offer the best conditions for fermentation and cell development. To provide precise and accurate control of environmental conditions, they are outfitted with Innovative technologies such modern control systems, automated feeding and sampling systems, and advanced sensors. You may achieve excellent yields and increase production in your laboratory with the help of our equipment.

Models for different applications and research requirements are available in our selection of in-lab fermentors and bioreactors. We provide both larger-scale bioreactors for commercial-scale production and smaller laboratory bioreactors and fermentors for use in research and development applications.

With the help of the user-friendly software that comes with our laboratory in situ fermentors and bioreactors, you can simply monitor and manage the fermentation process. You can regulate important environmental factors including temperature, pH, agitation, and dissolved oxygen levels using our equipment.

When it comes to bioprocessing, the quality of the equipment used can make or break the process. That is why it is critical to find a reputable and experienced fermenter manufacturer. With so many options available, it can be difficult to know which one to trust. But don’t look any further! For years, our company has been manufacturing high-quality fermenters, and we take pride in our commitment to providing the best equipment for your bio process needs.

SS Fermenter Manufacturer: Premium Quality Equipment for Your Bio process Needs

When it comes to stainless steel fermenters, you want to work with a company that produces high-quality equipment. Our company specializes in the production of stainless steel fermenters and provides a wide range of options. We have the expertise and experience to meet your needs, whether you need a small-scale laboratory fermenter or a large-scale production fermenter.

Industrial Bioreactor Price: Affordable Options for Your Bio process Needs

Bioreactors are an important part of any bio process, but the cost of industrial bioreactors can be prohibitively expensive. As a result, we provide a variety of affordable options to fit your budget. Our industrial bioreactors are available in a range of sizes and configurations, and we are confident that we can find the best solution for your specific requirements.

Industrial Fermenter Price: Competitive Pricing for Quality Equipment

Uma Pharmatech believe that quality should never be sacrificed for cost-effectiveness. As a result, we provide competitive pricing on our industrial fermenters. We understand that each bio process is unique, and we are committed to finding the right equipment for our customers at the right price.

Laboratory, Pilot Scale, and Production Fermenters: Meeting Your Bio processing Needs

Finding the right fermenter is Important to the success of your bio process, whether you’re working in a laboratory or a large-scale Fermenter production facility. We have options ranging from small-scale laboratory fermenters to large-scale production fermenters and everything in between. Our knowledgeable staff can assist you in determining the best solution for your specific requirements.

In conclusion, we believe that our company is the best choice for quality, affordability, and expertise when it comes to finding the Best Industrial fermenter manufacturer. Contact us today to learn more about our products and services, as well as how we can assist you with your bio processing requirements.

In the realm of bio processing, bioreactors are a Important instrument that provide several advantages like higher quality, reduced waste, and cost-effectiveness. We hope that this article has given you useful knowledge about bioreactors, their types, uses, and advantages. We are convinced that this knowledge will help you choose the appropriate bioreactor for your bio processing requirements.

India’s Industrial fermenter manufacturing environment is dominated by the states of Gujarat, Maharashtra, Punjab, Haryana, Rajasthan, Karnataka, Telangana, Tamil Nadu, Andhra Pradesh, Kerala, Madhya Pradesh, Uttar Pradesh, West Bengal, Assam, Chhattisgarh, Odisha, and Jharkhand. The fermenter Manufacturers and Suppliers in these states meet the various demands of sectors such pharmaceuticals, biotechnology, and others by bringing innovation, accuracy, and competence to the table. They now hold a prominent place in the international market because to their dedication to quality and customer satisfaction. Fermenter manufacturers will be important in determining how India’s path to independence and technical improvement is shaped as long as these states maintain an environment supportive to industrial growth.

In the realm of industrial production, fermenters play a vital role in various sectors such as pharmaceuticals, biotechnology, food processing, and more. The Indian states of Gujarat, Maharashtra, Punjab, Haryana, Rajasthan, Karnataka, Telangana, Tamil Nadu, Andhra Pradesh, Kerala, Madhya Pradesh, Uttar Pradesh, West Bengal, Assam, Chhattisgarh, Odisha, and Jharkhand have emerged as significant hubs for fermenter manufacturers. This comprehensive guide explores the top fermenter manufacturers in each of these states, highlighting their expertise, product offerings, and contributions to the industry.

Explore the Top Fermenter Manufacturers in Key Indian States

Fermenters are essential to many industries involved in industrial manufacturing, including biotechnology, pharmaceuticals, and the food processing industry. The fermenter industry has seen significant growth as a result of the emergence of significant manufacturing hubs in numerous Indian states, including Gujarat, Maharashtra, Punjab, Haryana, Rajasthan, Karnataka, Telangana, Tamil Nadu, Andhra Pradesh, Kerala, Madhya Pradesh, Uttar Pradesh, West Bengal, Assam, Chhattisgarh, Odisha, and Jharkhand. This thorough guide examines the top fermenter producers in each of these states, demonstrating their knowledge, line of goods, and contributions to the sector.

-

Gujarat: Powering Fermenter Innovation:

-

Maharashtra: Excellence in Fermenter Production

Another important state for the production of fermenters is Maharashtra. The area is home to renowned producers like Uma Pharmatech Machinery, known for their advance facilities and production methods. These businesses provide a wide variety of fermenters to meet the various requirements of sectors like pharmaceuticals, biotechnology, and food processing. Fermenter manufacturers in Maharashtra have become well-known both domestically and abroad thanks to their dedication to quality and client satisfaction.

Tamil Nadu and Andhra Pradesh: Enhancing Industrial Processes

India’s fermenter manufacturing industry has seen significant contributions from Tamil Nadu and Andhra Pradesh in recent years. Renowned producers, like Uma Pharma, are experts in Manufacturing fermenters that optimize productivity and streamline industrial processes. Their extensive product line and dedication to technological developments have cemented their position in the sector and acted as engines for development.

Kerala, Madhya Pradesh, Uttar Pradesh, West Bengal, Assam, Chhattisgarh, Odisha, and Jharkhand: Driving Regional Fermenter Development

The manufacture of fermenters has also increased in Kerala, Madhya Pradesh, Uttar Pradesh, West Bengal, Assam, Chhattisgarh, Odisha, and Jharkhand. Businesses like Uma Pharmatech Machinery(INDIA) have become well-known players and have helped the growth of local industry. These manufacturers are essential to the development of the fermenter industry in these states because of their emphasis on individualized solutions and ongoing improvement.

Rajasthan: Delivering Quality Fermenters

Rajasthan has developed become a center for fermenter producers. Businesses like Uma Pharmatech I have received praise for their dedication to provide fermenters of the finest quality. To guarantee that their products satisfy international standards, these manufacturers place a high priority on strict quality control procedures. Fermenter manufacturers in Rajasthan have established themselves as reliable partners for a variety of industries thanks to their modern facilities as well as skilled employees.

Karnataka and Telangana: Innovators in Fermenter Technology

Both Karnataka and Telangana in southern India have seen considerable improvements in fermentation production. Companies like Uma Pharmatech is leading the way in this development by utilizing their technical know-how to provide creative fermentation solutions. The fermenter market in Karnataka and Telangana is expanding as a result of the fact that these manufacturers serve a variety of sectors and work hard to improve their product lines.

Punjab and Haryana: Driving Fermenter Advancements:

Fermenter production has increased significantly in the states of Punjab and Haryana. UMP is notable participants in this area, both of which are known for their prowess in Manufacturing fermenters that are specifically tailored to the needs of the business. These manufacturers considerably improve the fermenter industry in Punjab and Haryana by utilizing their technical expertise and the most recent innovations.

Due to the existence of leading manufacturers in numerous states, the fermenter industry in India is thriving. Fermenter Suppliers have established themselves as market leaders across Gujarat, Maharashtra, Punjab, Haryana, and Rajasthan. Their knowledge, dedication to quality, and creative thinking have fueled the sector’s expansion and enabled developments in pharmaceutics, biotechnology, food processing, and other fields. These Bioreactor manufacturers‘ contributions have set the path for a thriving fermenter sector, advancing industrial development all around the country.

Gujarat

Some of India’s top fermenter manufacturers are located in Gujarat, a state that is leading the way in industrial development. These producers design fermenters that promise higher performance, robustness, and adaptability using their significant knowledge and technological breakthroughs. They provide services for a variety of industries, such as wastewater treatment, food and beverage production, and pharmaceuticals.

Haryana

Fermenter Manufacturers in Haryana work hard to keep up with the changing needs of the biotechnology sector. To create fermenters that display remarkable durability, scalability, and ease of use, these manufacturers prioritize precision engineering and strict quality control. They are devoted to fostering the expansion of the bioprocessing sector in the area.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.