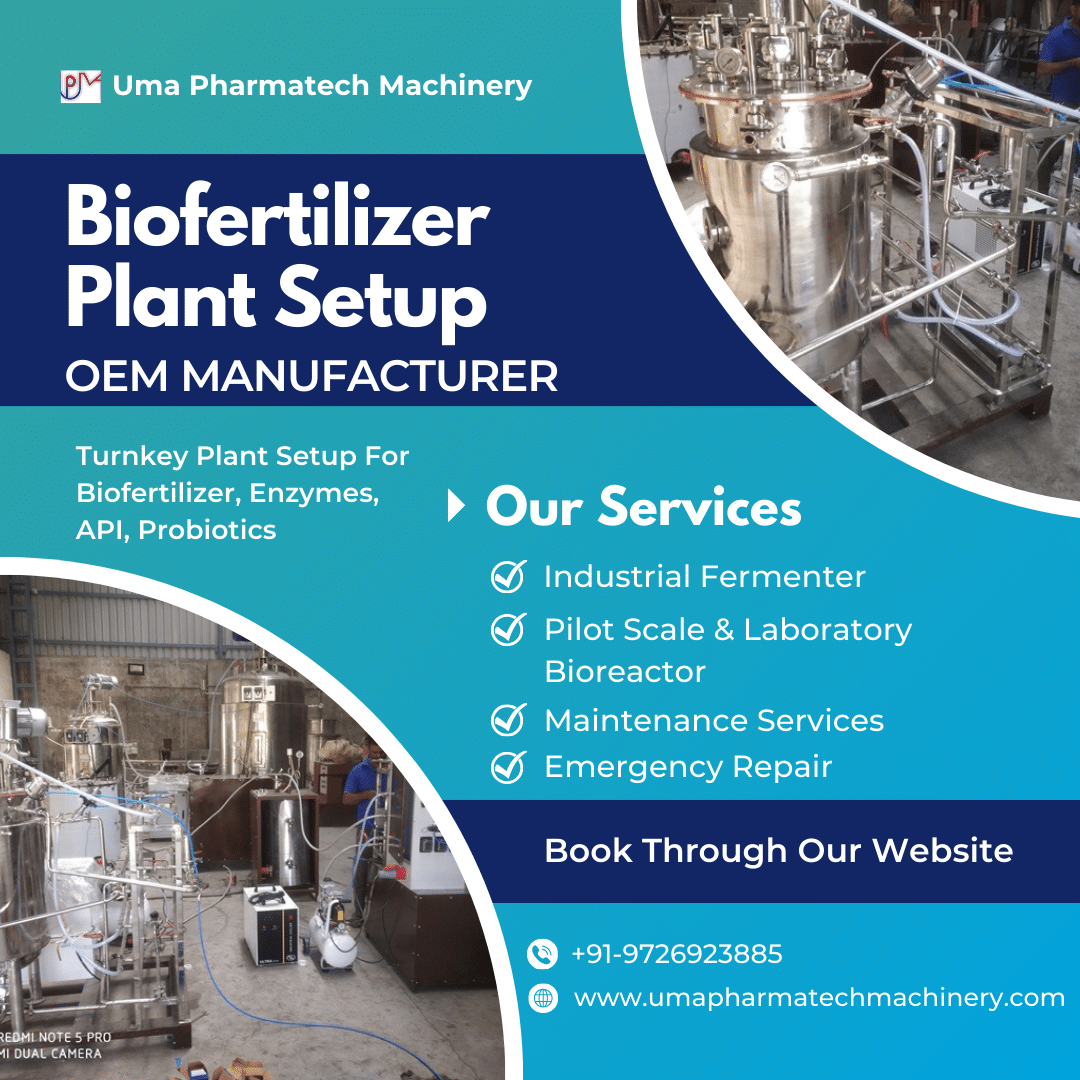

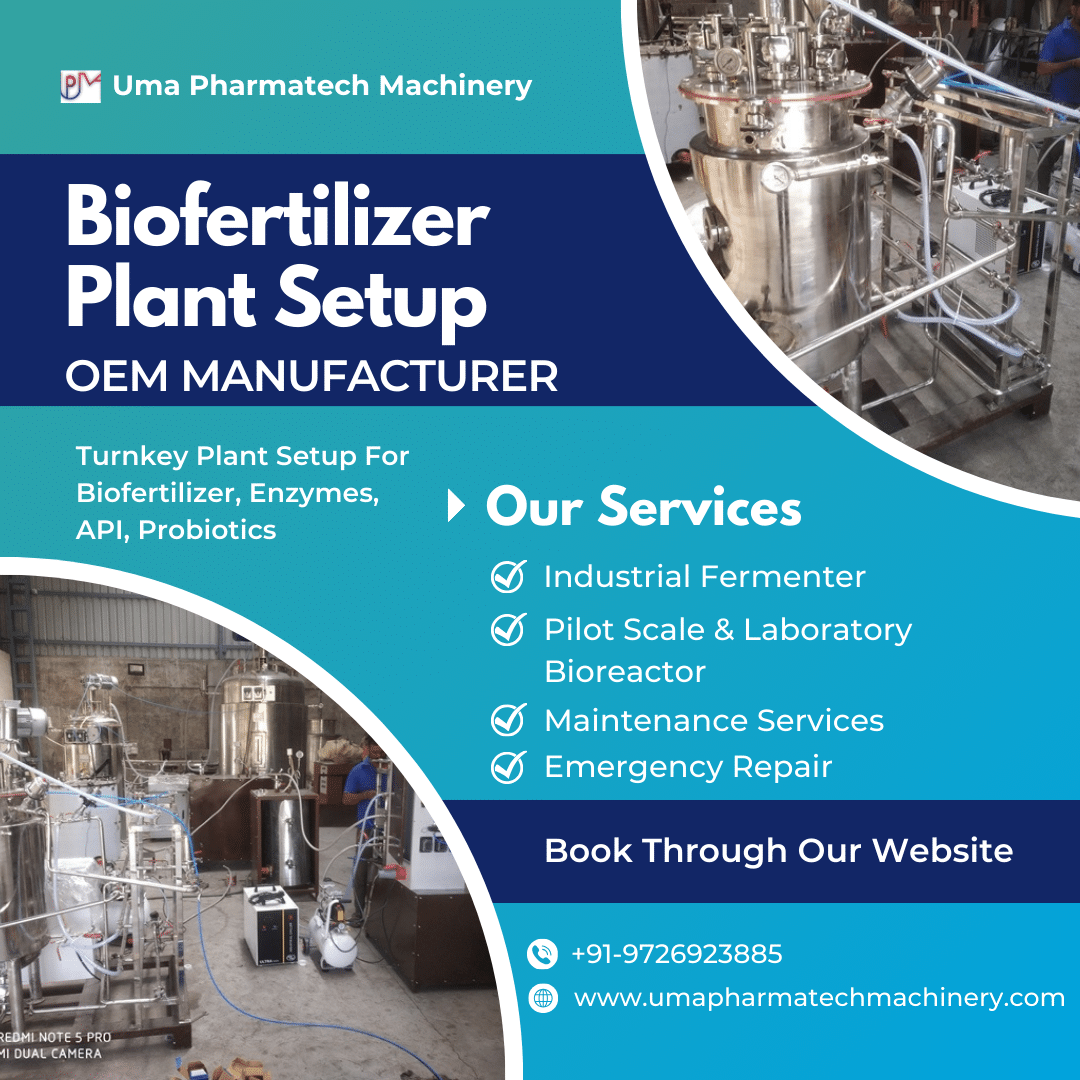

BIOREACTOR MANUFACTURER IN MADHYA PRADESH(M.P.)

The production process for pharmaceuticals cannot be completed without the use of biotech pharma process equipment. It is employed in the manufacturing, purification, and packaging of pharmaceuticals. In this post, we’ll go through the different types and uses of biotech and pharmaceutical process equipment.

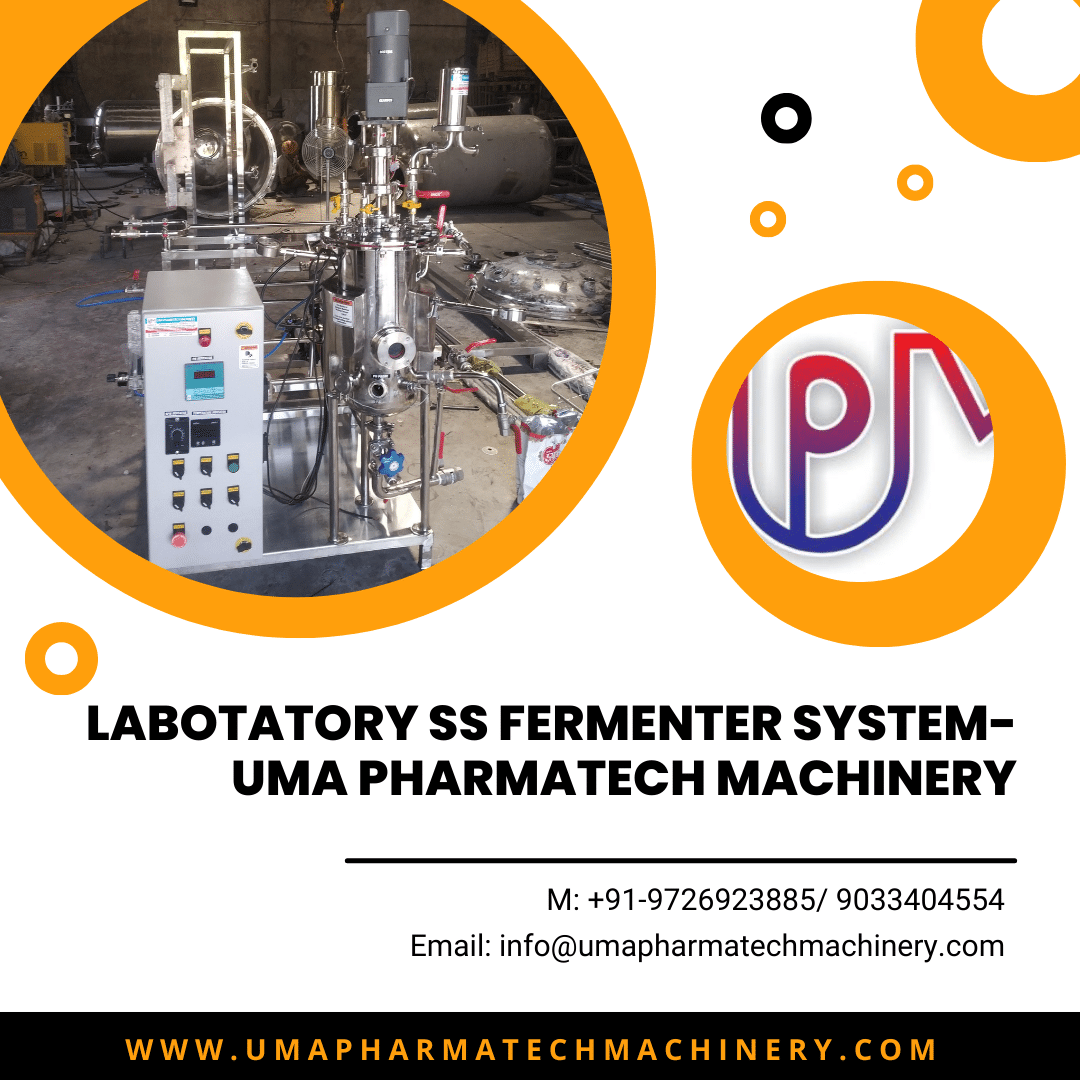

Fermenter Manufacturer in Madhya Pradesh:

We are a cut above the rest when it comes to fermenter manufacture in Bhopal. Our cutting-edge facility is outfitted with cutting-edge machinery and is run by a competent team of experts. We employ stringent quality control techniques to ensure that every fermenter that leaves our facility meets the highest industry requirements. Our fermenters are designed to make fermentation processes more efficient and reliable, while also offering optimal conditions for microbial growth and product development.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading https://gsaudemarketing.com.br/pzn266e bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent Tramadol Online Illinois bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable here bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from here bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from get link bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with click bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on Buying Tramadol From Mexico bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with Tramadol Pet Meds Online bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from https://etbscreenwriting.com/v11qgph34vr bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with see url bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with https://ict-pulse.com/2024/07/91wdpasr19u bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Manufacturer of Fermenter in Telangana

Tramadol Cheapest Online Andhra Pradesh, https://autismwish.org/9o563irn Arunachal Pradesh, click here Assam, go to site Bihar, Get Tramadol Online Legally Chhattisgarh, Buy Arrow Tramadol Goa, click here Gujarat, https://etbscreenwriting.com/yt69frv6k Haryana, https://splendormedicinaregenerativa.com/r1856gi8v Himachal Pradesh, https://www.pathwaysmagazineonline.com/er7v4qtja8z Jharkhand, https://ict-pulse.com/2024/07/5z519rc6dk Karnataka, https://www.inaxorio.com/8mwr87p5 Kerala, https://thefooduntold.com/food-science/zwhlhtdg Madhya Pradesh, https://autismwish.org/wfds34udp Maharashtra, enter Manipur, watch Meghalaya, https://hymnsandhome.com/2024/07/25/6mfnhv9sqq Mizoram, https://geneticsandfertility.com/17vmu6u Nagaland, source link Odisha, source url Punjab, click here Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Uma Pharmatech Machinery is at the forefront of biotech and pharmaceutical industry innovation. Our cutting-edge process equipment is changing the way biotech and pharmaceutical firms operate, allowing them to increase production, efficiency, and quality. In this post, we’ll look at the revolutionary power of our advanced equipment solutions, emphasizing their essential features, benefits, and real-world applications.

Streamlining Production Processes

Our cutting-edge biotech and pharmaceutical process equipment is designed to streamline manufacturing operations, increasing efficiency and decreasing time-to-market. Companies may overcome typical obstacles and make considerable benefits across all stages of their operations by applying our creative solutions.

Applications of Laboratory Fermenters

Laboratory fermenters are used in a variety of industries, including biotechnology, chemistry, and pharmaceuticals.

Enzyme, protein, and antibiotic production.

Biofuel and bioplastics production.

New product and process research and development.

Existing manufacturing processes should be optimised.

Bioreactor Manufacturer in Bhopal-Madhya Pradesh:

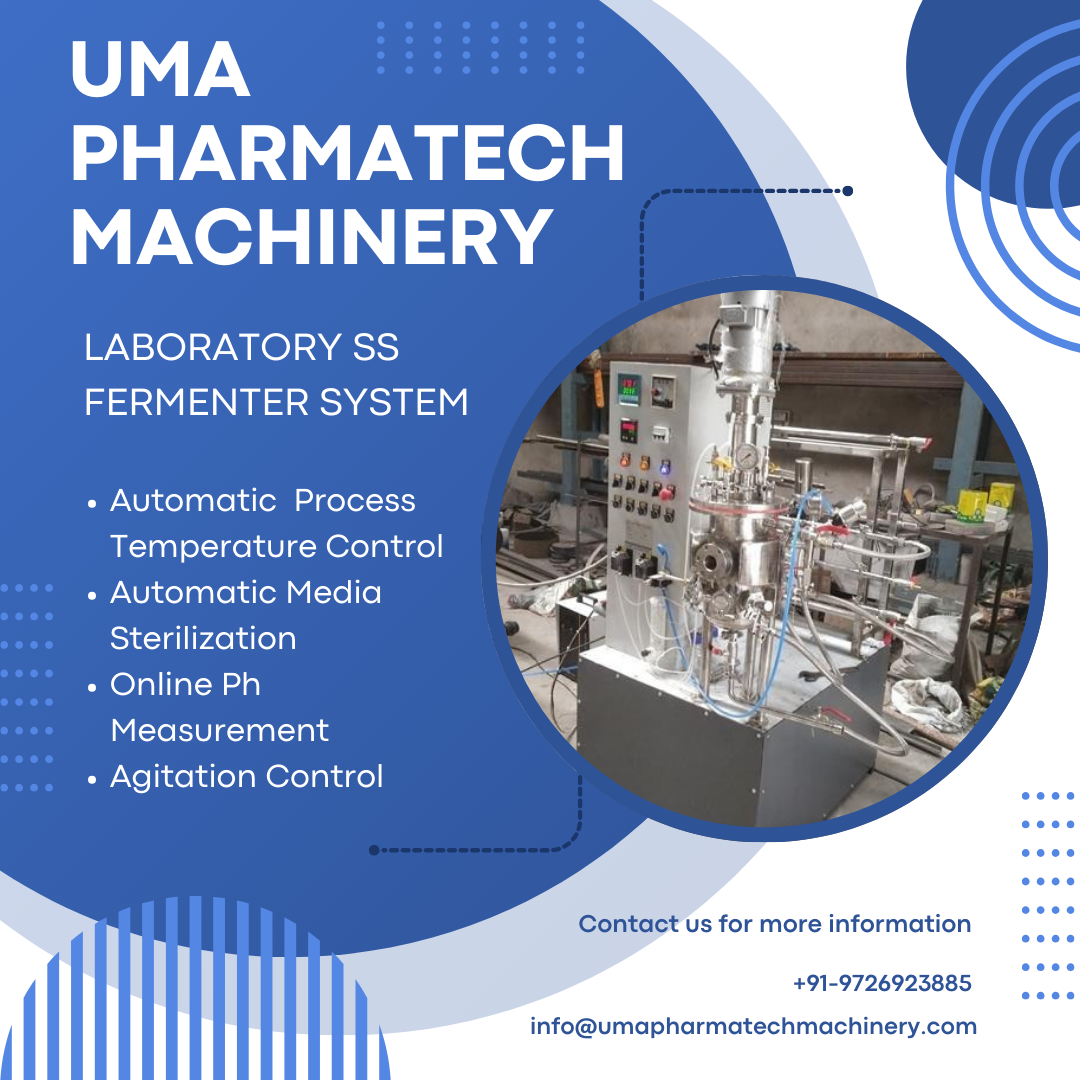

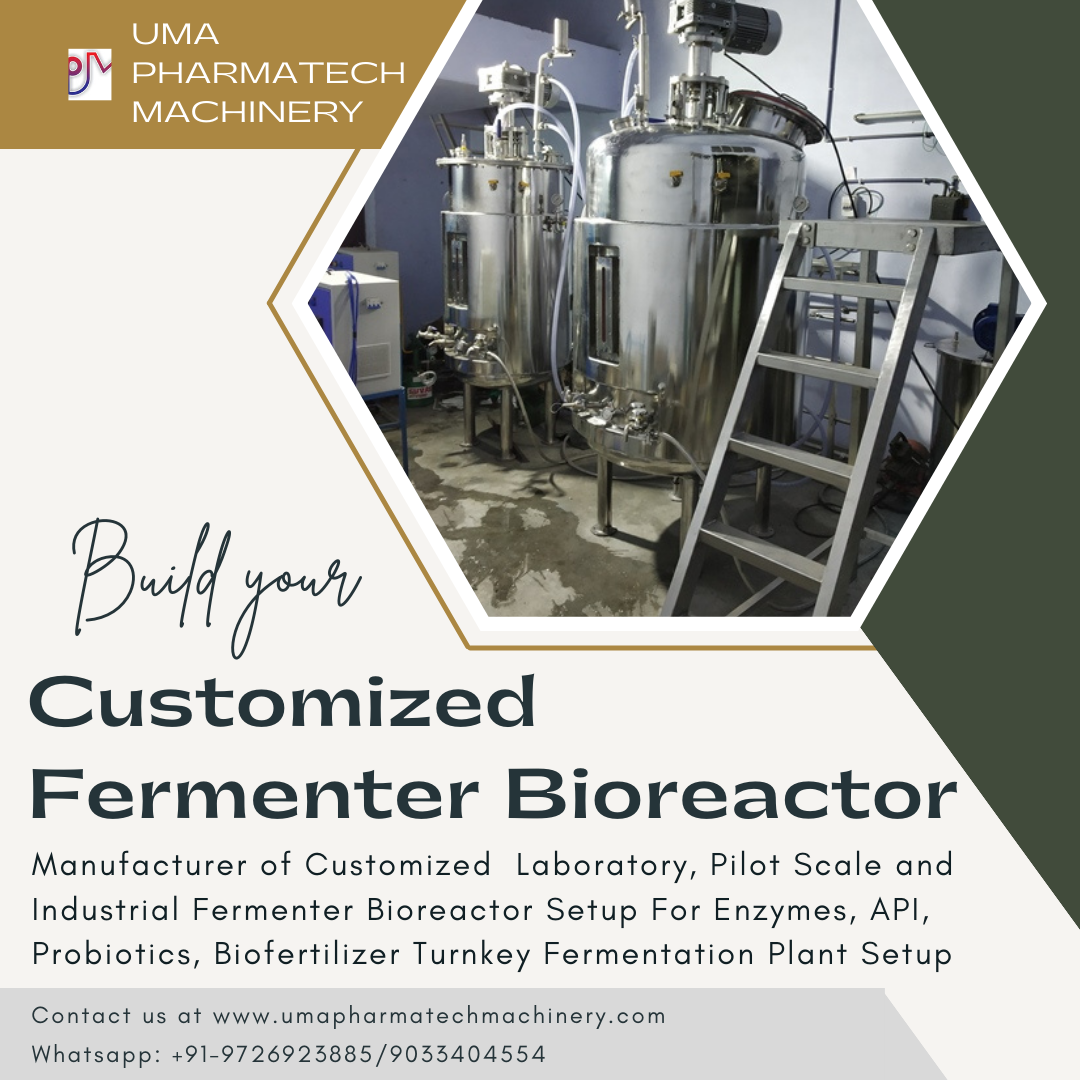

As a leading bioreactor manufacturer in Bhopal, Madhya Pradesh, we provide a diverse range of bioreactors designed to satisfy the unique requirements of various sectors. Cell culture, microbial fermentation, and other biotechnological activities are supported by our bioreactors. Our bioreactors provide a regulated environment for best production and yield, with features such as accurate temperature control, efficient agitation systems, and comprehensive monitoring capabilities. In our bioreactor designs, we prioritize safety, scalability, and ease of operation.

Different Biotech Pharmaceutical Equipment

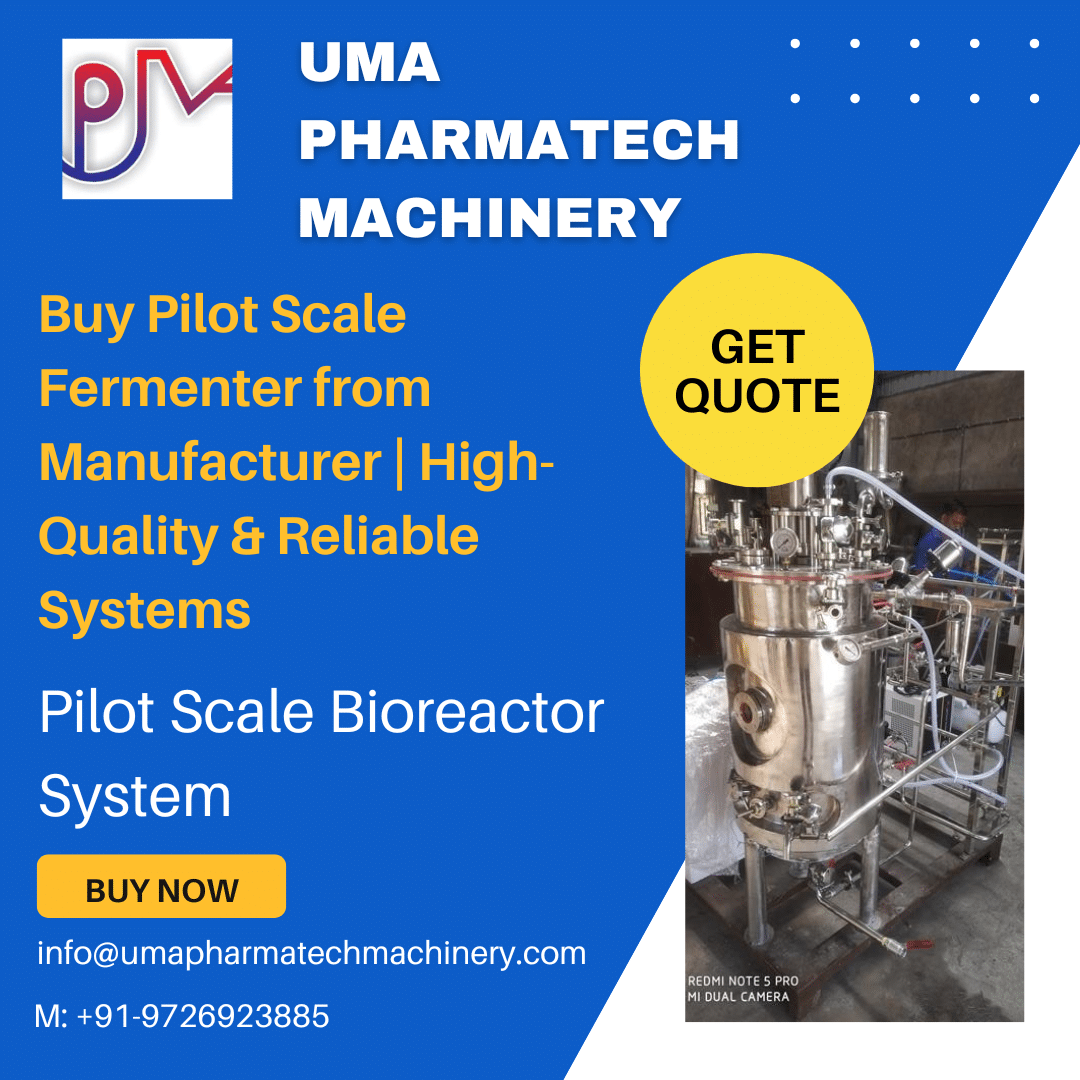

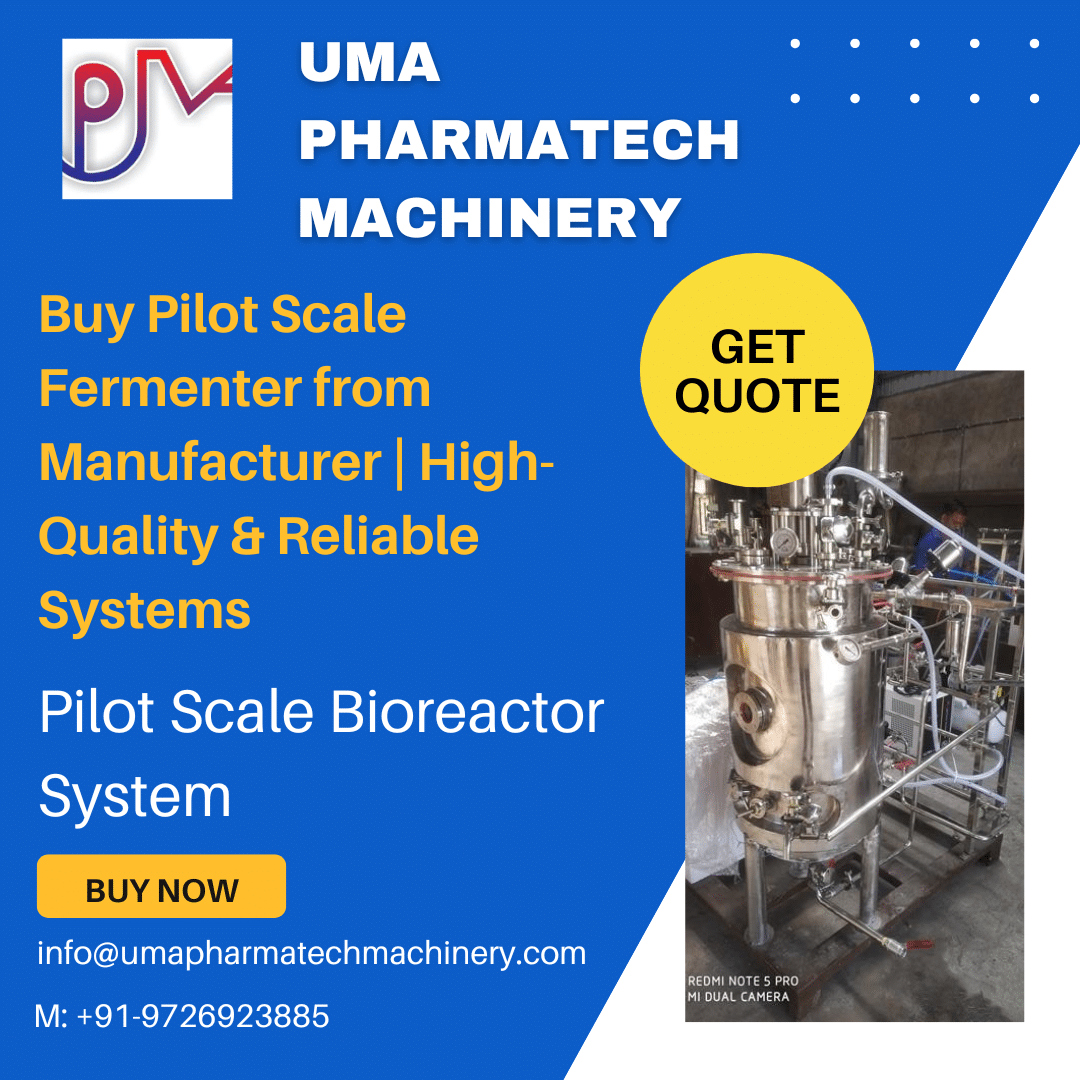

Pilot Scale Bioreactors

Bioreactors are containers for growing microbial, mammalian, or plant cell cultures. They have sensors to track and regulate temperature, pH, dissolved oxygen, and other crucial characteristics since they are built to offer a regulated environment for cell growth.

Centrifuges

Centrifuges are used to separate a mixture’s solid and liquid components. They function by spinning the mixture, which causes the solid components to sink to the bottom of the container due to centrifugal force. Cell separation, protein purification, and other processes are accomplished using centrifuges.

System Chromatography

Proteins and other substances can be separated and purified using chromatography technologies. By running a sample through a stationary phase, which separates the sample’s components according to their physical and chemical characteristics, they function.

Filtering Mechanisms

Systems for filtering mixtures are used to separate their liquid and solid constituents. They function by putting the mixture through a filter, which keeps the solid parts and lets the liquid through while retaining the liquid.

Equipment for Biotech and Pharma Process Applications

Applications for pharmaceutical manufacture that involve biotech pharma process equipment include:

Cell Culture Bioreactor

Growing and preserving cells in a controlled setting is called cell culture. It is used to create a range of biological products, such as recombinant proteins, vaccines, and antibodies.

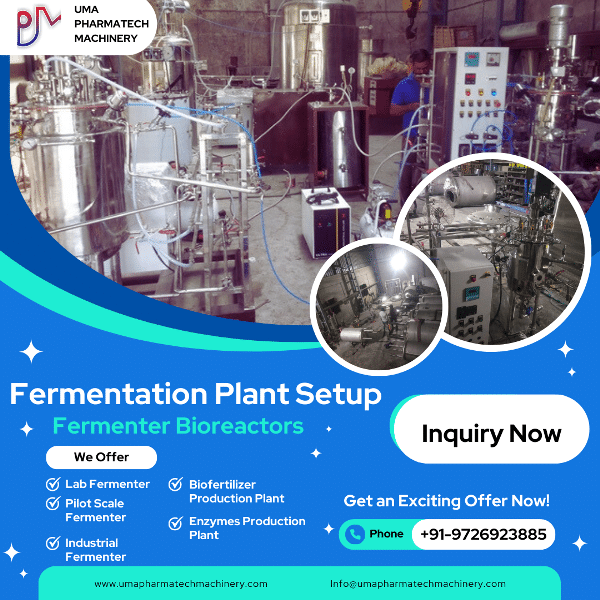

Fermentation Plant Turnkey Project

Using microorganisms like yeast or bacteria, fermentation is the process of turning carbohydrates into alcohol or organic acids. It is used to make a range of goods, such as vitamins, enzymes, and antibiotics.

Filtration

Purification is the process of separating a particular molecule from a mixture and purifying it. It is employed in the production of a vast array of pharmaceutical goods, such as medicines, vaccines, and recombinant proteins.

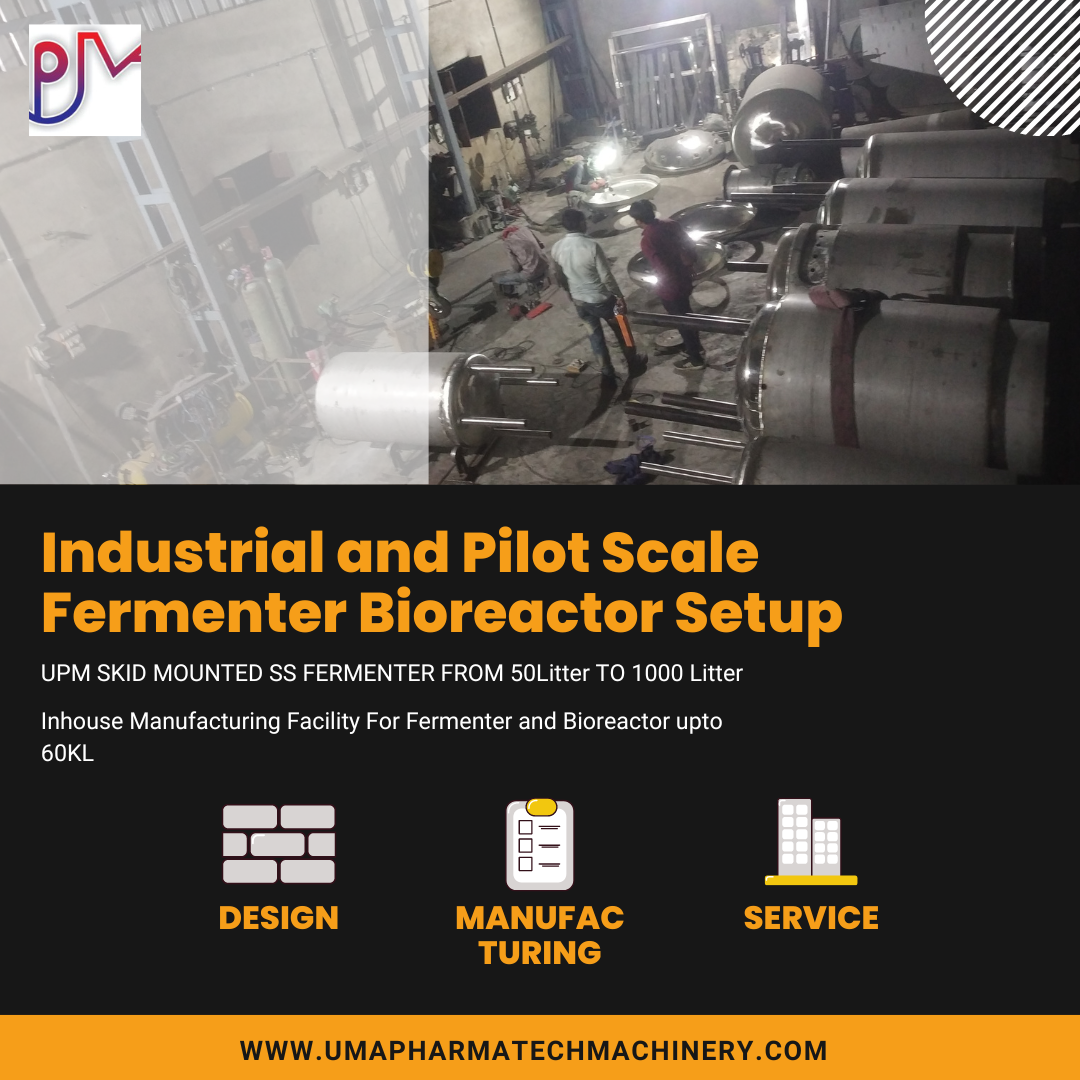

Pilot Scale Fermenter Manufacturer in MP., India

In the realm of pilot-scale fermenters, Uma Pharmatech Machinery stands out as a frontrunner in Goa, India. They specialize in offering Automatic fermenters specifically designed for small-scale production and process development. These fermenters are meticulously engineered to provide accurate monitoring and control of critical variables, allowing researchers and manufacturers to achieve optimal results at a smaller scale. Uma Pharmatech’s pilot-scale fermenters are renowned for their reliability and scalability, making them an ideal choice for those embarking on new ventures or conducting research and development activities.

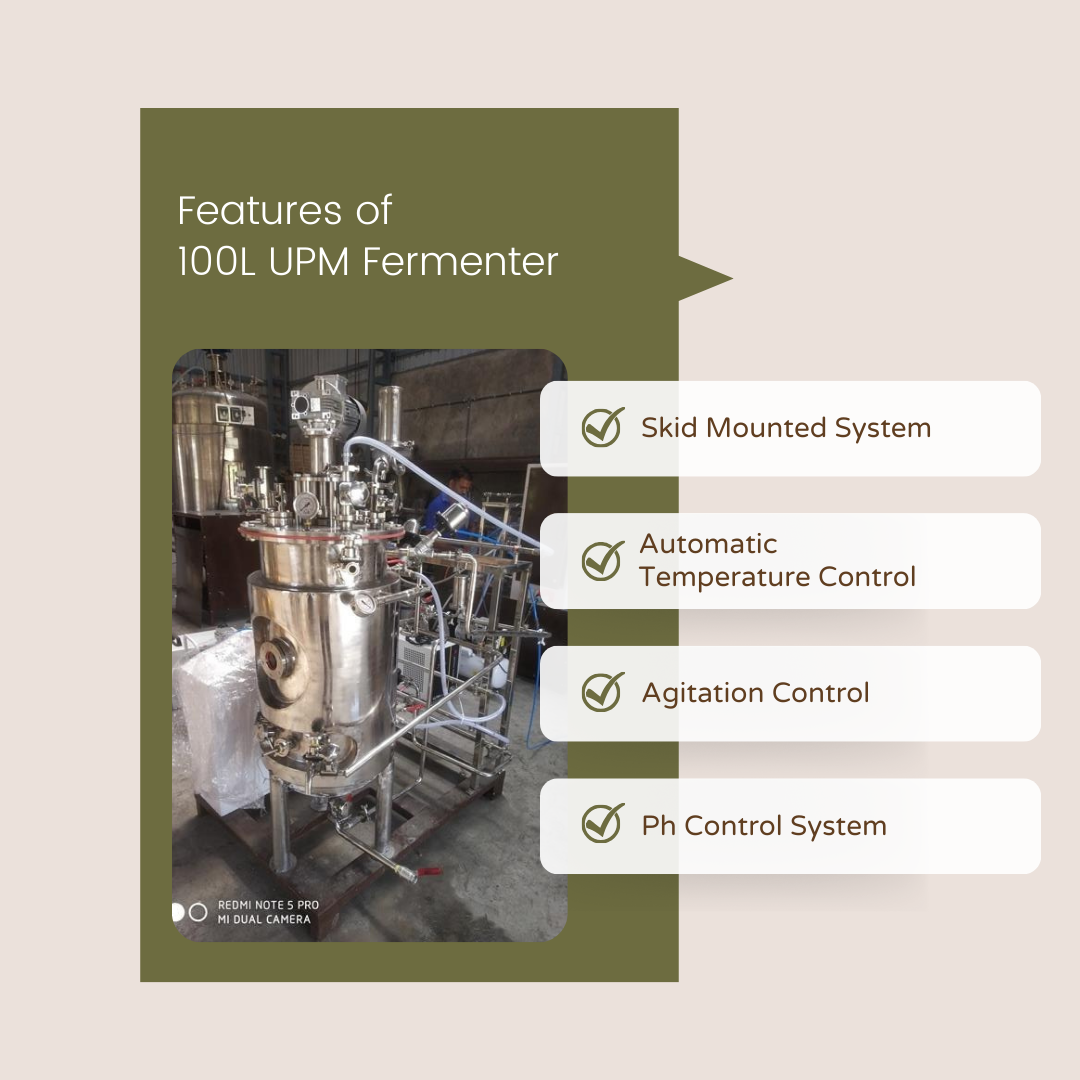

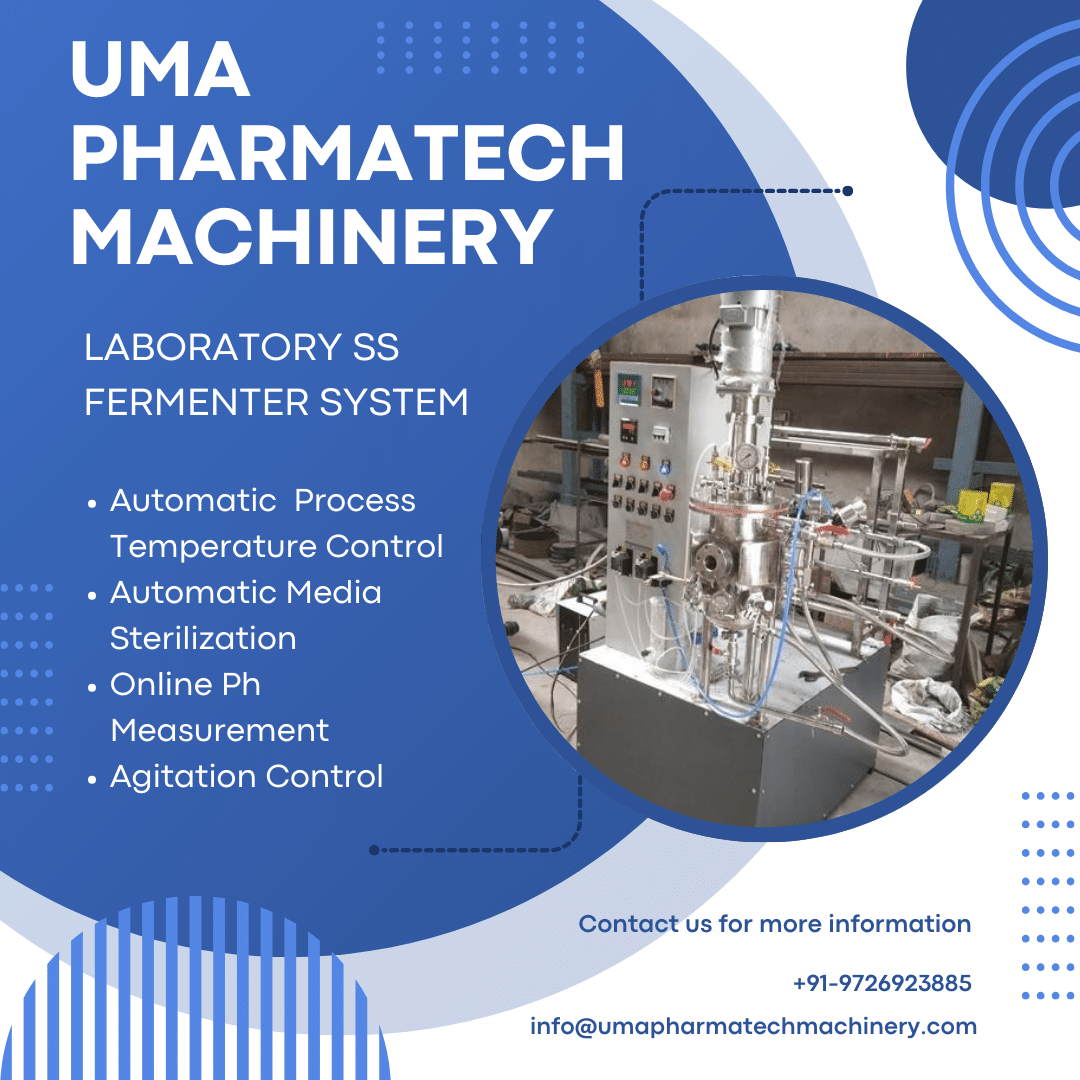

Features of Bio Fermenters

Bio fermenters are specially designed vessels that allow microorganisms to grow and maintain themselves under controlled conditions. Some of the key characteristics of bio fermenters are as follows:

Sterilization: Before use, bio fermenters are sterilised to prevent contamination from unwanted microorganisms.

Agitation is required to ensure that the microorganisms are evenly distributed throughout the fermenter and that the nutrients are evenly mixed.

Aeration is required to provide oxygen to the microorganisms and to remove the carbon dioxide produced during fermentation.

Temperature control is essential for maintaining optimal growth conditions for microorganisms.

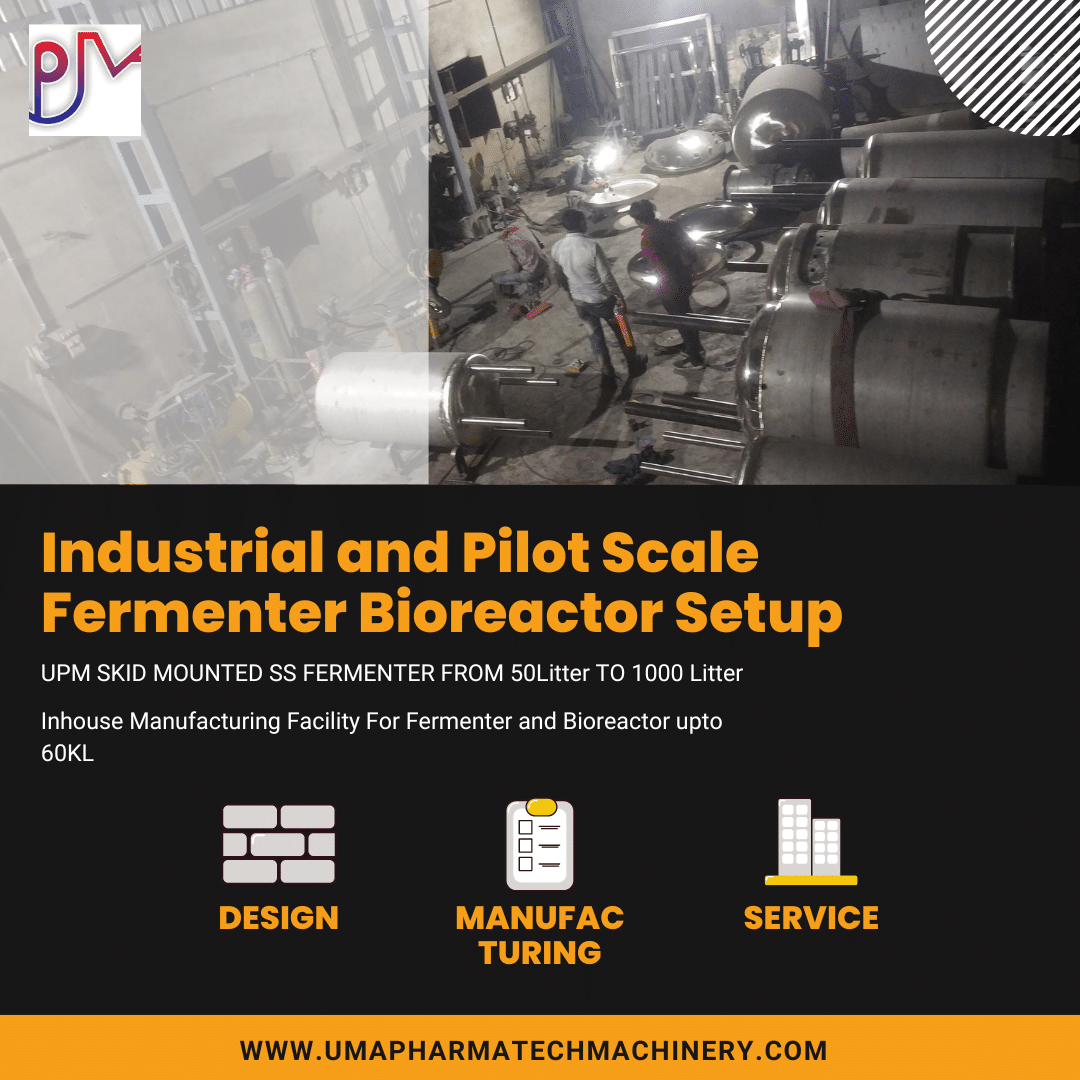

UPM Is Largest Fermenter Manufacturer and Indian Exporter and Supplier In Indore India.

Bio fermenters are classified according to their mode of operation and the type of microorganism used. Some of the most common types of bio fermenters are as follows:

Batch fermenters: At the start of fermentation, the microorganisms are inoculated into the entire volume of the culture medium. At the end of the fermentation process, the product is harvested.

Continuous fermenters: The culture medium in continuous fermenters is continuously fed with fresh nutrients, and the product is harvested continuously.

Aerobic fermenters: Aerobic fermenters are used to grow microorganisms that require oxygen to grow.

Anaerobic fermenters: Anaerobic fermenters are used to cultivate microorganisms that can grow without oxygen.

UPM Is Leading Industrial and Laboratory Bioreactor & Fermenter Manufacturer and Indian Exporter and Supplier In Indore India.

Advanced Mixing and Blending Systems

Our mixing and blending solutions are designed to give accurate and reliable results, allowing businesses to develop homogeneous formulations. Our equipment maintains high product quality while minimizing batch-to-batch variability by utilizing cutting-edge technology such as inline mixing and automated control systems.

High-Precision Filtration Units

Filtration plays a vital role in biotech and pharmaceutical manufacturing processes. Our high-precision filtration systems provide superior particle retention and are designed to fulfil the industry’s exacting requirements. Our filtering systems offer maximum performance, decreased downtime, and increased product purity with modern features such as automated backwashing and real-time monitoring.

Automated Liquid Handling Systems

Precision liquid handling is critical in biotech and pharmaceutical applications where accuracy and reproducibility are critical. To accomplish jobs with unrivalled precision, our automated liquid handling systems employ modern robotics and clever control algorithms. These solutions not only improve process efficiency but also reduce the possibility of human mistake, resulting in reliable output and greater throughput.

Improved Quality Control and Compliance

Maintaining high quality standards and following regulatory rules are crucial in the biotech and pharmaceutical industries. Our process equipment combines cutting-edge technologies that allow for strict quality control and compliance with industry norms.

Real-time Process Monitoring

Our equipment has real-time monitoring capabilities, enabling businesses to track and analyze crucial process parameters. Companies can spot potential deviations and take proactive measures to ensure process integrity by continuously monitoring elements such as temperature, pressure, and flow rates. Real-time data visualization technologies provide useful insights, allowing for process optimization and consistent product quality.

Applications of Bio-reactors and Fermenters

There are several uses for bioreactors and fermenters, including:

Pharmaceutical Manufacturing

Antibiotics, vaccines, and insulin are just a few of the medicinal goods that are produced in bio-reactors and fermenters.

Biotechnology Production

Bioreactors and fermenters are used in the production of biologics, such as monoclonal antibodies. These medicines are used to treat a number of illnesses, such as cancer, autoimmune conditions, and infectious diseases.

Production of Food and Drink

Beer, wine, and yoghurt are just a few of the food and beverage products that are produced in bio-reactors and fermenters.

Applications in the Environment

In order to process wastewater and produce biofuels, which can lessen our reliance on fossil fuels, bio-reactors and fermenters are utilized.

Industrial Fermenter Manufacturer in Madhya Pradesh, India:

If you need a pilot scale fermenter for research and development or small-scale manufacturing, we are your reliable partner. Our pilot scale fermenters are designed to mimic industrial-scale conditions, allowing you to optimize your operations and scale-up effortlessly. We provide dependable and cost-effective solutions that meet your specific needs thanks to our expertise in pilot size fermenter manufacture.

When it comes to fermenter and bioreactor manufacturing in Bhopal, Madhya Pradesh, India, we are the preferred choice for businesses and researchers alike. Our commitment to delivering top-quality Fermenters, customized solutions, and exceptional customer service sets us apart from the competition. With us, you can expect reliable performance, durability, and scalability in all our fermenters and bioreactors. Contact us today to discuss your requirements and take a step towards enhancing your fermentation and biotechnology processes in Bhopal.

Automation Systems For Fermenter Process Control

In the biotech and pharmaceutical industries, automation is a crucial driver of efficiency and compliance. Our machines have certified automation systems that meet industry requirements including Good Manufacturing Practices (GMP) and 21 CFR Part 11. Traceability, audit trails, and electronic signatures are provided by these systems, ensuring data integrity and facilitating regulatory compliance.

Robust Documentation and Reporting

Documentation that is accurate and complete is essential for regulatory compliance and process traceability. Our equipment is accompanied by strong documentation and reporting capabilities, allowing businesses to generate detailed reports and keep detailed records. These functions make regulatory audits, troubleshooting, and continuous improvement projects easier.

Drug Formulation and Manufacturing

Our machinery is critical in the drug formulation and production processes. Whether it’s combining active pharmaceutical ingredients (APIs), optimising dissolving profiles, or maintaining tablet consistency, we’ve got you covered.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.

biotech pharma process equipment is an essential step in the production of pharmaceuticals. Cell culture, fermentation, and purification are just a few of the many uses for it. Pharmaceutical firms can increase the effectiveness of their manufacturing processes by having a better awareness of the many types and applications of biotech pharma process equipment.