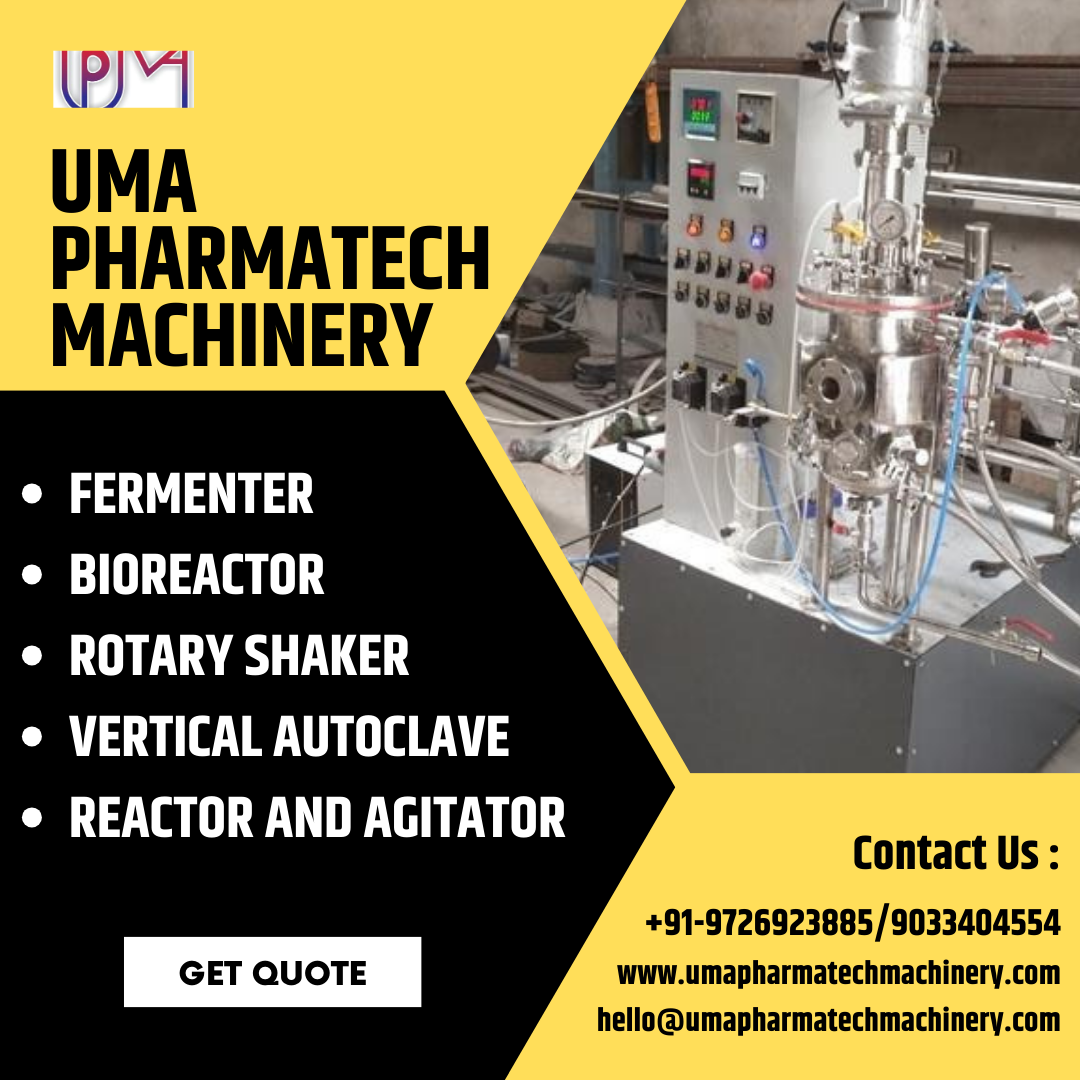

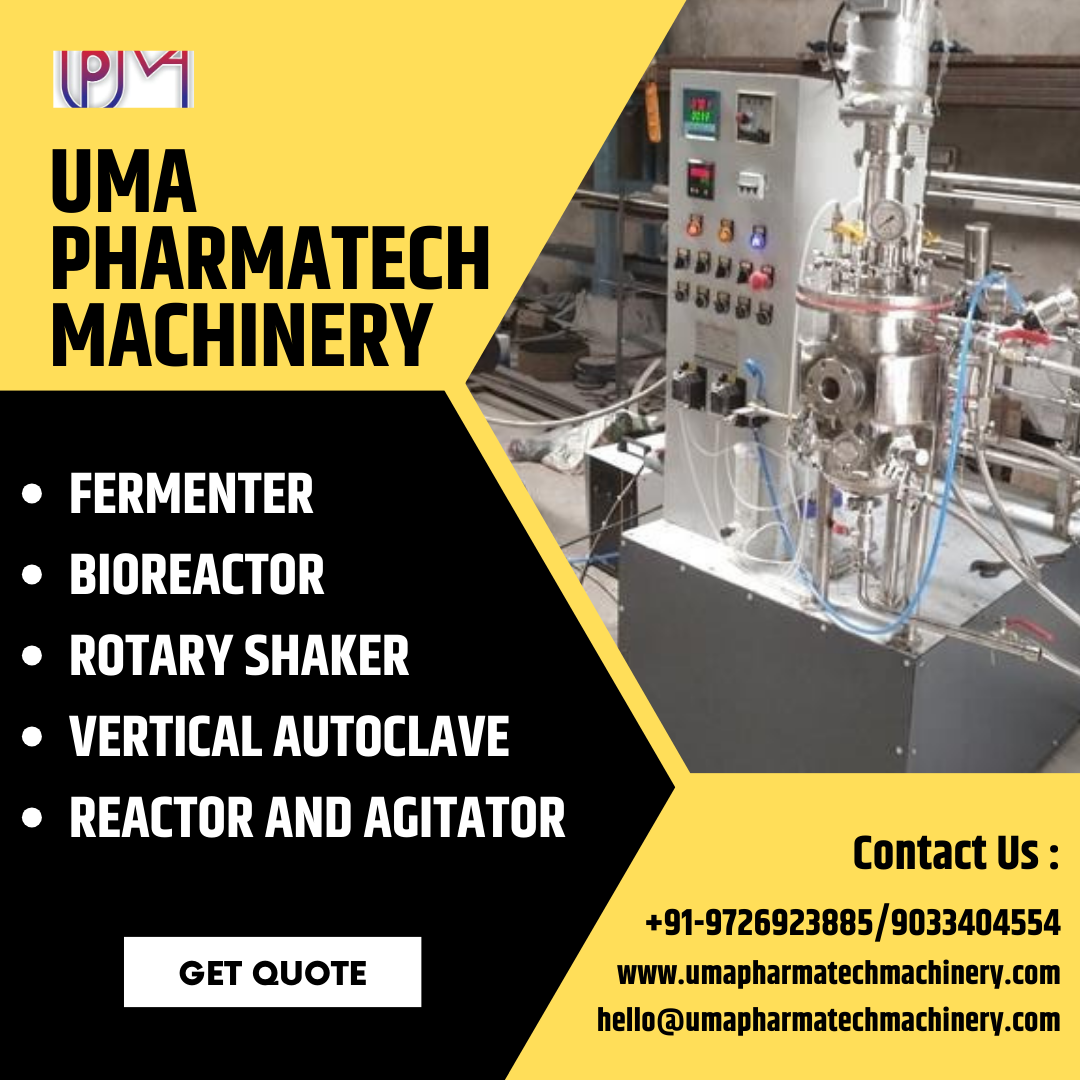

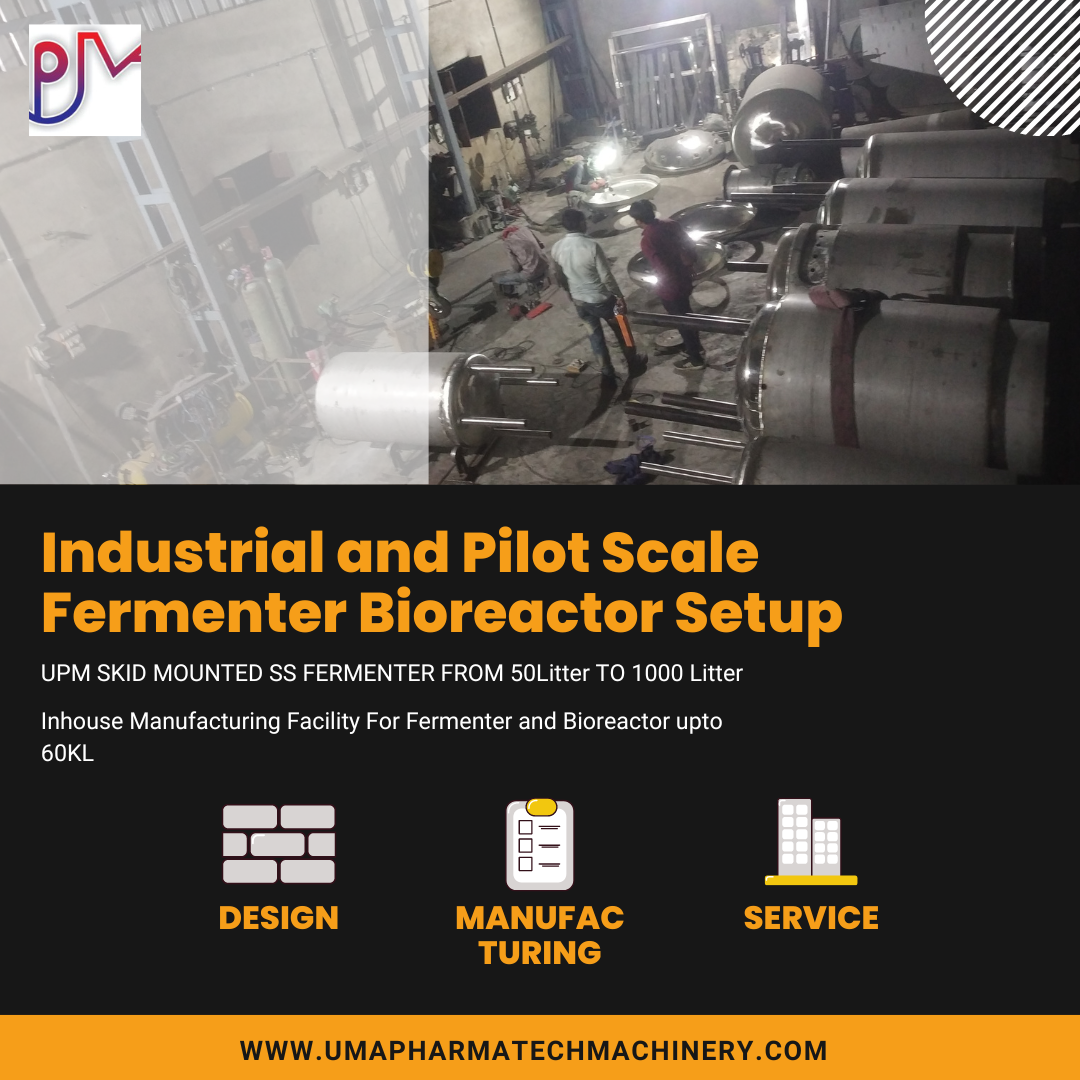

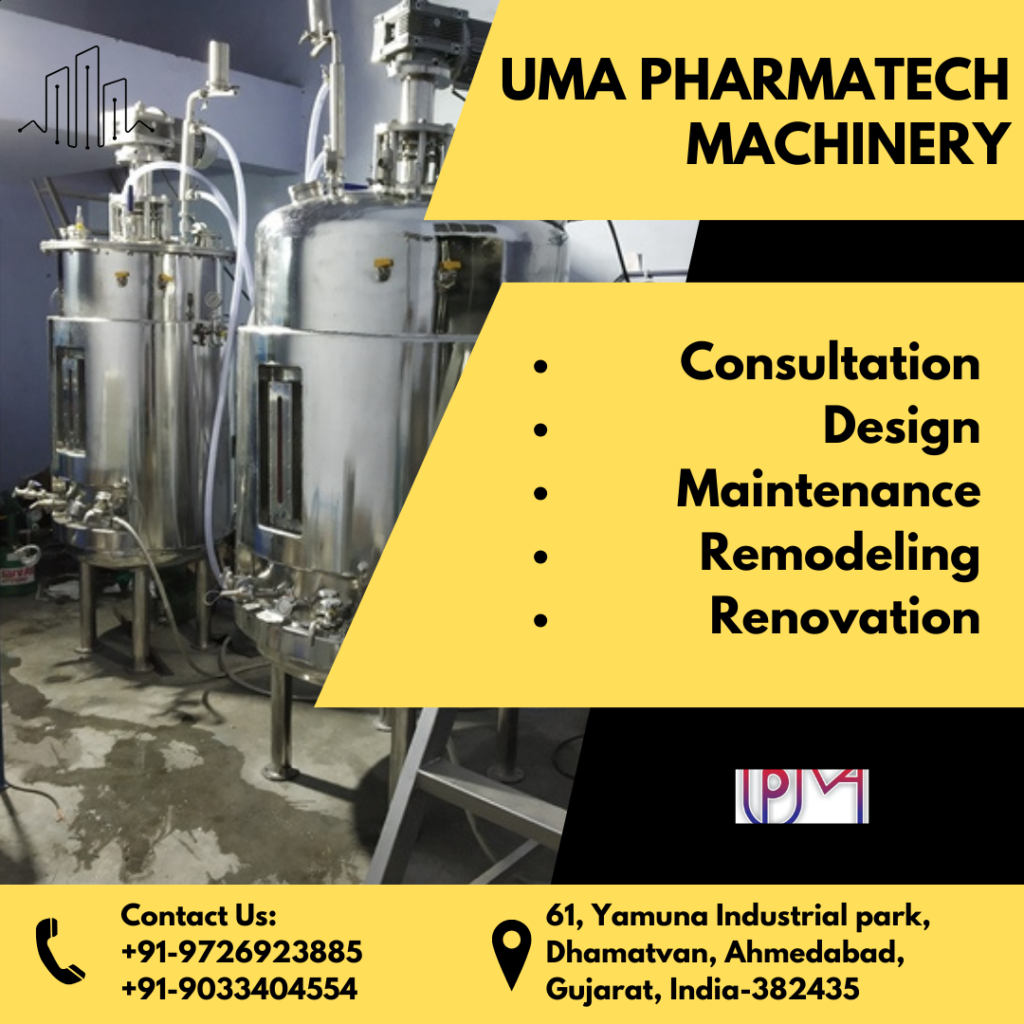

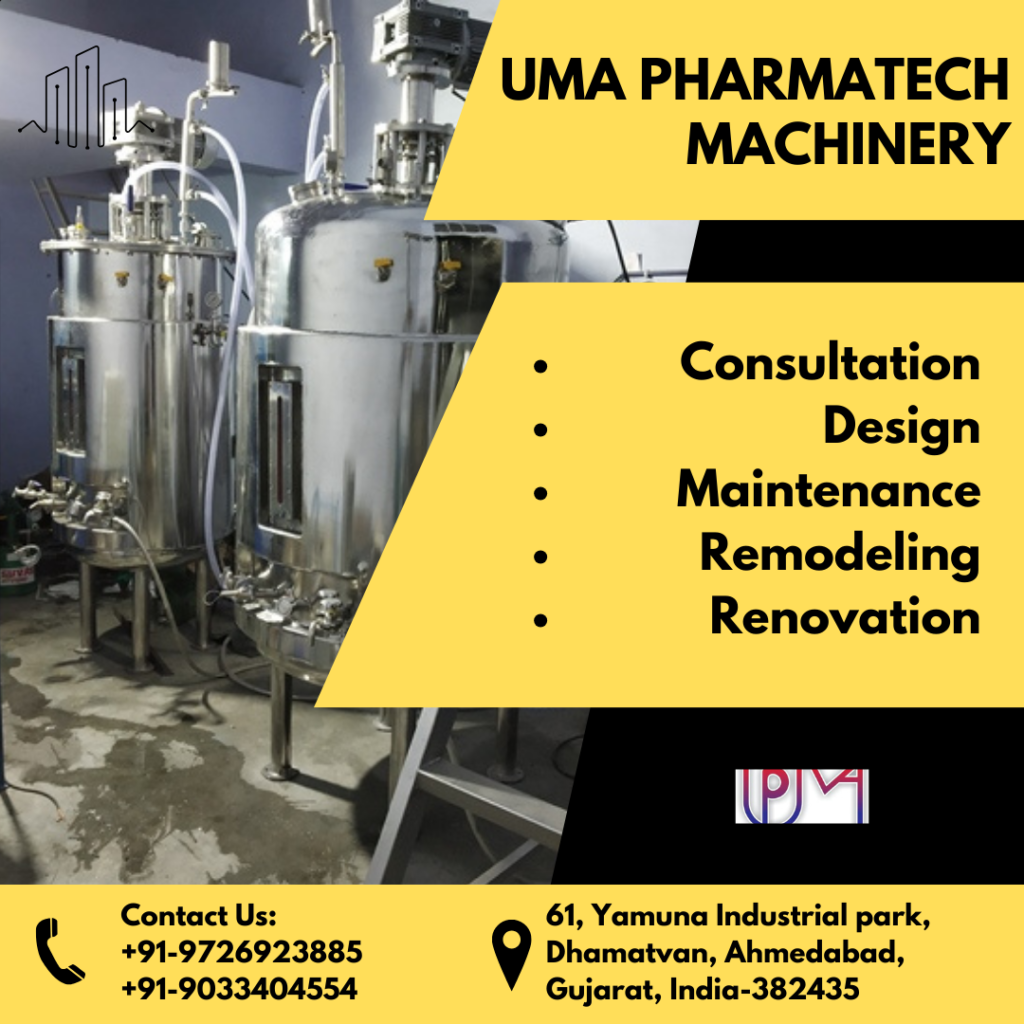

Manufacturer in Ahmedabad for Fermenter

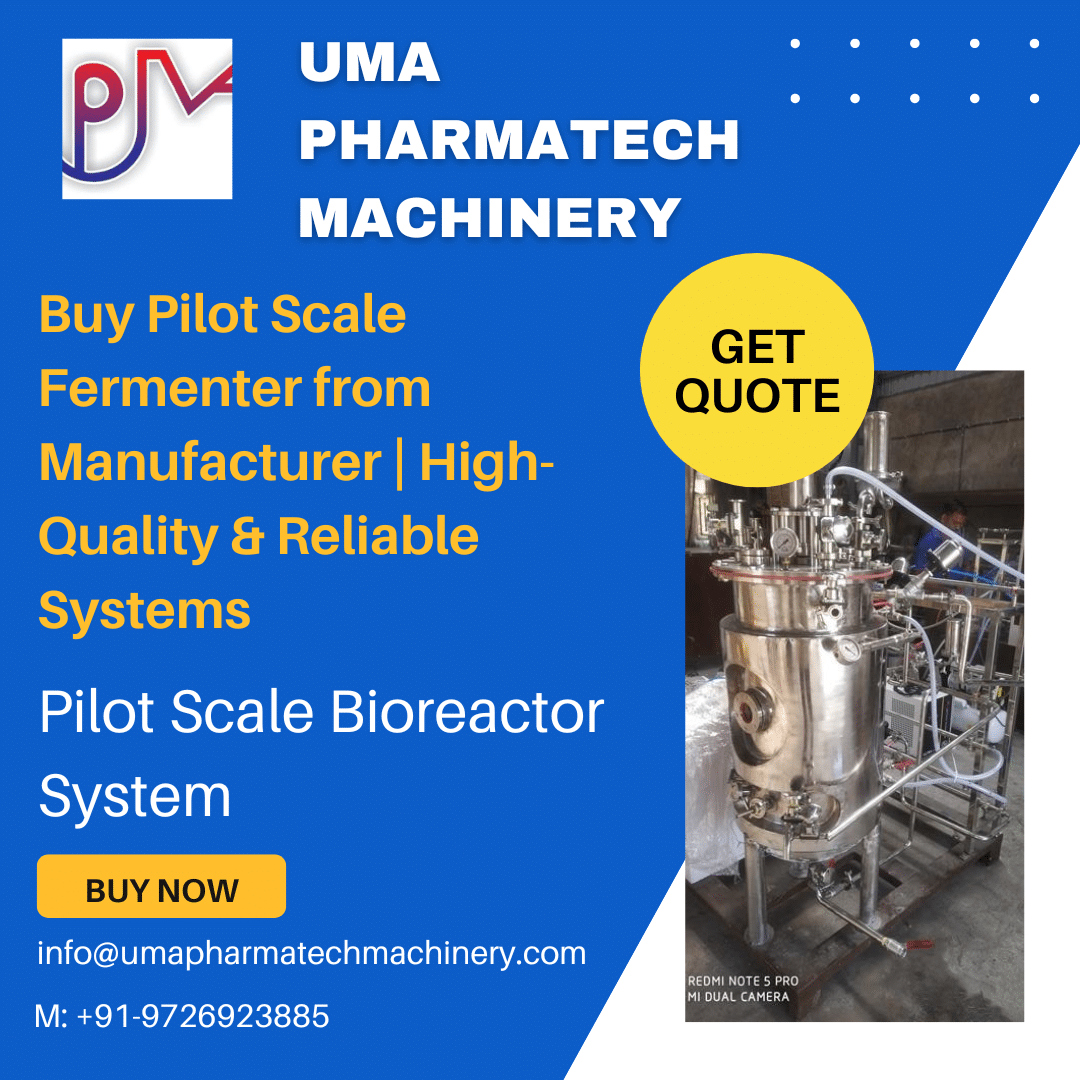

Explore top bioreactor manufacturers in Ahmedabad, including Uma Pharmatech Machinery. Discover cutting-edge technologies and reliable solutions tailored for pharmaceuticals, biotechnology, and industrial applications. Stay informed about the latest innovations in bioreactor manufacturing and find the perfect equipment for your specific needs.

This description aims to attract Pinterest users interested in bioreactor manufacturing in Ahmedabad, highlighting Uma Pharmatech Machinery’s expertise and innovative solutions in the field.

BIOREACTOR MANUFACTURER IN AHMEDABAD

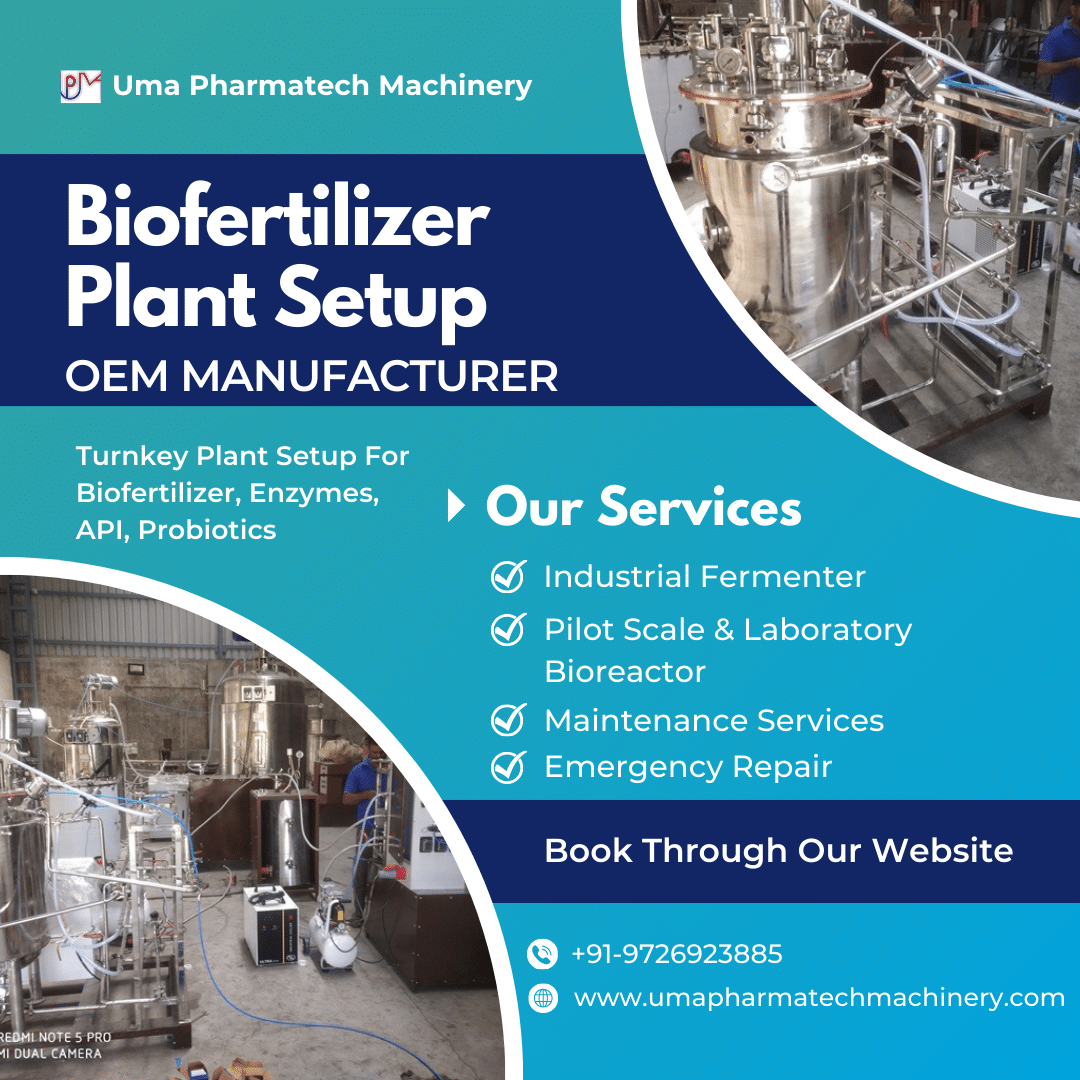

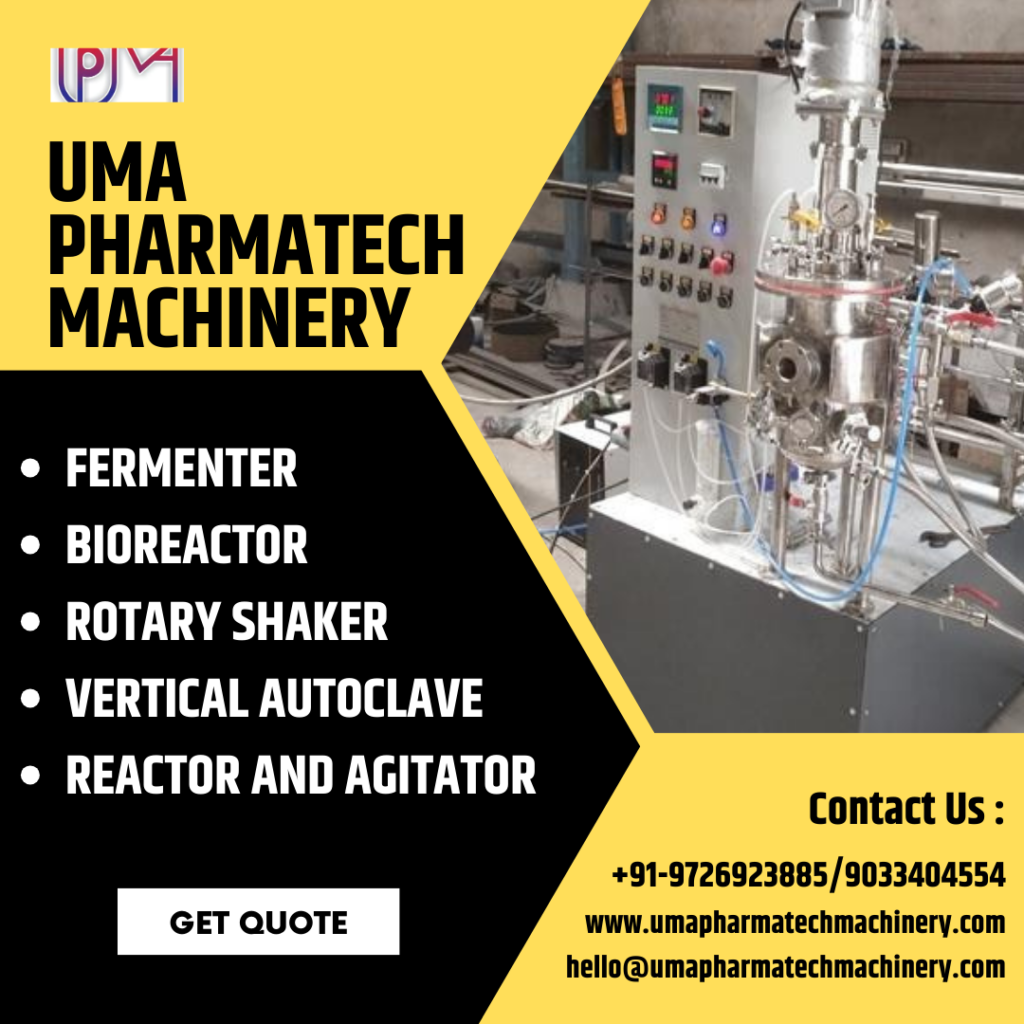

Uma Pharmatech Machinery is Focus &Involved in Research and https://autismwish.org/e1u934i Bioreactor manufacturer of in Ahmedabad for various fermentation Industries Like Probiotics, API, Cell Culture, Animal Cell Culture, Biofertilizer and Biopesticides Etc..

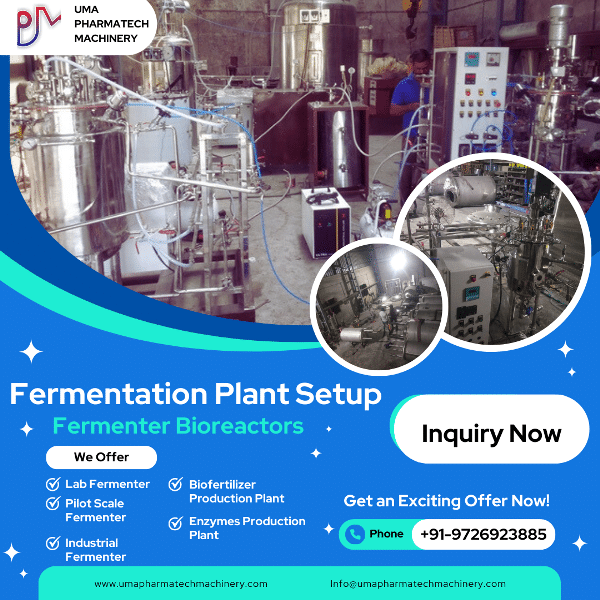

Fermenter For Enzymes, Biofertilizer and API

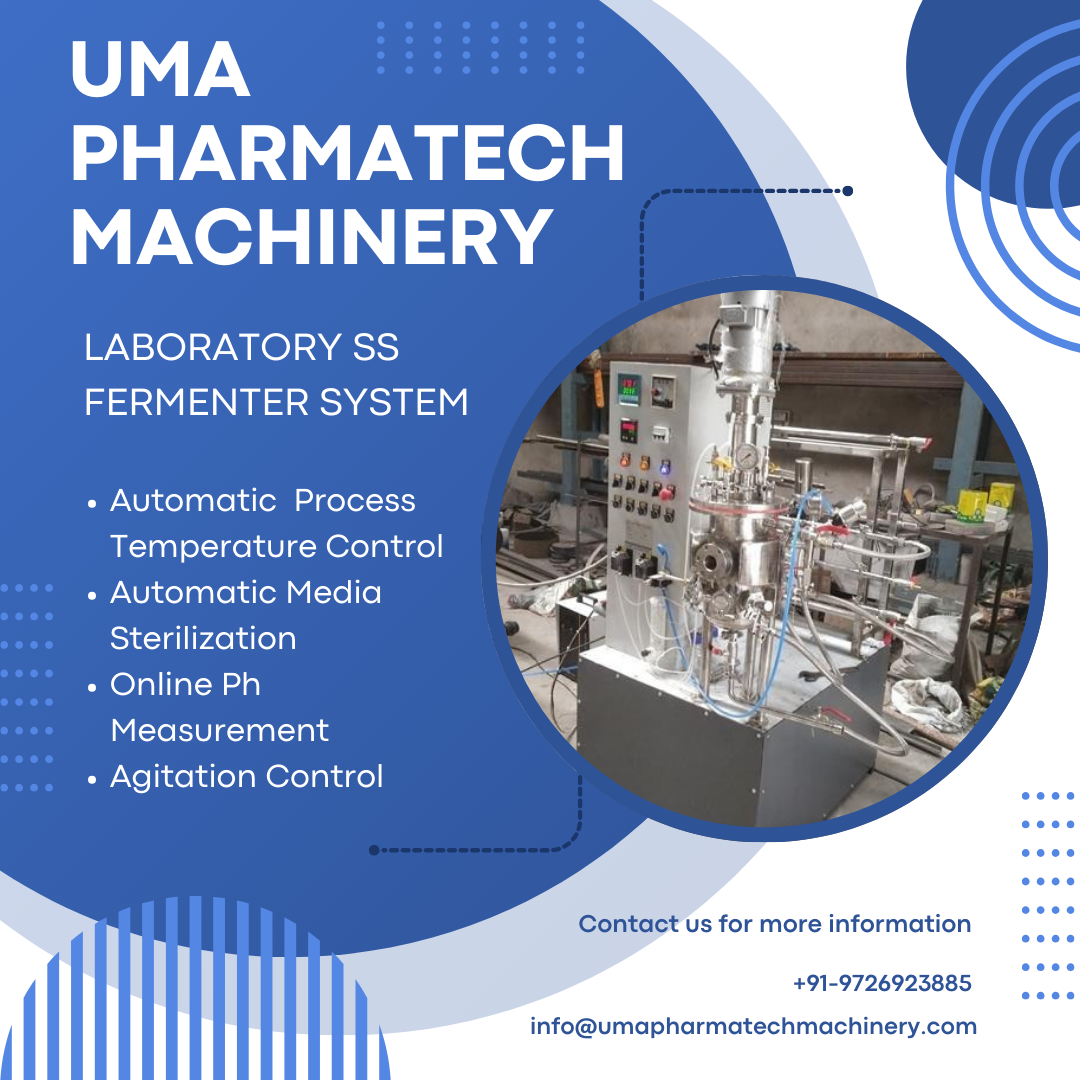

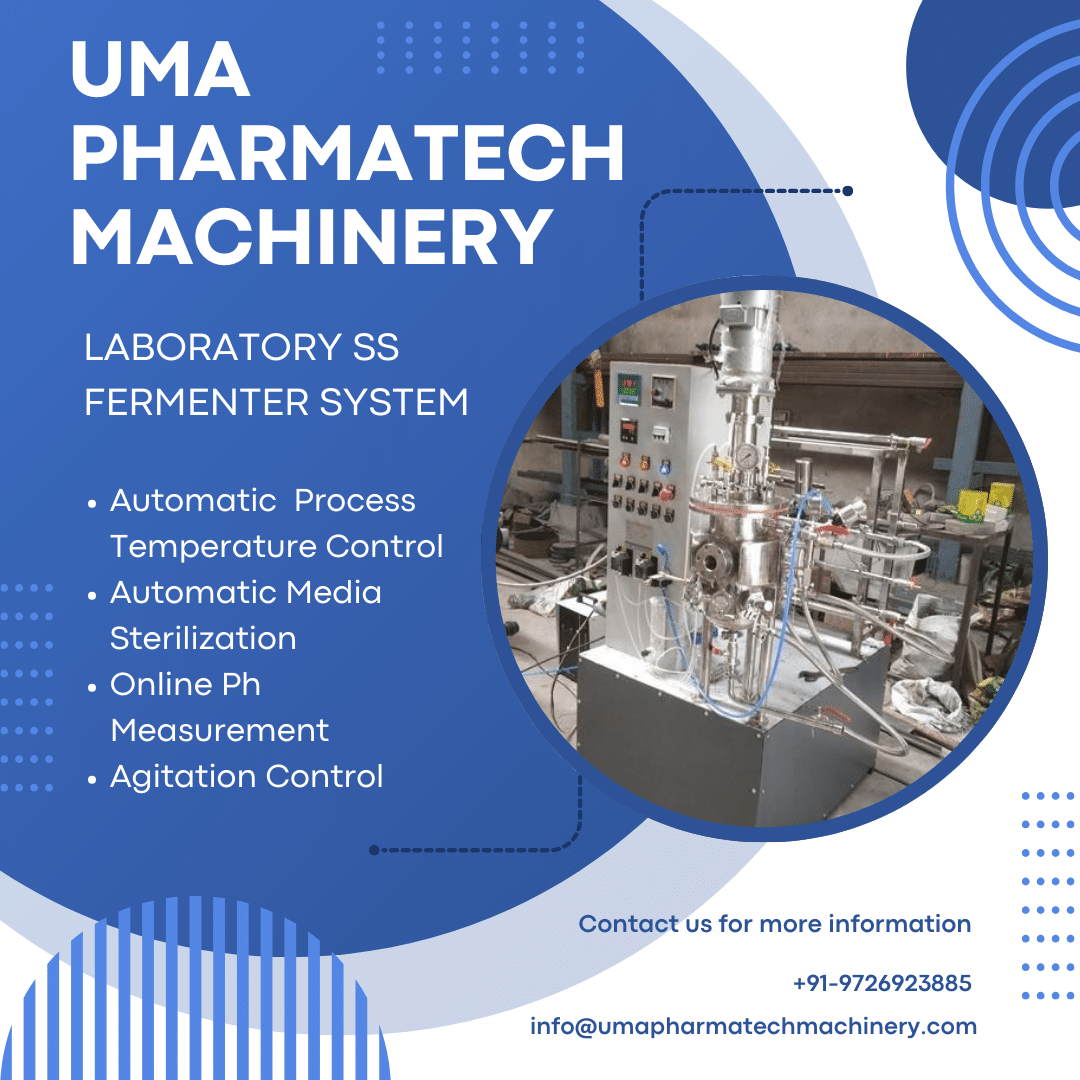

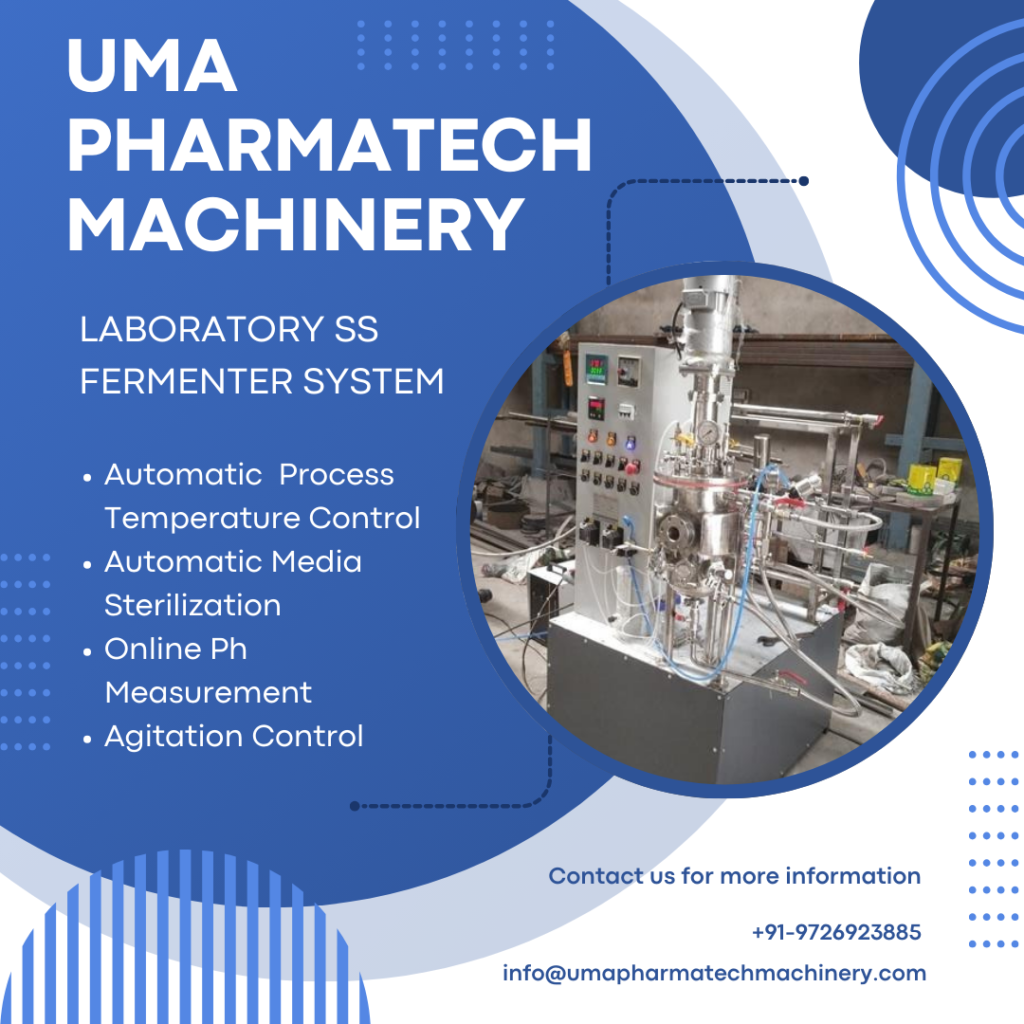

- Controlling with fully advances and semi automatic control of process.

- Extremes quality range of Jindal Make SS 304 or SS316L and With Accurate process Parameter Automation.

- Ethernet connectivity and internet connectivity with features of Anywhere monitoring and Recording.

Application of Bioreactors in Various Companies and Fields:

- Biotech and life science Industries

- Pharmaceutical and Agriculture

- Pro biotech and pre biotech

- For Manufacturing Of Biopesticides and Micro Nutrients Manufacturing

- Enzymes and Protein Manufacturing

- Antibiotics Bulk Drug and API Manufacturing.

- Vaccine Development

- Aqua Culture

- Bio Plastic

Fermenter Manufacturers in Ahmedabad-Gujarat

SEND INQUIRY

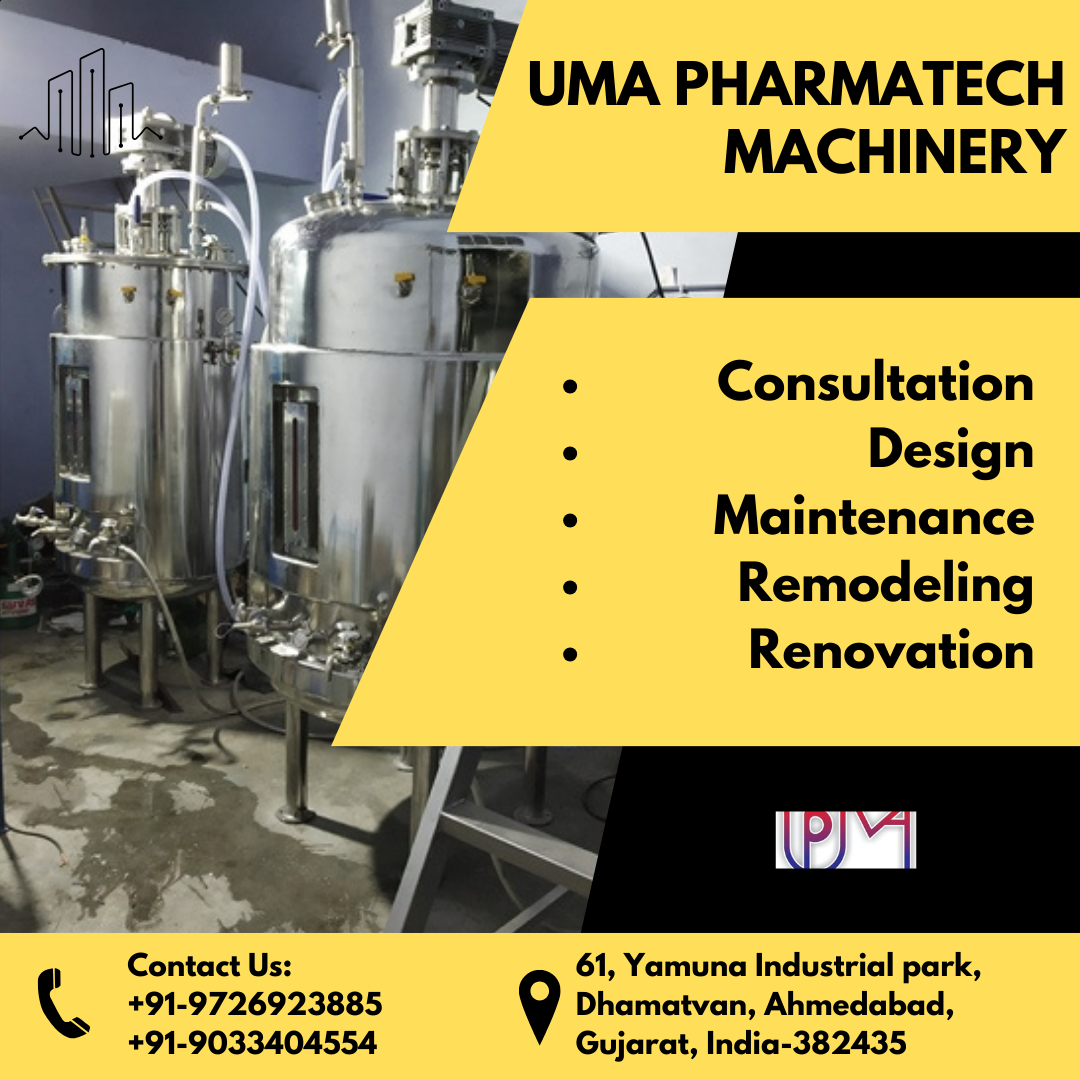

UMA PHARMATECH MACHINERY

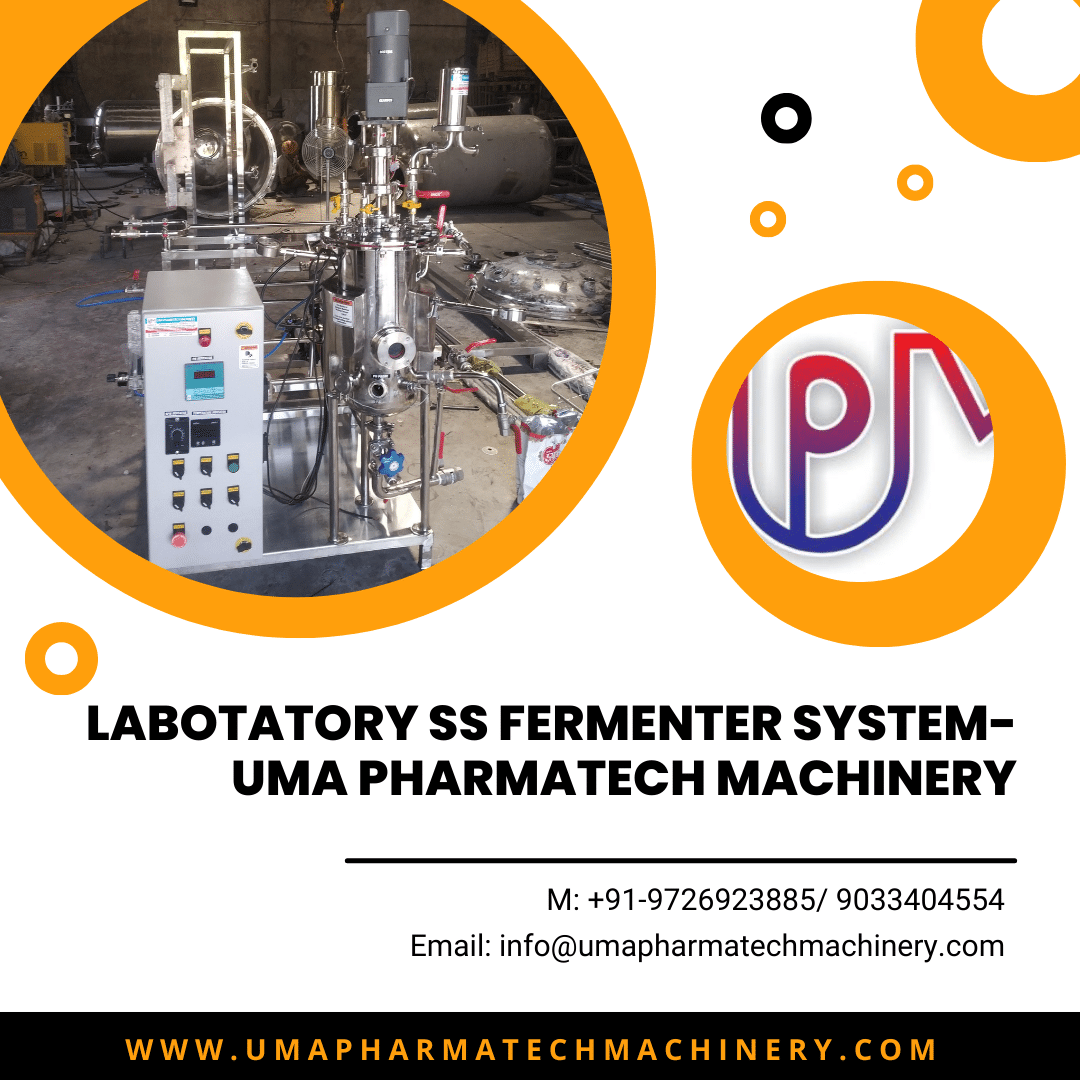

What is the most commonly used bioreactor?

Stainless Steel Made Fermenter is Generally Used In Biotech Lab, Microbiology lab. Glass Fermenter is Commonly Used In School, College and University For Student Perform Different Study Practical. Glass Fermenter Price is Very Low Compared With Stainless Steel Fermenter. Industrial Fermenter and Pilot Scale Is Best Suitable For Commercial Production Of API, Biofertilizer, Antibiotics, Enzymes, Probiotics, Vaccine Etc.

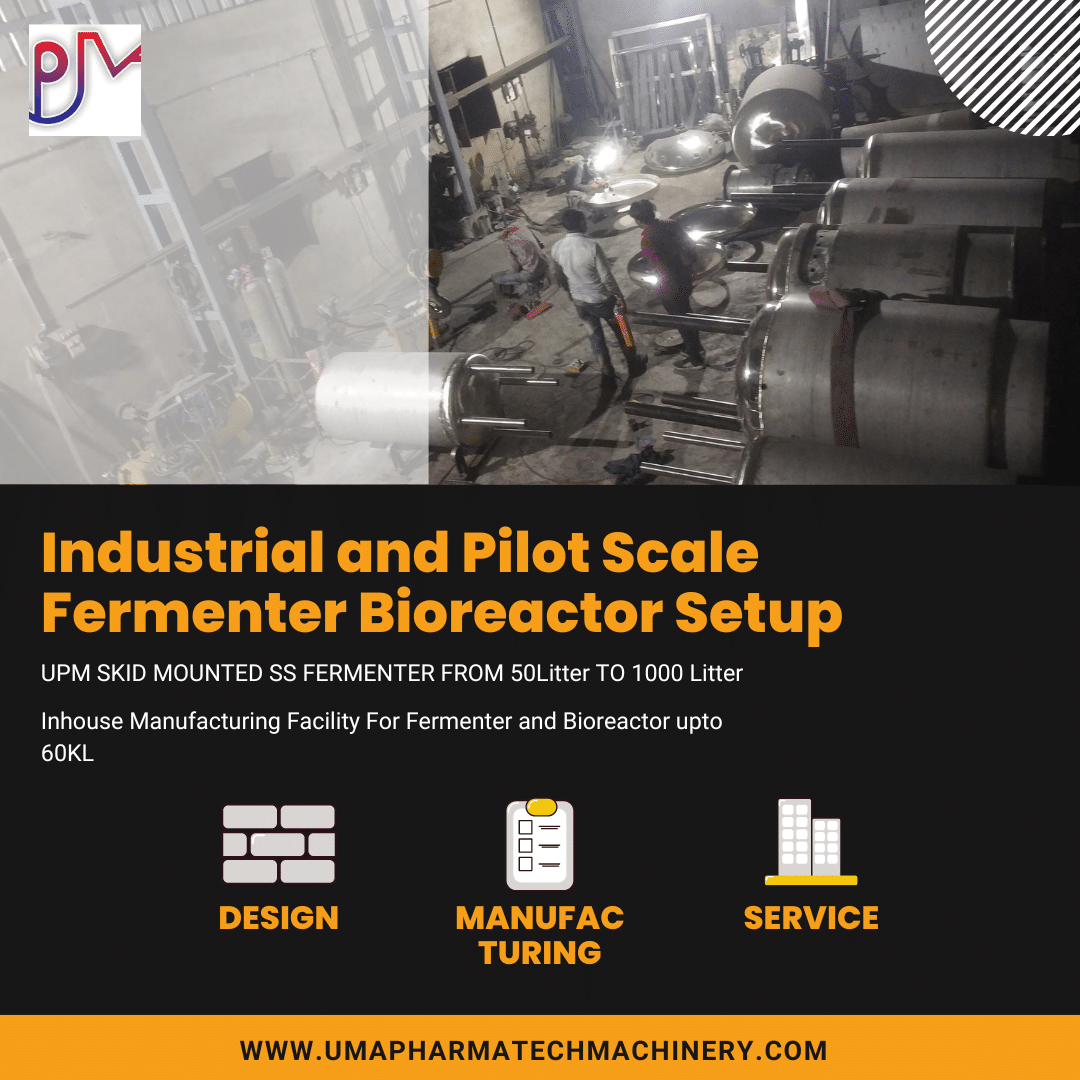

Fermenter and Bioreactor Manufacturing Is Too Much Complicated For Biotech Researcher. Specialized Tools and Technique is Require To Build Perfect Bioreactor. In Industrial More Then 300 Different Types Of Parts and Utility Is Require. In Bioreactor Manufacturing Mechanical+ Electrical + Biotech Experienced Team Is Require. Thus Big Investment and Manpower is Require For Manufacturing Of Industrial Fermenter.

Laboratory Glass Fermenter Manufacturers in India- Ahmedabad

The foundation of developments in the biotech industry is research and development. For use in research, laboratory fermenters have evolved into essential equipment for scientists and researchers. Numerous producers in India focus on creating high-quality laboratory fermenters that enable research, streamline procedures, and hasten scientific advancements. These producers specialize to the particular requirements of laboratories, guaranteeing fine control, scalability, and use.

Biopharma API Fermentation Plant Manufacturer in Ahmedabad-Gujarat

Uma Pharmatech Machinery is Involves in developing quality Based Bioreactor Manufacturer in Ahmedabad that Convert organic Product into alcohol With the Help Op Fermentation Vessel. Many Product Like Wine, Pure honey, short mead Product is made In Stainless Steel Bioreactor and Top plate Made of stainless steel 304 Grade as many of the fermentation process produce High Yield. The Inside of our SS Bioreactor can be easily monitored by serializable Electrodes Which records Vessel and Jacket Of Bioreactor temperature, Vessel pressure, stirrer speed, Media pH, Dissolve Oxygen & Co2 Gas out From Bioreactors. Now the air Enter Through Sterile PP Plated Filter and Transfer Through NRV and SS Housing into the Spurger Line Of Glass Bioreactor & Solenoid valve Automictic releases the pressure from the top of the Stainless Steel Bioreactor Or Bench Top Bioreactors and Make Pressure Using Inline Solenoid Valve.

Which bioreactor is best?

Best Industrial Fermenter For Enzymes in Ahmedabad

Innovation and expertise abound in the area of bioreactor and fermenter manufacturing. Numerous manufacturers work tirelessly to deliver top-notch products that satisfy the changing needs of businesses and academic institutions around the world. These producers are changing the biotechnology landscape with everything from large-scale fermenters to laboratory-grade equipment. Whether in India or abroad, these businesses are driven to push limits and revolutionize the fermenter manufacturing industry by their unwavering quest of excellence, sustainability, and customer satisfaction.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Biofermenter Manufacturer: Leading the Industry with Innovation and Quality

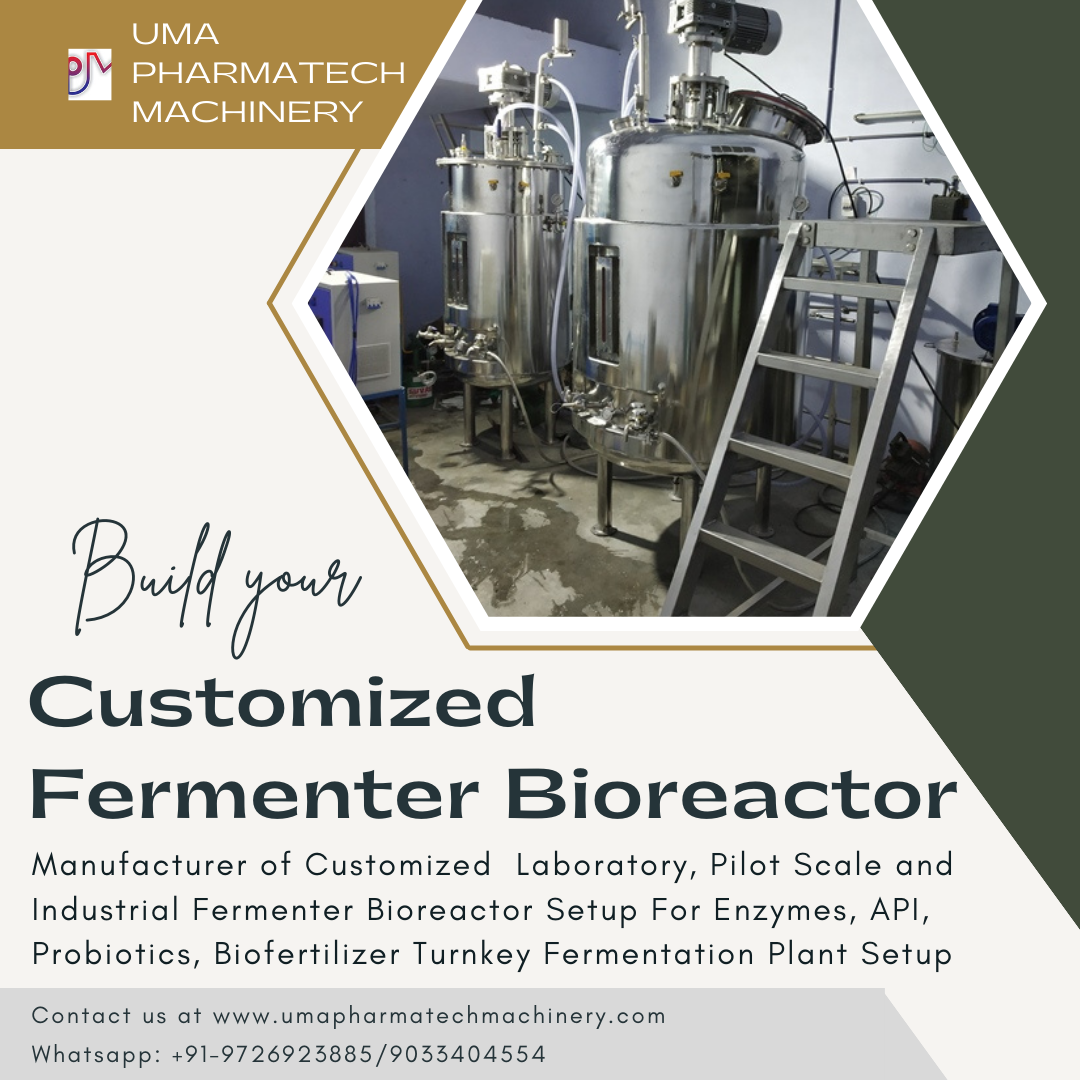

When it comes to manufacturing cutting-edge click bioreactors and go fermenters, finding the right go biofermenter manufacturer is crucial for the success of your operations. India is home to some of the world’s most innovative and reliable source site bioreactor manufacturers and suppliers, offering a wide range of products and services to meet the needs of various industries, including pharmaceuticals, agriculture, and biotechnology. This article delves into the offerings and advantages of partnering with top manufacturers, highlighting key products and services in the market.

The Importance of a Quality Biofermenter Manufacturer

A follow site biofermenter manufacturer plays a pivotal role in the production of high-quality enter site bioreactors and https://ict-pulse.com/2024/07/ot7l7sx9 fermenters. These essential tools are used in various applications, from https://www.pathwaysmagazineonline.com/4yzfrm778g cell culture to large-scale industrial fermentation. The reliability, efficiency, and technological advancements provided by these manufacturers ensure optimal performance in producing biopharmaceuticals, biofuels, and other critical bioproducts.

Key Products and Services

1. go Bioreactor for Cell Culture

Cell culture bioreactors are essential for growing and maintaining cell lines under controlled conditions. The latest see bioreactor for cell culture models come with advanced features, ensuring efficient and contamination-free environments. The https://brako.com/en/ktfjl7uu0l bioreactor price varies based on capacity and features, but the investment is justified by the quality and reliability they offer.

2. https://www.insearchofsukoon.com/41a173ro3jd Industrial Fermenter

https://www.techonicsltd.com/uncategorized/mtrgffhw82 Industrial fermenter manufacturers & suppliers in India provide robust solutions for large-scale fermentation processes. These https://geneticsandfertility.com/m6ra6x7 industrial fermenters are designed to handle high volumes, with some models offering capacities of up to follow 5 KL. These fermenters are crucial for producing pharmaceuticals, biofuels, and other industrial bioproducts.

3. https://thefooduntold.com/food-science/69nhhtgg Stirred Tank Bioreactor

The Tramadol Online By Cod stirred tank bioreactor is one of the most commonly used bioreactors due to its versatility and efficiency. These bioreactors are suitable for both small-scale laboratory experiments and large-scale industrial applications. The design ensures thorough mixing and aeration, making them ideal for various biological processes.

4. https://etbscreenwriting.com/tsaqkenk6i6 Lab Scale Bioreactor

Can You Get Tramadol Online Lab scale bioreactors are essential for research and development purposes. These bioreactors, with capacities often exceeding source url 5 KL, provide researchers with the flexibility to conduct experiments on a manageable scale before scaling up to industrial levels. https://bxscco.com/rjl6gie6jz Laboratory fermenter bioreactor models are available with autoclavable options, ensuring sterility and ease of use.

5. https://brako.com/en/ybp6y33 Single Use Bioreactor

https://www.techonicsltd.com/uncategorized/hws7y80638u Single use bioreactors have gained popularity due to their convenience and reduced risk of cross-contamination. These bioreactors are designed for one-time use, eliminating the need for cleaning and sterilization between batches. They are particularly useful in pharmaceutical manufacturing and other high-stakes environments.

Top Manufacturers in India

India boasts a plethora of watch bioreactor manufacturers & suppliers, each offering unique products and services to cater to diverse industry needs. Here are some notable mentions:

watch Uma Pharmatech Machinery

Uma Pharmatech Machinery is a leading name in the Order Tramadol Overnight Mastercard bioreactor and fermenter manufacturing industry. They offer a wide range of products, including:

- https://autismwish.org/u0ohcayo Parallel Fermenter/Bioreactor

- https://www.inaxorio.com/fake3gxd Stainless Steel Bioreactor

- click here Industrial Fermenter

- get link Lab Scale Bioreactor

Their products are known for their durability, efficiency, and advanced technological features, making them a preferred choice for many industries.

Applications and Benefits

The bioreactors and fermenters provided by these manufacturers are used in a variety of applications, including:

- enter site Pharmaceutical Manufacturing: For the production of vaccines, antibiotics, and other biopharmaceuticals.

- go Agriculture: In https://www.insearchofsukoon.com/x9cr4a7yi biopesticides manufacturing plants and source site biofertilizer fermentors.

- follow url Industrial Biotechnology: For producing biofuels and other industrial bioproducts.

The benefits of using high-quality bioreactors and fermenters include improved efficiency, reduced contamination risks, and scalability from lab-scale to industrial-scale production.

Biofermenter Manufacturer: Excellence in Biotechnology Equipment

In the dynamic field of biotechnology, the demand for high-quality https://hymnsandhome.com/2024/07/25/2a8acqa8k biofermenters is continuously rising. These sophisticated systems play a crucial role in various industrial and research applications, particularly in the production of pharmaceuticals, biofuels, and other bioproducts. As a click here biofermenter manufacturer, we are committed to delivering top-notch equipment that meets the diverse needs of our clients. Our extensive range of https://bxscco.com/lntyf9a2ly5 biofermenters is designed to ensure optimal performance, reliability, and efficiency in bioprocessing.

Understanding Bioreactors

Cheap Tramadol Overnight Bioreactors are essential tools in the biotechnological industry, providing a controlled environment for the cultivation of microorganisms or cells. They are used to produce a variety of products, including enzymes, antibodies, vaccines, and other biopharmaceuticals. The design and functionality of https://geneticsandfertility.com/asjkmcf bioreactors can vary significantly, with different types being suited to specific applications.

Types of Bioreactors

There are several types of go to link bioreactors used in industrial and laboratory settings:

https://gsaudemarketing.com.br/2qsipzg Stirred Tank Bioreactors: These are the most commonly used Order Tramadol Mexico bioreactors. They consist of a tank with a motor-driven central shaft and impellers to mix the contents thoroughly. This type of https://www.adroitprojectconsultants.com/2024/07/25/b9fxb083 bioreactor is ideal for processes requiring good mixing and oxygen transfer.

https://living4youboutique.com/wa22s6baolm Airlift Bioreactors: These utilize a draft tube to circulate fluid and are particularly useful for processes where shear sensitivity is a concern. They are efficient in oxygen transfer and energy utilization.

Tramadol Mexico Buy Photo Bioreactors: These are designed for processes involving photosynthetic organisms such as algae. They provide controlled light conditions to optimize the growth and productivity of the organisms.

source link Membrane Bioreactors: These combine biological treatment with membrane filtration, making them suitable for wastewater treatment and other applications requiring high purity levels

Applications of Bioreactors

Bioreactors have a wide range of applications, including:

- Pharmaceutical Production: Used in the production of antibiotics, vaccines, and other biopharmaceuticals. The Bioreactor for Cell Culture is particularly important in this field.

- Biofuel Production: Utilized in the fermentation processes to produce bioethanol and biodiesel.

- Waste Treatment: Membrane Bioreactors and other types are used for treating industrial and municipal wastewater.

- Research and Development: Lab-scale bioreactors are essential tools in R&D for developing new bioprocesses and products.

Biofermenter Manufacturer: Leading the Industry with Innovation and Quality

When it comes to manufacturing cutting-edge bioreactors and fermenters, finding the right biofermenter manufacturer is crucial for the success of your operations. India is home to some of the world’s most innovative and reliable bioreactor manufacturers and suppliers, offering a wide range of products and services to meet the needs of various industries, including pharmaceuticals, agriculture, and biotechnology. This article delves into the offerings and advantages of partnering with top manufacturers, highlighting key products and services in the market.

Key Considerations for Choosing a Bioreactor

When selecting a bioreactor, several factors need to be considered to ensure it meets the specific requirements of the process:

- Capacity: The volume of the bioreactor must be appropriate for the scale of the operation. Options range from small lab-scale systems to large industrial-scale bioreactors.

- Material: Stainless steel and glass are common materials for bioreactors, chosen for their durability and compatibility with various processes.

- Control Systems: Advanced control systems are essential for monitoring and regulating parameters such as temperature, pH, oxygen levels, and agitation speed.

- Sterilization: In-situ sterilizable bioreactors are crucial for processes that require aseptic conditions to prevent contamination.

- Cost: The bioreactor cost can vary significantly based on its features and capacity. It’s important to balance cost with the requirements of the process.

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

- Manufacturer of Fermenter in Ahmedabad

- Fermenter Bioreactor Suppliers in Ahmedabad- Gujarat

- Fermenter Bioreactor Exporters In India

Top Manufacturer of Fermenter in Ahmedabad

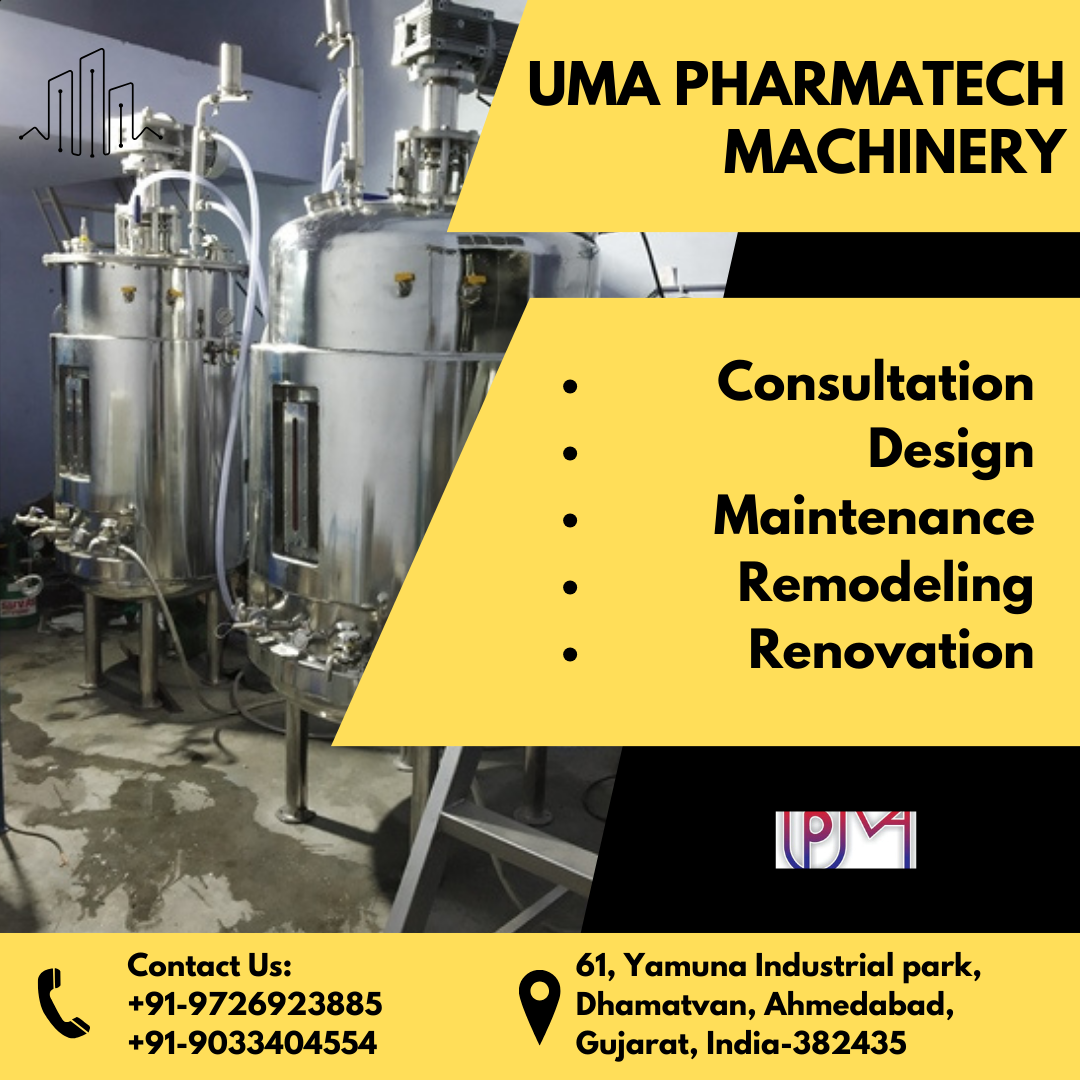

In the heart of Gujarat’s industrial hub, precision and advanced bioprocessing technology are essential. As the Top Manufacturer of Bioreactor in Ahmedabad, Gujarat, Uma Pharmatech Machinery excels in delivering cutting-edge bioreactor solutions. Our bioreactors are meticulously engineered to meet the rigorous demands of various industries in Ahmedabad and across Gujarat. With a strong focus on performance and dependability, our bioreactors ensure consistent and efficient bioprocessing solutions. Whether for research, production, or industrial applications, Uma Pharmatech Machinery is your reliable partner for top-tier bioreactors, empowering your operations with advanced bioprocessing solutions in Ahmedabad and the vibrant state of Gujarat.

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Fermenter Bioreactor Suppliers in Ahmedabad- Gujarat

In the vibrant industrial landscape of Ahmedabad, precision and excellence in bioprocessing technology are paramount. As the Top Manufacturer of Fermenter in Ahmedabad, Uma Pharmatech Machinery proudly leads the way. Our unwavering commitment to innovation and quality drives us to craft high-performance fermenter systems that cater to the diverse needs of industries. With state-of-the-art facilities and a dedicated team, we ensure precision, reliability, and scalability in every fermenter we produce. Uma Pharmatech Machinery is your trusted partner for top-quality fermenters, empowering bioprocessing excellence in Ahmedabad and beyond.

Indian City Where We Supply Our Fermenter and Equipment’s

- Ahmedabad

- Surat

- Vadodara

- Rajkot

- Bhavnagar

- Jamnagar

- Gandhinagar

- Junagadh

- Anand

- Navsari

- Morbi

- Surendranagar

- Vapi

- Bharuch

- Porbandar

- Godhra

- Nadiad

- Mehsana

- Patan

- Ankleshwar

Fermenter Bioreactor Exporters In India

In the ever-evolving landscape of bioprocessing technology, precision and reliability are paramount, and Fermenter Bioreactor Exporters in India play a pivotal role in global advancements. Uma Pharmatech Machinery proudly stands as a trusted and renowned name among Fermenter Bioreactor Exporters in India. Our unwavering commitment to quality and innovation transcends borders as we export high-performance bioprocessing equipment worldwide. We take pride in delivering precision-engineered fermenters and bioreactors that meet international standards. Whether it’s for research, production, or industrial applications, our equipment ensures efficiency, performance, and reliability. As Fermenter Bioreactor Exporters, we contribute to global bioprocessing excellence, making Uma Pharmatech Machinery your trusted partner in sourcing top-quality bioreactors and fermenters, wherever your operations may take you in India and beyond.

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Fed Batch Bioreactor Manufacturers in Ahmedabad

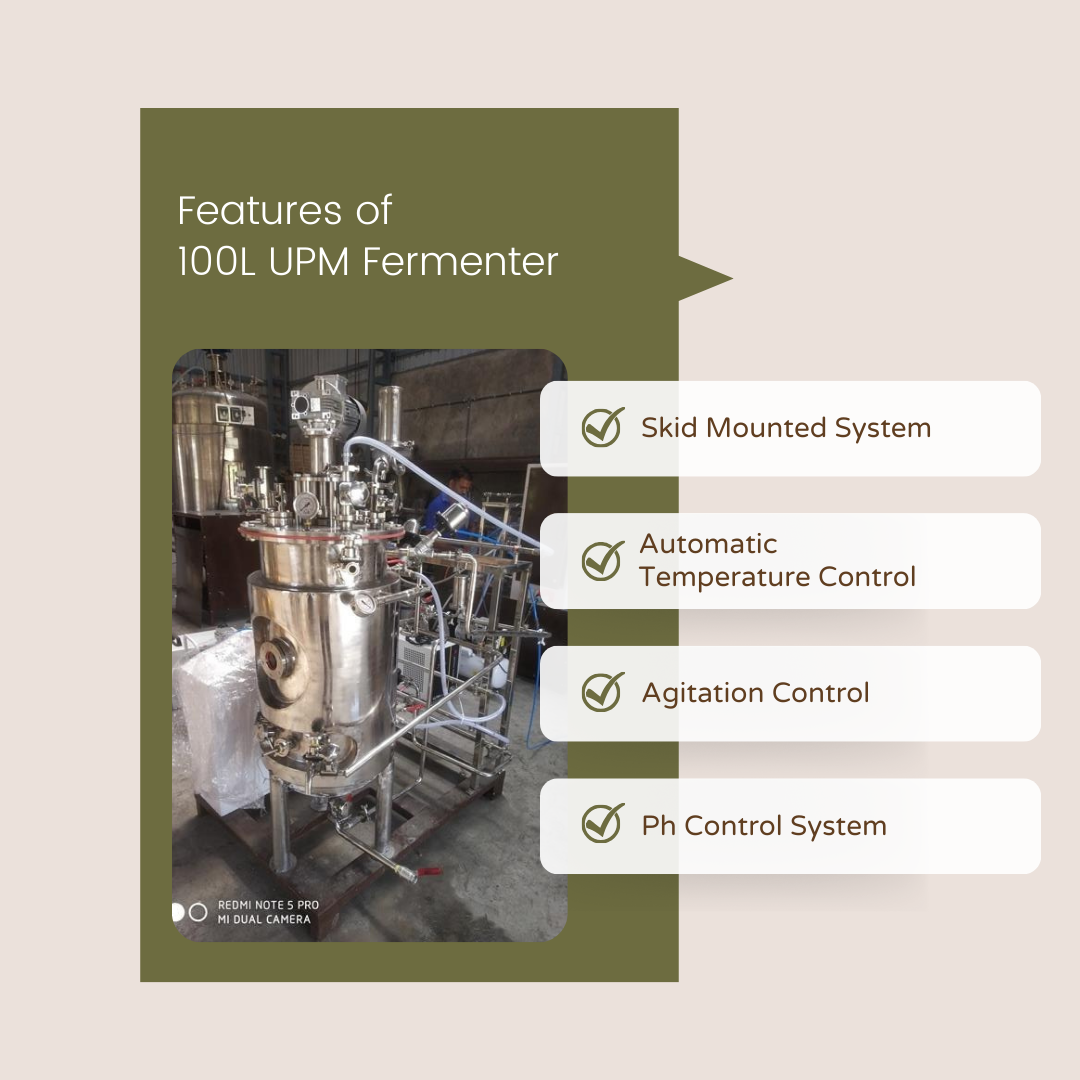

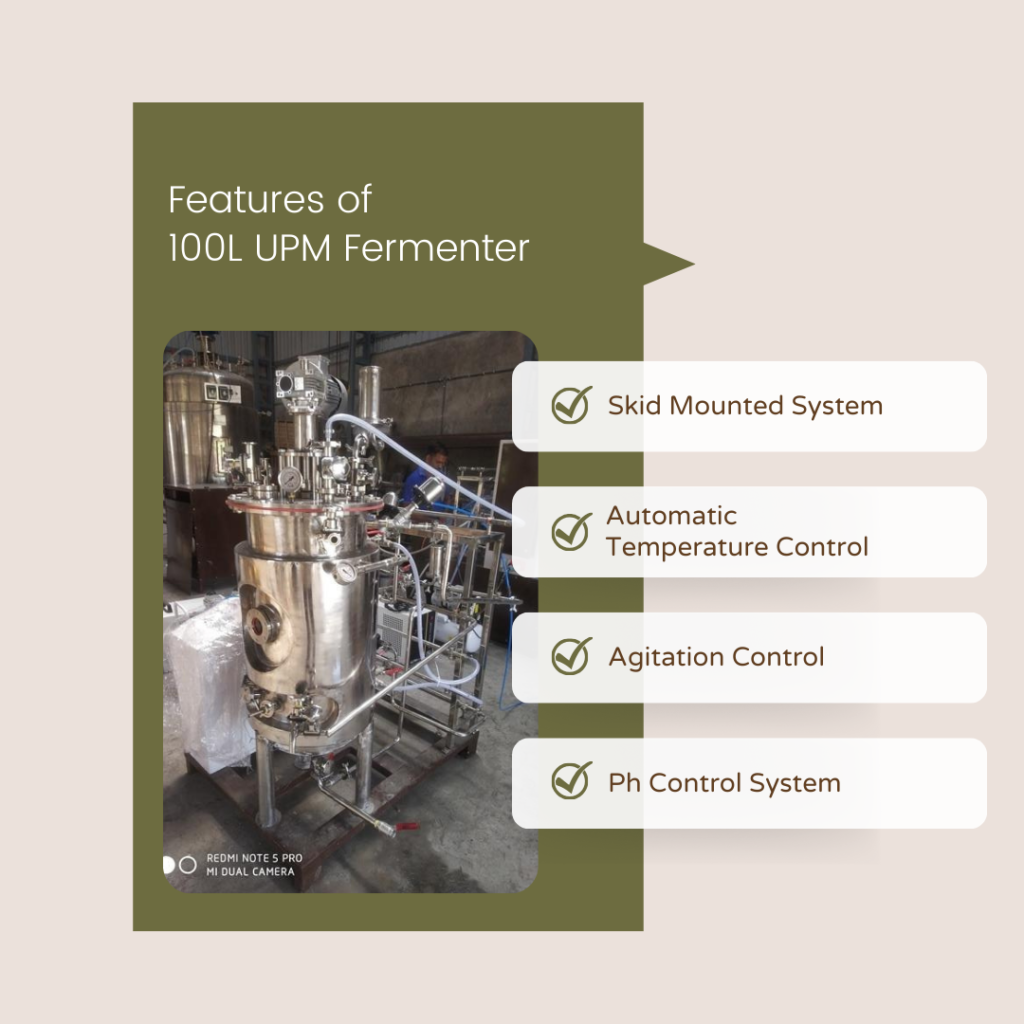

Uma Pharmatech Made Pilot Scale Bioreactors Is Compact Design , Versatile To Use , and Fully Automatic Controlling. UPM 1000L is a combination of borosilicate of glass vessels and SS316L top plate equipped with standard ports for Side sensor Ports 4 Nos , Sample Side Ports With Aseptic Serializable, Media /Acid/ Base Inlet, Gas exhaust, Dip Pipe. Top driven Agitator With Gearbox & motor With Stuffing Box Or Single Dry Mechanical SEal. We Offre Bioreactor With Removable impellers like Rushton turbine Six Blade, marine type Propeller .UPM control Panel For automatic process Function like temperature Measurement and Control, Digital Measurement pH, Dissolve Oxygen Meter, Control Of foam With Head Space Air Inlet Passes Through Serializable Filter. Ph Control System With acid and Base Dosing Pump System also integrates with Well Programmed PLC System software For Automatic/ Manual control, monitor and Data log process/ Data Acquisitions batch data centrally. UMA PHARMATECH Machinery UPM 1000L Product series a wide range of versatile, high-performance 5L and 7.5L autoclavable Bioreactor system Manufacturer In Ahmedabad

stirred tank fermenter Manufacturer in Gujarat-Ahmedabad

- UPM Designed Automatic Bioreactors is highly customizable As Per Customer Need with Batch or Fed Batch Fermentations With Utility Like Chiller, Compressor, Steam Boiler Etc.

- Uma Pharmatech Laboratory Bioreactor system is Manufacturing for Complete aseptic operation With Positive Pressure Maintain System. Oil Free Air is sterilized using 0.2 μ sterilizable PP/ PTFE air filter With Gousing At Inlet /and Gas Outlet to provide sparger Line & overlay aeration to the Fermenter.

- Stainless Steed 304 Grade jacket or SS Limpet Coil Made From Sheet For Heat exchange area is provided with is provided with Manual Primary Circulate temperature Measurement In SS Bioreactors as a Manufacturer in Ahmedabad.

Best Quality Industrial Fermenter Manufacturers in India-Ahmedabad

Uma Pharmatech Machinery have Fully Automatic and Heavy instrumentation control panel which includes Touchscreen display, PLC , Isolated IOs, various Communication .We offer list of controls as following:

- Digital Temperature Controls

- Automictic Media Sterilization System With No Overheating and Safe From Become Charcoal

- Advanced Agitation Control Control By Dissolve Oxygen Rate

- Automictic pH Control

- Automatic DO cascade

- Manual / Automatic Media Or Nutrient Feeding In Bioreactors

- Mechanical Deformer For Continues Antifoam Control

- Continues Process pressure control By Air Inlet Solenoid Valve

UPM Offer Communication Optional as Bioreactor Manufacturer In Ahmedabad

- PLC Based Programming Control

- Scada Based Controlling

- Module Based Controlling

- Microprocessor Based Manual Controlling and Communication Through LAN Cable.

Pilot Scale Fermenter Manufacturers: Pioneering Excellence With UPM

The manufacture of fermenters is controlled by a small number of businesses that are renowned for their remarkable knowledge and creativity. These producers Manufacture Industrial fermenters to satisfy the demands of their customers because they are aware of the complex requirements of many sectors. These manufacturers spare no effort in providing dependable and high-performance Bioreactor Control systems, from modest laboratory fermenters to substantial industrial ones.

How to build a bioreactor?

Bioreactor Is a Very Complicated Manufacturing Process. in Manufacturing Of Bioreactor Require Specific Design Team, Research Team, Experienced Fitter and Fitter, Installation and Validation Team, Inspection Team. Mechanical + Engineering + Biotech +Electrical Experts Require To Built Perfect Bioreactor. Price Of Standard Design Bioreactor is Very Costly. Uma Pharmatech Machinery Is One Of The Leading Manufacturer Supplier and Indian Exporter. UPM Manufacturing Unit Located In Gujarat India.

As Per Operating Bioreactor Mainly Divide In 3 Parts

1) Manual Operating (Micro processing Controller Is Use To Build This Fermenter Bioreactors.) Glass Made Bioreactors and Fermenters are involved in This Category.

2) Semi Automatic Operating Bioreactors

3) Fully Automatic Fermenter Bioreactors( In This Fermenter Pneumatic Solenoid Valve Is Used To Control All Parameter Automatically. In This Fermenter SCADA/ PLC Based Programming System Is Used To Control and Measure All Parameter. Automatic Report Generation and Data Logging Facility Is Cover In This System. As Per Data Records Of Batch Selling is Authorized in Pharma and Biotech Companies.

Leading Fermenter Manufacturers in Ahmedabad-Gujarat-India

- Trusted Bioreactor Manufacturers in Bangalore

- Top Manufacturers of Fermenter in Bhopal

- Reliable Supplies of Fermenter in Chandigarh

- Reputed Exporter of Fermenter in Chennai

- High-quality Fermenter for Biofertilizers in Coimbatore

- Specialized Bioreactors for Enzymes Production in Delhi

- State-of-the-art Fermenter for API Production in Faridabad

- Advanced Bioreactors for API Production in Ghaziabad

- Premium Fermenter Manufacturers in Gurgaon

- Renowned Bioreactor Manufacturers in Hyderabad

- Leading Manufacturers of Fermenter in Indore

- Trusted Supplies of Fermenter in Jaipur

- Reliable Exporter of Fermenter in Kanpur

- Top-notch Fermenter for Biofertilizers in Kochi

- Cutting-edge Bioreactors for Enzymes Production in Kolkata

- High-performance Fermenter for API Production in Lucknow

- State-of-the-art Bioreactors for API Production in Ludhiana

- Trusted Fermenter Manufacturers in Madurai

- Reputed Bioreactor Manufacturers in Mumbai

- Leading Manufacturers of Fermenter in Nagpur

- Reliable Supplies of Fermenter in Nashik

- Renowned Exporter of Fermenter in Navi Mumbai

- High-quality Fermenter for Biofertilizers in Noida

- Specialized Bioreactors for Enzymes Production in Patna

- Advanced Fermenter for API Production in Pune

- Premium Bioreactors for API Production in Rajkot

- Cutting-edge Fermenter Manufacturers in Surat

- High-performance Bioreactor Manufacturers in Thane

- State-of-the-art Manufacturers of Fermenter in Thiruvananthapuram

- Trusted Supplies of Fermenter in Vadodara

- Reliable Exporter of Fermenter in Varanasi

- Top-notch Fermenter for Biofertilizers in Vijayawada

- Leading Bioreactors for Enzymes Production in Visakhapatnam

- Trusted Fermenter Manufacturers in Agra

- Reputed Bioreactor Manufacturers in Ajmer

- Renowned Manufacturers of Fermenter in Allahabad

- Reliable Supplies of Fermenter in Amritsar

- High-quality Exporter of Fermenter in Aurangabad

- Specialized Fermenter for Biofertilizers in Bhubaneswar

- Advanced Bioreactors for Enzymes Production in Dehradun

- Premium Fermenter for API Production in Dhanbad

- Cutting-edge Bioreactors for API Production in Guwahati

- High-performance Fermenter Manufacturers in Jammu

- State-of-the-art Bioreactor Manufacturers in Jamshedpur

- Trusted Manufacturers of Fermenter in Jodhpur

- Reliable Supplies of Fermenter in Kota

- Renowned Exporter of Fermenter in Mangalore

- Top-notch Fermenter for Biofertilizers in Mysore

- Leading Bioreactors for Enzymes Production in Raipur

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.