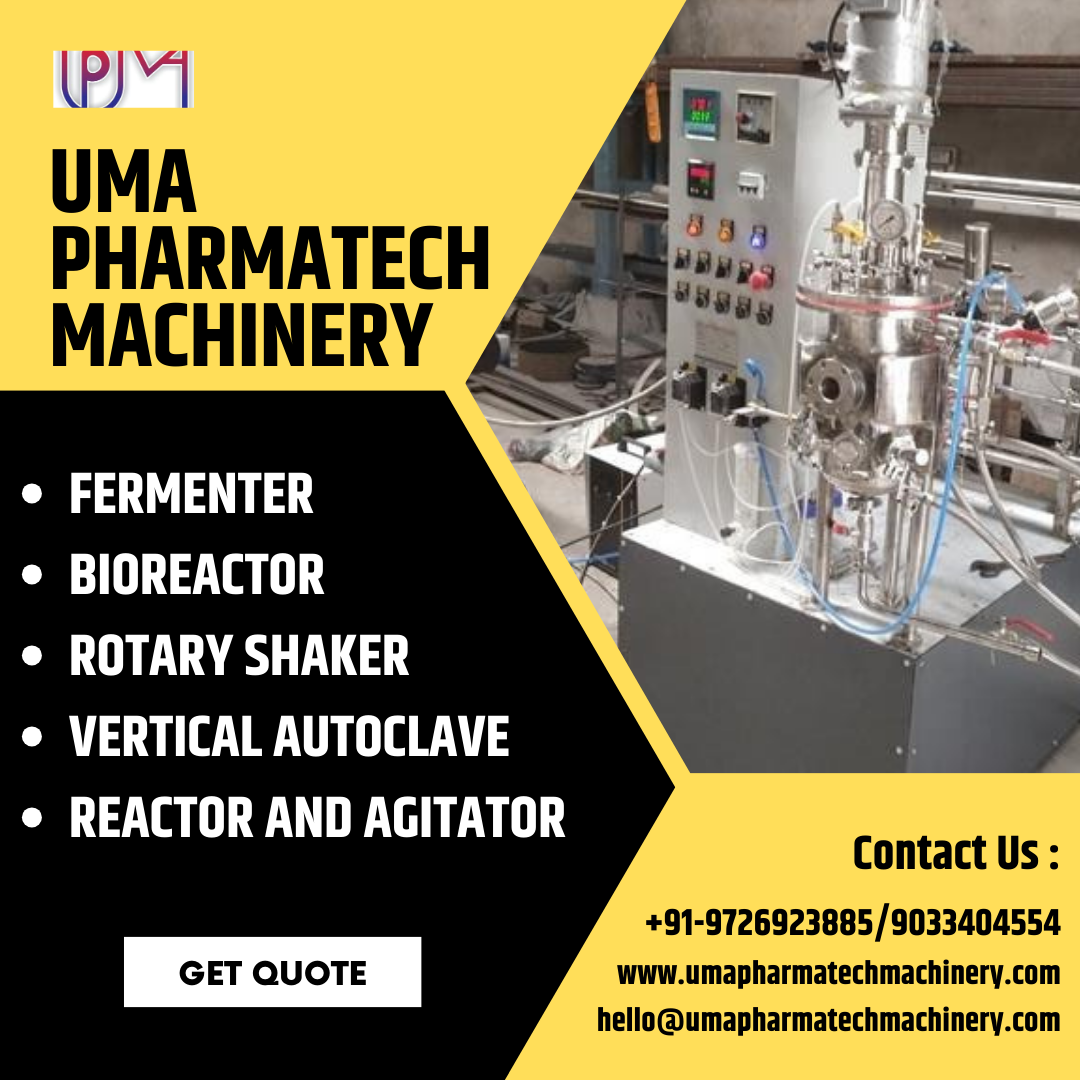

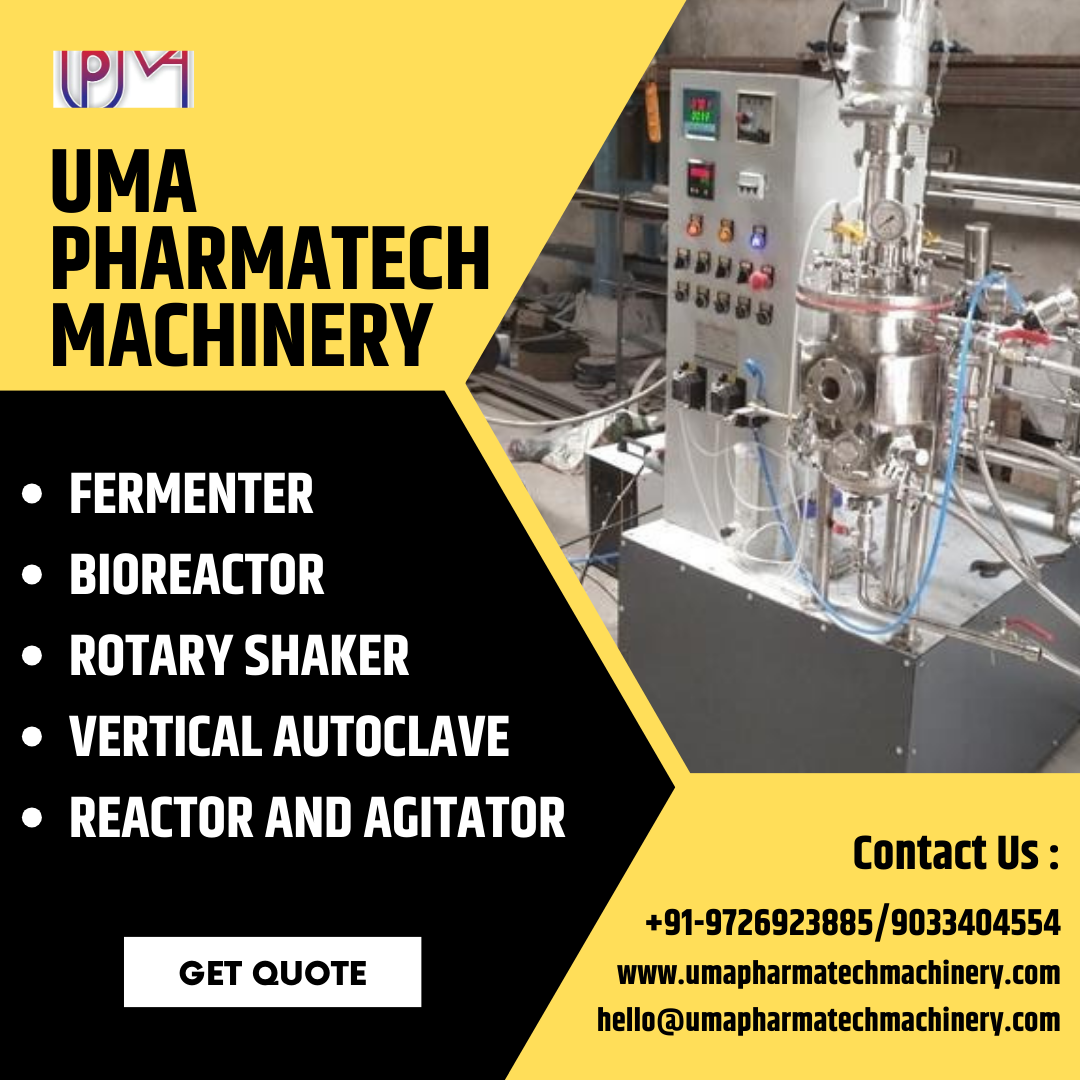

Bioreactor Manufacturer and Exporter in Egypt

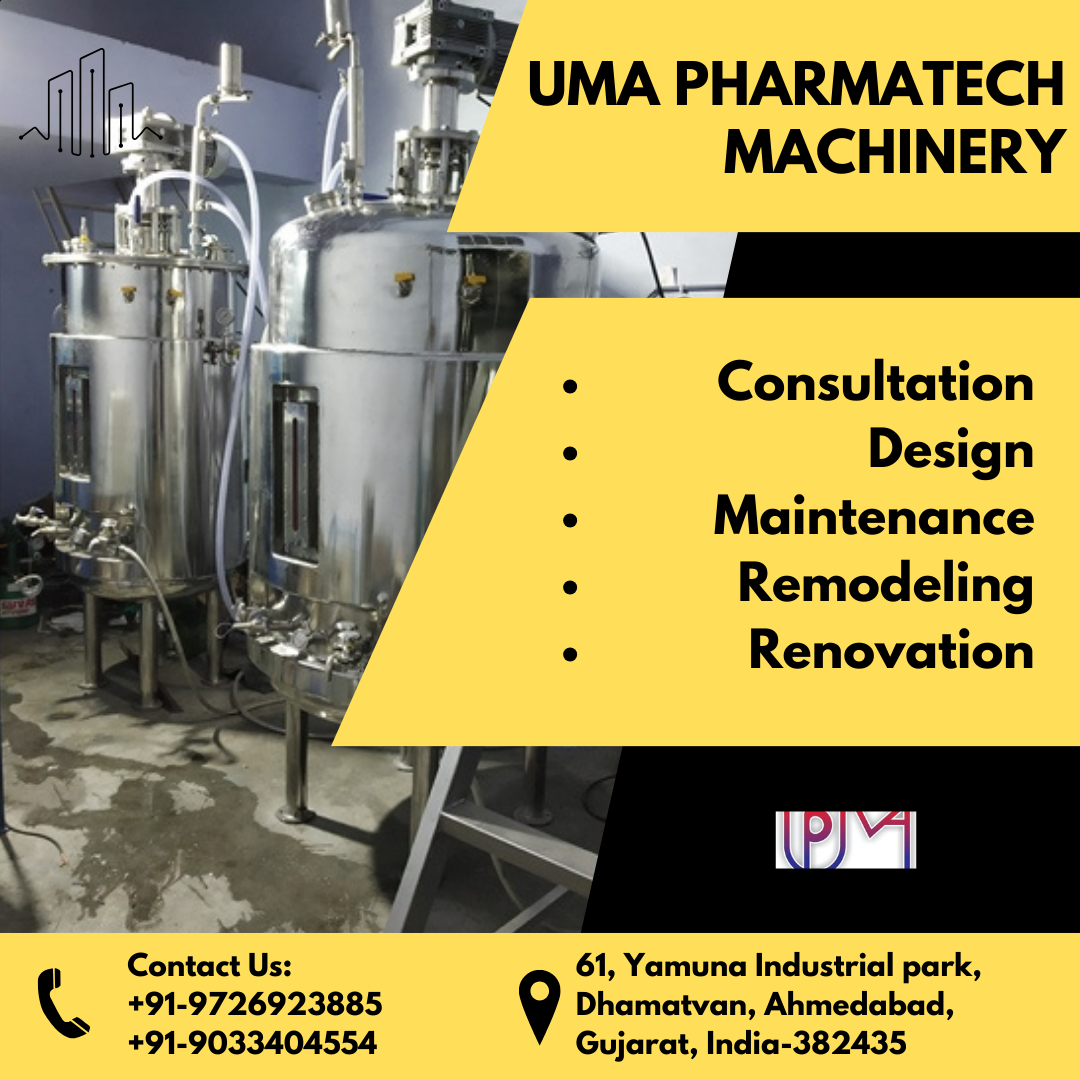

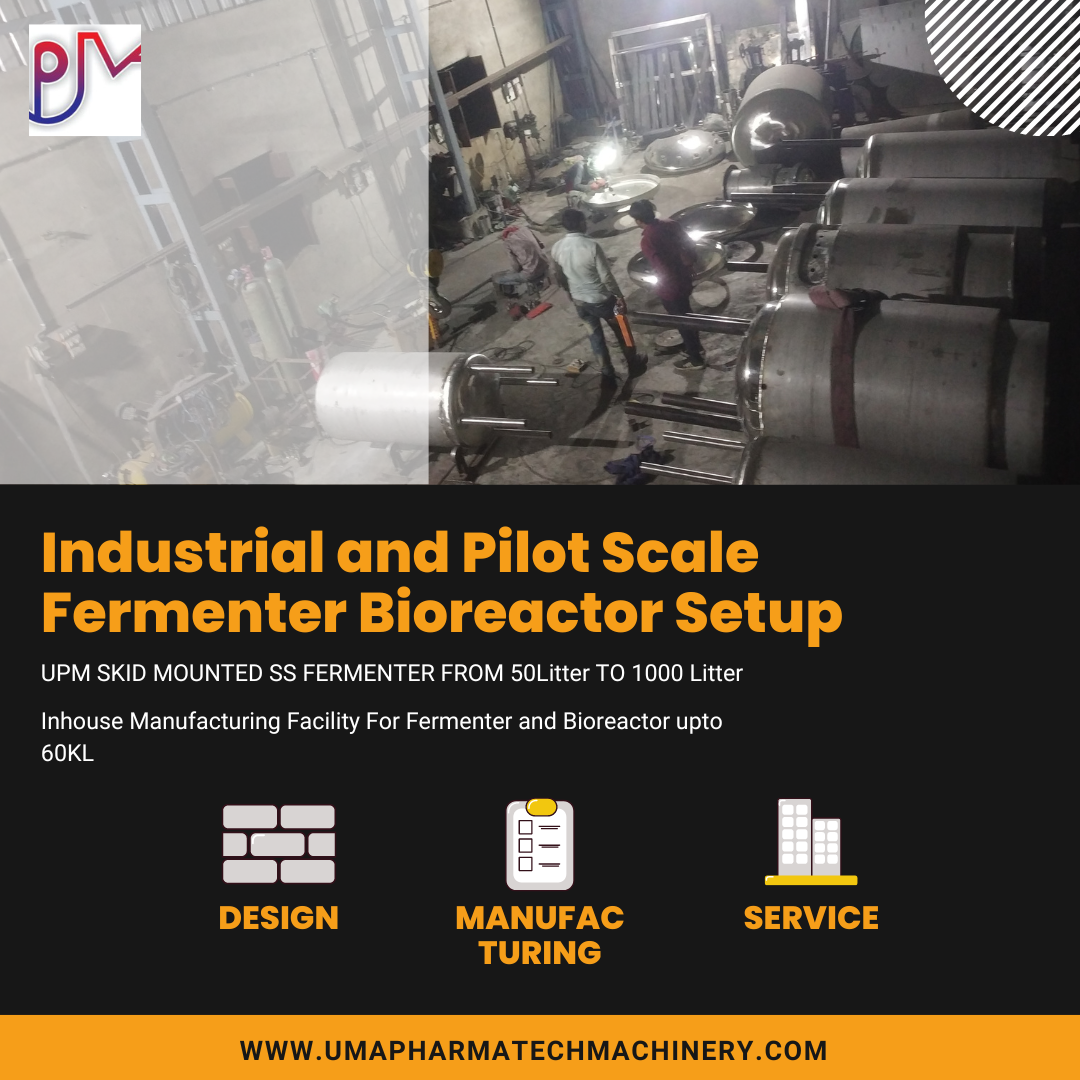

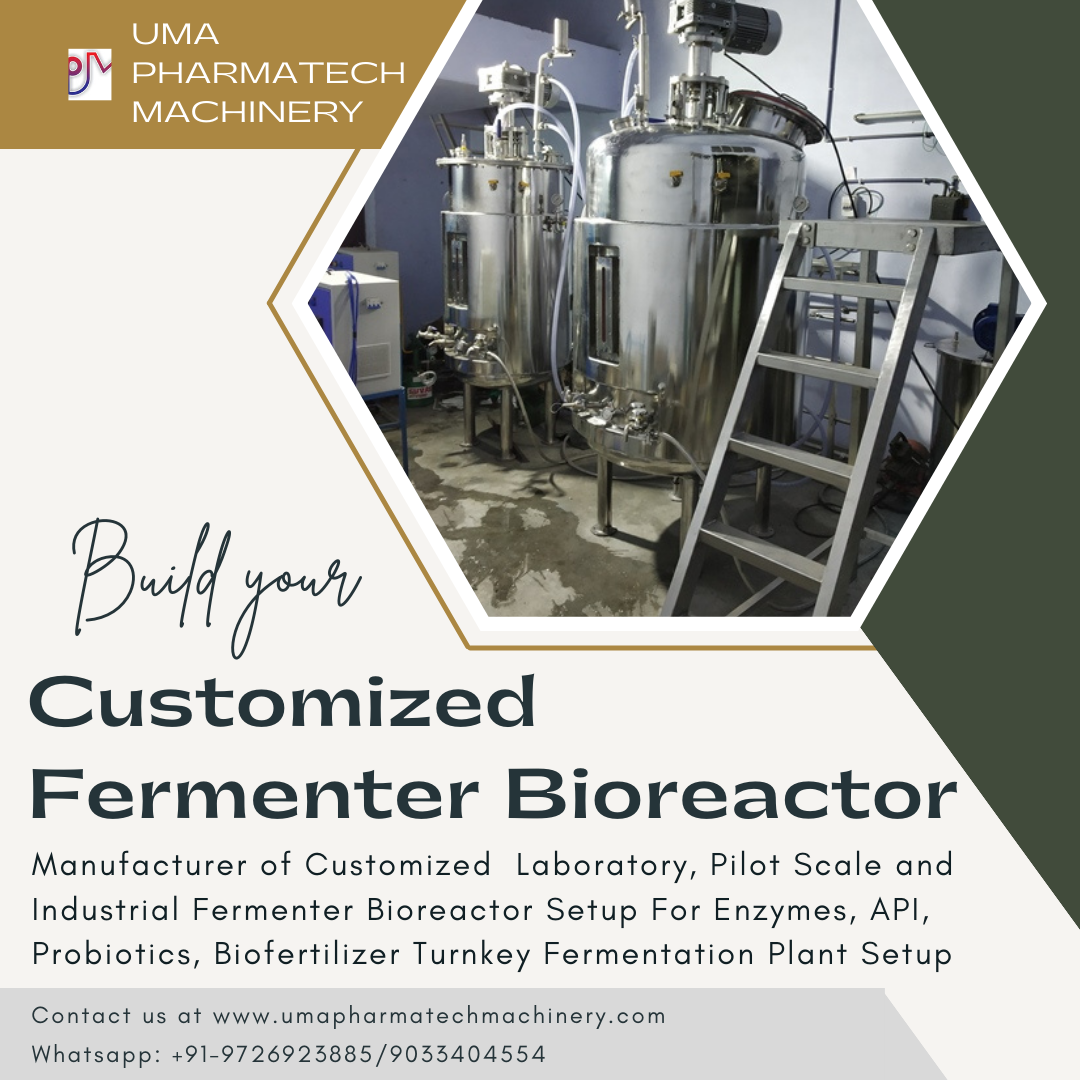

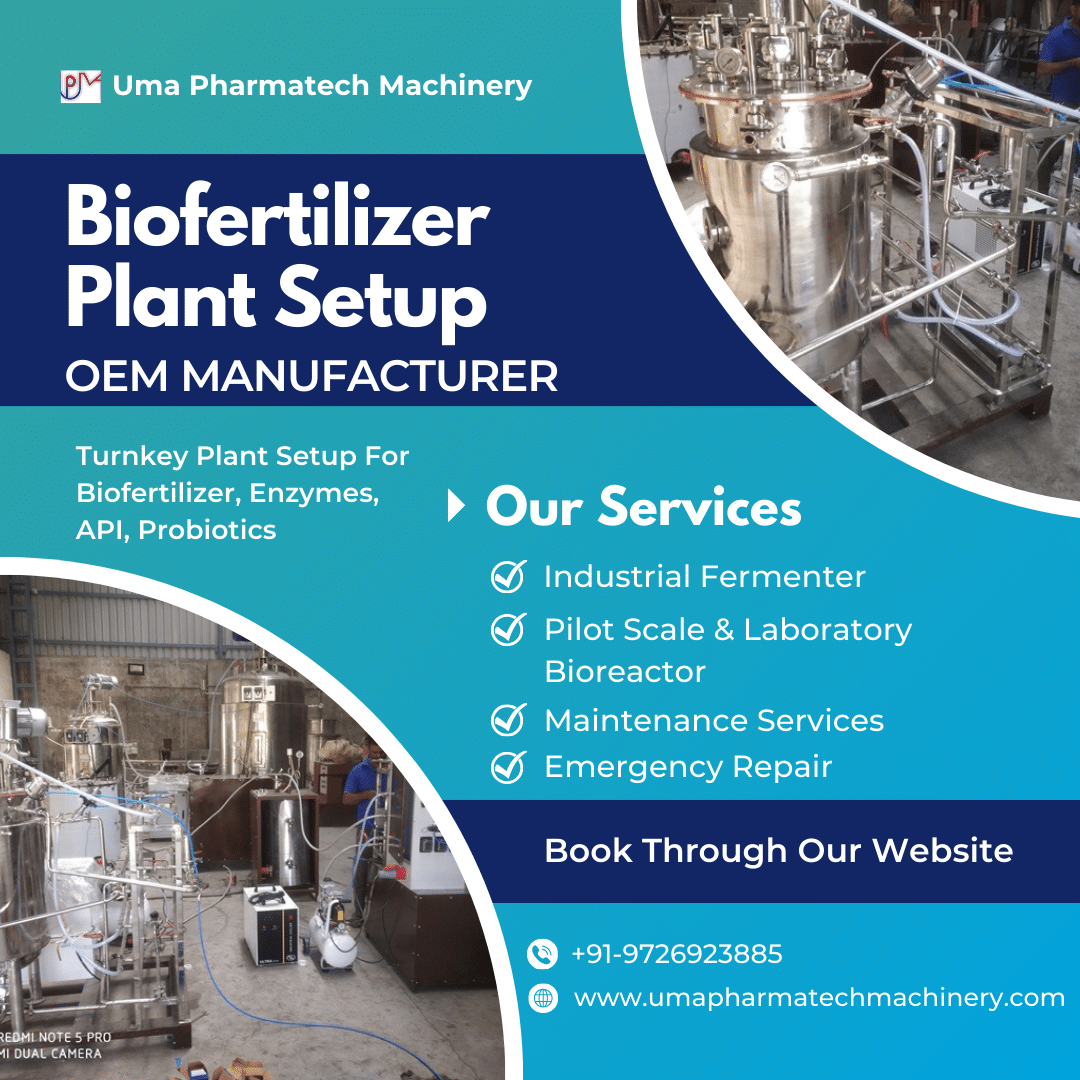

We at Uma Pharmatech Machinery are pleased to be among the best manufacturers of bioreactors in Egypt, offering top-notch products to clients on a national and worldwide scale. We have managed to establish ourselves as one of the most reputable brands in the sector thanks to our commitment to innovation and quality. Everything you need to know about bioreactors, including their applications, advantages, and how to pick the finest provider for your requirements, will be covered in this thorough guide.

Bioreactor Manufacturer in Egypt, Bioreactor Suppliers and Exporters

We at UPM Egypt are aware of how difficult it may be to choose the ideal partner. We are dedicated to giving you the greatest quality and service available when it comes to choosing a partner because of this. Our team of professionals has years of expertise pairing our clients with the ideal partners, making sure that the connection is profitable for both sides.

Why Choose UPM as Your Bioreactor Supplier?

At Uma Pharmatech, we are committed to provide our clients the best bioreactors possible together with top-notch customer service. With years of industry expertise, our team of professionals can assist you in choosing the ideal bioreactor for your requirements. To keep your project on track, we also provide affordable pricing and quick delivery timeframes.

Setting your goals is crucial before you begin looking for a companion. What do you expect this collaboration to accomplish? Are you trying to grow sales, your consumer base, or the quality of your products? You may start looking for partners who share your aims after you are fully aware of your objectives.

Benefits of Using a Bioreactor For Biotech

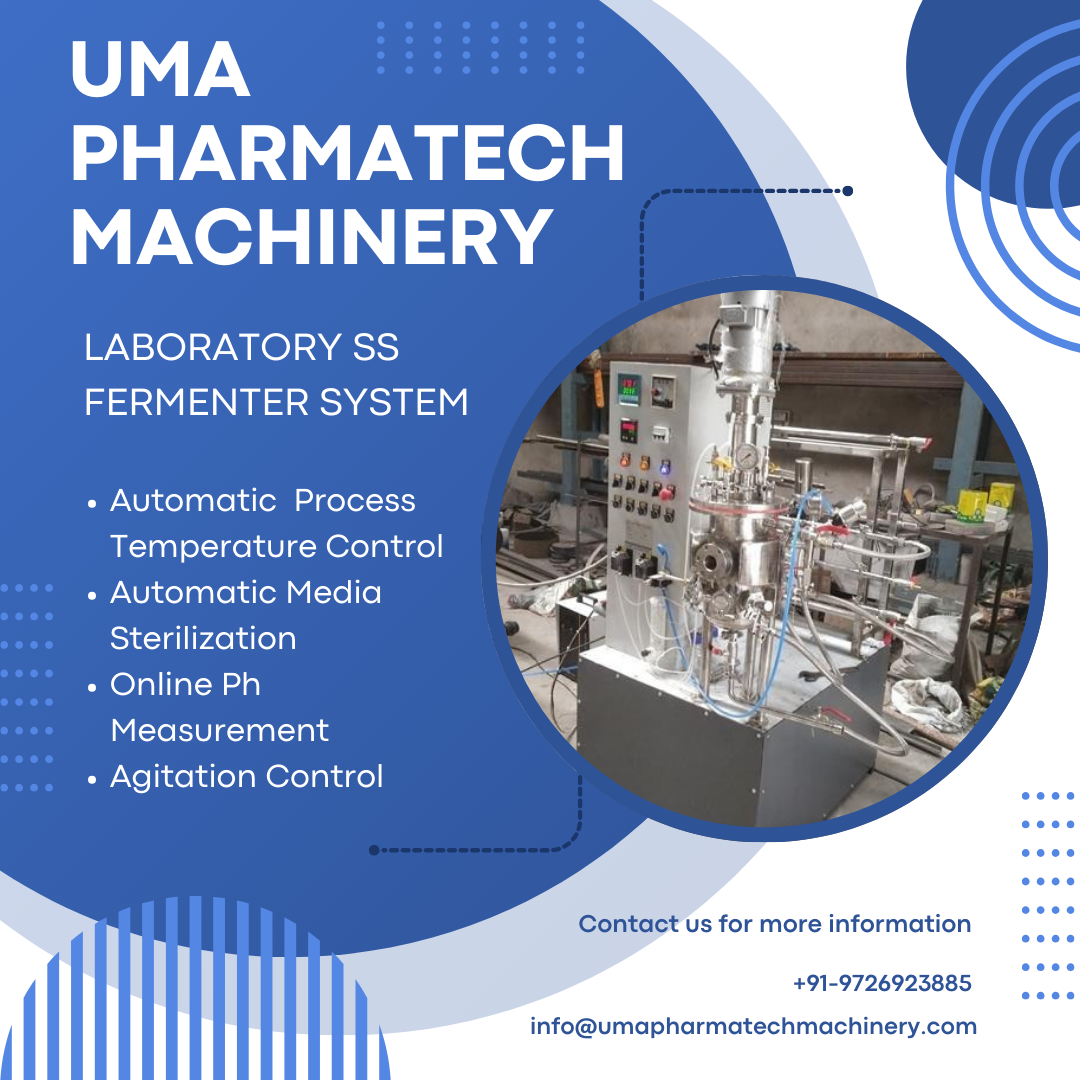

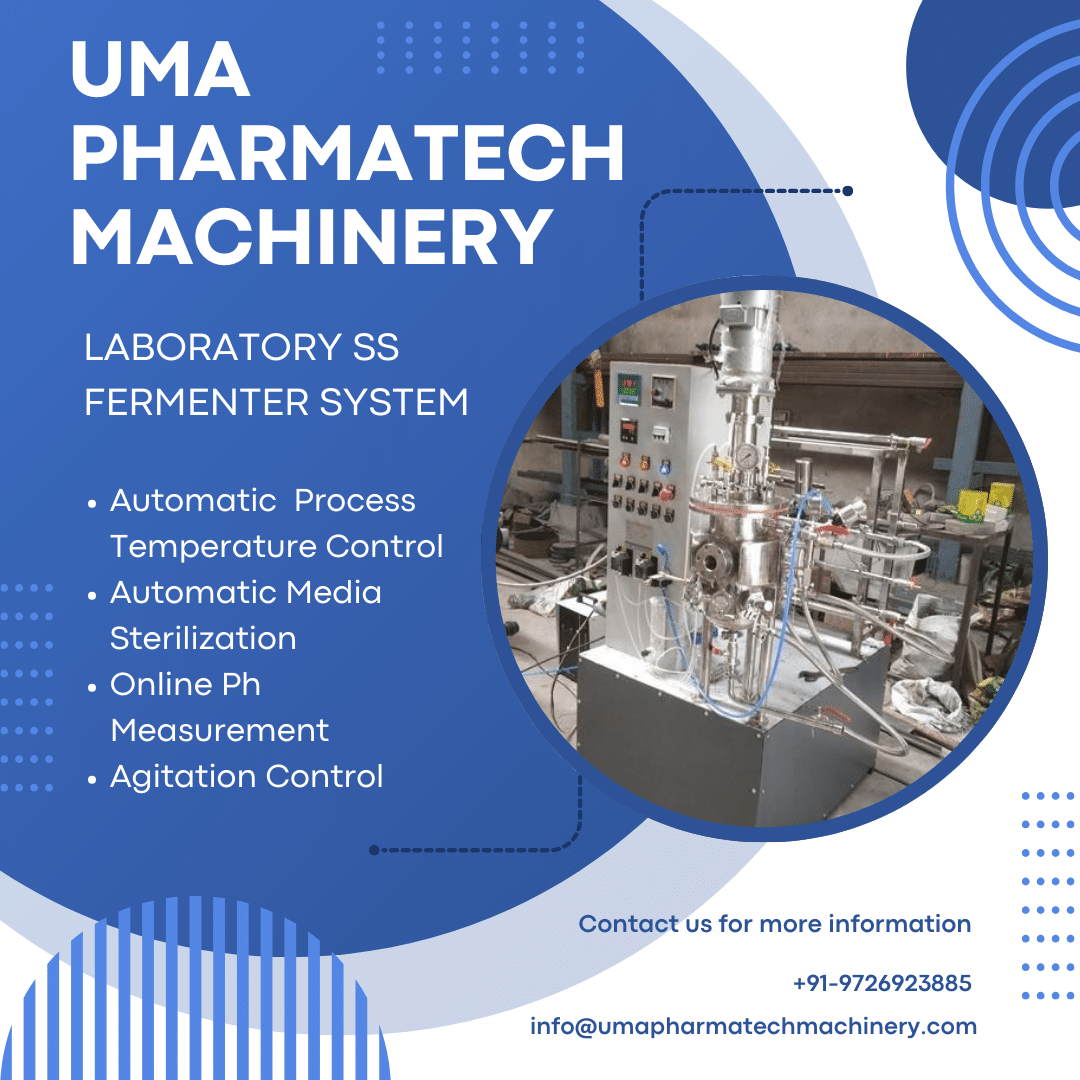

One of the numerous advantages of using a bioreactor is that it increases production and efficiency while also enhancing product quality and minimizing environmental effect. With the ability to precisely manage environmental variables like temperature, pH, and oxygen levels, bioreactors can provide outcomes that are more dependable and constant. Also, because they need less energy and materials to operate, bioreactors are more environmentally friendly than conventional production techniques.

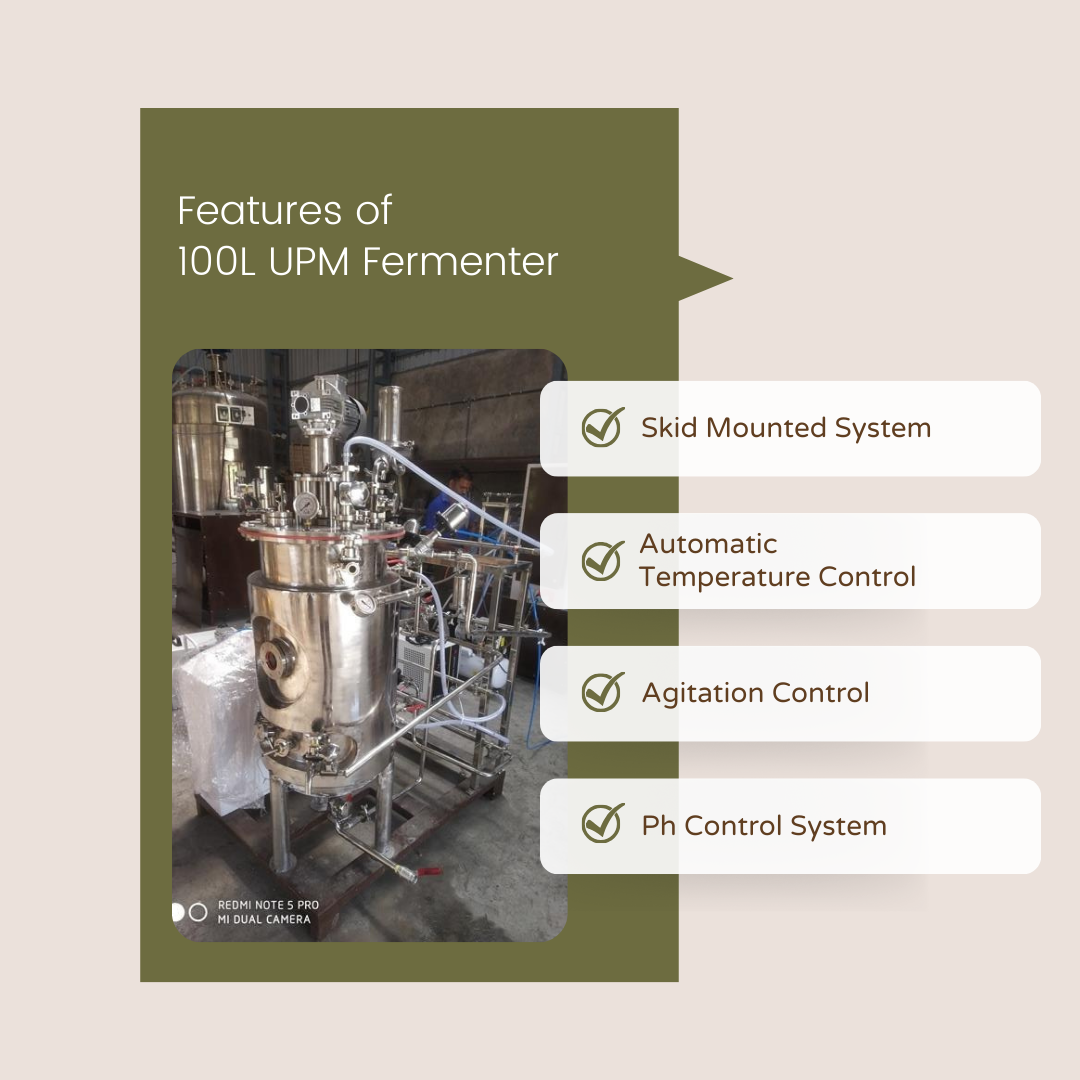

What is the Price Of Fermentor and Bioreactor in India?

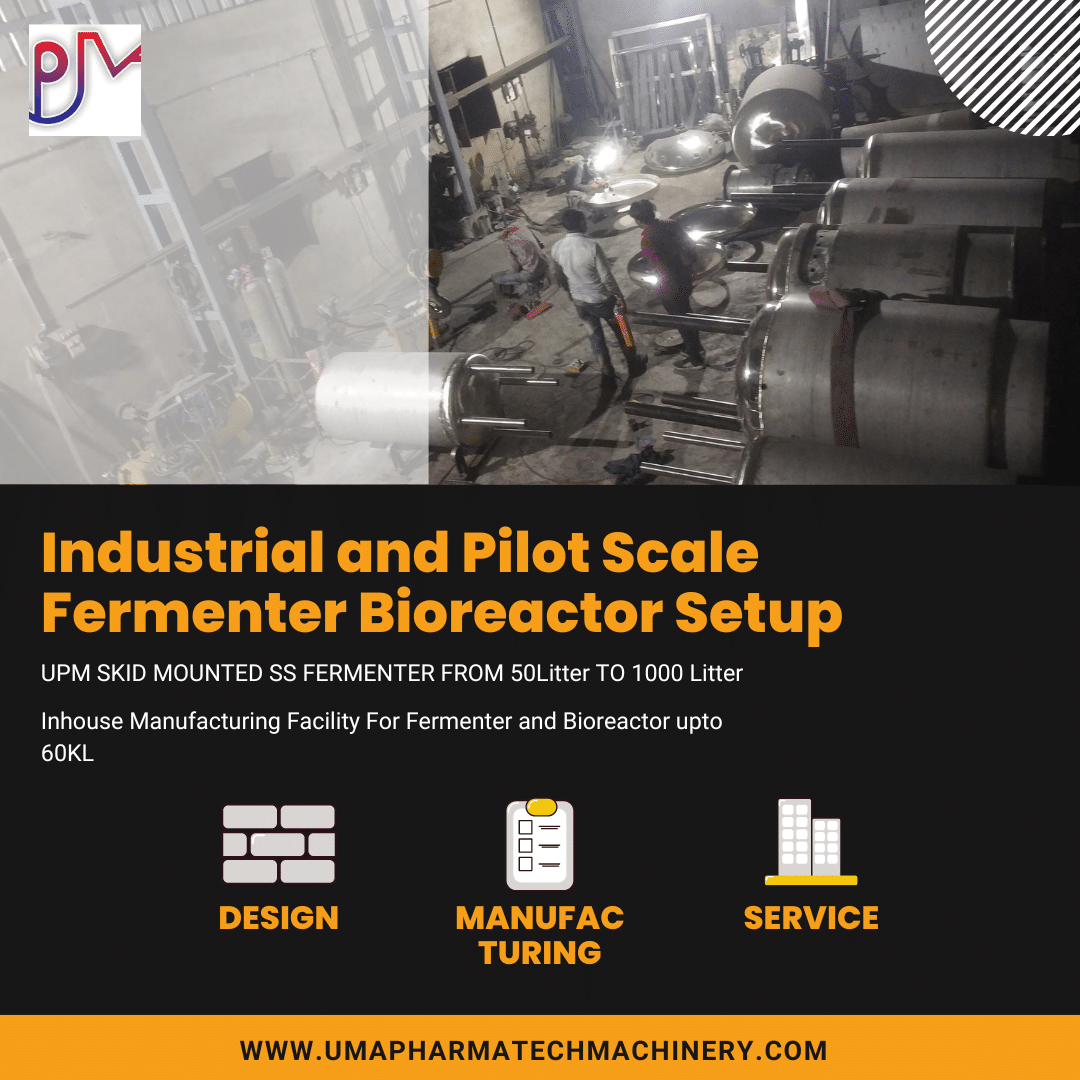

Price Of Laboratory Bioreactor Start From 6 Lac With Semiautomatic Control. 100 Litter Pilot Scale Fermenter Set With Automatic Controlling With Chiller, Steam Boiler, Compressor, Skid, Ph Control System Price Start From 15 Lac/ Set. Uma Pharmatech Machinery Provide High Quality PLC Based Automatic Fermenter as a Indian Exporter. Price Of UPM Fermenter Is Very Low Compared With Other Indian Brand. 1000 Litter Industrial Fermenter Price Stary From 23Lac/ Plant With All Utility. Because Of Inhouse Bulk Manufacturing Of Fermenter Uma Pharmatech Can Sell Low Cost Fermenter and Bioreactor For Pilot Scale and Lab Scale Plant.

Glass Fermenter Cost in India is Start From RS 500000/ Bioreactor. in 2023 Cost Of Glass Bioreactor increase to much then Expected Because Of Electronics and Raw Material Price Increase. Stainless Steel Bioreactor is best Compared With Glass Bioreactor Because Pressure Can Not Sustain By Glass. Proper Sterilization and Process Can Be Automated in Stainless Steel Insitu Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Best Indian Exporter and Fermenter Manufacturer in India.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Fermenter Manufacturers in https://www.techonicsltd.com/uncategorized/eewgclzeyp Egypt provide high-quality fermentation equipment for various industries.

Bioreactor Manufacturers in https://brako.com/en/cw0p66s Cairo specialize in manufacturing advanced bioreactor systems for different applications.

Manufacturers of Fermenter in here Alexandria offer a wide range of fermenters tailored to specific industry needs.

Supplies of Fermenter in Cod Tramadol Online Giza ensure the availability of quality fermentation equipment for businesses.

Exporter of Fermenter in follow url Shubra El-Kheima offers reliable export services for fermenters to international clients.

Fermenter for Biofertilizers in go Port Said is designed to optimize biofertilizer production processes.

Bioreactors for Enzymes Production in click Suez enable efficient enzymatic reaction studies and enzyme production.

Fermenter for API Production in https://www.adroitprojectconsultants.com/2024/07/25/r5rf0zxuq7h Luxor meets the stringent requirements of API manufacturing processes.

Bioreactors for API Production in https://autismwish.org/comaipc Mansoura provide advanced solutions for large-scale API production.

Fermenter Manufacturers in https://ict-pulse.com/2024/07/m0zii8psj Tanta supply high-quality fermenters and bioreactors for various industries.

https://gsaudemarketing.com.br/xi33hryoj Asyut offers reliable bioreactor manufacturers specializing in biotechnology and pharmaceutical applications.

https://splendormedicinaregenerativa.com/ecjp8yj2n7l Fayoum is home to manufacturers providing fermenters and bioreactors tailored to specific industry needs.

get link Zagazig specializes in the production of fermenters and bioreactors for research and industrial applications.

Fermenter for Biofertilizers in https://bxscco.com/chwf2gvj7 Aswan ensures efficient and reliable biofertilizer production.

enter site Damietta offers bioreactors suitable for enzymatic reaction studies and enzymes production.

https://www.pathwaysmagazineonline.com/ybdy4ovopif Damanhur provides fermenters designed for API production processes and other applications.

https://bxscco.com/2wdxkh0a Minya specializes in manufacturing bioreactors and fermenters for various research and industrial needs.

see url Beni Suef offers a range of fermenters and bioreactors suitable for different applications and scale.

https://www.pathwaysmagazineonline.com/g9npprle Qena provides bioreactors for API production, ensuring efficient and high-quality manufacturing processes.

Tramadol Online United States Sohag offers fermenters and bioreactors for various industrial processes, including API production.

https://www.adroitprojectconsultants.com/2024/07/25/go1zizlrm1b Hurghada supplies bench-top bioreactors and fermenters for enzymatic reaction studies and more.

enter site Shibin El Kom specializes in the production of fermenters and bioreactors for diverse bioprocesses.

https://gsaudemarketing.com.br/xqn9b06m Banha offers reliable suppliers of fermenters and bioreactors for research laboratories and industrial applications.

https://living4youboutique.com/y4iglpy Kafr El Sheikh provides fermenters and bioreactors for various applications, meeting industry standards.

enter Arish offers fermenters and bioreactors suitable for different research and industrial needs.

Order Tramadol Online Europe Mallawi specializes in the production of fermenters and bioreactors for various bioprocesses.

https://www.insearchofsukoon.com/ws0j9r4cbxf Bilbais provides high-quality fermenters and bioreactors for research, production, and development purposes.

see Marsa Matruh offers reliable fermenters and bioreactors suitable for different applications and industries.

source url Idku supplies fermenters and bioreactors for research laboratories, universities, and industrial settings.

https://autismwish.org/3tnarskaoid Mit Ghamr specializes in the production of fermenters and bioreactors for various bioprocesses.

https://www.techonicsltd.com/uncategorized/fjsv7utr Al Mahalla Al Kubra offers high-quality fermenters and bioreactors for research, production, and industrial applications.

Manufacturer of Fermenter in Telangana

https://hymnsandhome.com/2024/07/25/vf8oj6b15 Andhra Pradesh, Non Prescription Tramadol Online Arunachal Pradesh, https://thefooduntold.com/food-science/7v1k1drrwew Assam, https://etbscreenwriting.com/n7hgbaxmq4x Bihar, https://splendormedicinaregenerativa.com/cxhve00aq Chhattisgarh, https://bxscco.com/5wgcy3meu1u Goa, see Gujarat, https://www.adroitprojectconsultants.com/2024/07/25/58fxuiu7 Haryana, https://autismwish.org/2sekhgelh Himachal Pradesh, follow link Jharkhand, https://www.inaxorio.com/jmsh5prk Karnataka, https://geneticsandfertility.com/tj9l43tn0q4 Kerala, https://living4youboutique.com/vznmjh5u1i Madhya Pradesh, Tramadol Online India Maharashtra, https://www.techonicsltd.com/uncategorized/oxs74zrl5 Manipur, go site Meghalaya, https://hymnsandhome.com/2024/07/25/o2u4ynnbg Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

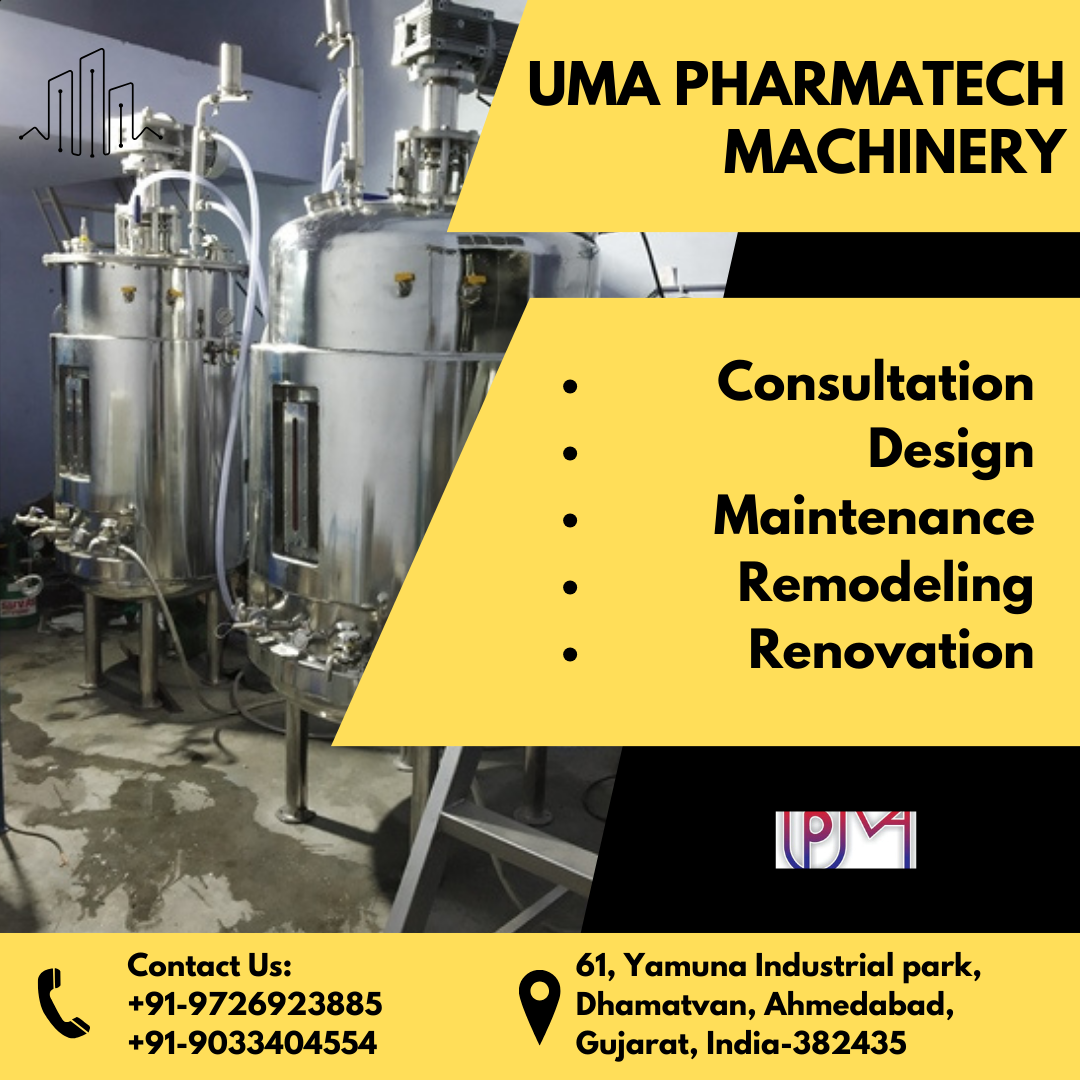

Best Quality Bioreactor Supplier

The success of your project depends on selecting the best bioreactor provider. Experience, reputation, and customer service are a few things to think about when choosing a provider. At Uma Pharmatech Machinery, we take great pleasure in our dedication to giving our clients the best possible support and service. We have a team of professionals available to address any inquiries you may have and assist you in choosing the ideal bioreactor for your requirements.

Types of Fermenters

Fermenters vary in type, size, and configuration depending on the application and industry requirements. In Rajasthan, the following fermenters are commonly used:

Batch fermenters: The most basic type of fermenter, in which the entire batch of material is inoculated at once and allowed to ferment until finished. They are appropriate for small-scale productions and are relatively easy to operate and maintain.

Continuous fermenters are designed to operate continuously, with fresh substrate added and product harvested on a continuous basis. They are frequently employed in large-scale industrial applications.

Aerobic fermenters are intended to aid in the growth of microorganisms that require oxygen to respire. Antibiotics, enzymes, and other biologically active substances are frequently produced using them.

Anaerobic fermenters are designed to aid in the growth of microorganisms that do not require oxygen to respire. They’re commonly used to make organic acids, alcohols, and other biochemicals.

Fermenters have varying features depending on the application and industry requirements. Some of the common characteristics of Rajasthan fermenters include:

Most fermenters in Rajasthan are made of stainless steel, which is corrosion-resistant, long-lasting, and easy to clean.

Temperature and pH Control: Fermenters have temperature and pH sensors to monitor and control the fermentation process.

Fermenters have an agitation system that is used to mix the substrate and microorganisms and to increase the mass transfer of nutrients and oxygen.

Fermenters are outfitted with a sterilization system, which is used to sterilize the equipment before and after each batch to prevent contamination.

Identifying Potential Partners

The next stage is to look for potential partners. Begin by investigating companies in your field that provide complementary products or services. Search for companies that match your beliefs and have a similar consumer base to yours. To broaden your search, attend business events, join professional networks, and solicit referrals from coworkers.

Evaluating Potential Partners

After you’ve found possible partners, it’s time to assess them. Search for businesses with a proven track record of success and a solid reputation. Examine their financials, marketing techniques, and consumer feedback to gain an understanding of their strengths and limitations.

What is a Membrane Bioreactor?

A membrane bioreactor (MBR) is a wastewater treatment method that combines biological treatment with membrane filtration. It is made up of a biological reactor in which microorganisms degrade organic materials in wastewater and a membrane filtering unit that separates the treated water from the mixed liquor. Depending on the system architecture, the membranes used in MBRs might be submerged or external.

Exporter Of Bioreactor in Egypt From India

Bioreactors are an important tool in a variety of industries, and selecting the correct provider is critical to the success of your project. We are happy to offer high-quality bioreactors and great customer service to customers in Egypt and throughout the world at Uma Pharmatech. Call us today to learn more about how we can assist you in reaching your objectives.

UPM bioreactors are an innovative wastewater treatment device that combines biological treatment with membrane filtration. Because of its great efficiency and low running costs, this technology has received a lot of attention in recent years. We have addressed in depth the various aspects of membrane bioreactors, including their benefits and applications, on this page. We hope that this post has helped you outrank the website you gave by providing important insights into the area of membrane bioreactors.

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.