Bioreactor Fermenter Manufacturer IN Punjab

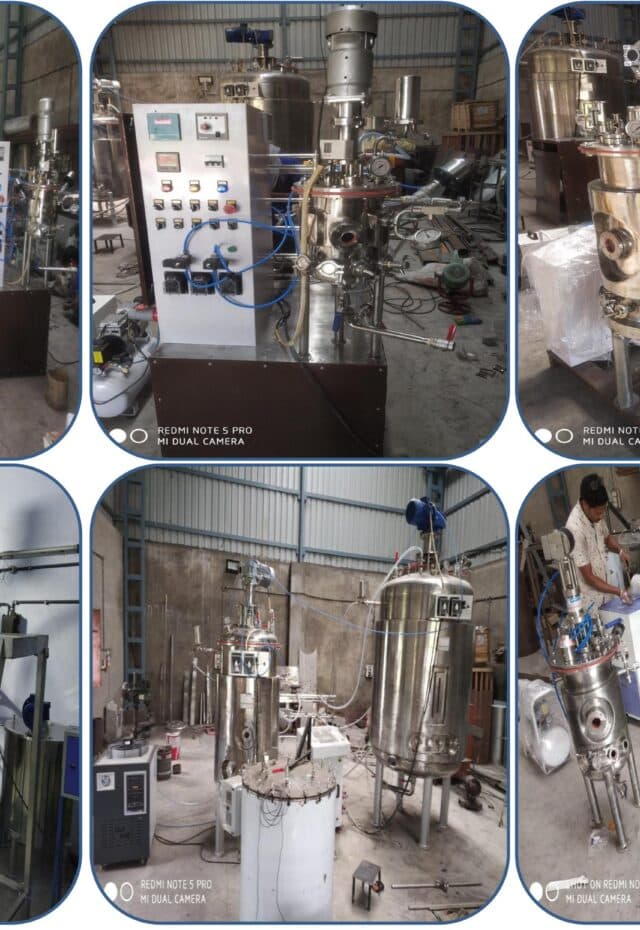

Bioreactor Manufacturer in Punjab: The demand for bioreactors in Punjab’s burgeoning biotechnology and pharmaceutical industries is met by dedicated manufacturers. Uma Pharmatech Machinery stands out as a leading bioreactor manufacturer in the region. They specialize in crafting state-of-the-art bioreactors that facilitate the growth of microorganisms essential for various industrial processes.

Uma Pharmatech Machinery is a Punjab-based company that excels in producing a diverse range of bioreactors, tailored to meet the specific requirements of different industries. Their commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation in the field. As Punjab continues to witness industrial growth, manufacturers like Uma Pharmatech Machinery play a crucial role in providing cutting-edge bioreactor solutions, thereby contributing significantly to the region’s industrial advancement.

In the Indian market, Uma Pharmatech Machinery is a top provider of solutions for fermentation and bioprocessing. They specialize in offering top-notch goods and services to a range of sectors, including the pharmaceutical, biotech, and food and beverage industries. Uma Pharmatech Machinery has established a reputable name in the market thanks to its cutting-edge manufacturing facilities, knowledgeable employees, and dedication to quality.

Manufacturer of Pilot Scale Fermenter In Punjab

We will provide you a thorough overview of bioreactor fermentors in this article. In the biotechnology sector, Pilot Scale bioreactor fermenters are crucial because they are used to produce and maintain cells or microorganisms for a variety of uses. We’ll give you a thorough rundown on Industrial bioreactor fermenters, their varieties, and their uses.

Manufacturer of Bioreactor in bioreactor

Fermenter Manufacturer in Punjab: Punjab’s industrial landscape thrives, and at the heart of its biotechnology and pharmaceutical sectors lies the critical role of Fermenter Manufacturers. Uma Pharmatech Machinery shines as a premier Fermenter Manufacturer in Punjab, specializing in crafting cutting-edge fermentation equipment.

Uma Pharmatech Machinery is a Punjab-based company known for its commitment to innovation and excellence in fermenter production. They offer a diverse range of fermenters, tailored to meet the unique needs of various industries. These fermenters are vital for the growth of microorganisms used in the production of pharmaceuticals, enzymes, and more.

As Punjab continues to make strides in industrial growth, manufacturers like Uma Pharmatech Machinery play a pivotal role in providing state-of-the-art fermenter solutions, contributing significantly to the region’s prominence in biotechnology and pharmaceutical sectors.

In conclusion, Uma Pharmatech Machinery, as a leading Fermenter Manufacturer in Punjab, is instrumental in supporting the region’s biotechnology and pharmaceutical industries by delivering top-quality fermenter solutions, promoting innovation and growth.

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Suppliers of Fermenter Bioreactor

Fermenter Suppliers in Punjab: In Punjab’s thriving industrial landscape, Fermenter Suppliers hold a vital position, catering to the diverse needs of the biotechnology and pharmaceutical sectors. Uma Pharmatech Machinery stands as a prominent Fermenter Supplier in Punjab, providing essential equipment for various industrial processes.

Uma Pharmatech Machinery is a reputable Punjab-based company renowned for its commitment to excellence in supplying fermenters. Their extensive range of fermenter solutions caters to the precise requirements of different industries, ensuring the growth of microorganisms essential for pharmaceuticals, biofuels, and more.

As Punjab continues its upward trajectory in industrial growth, suppliers like Uma Pharmatech Machinery play a crucial role in furnishing cutting-edge fermenter solutions, bolstering the region’s reputation in biotechnology and pharmaceutical sectors.

Fermenter Manufacturers in Punjab

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Fermenter Suppliers in Punjab

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Bioreactor Manufacturers in Punjab

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Fermenter Exporter From India

Australian producers specialize in cutting-edge monitoring and control systems that let farmers adjust the production of biofertilizer depending on current information. Due to the restricted amount of agricultural land in the nation, Korean manufacturers place a high priority on small, space-saving bioreactors. The manufacturers in Romania concentrate on finding economical methods to give a variety of farmers access to biofertilizers. Manufacturers in the Netherlands use their knowledge of precision agriculture and hydroponics to incorporate bioreactor technology into these systems. The producers in Oman focus on agriculture in the desert and create biofertilizers that improve soil fertility in dry regions. The process is made simpler by Filipino manufacturers that place a high priority on user-friendly bioreactors.

Fermenter manufacturers in Lahore: Suppliers of fermenters in the Lahore area.

Bioreactor manufacturers in Rawalpindi: Companies producing bioreactors in Rawalpindi.

Manufacturers of fermenter in Faisalabad: Suppliers of fermenters in Faisalabad.

Supplies of fermenter in Gujranwala: Providers of fermenters in Gujranwala.

Exporter of fermenter in Multan: Manufacturer exporting fermenters in Multan.

Fermenter for biofertilizers in Sargodha: Bioreactor used for biofertilizer production in Sargodha.

Bioreactors for enzyme production in Sheikhupura: Manufacturers of bioreactors for enzyme production in Sheikhupura.

Fermenter for API production in Gujrat: Bioreactor used for API (Active Pharmaceutical Ingredient) production in Gujrat.

Bioreactors for API production in Bahawalpur: Manufacturers of bioreactors for API production in Bahawalpur.

Low Cost Fermenter For Biofertilizer in Punjab

An instrument used to assist the growth of cells or microorganisms in a regulated environment is a Lab Scale bioreactor fermentor. These tools offer the ideal conditions for growing cells or microorganisms, including the right temperature, pH, oxygen level, and availability of nutrients. Pharmaceutical, biofuel, and industrial enzyme manufacturing are just a few of the uses for bioreactor fermenters.

Suppliers of Fermenter Bioreactor In Punjab

We recognise the value of producing information that is both educational and interesting for our readers as experts in the field of fermentation and bioprocessing solutions. In addition to highlighting their key differentiators, our article will provide comprehensive information on the goods and services provided by Uma Pharmatech.

Superior Products

Bioreactors, fermenters, and sterilizers are just a few of the fermentation and bioprocessing solutions Uma Pharma provides. All of their products are made using premium components and put through stringent testing to ensure they adhere to global standards. Also, because of their flexibility, customers can have their products customized to match their unique needs.

Experienced Professionals

The team of experts at Uma Pharmatech Machinery has a wealth of knowledge in fermentation and bioprocessing. They have worked on countless projects for various industries, and their knowledge is shown in the quality of their products and services.

Dedicated to Quality

Quality is of the utmost importance to UPM. To make sure that their services and goods meet the highest standards, they have rigorous quality control procedures in place. Additionally, they have a committed group of experts who are in charge of ensuring quality all the way through the manufacturing process.

Affordable Prices

UPM has affordable prices yet offering top-notch goods and services. They provide cost-effective solutions without sacrificing quality, which makes them a well-liked option among clients.

What is the maximum capacity of a bioreactor?

Lab Model Bioreactor Maximum Capacity- Up to 20 Litter

For Pilot Scale Bioreactors-Maximum Capacity- From 100 Litter To 2kl

For Industrial Scale Fermenter Bioreactors Capacity- From 2 kl To 60 kl

Uma Pharmatech Machinery Is One Of The Best and Turnkey Plant Manufacturer and Indian Exporter.

Bioreactors Having Made Of Glass is Very Cheap then Stainless Steel Bioreactors. Manual Operated Bioreactor Start From 5lac/ Fermenter. Where as Pilot Scale Fermenter Made Of Uma Pharmatech Brand Stary From 15Lac With All Utility in India. UPM Fermenter Plant Comes With Automatic Sterilization, Automatic Ph Controlling, Automatic Dissolve Oxygen Control, Automatic Process Pressure and Temperature Control.

Top Manufacturers of Bioreactor Fermenters

There are different kinds of Laboratory bioreactor fermenters, and each has particular benefits and drawbacks. The following are a few of the popular kinds of bioreactor fermenters:

Stirred Tank Bioreactors is The most popular type of Pilot Scale bioreactor fermenter is the stirred tank bioreactor. They are cylindrical in shape and have an impeller that stirs the reactor’s contents. This particular style of Glass bioreactor fermentor is perfect for both aerobic and anaerobic cultures and is appropriate for large-scale manufacturing.

Photo-Bioreactors are Cells or microorganisms are grown in photo-bioreactors, which are Table Top bioreactor fermentors that use light as their main energy source. They are perfect for growing photosynthetic bacteria and are frequently employed in the manufacture of biofuels.

Membrane Bench Top bioreactors use a membrane to separate the cells or microorganisms from the growth medium in a bioreactor fermenter. High-value items like medications can be produced with this kind of bioreactor fermenter.

In the biotechnology sector, bioreactor fermentors are crucial because they offer a regulated environment for the development of cells or microorganisms. There are many different kinds of bioreactor fermenters, each with specific benefits and drawbacks, and they have a wide range of uses, including the generation of pharmaceuticals, biofuels, and industrial enzymes.

In summary, Fermex India is a trustworthy and reputable provider of fermentation and bioprocessing solutions in the Indian market. They have won the favour of clients with their high-quality goods, knowledgeable staff, dedication to quality, and affordable prices. In-depth information about Fermex India and its main differentiators is provided in our article.

- Fermenter Manufacturers in Andhra Pradesh: Discover reliable fermenter manufacturers in Andhra Pradesh offering top-notch biotech equipment.

- Bioreactor Manufacturers in Arunachal Pradesh: Explore Arunachal Pradesh’s leading bioreactor manufacturers, providing cutting-edge solutions for diverse industries.

- Fermenter Manufacturers in Assam: Assam boasts reputable fermenter manufacturers, delivering high-quality equipment to cater to the biotech sector’s needs.

- Fermenter Supplies in Bihar: Bihar offers a wide range of fermenter supplies, ensuring a seamless supply chain for the biotech industry.

- Fermenter Exporter in Chhattisgarh: Chhattisgarh is home to renowned fermenter exporters, facilitating the global distribution of advanced biotech equipment.

- Fermenter For Biofertilizers in Goa: Goa presents advanced fermenters tailored for biofertilizer production, supporting sustainable agricultural practices.

- Bioreactors For Enzymes Production in Gujarat: Gujarat houses state-of-the-art bioreactors specifically designed for efficient enzymes production.

- Fermenter For API Production in Haryana: Haryana offers high-performance fermenters optimized for API (Active Pharmaceutical Ingredient) production.

- Bioreactors For API Production in Himachal Pradesh: Himachal Pradesh features cutting-edge bioreactors, empowering API manufacturers with superior production capabilities.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.

Manufacture of Fermenter For Industrial Enzymes

Proteases and amylases are two examples of industrial enzymes that are produced in bioreactor fermentors.

Uses for Bioreactor Fermentors

There are several uses for bioreactor fermentors, including:

Pharmaceutical Production: The fermentation process in bioreactors is used to create a variety of drugs, including insulin, vaccines, and antibiotics.

Biofuel Production:

The fermentation process in bioreactors is used to make biofuels like biodiesel and bioethanol.