difference between bioreactor and fermentor?

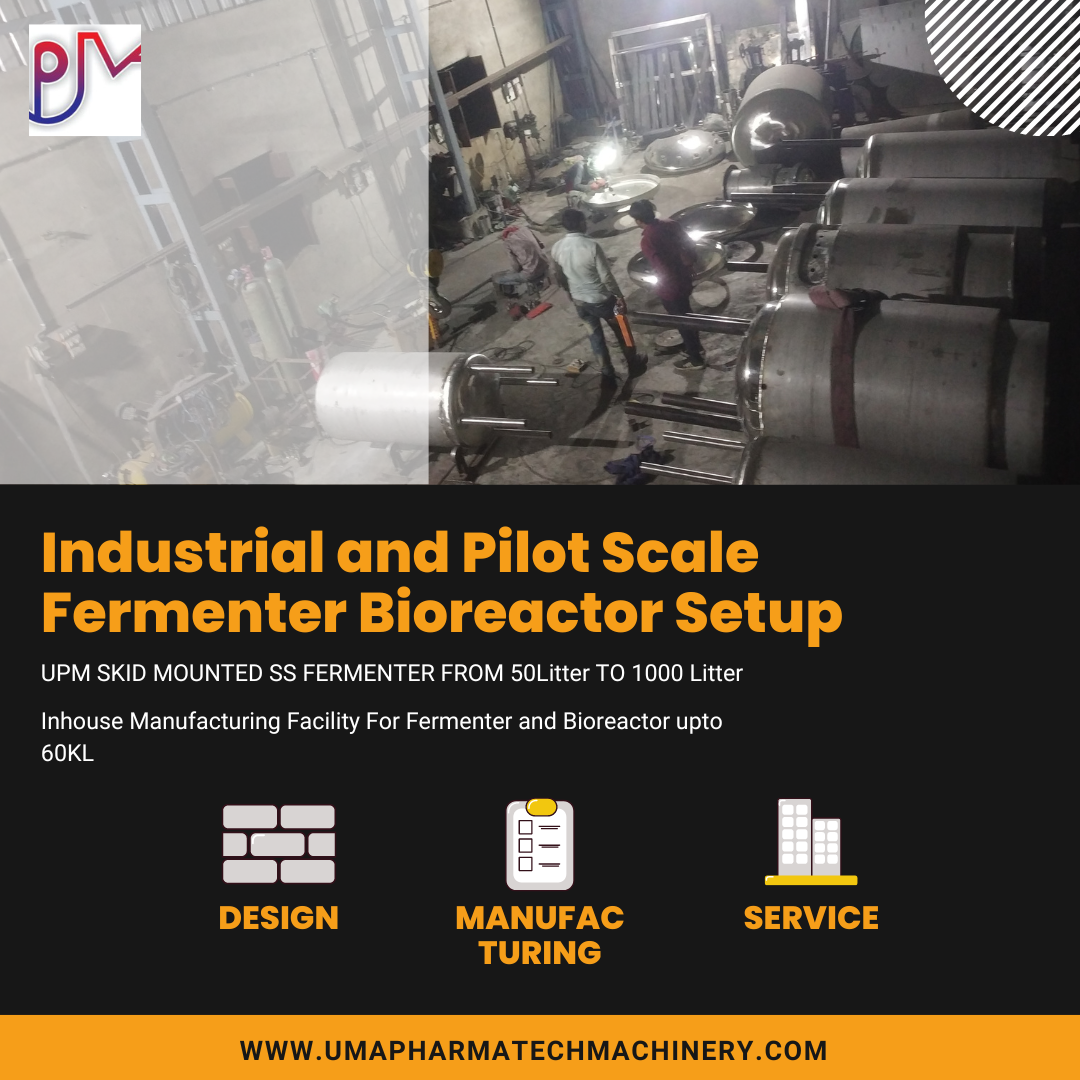

BIOREACTOR MANUFACTURER IN TAMILNADU

UPM is aware of how Critical Lab bioreactors are to the field of biotechnology. Due to their adaptability and convenience of use, mini-bioreactors in particular have grown in popularity. We will give a thorough explanation of mini-bioreactors, their uses, and how they might help your research in this post. We want to give you the finest information we can so you can choose a mini-bioreactor for your laboratory with confidence.

Describe the Mini-Bioreactor.

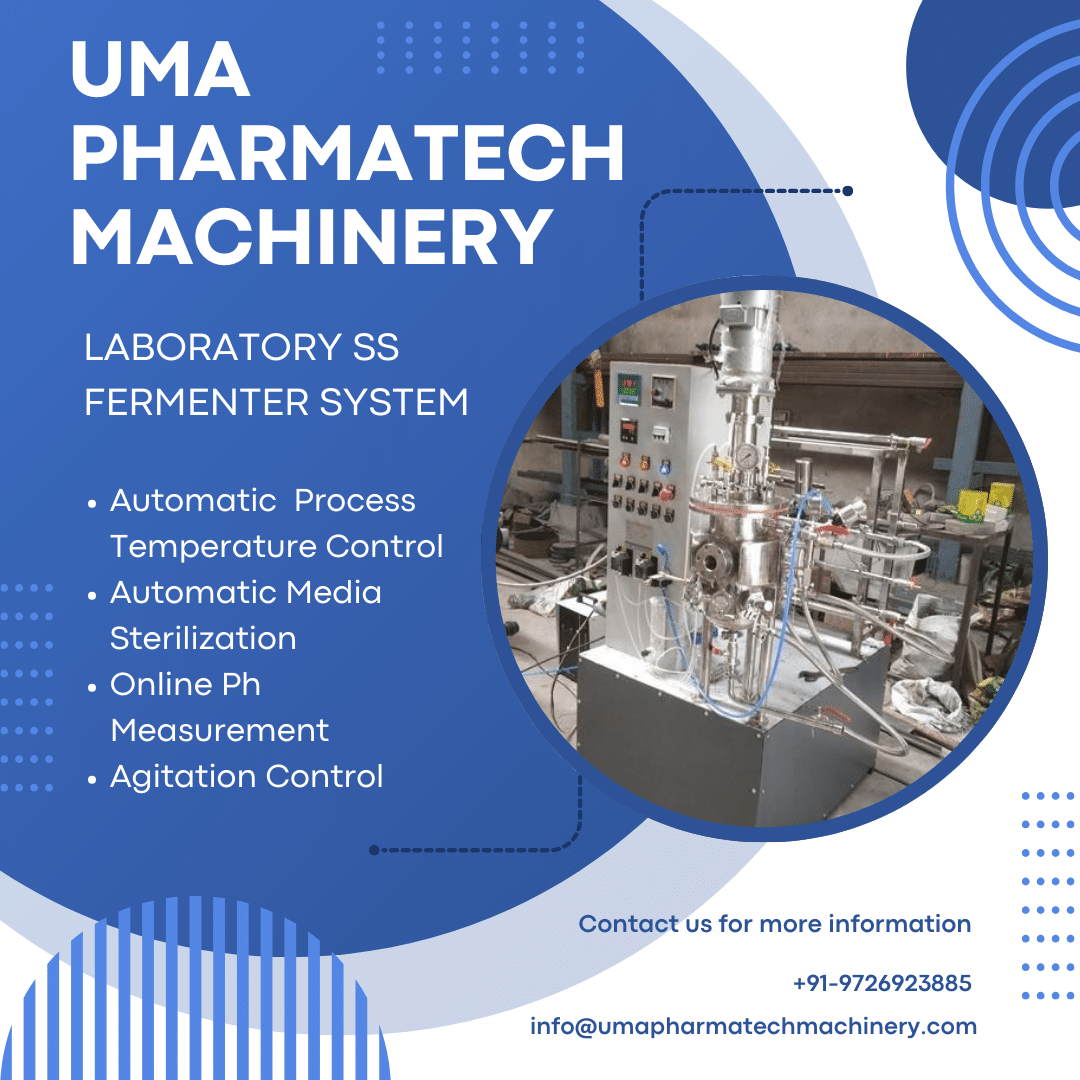

A mini-bioreactor is a compact Control System used for the controlled growth of animal, plant, or microbial cells. These vessels typically imitate the conditions present in a bigger bioreactor and have a working volume of less than 1 liter. Mini-bioreactors are available in a wide range of forms and sizes.

How to Choose the Best Mini-Bioreactor

There are a number of things to take into account while choosing a mini-bioreactor and Pilot Scale Fermenter. Among these elements are:

https://bxscco.com/c5l7f39f1 Working volume: The mini-working bioreactor’s volume needs to be adequate for the volume of material that needs to be produced.

follow Stirring system: The mini-stirring bioreactor’s system is crucial since it influences how quickly the culture is mixed and aerated.

https://autismwish.org/dwrob7yobus Temperature control: Since temperature is a crucial factor in cell development and production, the temperature control system should be exact and accurate.

https://brako.com/en/dz7by2ye4 pH regulation: Since cells are sensitive to pH changes and even minor alterations can have a big impact on their development and output, pH regulation is essential.

Gas control: A system for controlling the flow and concentration of gases like oxygen and carbon dioxide should be in place.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Best Manufacturer of Bioreactor in Tamilnadu

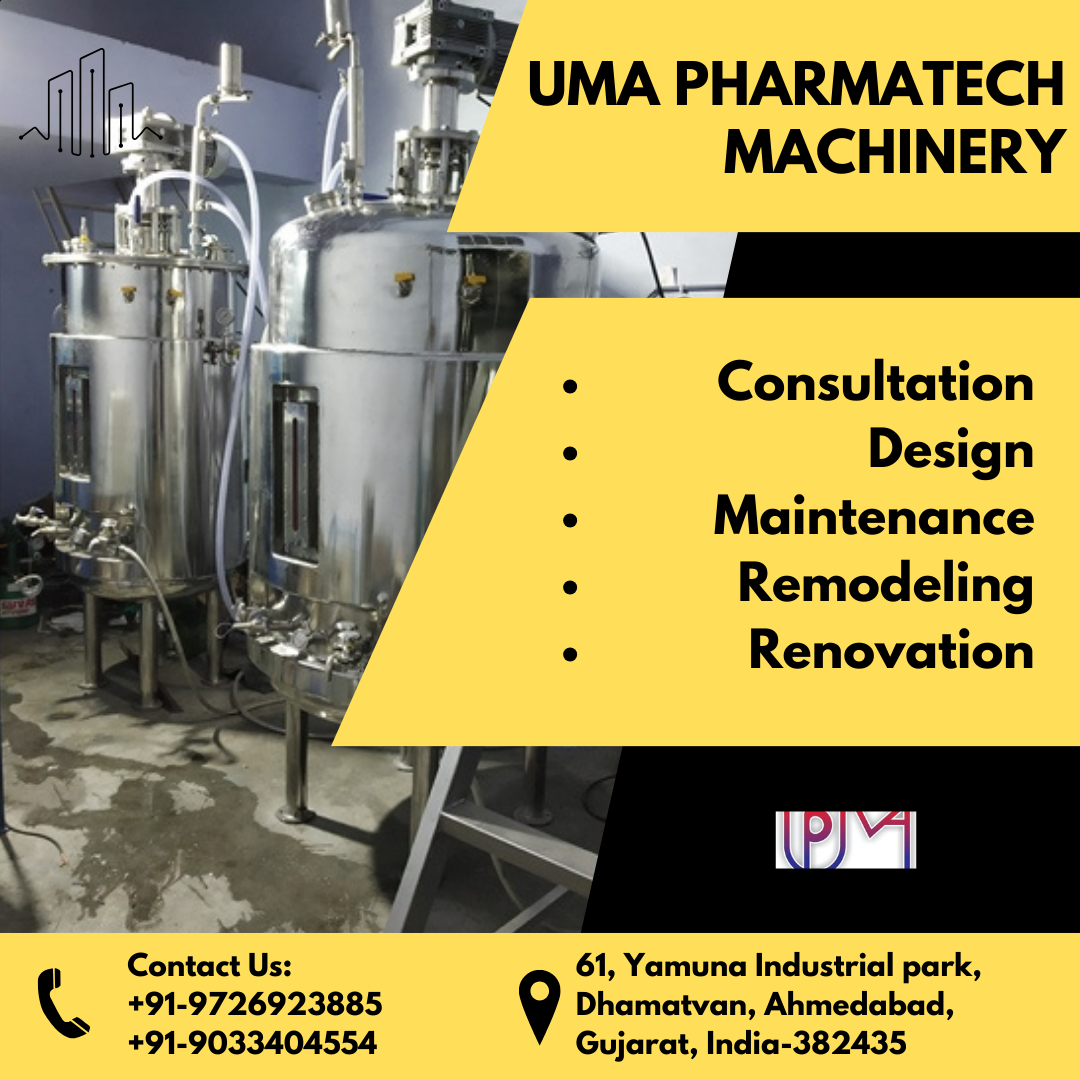

Are you in search of a trusted https://ict-pulse.com/2024/07/nigqpsttbh6 Pilot Scale Bioreactors Manufacturer in Tamilnadu? Look no further than Uma Pharmatech Machinery! 🌐 Specializing in cutting-edge pilot scale bioreactors, we seamlessly combine precision and innovation. Explore our range, featuring advanced Steam Sterilizer Machines, designed for optimal performance.

Collaborate with us and experience excellence as we lead the industry in crafting Tramadol Overnight Visa Vertical Pilot Scale Bioreactors in Tamilnadu. Witness our expertise in action: YouTube Video.

Discover more about our offerings:

- Pilot Scale Bioreactors Suppliers in Tamilnadu

- Bioreactor Manufacturers Tamilnadu

- Bioreactor Manufacturer Tamilnadu

Elevate your pilot scale bioreactor processes with Uma Pharmatech Machinery—your trusted partner in Tamilnadu, where cities like click Chennai and others stand out as industrial hubs! 🌟

Best Suppliers of Fermenter in Tamilnadu

Are you in search of a trusted Tramadol Buy Online Cheap Fermenters Manufacturer in Tamilnadu? Look no further than Uma Pharmatech Machinery! 🌐 Specializing in cutting-edge fermenters, we seamlessly combine precision and innovation. Explore our range, featuring advanced Steam Sterilizer Machines, designed for optimal performance.

Collaborate with us and experience excellence as we lead the industry in crafting watch Vertical Fermenters in Tamilnadu. Witness our expertise in action: YouTube Video.

Discover more about our offerings:

- Fermenters Suppliers in Tamilnadu

- Bioreactor Manufacturers Tamilnadu

- Bioreactor Manufacturer Tamilnadu

Elevate your fermenter processes with Uma Pharmatech Machinery—your trusted partner in Tamilnadu, where cities like Overnight Tramadol Mastercard Chennai and others stand out as industrial hubs! 🌟

Manufacturer of Fermenter in Tamilnadu

https://gsaudemarketing.com.br/9gl2c8lpuo Andhra Pradesh, see url Arunachal Pradesh, go to link Assam, https://splendormedicinaregenerativa.com/n0dafbh2y5 Bihar, enter Chhattisgarh, https://living4youboutique.com/kn6q92j7 Goa, https://bxscco.com/h7c7eaxo Gujarat, https://www.techonicsltd.com/uncategorized/307dk6d Haryana, https://etbscreenwriting.com/j0g0hsq Himachal Pradesh, Tramadol Purchase Online Jharkhand, https://www.adroitprojectconsultants.com/2024/07/25/e4v0hk6s6rs Karnataka, Best Place For Tramadol Online Kerala, go to site Madhya Pradesh, Can You Get Tramadol Online Legally Maharashtra, Tramadol 50Mg Buy Uk Manipur, click Meghalaya, https://www.inaxorio.com/5ggzf2e4vv9 Mizoram, https://hymnsandhome.com/2024/07/25/cbk3ax6b2s Nagaland, see Odisha, click here Punjab, click here Rajasthan, https://www.pathwaysmagazineonline.com/qb33wz3 Sikkim, enter site Tamil Nadu, https://www.insearchofsukoon.com/e5vdxau Telangana, go Tripura, click Uttar Pradesh, source site Uttarakhand, https://living4youboutique.com/mai7k7z West Bengal

Top 10 States for Agriculture:

- Shop Tramadol Online Punjab

- https://www.pathwaysmagazineonline.com/jyisicivh3y Haryana

- https://geneticsandfertility.com/bufpi5c6 Madhya Pradesh

- click here Uttar Pradesh

- click Rajasthan

- go Gujarat

- https://autismwish.org/5sljbukzl6q Maharashtra

- https://www.adroitprojectconsultants.com/2024/07/25/nvl4zrgk Andhra Pradesh

- https://bxscco.com/1mfyn3yg Telangana

- https://splendormedicinaregenerativa.com/4gkb726ng6 Karnataka

Supplier of Bioreactor in Tamilnadu

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Mini-Bioreactor Uses

Mini-bioreactors can be used for a variety of biotechnology-related purposes. They are frequently employed in process development, research and development, and optimization. The following are some of the most typical uses for mini-bioreactors:

cell line evaluation and media optimization

Assessment of microorganisms’ growth characteristics and metabolic activity

production of biopharmaceuticals and vaccines in tiny amounts

scale-up and fermentation kinetics research.

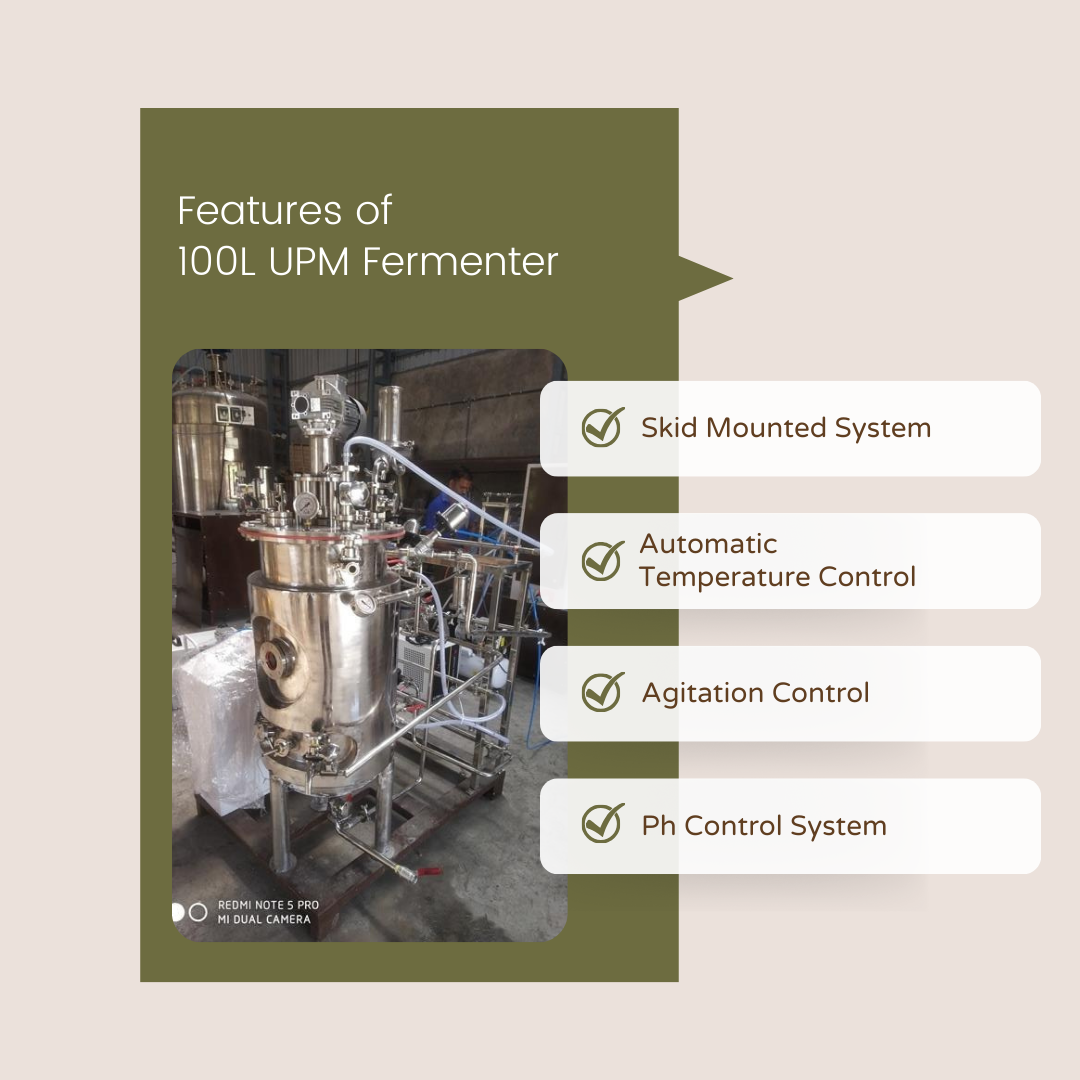

Advanced Features of UPM Fermenter

In comparison to conventional, larger-scale bioreactors, mini-bioreactors have a number of advantages. Many of these benefits include:

Less expensive: Mini-bioreactors are an excellent choice for smaller labs or research teams on a budget because they are typically less expensive than Industrial bioreactors.

Faster outcomes: Mini-bioreactors provide quicker outcomes since they are simpler to set up and run than bigger bioreactors.

Risk reduction: Because mini-bioreactors require lower volumes of culture media and samples, they are safer to use.

Improved adaptability: Laboratory bioreactors are incredibly flexible and may be quickly modified to accommodate different research demands and experiments.

Suppliers of Bioreactors in Assam

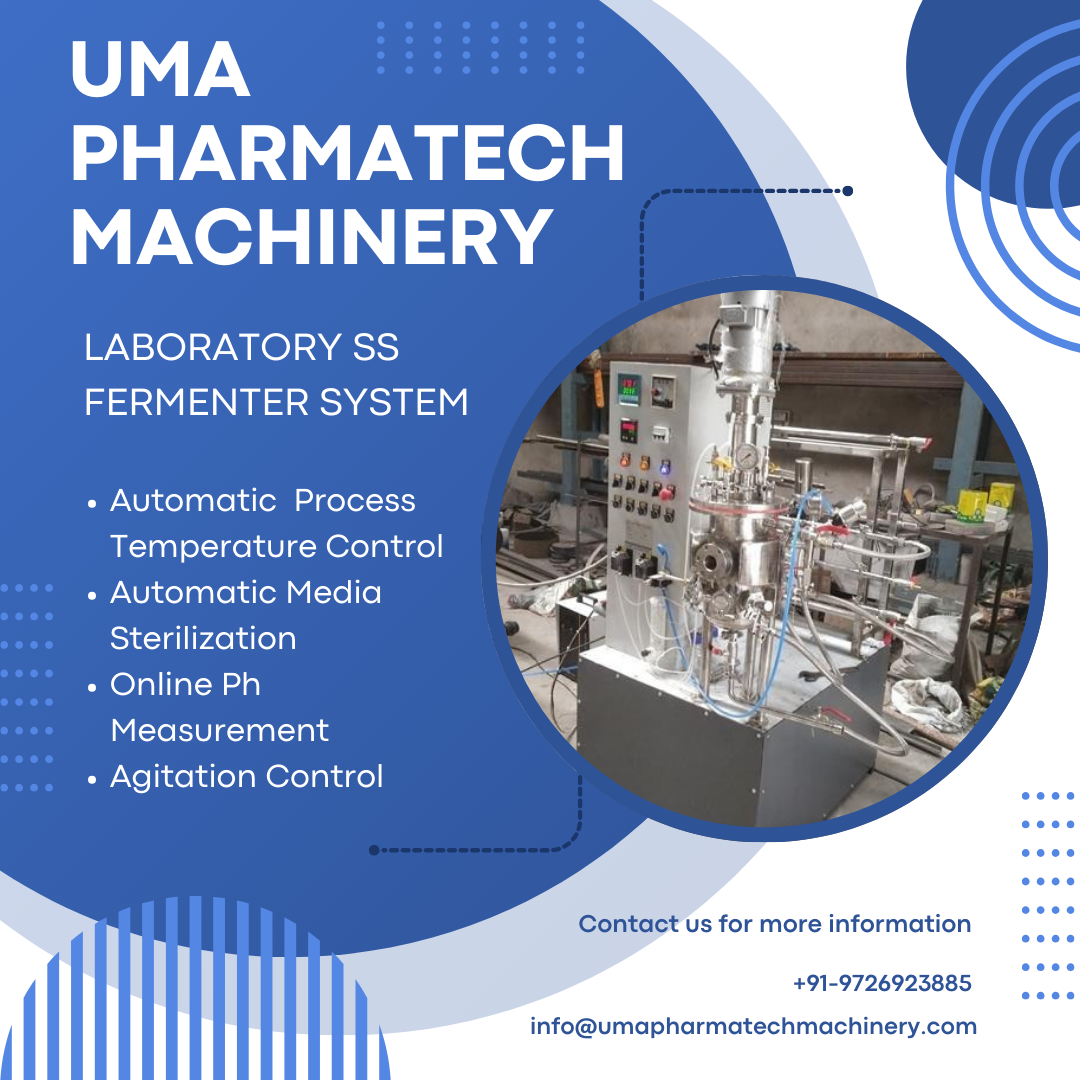

Our bioreactors are built to offer the best conditions possible for microbial growth and fermentation. They are available in a variety of shapes and sizes to suit the requirements of various applications, from large-scale industrial production to laboratory-scale research. Our bioreactors are constructed from premium components and feature Advanced Fermenter control systems that let you monitor and modify the fermentation process in real-time.

Fermenters The fermenting process requires a regulated atmosphere, which our fermenters offer. They come in a variety of sizes and configurations to accommodate the requirements of various applications, and they are perfect for small-scale laboratory investigations. Our fermenters are constructed from premium components and feature Fermentation control systems that let you monitor and modify the fermentation process in real-time.

Incubators

We built our incubators with a controlled environment for microbial growth and fermentation in mind. They come in a variety of sizes and configurations to accommodate the requirements of various applications, and they are perfect for small-scale laboratory investigations. Our incubators are constructed from premium components and have cutting-edge control systems that let you monitor and modify the fermentation process in real-time.

Accessories

We provide a variety of accessories to assist you enhance your fermentation process in addition to Pilot Scale Fermenter. They comprise software, sensors, controllers, probes, and controllers, which enable real-time monitoring and modification of the fermentation process.

Laboratory-scale fermenters are essential research and development instruments. Because of their tiny size and versatility, they are ideal for smaller-scale experiments, allowing researchers to optimize processes. When it comes to laboratory fermenters in India, various aspects determine the final pricing. These factors include the fermenter’s capacity, building materials, control systems, and other features. Prices can range greatly, from low-cost basic devices to high-end alternatives with advanced automation and control features.

Automation of Bioreactor

In comparison to conventional, larger-scale bioreactors, mini-bioreactors have a number of advantages. Many of these benefits include:

Less expensive: Mini-bioreactors are an excellent choice for smaller labs or research teams on a budget because they are typically less expensive than bigger bioreactors.

Faster outcomes: Mini-bioreactors provide quicker outcomes since they are simpler to set up and run than bigger bioreactors.

Risk reduction: Because mini-bioreactors require lower volumes of culture media and samples, they are safer to use.

Improved adaptability: Mini-bioreactors are incredibly flexible and may be quickly modified to accommodate different research demands and experiments.

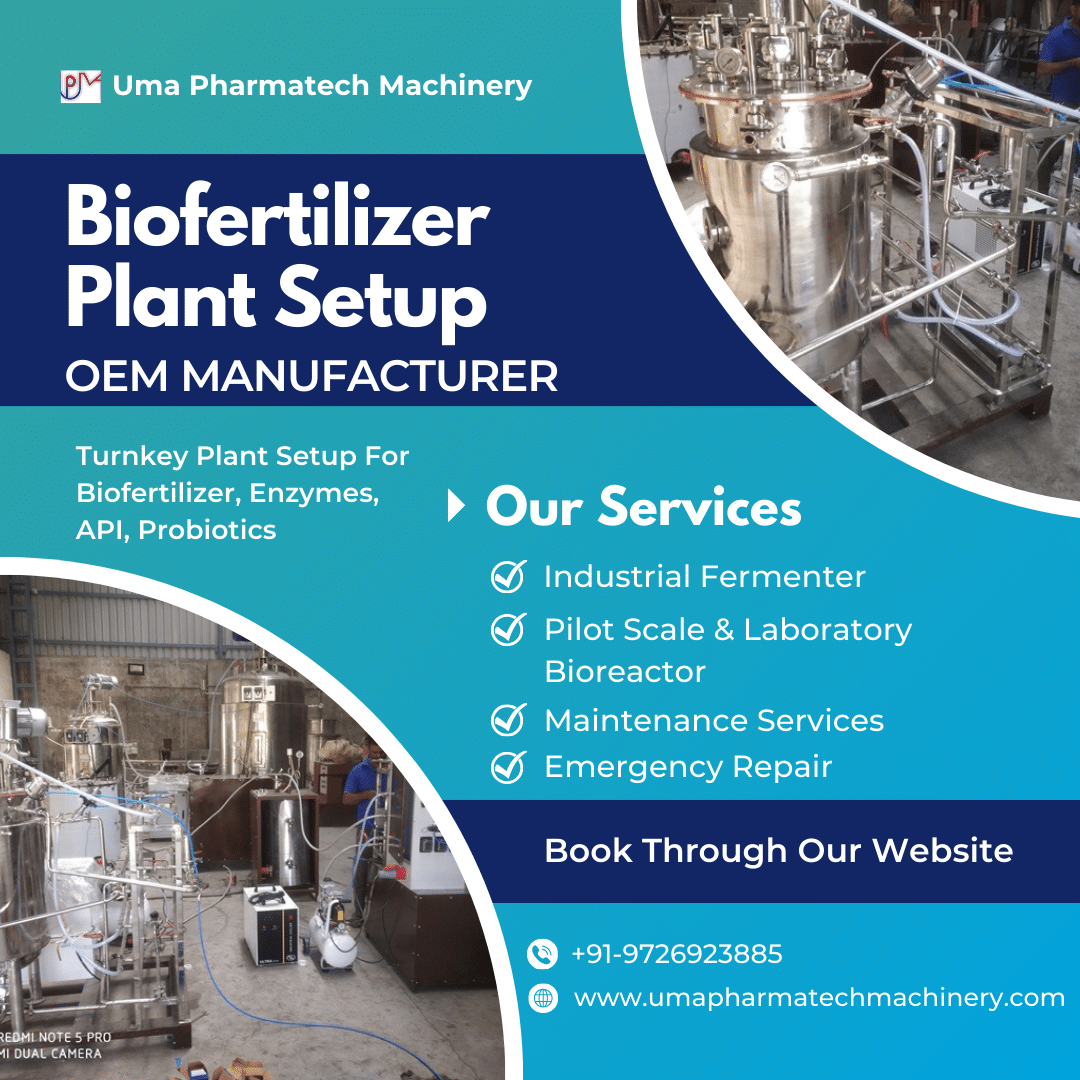

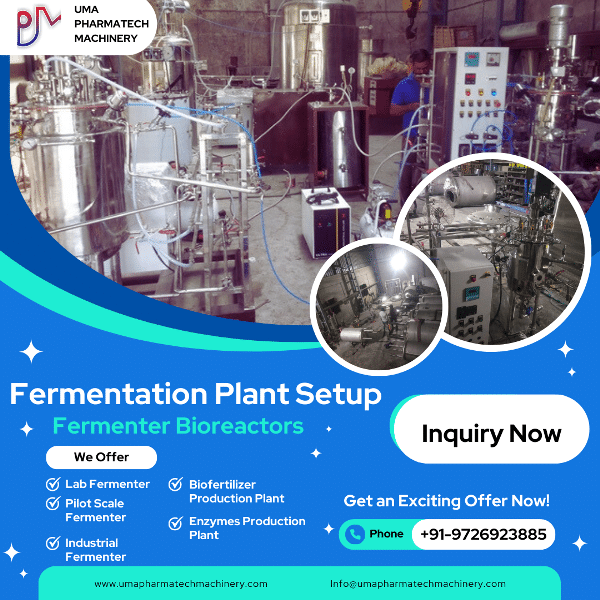

At Uma Pharmatech Machinery, we specialize in offering customers from all around the world Top Industrial Fermenter Suppliers and Exporters. Our goods are made to satisfy the demands of customers working in a range of sectors, such as the food and beverage, pharmaceutical, and biotech industries. In this article, we’ll look at the various fermentation equipment options we provide and discuss how they might help your company.

Fermentation System

Using microorganisms like yeast and bacteria, fermentation is the process of turning carbohydrates into alcohol or organic acids. Many items, including beer, wine, cheese, yoghurt, and antibiotics, are produced using this method. In order to satisfy the requirements of various clients, Uma Pharmatech Machinery provides a broad range of fermentation equipment.

Types of Fermenters

Fermenters vary in type, size, and configuration depending on the application and industry requirements. In Rajasthan, the following fermenters are commonly used:

Batch fermenters: The most basic type of fermenter, in which the entire batch of material is inoculated at once and allowed to ferment until finished. They are appropriate for small-scale productions and are relatively easy to operate and maintain.

Continuous fermenters are designed to operate continuously, with fresh substrate added and product harvested on a continuous basis. They are frequently employed in large-scale industrial applications.

Aerobic fermenters are intended to aid in the growth of microorganisms that require oxygen to respire. Antibiotics, enzymes, and other biologically active substances are frequently produced using them.

Anaerobic fermenters are designed to aid in the growth of microorganisms that do not require oxygen to respire. They’re commonly used to make organic acids, alcohols, and other biochemicals.

Fermenters have varying features depending on the application and industry requirements. Some of the common characteristics of Rajasthan fermenters include:

Most fermenters in Rajasthan are made of stainless steel, which is corrosion-resistant, long-lasting, and easy to clean.

Temperature and pH Control: Fermenters have temperature and pH sensors to monitor and control the fermentation process.

Fermenters have an agitation system that is used to mix the substrate and microorganisms and to increase the mass transfer of nutrients and oxygen.

Fermenters are outfitted with a sterilization system, which is used to sterilize the equipment before and after each batch to prevent contamination.

Benefits of Our Fermentation Equipment

Higher Productivity

Our tools are made to create a regulated environment for microbial growth and fermentation, which can assist your fermentation process be more productive. Modern control systems allow for real-time monitoring and modification of the fermentation process, which can help optimize the procedure and raise product production.

Greater Quality

Our machinery is constructed from premium components and is intended to offer the best conditions for microbial development and fermentation. This can help you raise the Production of your output and guarantee production process uniformity.

cost reduction

Our machinery is built to be both energy-efficient and to need as little manual labor as possible. Your operational costs could be decreased as a result, improving your bottom line.

We at Uma Pharmatech Machinery are dedicated to giving customers all over the world top Quality Pilot Scale Fermenter Supply. Our machinery is made to offer a regulated environment for microbial growth and fermentation, which can aid in boosting output, enhancing quality, and lowering expenses. To learn more about how we can assist you with enhancing your fermentation process, get in touch with us right away.

Bioreactor Manufacturers

Bioreactor Manufacturer in Odisha

Uma Pharmatech Machinery is a leading bioreactor manufacturer in Odisha, contributing to the state’s biotechnology industry with its high-quality equipment.

Bioreactor Manufacturer in Tamilnadu

In Tamil Nadu, Uma Pharmatech Machinery is recognized as a prominent bioreactor manufacturer, bolstering the state’s biotech sector.

Bioreactor Manufacturer in Andhra Pradesh

Uma Pharmatech Machinery serves as a reputable bioreactor manufacturer in Andhra Pradesh, providing essential equipment for the region’s biotech industry.

Bioreactor Manufacturers in Maharashtra

Maharashtra’s thriving biotech sector benefits from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Sikkim

Sikkim’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Jharkhand

Jharkhand’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Bihar

Bihar’s biotechnology industry relies on bioreactor manufacturers like Uma Pharmatech Machinery, recognized for their expertise.

Bioreactor Manufacturers in Uttarakhand

Uttarakhand’s reputation for precision aligns with bioreactor manufacturers like Uma Pharmatech Machinery, known for their expertise.

Bioreactor Manufacturers in Goa

Goa’s industries, including biotechnology, benefit from bioreactor manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Haryana

Haryana’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Belgium

Belgium’s biotech sector thrives with bioreactor manufacturers like Uma Pharmatech Machinery, providing essential equipment.

Bioreactor Manufacturers in Egypt

Egypt’s biotechnology industry benefits from the expertise of bioreactor manufacturers, with companies like Uma Pharmatech Machinery contributing to its growth.

Bioreactor Manufacturers in Gujarat

Gujarat’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Telangana

Telangana’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, renowned for their bioreactor solutions.

Bioreactor Manufacturers in Rajasthan

Rajasthan’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Argentina

Argentina’s biotech sector is bolstered by manufacturers such as Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Turkey

Turkey’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Switzerland

Switzerland’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Bangladesh

Bangladesh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor solutions.

Bioreactor Manufacturers in Kenya

Kenya’s biotech industry benefits from manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Karnataka

Karnataka’s biotechnology sector is supported by manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in West Bengal

West Bengal’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Himachal Pradesh

Himachal Pradesh’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Manipur

Manipur’s biotechnology industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Rajkot

Rajkot’s industries benefit from bioreactor manufacturers like Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Ahmedabad

Ahmedabad’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor solutions.

Bioreactor Manufacturers in Kerala

Kerala’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Punjab

Punjab’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Pune

Pune’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Bioreactor Manufacturers in Chhattisgarh

Chhattisgarh’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Madhya Pradesh

Madhya Pradesh’s biotechnology industry thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Germany

Germany’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, specializing in bioreactor production.

Bioreactor Manufacturers in Australia

Australia’s biotechnology sector is supported by manufacturers such as Uma Pharmatech Machinery, known for their quality equipment.

Bioreactor Manufacturers in Russia

Russia’s biotech industry relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in Nigeria

Nigeria’s industries, including biotechnology, benefit from manufacturers like Uma Pharmatech Machinery.

Bioreactor Manufacturers in Morocco

Morocco’s biotech sector thrives with manufacturers like Uma Pharmatech Machinery providing essential equipment.

Bioreactor Manufacturers in Vietnam

Vietnam’s reputation for precision aligns with manufacturers like Uma Pharmatech Machinery, known for their bioreactor expertise.

Bioreactor Manufacturers in Algeria

Algeria’s biotechnology industry benefits from manufacturers such as Uma Pharmatech Machinery, known for their bioreactor solutions.

Bioreactor Manufacturers in Thailand

Thailand’s biotech sector relies on manufacturers like Uma Pharmatech Machinery, recognized for their bioreactor expertise.

Bioreactor Manufacturers in UAE

The UAE’s thriving industrial landscape is supported by bioreactor manufacturers, including Uma Pharmatech Machinery, known for its quality equipment.

Types of Fermenters

Fermenter Manufacturers

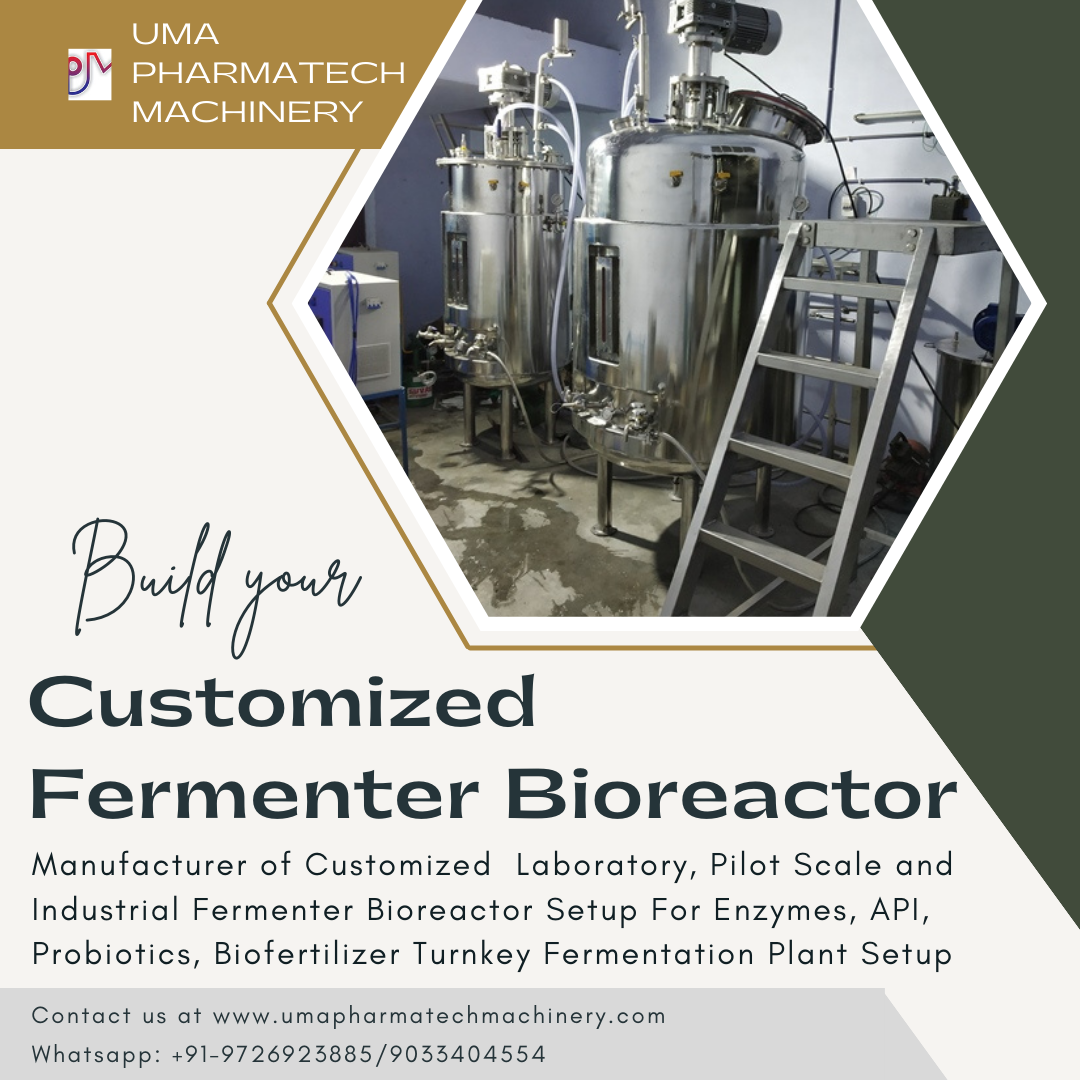

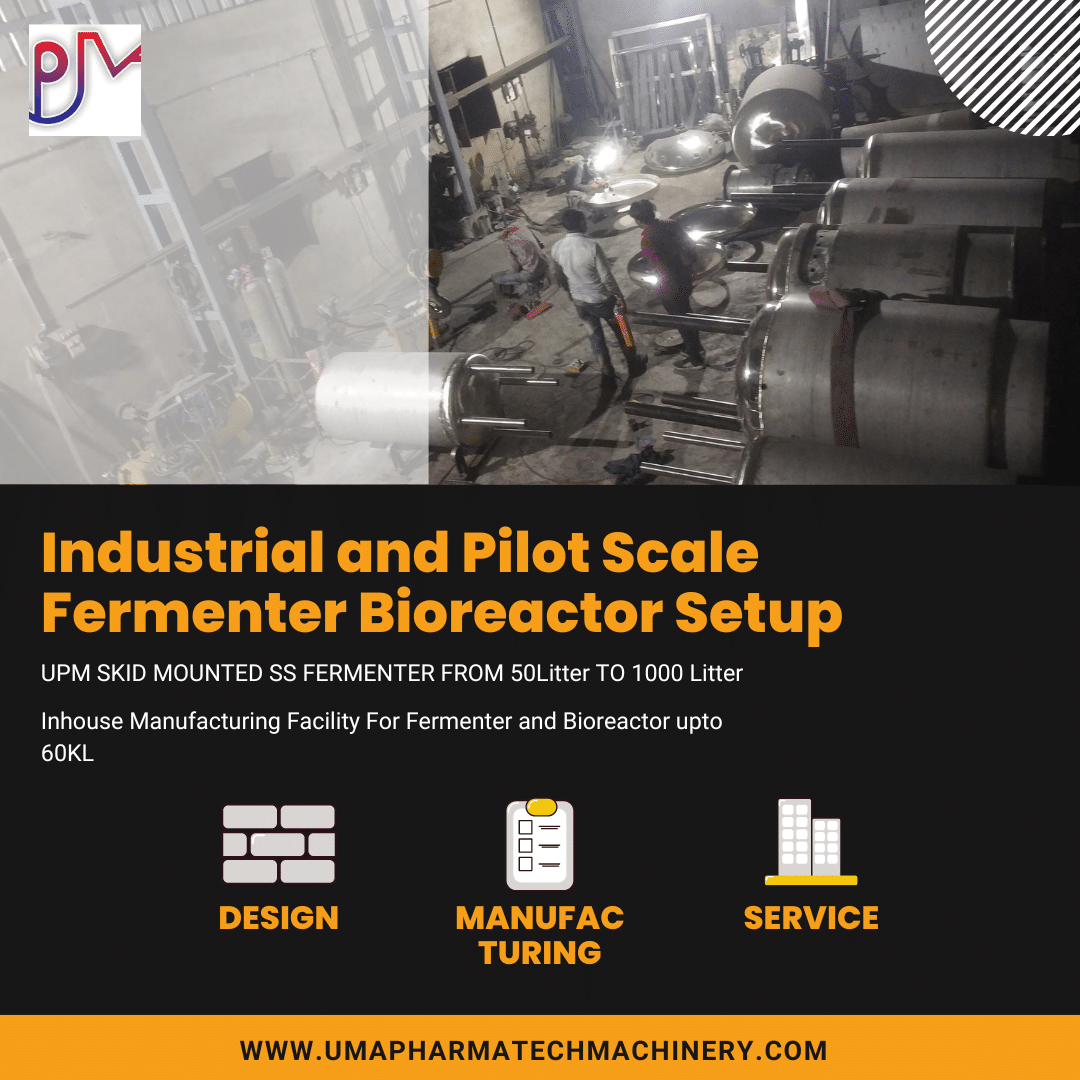

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.

In conclusion, mini-bioreactors have a variety of uses in the field of biotechnology and offer a number of advantages. For laboratories and research teams wishing to create little quantities of material or assess different growth characteristics, they provide a flexible and affordable solution. It is crucial to take into account aspects like working volume, stirring system, temperature control, pH control, and gas management when choosing a Lab Scale bioreactor. We at [Company Name] provide a selection of premium mini-bioreactors to meet your unique requirements. To find out more about our goods and how they can help your research, get in touch with us right now.