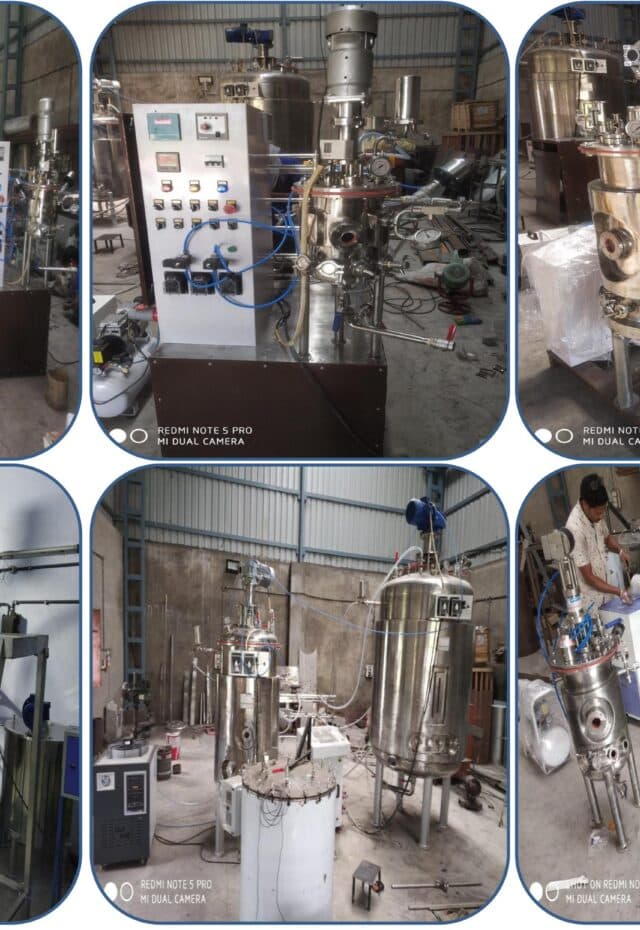

PROCESS REACTOR MANUFACTURER

Chemical processing facilities are not complete without process reactors, which are fundamental to the creation of a wide variety of chemical products. These vessels, or reactors, are created to support chemical reactions at high temperatures and pressures. Process reactors, their varieties, and their uses will all be thoroughly examined in this article.

- SS Reactor Manufacturers

- Jacketed Reactor Manufacturers

- Limpet Coil Reactor Manufacturers

- Stainless Steel Reactor Manufacturer

SS Reactor Manufacturers

Uma Pharmatech stands out as one of the leading SS Reactor manufacturers in the industry. Their unwavering commitment to quality and innovation has earned them a stellar reputation. Uma Pharmatech’s state-of-the-art facilities and a team of skilled engineers ensure that their stainless steel reactors meet the highest industry standards. These reactors are not only durable but also designed for optimal performance in various chemical processes. Uma Pharmatech’s dedication to customer satisfaction is evident in their tailor-made solutions, catering to the unique needs of every client. When it comes to reliable SS reactor manufacturers, Uma Pharmatech consistently delivers excellence, making them a top choice in the market.

Jacketed Reactor Manufacturers

Jacketed reactor manufacturers of distinction, Uma Pharmatech stands at the forefront of this specialized industry. With a sterling reputation for excellence, Uma Pharmatech has earned its place as a trusted name in the realm of chemical equipment. Their jacketed reactors are a testament to precision engineering and quality craftsmanship. Uma Pharmatech’s reactors are thoughtfully designed with double walls, allowing for temperature control, making them indispensable for a range of processes in pharmaceuticals, chemicals, and more. What sets Uma Pharmatech apart is not just their cutting-edge technology, but their commitment to customer satisfaction, offering tailored solutions that meet the unique requirements of each client. When it comes to jacketed reactors, Uma Pharmatech is the industry leader you can rely on.

Limpet Coil Reactor Manufacturer

As premier Limpet Coil Reactor manufacturers, Uma Pharmatech is renowned for its excellence in chemical equipment. Their dedication to precision and innovation has solidified their position as industry leaders. Uma Pharmatech’s Limpet Coil Reactors are a testament to their commitment to quality. These reactors are equipped with specially designed coils that provide efficient heating or cooling, making them indispensable in various industrial processes. What sets Uma Pharmatech apart is their unwavering focus on customer satisfaction. They offer customized solutions tailored to meet the unique requirements of each client. When seeking top-tier Limpet Coil Reactor manufacturers, Uma Pharmatech is the name that consistently delivers superior products and service.

Stainless Steel Reactor Manufacturer

Uma Pharmatech stands tall as a premier choice among Stainless Steel Reactor manufacturers. Renowned for their unwavering commitment to quality, Uma Pharmatech has earned its esteemed reputation in the chemical equipment industry. Their Stainless Steel Reactors are a testament to their dedication to precision engineering and innovation. Crafted with top-grade stainless steel, these reactors are not only durable but also versatile, catering to a wide range of industrial processes. What truly sets Uma Pharmatech apart is their customer-centric approach, offering tailored solutions to meet the unique requirements of each client. When it comes to Stainless Steel Reactor manufacturers, Uma Pharmatech consistently proves to be the industry’s frontrunner in both product quality and customer satisfaction.

What is an agitator?

Process reactor types

Process reactors come in a variety of varieties, and each kind is created to satisfy certain processing needs. Process reactors of the most widespread varieties include:

Mixing Agitator With Reactors

The easiest and most popular kind of process reactors are batch reactors. They are employed in the chemical industry to produce tiny to medium-sized batches of goods. Batch reactors are perfect for generating small batches of high-quality products because they provide you a lot of control over the reaction circumstances.

Continuous Process Reactors

Chemical products are produced in Large quantities using continuous reactors, also referred to as flow reactors. These reactors are perfect for large-scale chemical processing plants because they permit minimally interrupted continuous product production.

SS Batch Reactors

For the production of SS Reactor that need particular reaction conditions, semi-batch reactors combine batch and continuous reactors. These reactors combine continuous reactor output with the adaptability of batch reactors.

SS Tank reactors With Agitator

Stirred tank reactors are frequently used in the chemical industry to produce goods that demand intensive mixing Reactor since they are intended for mixing and heat transmission.

Reactor Vessel Application

In the chemical industry, process reactors are utilized in a variety of applications, such as:

Petrochemicals

The creation of petrochemicals, such as plastics, synthetic fibers, and rubber, depends heavily on process reactors.

Pharmaceuticals

Pharmaceutical companies employ process reactors to create active pharmaceutical ingredients (APIs), which are the main chemicals in medicines.

Chemical Specialties

In the manufacturing of specialty chemicals including flavors, perfumes, and colors, process reactors are also employed.

Food and Drinks

Process reactors are employed in the food and beverage sector to manufacture a variety of goods, such as beverages, snacks, and sauces.

Types of Industrial Reactors

What is a Limpet Coil Reactor?

Which reactor is used in chemical industry?

Our Manufacturing Product Range

SS Vessel Manufacturers

SS Vessel Manufacturers in Gujarat

SS Vessel Manufacturers in Gujarat are crucial players in the industrial landscape, and Uma Pharmatech Machinery Company proudly stands out among them. Based in Gujarat, Uma Pharmatech specializes in crafting top-quality stainless steel vessels. These vessels are engineered with precision and adhere to stringent industry standards, ensuring reliability and longevity.

What sets Uma Pharmatech apart is its unwavering commitment to customization, tailoring vessels to exact client specifications. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels are designed to excel. With a reputation for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company is the trusted choice for those seeking superior stainless steel vessels in Gujarat.

SS Vessel Manufacturers in Ahmedabad

SS Vessel Manufacturers in Ahmedabad play a pivotal role in meeting the industrial demands of the region, and Uma Pharmatech Machinery Company stands as a distinguished name among them. Based in Ahmedabad, Uma Pharmatech specializes in crafting top-quality stainless steel vessels. These vessels are meticulously engineered to meet stringent industry standards, ensuring durability and safety.

Uma Pharmatech’s unique strength lies in its commitment to customization, tailoring vessels precisely to client specifications. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels are designed to excel. With a reputation for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company is the trusted choice for superior stainless steel vessels in Ahmedabad.

SS Vessel Manufacturers in Vadodara

SS Vessel Manufacturers in Vadodara are pivotal to the region’s industrial landscape, and Uma Pharmatech Machinery Company proudly leads the way. Situated in Vadodara, Uma Pharmatech specializes in crafting high-quality stainless steel vessels. These vessels are precision-engineered, meeting stringent industry standards, ensuring longevity and safety.

Uma Pharmatech’s unique advantage lies in its dedication to customization, tailoring vessels precisely to client requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels excel. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company stands as the trusted choice for exceptional stainless steel vessels in Vadodara.

SS Vessel Manufacturers in Surat

SS Vessel Manufacturers in Surat, specifically within the Sachin GIDC area, play a pivotal role in catering to the industrial needs of this thriving region. Among them, Uma Pharmatech Machinery Company emerges as a standout name. Located in Surat-Sachin GIDC, Uma Pharmatech specializes in crafting high-quality stainless steel vessels. These vessels are meticulously engineered, adhering to stringent industry standards, ensuring both durability and safety.

Uma Pharmatech’s unique strength lies in its unwavering commitment to customization, tailoring vessels precisely to meet each client’s unique requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels excel. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company stands as the trusted choice for exceptional stainless steel vessels in Surat, particularly within the Sachin GIDC area.

SS Vessel Manufacturers in Ankleshwar

SS Vessel Manufacturers in Ankleshwar are instrumental in catering to the industrial demands of the region, and at the forefront of this sector stands Uma Pharmatech Machinery Company. Located in Ankleshwar, Uma Pharmatech specializes in the production of high-quality stainless steel vessels. These vessels are precision-engineered, meeting rigorous industry standards to ensure longevity and safety in various applications.

Uma Pharmatech’s unique strength lies in its unwavering commitment to customization, tailoring vessels to meet the exact specifications of each client. Whether used in pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels consistently deliver outstanding performance. With a reputation for punctual delivery and competitive pricing, Uma Pharmatech Machinery Company is the trusted choice for superior stainless steel vessels in Ankleshwar.

SS Vessel Manufacturers in Bharuch

SS Vessel Manufacturers in Bharuch play a pivotal role in meeting the industrial needs of this thriving region, and Uma Pharmatech Machinery Company proudly leads the way. Situated in Bharuch, Uma Pharmatech specializes in crafting high-quality stainless steel vessels. These vessels are precision-engineered, meeting stringent industry standards, ensuring longevity and safety in diverse applications.

Uma Pharmatech’s unique advantage lies in its dedication to customization, tailoring vessels precisely to client requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels excel. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company stands as the trusted choice for exceptional stainless steel vessels in Bharuch.

SS Vessel Manufacturers in Rajkot

SS Vessel Manufacturers in Rajkot play a pivotal role in supplying the industrial demands of the region, and Uma Pharmatech Machinery Company proudly takes the lead. Based in Rajkot, Uma Pharmatech specializes in crafting high-quality stainless steel vessels. These vessels are precision-engineered, adhering to stringent industry standards, ensuring durability and safety in diverse applications.

Uma Pharmatech’s unique strength lies in its unwavering commitment to customization, tailoring vessels precisely to meet each client’s specific requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels excel. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company stands as the trusted choice for exceptional stainless steel vessels in Rajkot.

SS Vessel Manufacturers in Valsad

SS Vessel Manufacturers in Valsad are vital to sustaining the industrial fabric of the region, and Uma Pharmatech Machinery Company takes a prominent position among them. Based in Valsad, Uma Pharmatech specializes in crafting top-quality stainless steel vessels. These vessels are engineered with precision, adhering to rigorous industry standards, ensuring both durability and safety.

Uma Pharmatech’s standout feature is its unwavering commitment to customization, tailoring vessels precisely to meet each client’s unique requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels excel. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company stands as the trusted choice for exceptional stainless steel vessels in Valsad.

SS Vessel Manufacturers in Vapi

SS Vessel Manufacturers in Vapi play a pivotal role in catering to the industrial needs of the region, and Uma Pharmatech Machinery Company proudly leads this niche. Situated in Vapi, Uma Pharmatech specializes in crafting high-quality stainless steel vessels. These vessels are meticulously engineered, adhering to stringent industry standards, ensuring longevity and safety in diverse applications.

Uma Pharmatech’s unique advantage lies in its dedication to customization, tailoring vessels precisely to meet client requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels consistently deliver exceptional performance. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company is the trusted choice for superior stainless steel vessels in Vapi.

SS Vessel Manufacturers in Dahej

SS Vessel Manufacturers in Dahej are instrumental in serving the industrial needs of this thriving region, and Uma Pharmatech Machinery Company proudly stands at the forefront. Located in Dahej, Uma Pharmatech specializes in crafting top-quality stainless steel vessels. These vessels are precision-engineered, meeting stringent industry standards to ensure durability and safety in diverse applications.

Uma Pharmatech’s unique strength lies in its unwavering commitment to customization, tailoring vessels precisely to meet each client’s unique requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel vessels consistently deliver outstanding performance. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company stands as the trusted choice for exceptional stainless steel vessels in Dahej.

Mixing Vessel Manufacturers

SS Mixing Vessel Manufacturers in Gujarat

Mixing Vessel Manufacturers in Gujarat are pivotal to industries relying on precision blending, and Uma Pharmatech Machinery Company stands as a distinguished leader in this sector. Operating in Gujarat, Uma Pharmatech specializes in crafting top-quality mixing vessels that meet stringent industry standards. These vessels play a critical role in pharmaceutical, chemical, and food processing applications, ensuring uniform mixing and consistency.

What sets Uma Pharmatech apart is their unwavering commitment to customization, tailoring mixing vessels precisely to client specifications. With a reputation for reliability and competitive pricing, Uma Pharmatech Machinery Company is the trusted choice for superior mixing vessels in Gujarat, delivering impeccable performance every time.

Stainless Steel Mixing Vessel Manufacturers in Ahmedabad

Stainless Steel Mixing Vessel Manufacturers in Ahmedabad are crucial for industries demanding precise blending solutions, and Uma Pharmatech Machinery Company proudly excels in this domain. Operating in Ahmedabad, Uma Pharmatech specializes in crafting high-quality stainless steel mixing vessels. These vessels are renowned for their precision engineering and strict adherence to industry standards, ensuring efficiency and durability.

Uma Pharmatech’s distinguishing feature is its dedication to customization, tailoring mixing vessels to precise client specifications. This adaptability makes them a preferred choice for clients seeking tailor-made solutions. With a reputation for reliability and competitive pricing, Uma Pharmatech Machinery Company remains the trusted leader in stainless steel mixing vessel manufacturing in Ahmedabad.

Stainless Steel Mixing Vessel Manufacturers in Vadodara

Stainless Steel Mixing Vessel Manufacturers in Vadodara play a pivotal role in supplying industrial demands, and Uma Pharmatech Machinery Company proudly leads this sector. Located in Vadodara, Uma Pharmatech specializes in crafting top-quality stainless steel mixing vessels. These vessels are precision-engineered, adhering to stringent industry standards, ensuring longevity and safety in various applications.

Uma Pharmatech’s unique advantage lies in its unwavering commitment to customization, tailoring mixing vessels precisely to meet each client’s unique requirements. Whether for pharmaceuticals, chemicals, or food processing, Uma Pharmatech’s stainless steel mixing vessels consistently deliver exceptional performance. Renowned for on-time delivery and competitive pricing, Uma Pharmatech Machinery Company is the trusted choice for superior mixing vessels in Vadodara.

When it comes to Stainless Steel Mixing Vessel Manufacturers in Vadodara, Vadodara-based Uma Pharmatech Machinery Company unquestionably leads the pack. Uma Pharmatech specializes in crafting high-quality stainless steel mixing vessels, tailored precisely to client requirements. Their precision-engineered vessels adhere to stringent industry standards, ensuring reliability and safety in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s commitment to customization sets them apart in Vadodara’s manufacturing landscape. They excel at creating stainless steel mixing vessels that perfectly align with their clients’ unique needs. With a stellar reputation for on-time delivery, competitive pricing, and unmatched quality, Uma Pharmatech Machinery Company is Vadodara’s go-to choice for superior stainless steel mixing vessels.

Stainless Steel Mixing Vessel Manufacturers in Rajkot

When it comes to Stainless Steel Mixing Vessel Manufacturers in Rajkot, Uma Pharmatech Machinery Company is the undisputed leader. Uma Pharmatech, hailing from Rajkot, specializes in crafting high-quality stainless steel mixing vessels, ensuring precision engineering, and adhering to industry standards. These vessels play a pivotal role in pharmaceutical, chemical, and food processing applications, ensuring consistent and uniform mixing.

What sets Uma Pharmatech apart is its unwavering commitment to customization. They tailor stainless steel mixing vessels to meet precise client requirements, offering bespoke solutions. With a reputation for on-time delivery, competitive pricing, and a strong emphasis on quality, Uma Pharmatech Machinery Company is Rajkot’s premier choice for exceptional mixing vessels.

Mixing Vessel Manufacturers in Ankleshwar

Mixing Vessel Manufacturers in Ankleshwar rely on precision engineering to meet the demands of various industries, and Uma Pharmatech Machinery Company excels in this domain. Uma Pharmatech, based in Ankleshwar, specializes in crafting top-quality mixing vessels, adhering to stringent industry standards. These vessels are indispensable in pharmaceutical, chemical, and food processing applications, ensuring consistent and uniform mixing.

Uma Pharmatech’s unique advantage is their unwavering commitment to customization. They tailor mixing vessels to meet precise client specifications, offering tailored solutions. Renowned for on-time delivery, competitive pricing, and exceptional quality, Uma Pharmatech Machinery Company stands as Ankleshwar’s preferred choice for superior mixing vessels.

Mixing Vessel Manufacturers in Bharuch

Mixing Vessel Manufacturers in Bharuch are pivotal in catering to diverse industrial needs, and Uma Pharmatech Machinery Company takes center stage in this arena. Situated in Bharuch, Uma Pharmatech specializes in crafting top-tier mixing vessels adhering to the most stringent industry standards. These vessels play a critical role in pharmaceutical, chemical, and food processing applications, ensuring uniform and efficient mixing.

What truly sets Uma Pharmatech apart in Bharuch’s manufacturing landscape is its unwavering commitment to customization. They tailor mixing vessels to meet precise client specifications, providing bespoke solutions for unique requirements. With a reputation for on-time delivery, competitive pricing, and an unwavering emphasis on quality, Uma Pharmatech Machinery Company stands as Bharuch’s go-to choice for exceptional mixing vessels.

In Bharuch, the demand for mixing vessels continues to grow, and Uma Pharmatech Machinery Company rises to the occasion. Their precision-engineered vessels, meticulously crafted to meet the demands of various industries, are a testament to their commitment to excellence. For Bharuch’s industrial needs, Uma Pharmatech’s mixing vessels remain unrivaled in terms of quality, reliability, and customization options.

Mixing Vessel Manufacturers in Valsad

Mixing Vessel Manufacturers in Valsad are instrumental in supporting the diverse industrial landscape, and Uma Pharmatech Machinery Company proudly leads the way. Operating in Valsad, Uma Pharmatech specializes in crafting top-quality mixing vessels that adhere to the most stringent industry standards. These vessels are indispensable in pharmaceutical, chemical, and food processing applications, ensuring consistent and efficient mixing.

Uma Pharmatech’s distinguishing feature is its unwavering commitment to customization. They tailor mixing vessels to meet precise client specifications, providing tailor-made solutions for unique requirements. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company remains Valsad’s trusted choice for superior mixing vessels.

Mixing Vessel Manufacturers in Vapi

Mixing Vessel Manufacturers in Vapi are pivotal in supporting the industrial fabric of the region, and leading this sector is Uma Pharmatech Machinery Company. Situated in Vapi, Uma Pharmatech specializes in crafting top-quality mixing vessels, meticulously engineered to meet the most stringent industry standards. These vessels are indispensable in pharmaceutical, chemical, and food processing applications, ensuring uniform and efficient mixing.

What truly sets Uma Pharmatech apart is its unwavering commitment to customization. They tailor mixing vessels to meet precise client specifications, delivering bespoke solutions for unique requirements. Renowned for on-time delivery, competitive pricing, and a steadfast focus on quality, Uma Pharmatech Machinery Company remains Vapi’s preferred choice for exceptional mixing vessels.

Mixing Vessel Manufacturers in Dahej

Mixing Vessel Manufacturers in Dahej play a pivotal role in serving the industrial needs of this thriving region, and Uma Pharmatech Machinery Company proudly stands at the forefront. Located in Dahej, Uma Pharmatech specializes in crafting high-quality mixing vessels that adhere to the most stringent industry standards. These vessels are indispensable in pharmaceutical, chemical, and food processing applications, ensuring consistent and efficient mixing.

What truly sets Uma Pharmatech apart is its unwavering commitment to customization. They tailor mixing vessels to meet precise client specifications, offering bespoke solutions for unique requirements. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company remains Dahej’s preferred choice for superior mixing vessels.

Storage Vessel Manufacturers

SS Storage Vessel Manufacturers in Gujarat

SS Storage Vessel Manufacturers in Gujarat are vital to industries reliant on safe material storage, and Uma Pharmatech Machinery Company stands as a beacon in this sector. Operating within Gujarat, Uma Pharmatech specializes in crafting top-quality stainless steel storage vessels. These vessels are meticulously engineered, adhering to the most stringent industry standards, ensuring both durability and safety in various applications.

Uma Pharmatech’s unique advantage is its unwavering commitment to customization. They tailor storage vessels to meet precise client specifications, offering tailored solutions for unique requirements. With a reputation for on-time delivery, competitive pricing, and a steadfast focus on quality, Uma Pharmatech Machinery Company is Gujarat’s preferred choice for exceptional stainless steel storage vessels.

SS Storage Vessel Manufacturers in Rajkot

SS Storage Vessel Manufacturers in Rajkot are indispensable to various industries, and Uma Pharmatech Machinery Company shines brightly in this domain. Based in Rajkot, Uma Pharmatech specializes in crafting high-quality stainless steel storage vessels engineered to meet the most stringent industry standards. These vessels are crucial for safe material storage in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s standout feature is its dedication to customization. They tailor storage vessels precisely to meet the unique requirements of each client, providing bespoke solutions. With a reputation for on-time delivery, competitive pricing, and unwavering commitment to quality, Uma Pharmatech Machinery Company remains Rajkot’s trusted choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Ahmedabad

SS Storage Vessel Manufacturers in Ahmedabad are instrumental in providing reliable storage solutions, and Uma Pharmatech Machinery Company excels in this field. Based in Ahmedabad, Uma Pharmatech specializes in crafting high-quality stainless steel storage vessels that adhere to rigorous industry standards. These vessels are essential for safe material storage in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s distinguishing feature is its unwavering commitment to customization. They tailor storage vessels precisely to meet each client’s unique requirements, offering bespoke solutions. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company is Ahmedabad’s preferred choice for exceptional stainless steel storage vessels.

SS Storage Vessel Manufacturers in Vadodara

SS Storage Vessel Manufacturers in Vadodara play a pivotal role in industries relying on secure material storage, and Uma Pharmatech Machinery Company leads the way in this sector. Located in Vadodara, Uma Pharmatech specializes in crafting top-quality stainless steel storage vessels engineered to meet the most stringent industry standards. These vessels are indispensable for the safe storage of materials in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s unique advantage is its unwavering commitment to customization. They tailor storage vessels precisely to meet the unique requirements of each client, offering tailored solutions. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company is Vadodara’s trusted choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Ankleshwar

SS Storage Vessel Manufacturers in Ankleshwar play a vital role in providing safe and reliable material storage solutions, and Uma Pharmatech Machinery Company stands as a leading force in this sector. Based in Ankleshwar, Uma Pharmatech specializes in crafting top-quality stainless steel storage vessels, engineered to meet the most rigorous industry standards. These vessels are essential for secure material storage in pharmaceutical, chemical, and food processing applications.

What sets Uma Pharmatech apart is its unwavering commitment to customization. They tailor storage vessels precisely to meet the unique requirements of each client, offering bespoke solutions. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company is Ankleshwar’s preferred choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Surat

SS Storage Vessel Manufacturers in Surat are pivotal in ensuring secure and efficient material storage, and Uma Pharmatech Machinery Company excels in this domain. Located in Surat, Uma Pharmatech specializes in crafting top-quality stainless steel storage vessels engineered to meet the most stringent industry standards. These vessels are essential for safe material storage in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s distinguishing feature is its unwavering commitment to customization. They tailor storage vessels precisely to meet each client’s unique requirements, offering tailored solutions. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company is Surat’s trusted choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Surat are vital for secure and efficient material storage solutions, and Uma Pharmatech Machinery Company is the foremost player in this arena. Located in Surat, Uma Pharmatech specializes in designing top-quality stainless steel storage vessels that adhere to rigorous industry standards. These vessels are essential for safe material storage in pharmaceutical, chemical, and food processing applications.

What truly sets Uma Pharmatech apart is its unwavering commitment to customization. They tailor storage vessels precisely to meet each client’s unique requirements, considering factors like design, cost, and material grade, be it SS304, SS316, or Mild Steel. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company is Surat’s trusted choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Valsad

SS Storage Vessel Manufacturers in Valsad are paramount for efficient material storage, and Uma Pharmatech Machinery Company leads the charge in this sector. Situated in Valsad, Uma Pharmatech specializes in designing top-notch stainless steel storage vessels that adhere to stringent industry standards. These vessels play a pivotal role in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s distinctive strength lies in its unwavering commitment to customization. They meticulously tailor storage vessels to meet each client’s unique requirements, considering aspects such as design, cost, and material grade, be it SS304, SS316, or Mild Steel. Renowned for on-time delivery, competitive pricing, and a steadfast focus on quality, Uma Pharmatech Machinery Company remains Valsad’s trusted choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Vapi

SS Storage Vessel Manufacturers in Vapi are pivotal for efficient material storage solutions, and Uma Pharmatech Machinery Company excels in this domain. Located in Vapi, Uma Pharmatech specializes in designing top-quality stainless steel storage vessels that adhere to rigorous industry standards. These vessels are crucial for secure material storage in pharmaceutical, chemical, and food processing applications.

What truly sets Uma Pharmatech apart is its unwavering commitment to customization. They meticulously tailor storage vessels to meet each client’s unique requirements, considering factors like design, cost, and material grade, be it SS304, SS316, or Mild Steel. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company is Vapi’s trusted choice for superior stainless steel storage vessels.

SS Storage Vessel Manufacturers in Dahej

SS Storage Vessel Manufacturers in Dahej are indispensable for efficient and secure material storage solutions, and Uma Pharmatech Machinery Company leads the way in this sector. Situated in Dahej, Uma Pharmatech specializes in designing top-quality stainless steel storage vessels that strictly adhere to the most stringent industry standards. These vessels play a pivotal role in ensuring the safe storage of materials in pharmaceutical, chemical, and food processing applications.

Uma Pharmatech’s distinguishing feature is its unwavering commitment to customization. They meticulously tailor storage vessels to meet each client’s unique requirements, considering factors such as design, cost, and material grade, including SS304, SS316, and Mild Steel. Renowned for on-time delivery, competitive pricing, and an unwavering focus on quality, Uma Pharmatech Machinery Company remains Dahej’s trusted choice for superior stainless steel storage vessels.

Mixing Tank Manufacturers

SS Mixing Tank Manufacturers in Gujarat

SS Mixing Tank Manufacturers in Gujarat are instrumental in delivering efficient solutions for various industries. These tanks are essential for the precise blending of materials in pharmaceutical, chemical, and food processing applications. When it comes to choosing the right mixing tank, considerations like design, cost, and material grade are paramount. Stainless steel grades like SS304 and SS316, as well as Mild Steel, are commonly used, each offering its unique advantages.

For Gujarat-based industries seeking reliable SS mixing tank manufacturers, it’s crucial to choose a reputable company known for producing tanks that meet stringent industry standards. Such tanks ensure efficient mixing while guaranteeing durability and safety.

SS 316 Mixing Tank Manufacturers in Ahmedabad

SS 316 Mixing Tank Manufacturers in Ahmedabad provide critical solutions for industries requiring precision blending. These tanks, constructed from durable stainless steel, are vital for pharmaceutical, chemical, and food processing applications. When selecting a mixing tank, factors like design, cost, and material grade must be considered. Stainless steel grades like SS304 and SS316, along with Mild Steel, come into play, each offering its unique advantages.

In Ahmedabad, finding a reputable manufacturer is essential for ensuring the production of top-quality SS 316 mixing tanks that meet rigorous industry standards. These tanks not only guarantee efficient mixing but also ensure longevity and safety, making them a valuable asset for various industrial applications.

SS 304 Mixing Tank Manufacturers in Vadodara

SS 304 Mixing Tank Manufacturers in Vadodara offer critical solutions for industries requiring precision blending. These tanks, crafted from robust stainless steel, play a pivotal role in pharmaceutical, chemical, and food processing applications. When selecting a mixing tank, considerations like design, cost, and material grade must be taken into account. Stainless steel grades such as SS304 and SS316, as well as Mild Steel, offer distinct advantages.

In Vadodara, choosing a reputable manufacturer is essential to ensure the production of high-quality SS 304 mixing tanks that adhere to stringent industry standards. These tanks not only guarantee efficient mixing but also assure durability and safety, making them indispensable for a wide range of industrial applications.

Stainless Steel Mixing Tank Manufacturers in Rajkot

Stainless Steel Mixing Tank Manufacturers in Rajkot are indispensable for industries demanding precise blending solutions. These tanks, constructed from robust stainless steel, are pivotal for pharmaceutical, chemical, and food processing applications. When selecting a mixing tank, factors like design, cost, and material grade must be considered. Stainless steel grades like SS304 and SS316, along with Mild Steel, each offer unique advantages.

In Rajkot, choosing a reputable manufacturer is crucial to ensure the production of high-quality stainless steel mixing tanks that meet rigorous industry standards. These tanks not only ensure efficient mixing but also guarantee longevity and safety, making them a valuable asset for various industrial applications.

MS Mixing Tank Manufacturers in Surat

MS Mixing Tank Manufacturers in Surat play a pivotal role in industries requiring efficient blending solutions. These tanks, constructed from robust Mild Steel (MS), find applications in various industrial processes. When selecting a mixing tank, considerations like design, cost, and material grade are crucial. While stainless steel grades like SS304 and SS316 offer their advantages, Mild Steel remains a dependable choice.

In Surat, choosing a reputable manufacturer is vital to ensure the production of high-quality MS mixing tanks that meet stringent industry standards. These tanks not only ensure efficient mixing but also provide durability and reliability, making them a valuable asset across different industrial applications.

SS Mixing Tank Manufacturers in Vapi

SS Mixing Tank Manufacturers in Vapi are pivotal for industries demanding precise blending solutions. These tanks, constructed from robust stainless steel, are indispensable for pharmaceutical, chemical, and food processing applications. When selecting a mixing tank, factors like design, cost, and material grade must be considered. Stainless steel grades like SS304 and SS316, as well as Mild Steel, offer distinct advantages.

In Vapi, choosing a reputable manufacturer is essential to ensure the production of top-quality SS mixing tanks that adhere to stringent industry standards. These tanks not only guarantee efficient mixing but also assure longevity and safety, making them a valuable asset for various industrial applications.

SS Mixing Tank Manufacturers in Valsad

SS Mixing Tank Manufacturers in Valsad are indispensable for industries seeking precision blending solutions. These tanks, crafted from durable stainless steel, are crucial for pharmaceutical, chemical, and food processing applications. When selecting a mixing tank, considerations like design, cost, and material grade are pivotal. Stainless steel grades such as SS304 and SS316, along with Mild Steel, each offer unique advantages.

In Valsad, choosing a reputable manufacturer is essential to ensure the production of high-quality SS mixing tanks that adhere to stringent industry standards. These tanks not only ensure efficient mixing but also assure longevity and safety, making them an invaluable asset for a variety of industrial applications.

Stainless Steel Mixing Tank Manufacturers in Dahej

Stainless Steel Mixing Tank Manufacturers in Dahej are essential for industries demanding precision blending solutions. These tanks, crafted from durable stainless steel, are pivotal for pharmaceutical, chemical, and food processing applications. When selecting a mixing tank, factors like design, cost, and material grade must be considered. Stainless steel grades like SS304 and SS316, as well as Mild Steel, offer unique advantages.

In Dahej, choosing a reputable manufacturer is crucial to ensure the production of high-quality stainless steel mixing tanks that meet stringent industry standards. These tanks not only ensure efficient mixing but also provide durability and safety, making them an invaluable asset across various industrial applications.

Mild Steel Mixing Tank Fabricator in Ankleshwar

Mild Steel Mixing Tank Fabricator in Ankleshwar plays a crucial role in industries requiring robust blending solutions. These tanks, expertly crafted from durable Mild Steel (MS), find applications in various industrial processes. When considering a mixing tank, elements like design, cost, and material grade are essential. While stainless steel grades like SS304 and SS316 have their advantages, Mild Steel remains a reliable choice.

In Ankleshwar, choosing a reputable fabricator is vital to ensure the production of top-quality Mild Steel mixing tanks that meet stringent industry standards. These tanks not only guarantee efficient mixing but also offer durability and cost-effectiveness, making them a valuable asset across different industrial applications.

SS Mixing Tank Suppliers in Bharuch

SS Mixing Tank Suppliers in Bharuch are instrumental in providing industries with high-quality blending solutions. These tanks, constructed from durable stainless steel, play a vital role in pharmaceutical, chemical, and food processing applications. When choosing a mixing tank, considerations such as design, cost, and material grade are paramount. Stainless steel grades like SS304 and SS316, along with Mild Steel, each offer distinct advantages.

In Bharuch, selecting a reputable supplier is essential to ensure the procurement of top-notch SS mixing tanks that adhere to rigorous industry standards. These tanks not only ensure efficient mixing but also assure longevity and safety, making them an invaluable asset for a variety of industrial applications.

Storage Tank Manufacturers

SS Storage Tank Manufacturers in Gujarat

SS Storage Tank Manufacturers in Gujarat cater to diverse industrial needs, providing top-notch solutions. Stainless steel storage tanks, crucial for various applications, are engineered to the highest standards. When seeking quality SS storage tanks in Gujarat, these manufacturers offer reliability, durability, and efficiency, making them indispensable for industries across the region.

SS Storage Tank Manufacturers in Ahmedabad

SS Storage Tank Manufacturers in Ahmedabad lead the industry with their high-quality stainless steel storage tanks. When searching for reliable SS storage tanks in Ahmedabad, these manufacturers offer durability, safety, and efficiency. They are the go-to choice for various industries, providing top-notch storage solutions in the region.

SS Storage Tank Manufacturers in Vadodara

SS Storage Tank Manufacturers in Vadodara excel in crafting top-quality stainless steel storage tanks. When it comes to reliable SS storage tanks in Vadodara, these manufacturers ensure durability, safety, and efficiency. They are the preferred choice for various industries in the region, offering top-notch storage solutions.

SS Storage Tank Manufacturers in Surat

SS Storage Tank Manufacturers in Surat are industry leaders, providing premium stainless steel storage tanks. When seeking dependable SS storage tanks in Surat, these manufacturers ensure durability, safety, and efficiency. They are the trusted choice for various industries in the region, offering top-notch storage solutions.

SS Storage Tank Manufacturers in Rajkot

SS Storage Tank Manufacturers in Rajkot stand out in crafting high-quality stainless steel storage tanks. When in search of dependable SS storage tanks in Rajkot, these manufacturers prioritize durability, safety, and efficiency. They are the preferred choice for various industries in the region, offering top-notch storage solutions.

SS Storage Tank Manufacturers in Valsad

SS Storage Tank Manufacturers in Valsad excel in producing premium stainless steel storage tanks. When seeking reliable SS storage tanks in Valsad, these manufacturers prioritize durability, safety, and efficiency. They are the trusted choice for various industries in the region, offering top-notch storage solutions.

SS Storage Tank Manufacturers in Vapi

SS Storage Tank Manufacturers in Vapi are known for their top-quality stainless steel storage tanks. When you need dependable SS storage tanks in Vapi, these manufacturers ensure durability, safety, and efficiency. They are the preferred choice for various industries in the region, providing excellent storage solutions.

SS Storage Tank Manufacturers in Ankleshwar

SS Storage Tank Manufacturers in Ankleshwar are renowned for their premium stainless steel storage tanks. When seeking reliable SS storage tanks in Ankleshwar, these manufacturers prioritize durability, safety, and efficiency. They are the preferred choice for various industries in the region, offering top-notch storage solutions.

SS Storage Tank Manufacturers in Bharuch

SS Storage Tank Manufacturers in Bharuch are known for their exceptional stainless steel storage tanks. When in need of reliable SS storage tanks in Bharuch, these manufacturers prioritize durability, safety, and efficiency. They are the trusted choice for various industries in the region, offering top-tier storage solutions.

Suppliers of Vessel and Tank

SS Vessel Suppliers

SS Vessel Suppliers play a vital role in providing industries with high-quality stainless steel vessels. When searching for dependable SS vessel suppliers, these professionals offer durability, safety, and efficiency. They are the preferred choice for various industries, providing top-notch stainless steel vessels.

Stainless Steel Vessel Suppliers

Stainless Steel Vessel Suppliers are essential for industries seeking top-quality stainless steel vessels. When in need of dependable stainless steel vessel suppliers, these experts prioritize durability, safety, and efficiency. They are the go-to choice for various industries, offering premium stainless steel vessels that meet rigorous standards.

Suppliers of Mixing Vessel

Suppliers of Mixing Vessel are crucial for industries requiring top-notch mixing vessels. When searching for dependable mixing vessel suppliers, these professionals prioritize design, cost, and material grade. They are the preferred choice for various industries, providing high-quality mixing vessels that meet rigorous standards.

Suppliers of Storage Tank

Suppliers of Storage Tank are essential for industries in need of high-quality storage solutions. When seeking reliable storage tank suppliers, these experts prioritize durability, safety, and efficiency. They are the preferred choice for various industries, offering top-notch storage tanks that meet rigorous standards.

Suppliers of Storage Vessel

Suppliers of Storage Vessel are pivotal for industries seeking top-quality storage solutions. When in need of dependable storage vessel suppliers, these experts prioritize durability, safety, and efficiency. They are the go-to choice for various industries, offering high-quality storage vessels that meet rigorous standards.

Suppliers of Mixing Tank

Suppliers of Mixing Tank are essential for industries requiring efficient blending solutions. When searching for dependable mixing tank suppliers, these professionals prioritize design, cost, and material grade. They are the preferred choice for various industries, providing high-quality mixing tanks that meet rigorous standards.

In summary, process reactors are an integral part of chemical processing facilities and are critical in the creation of a variety of chemical products. Process reactors, their varieties, and their uses have all been thoroughly examined in this article. Chemical processing businesses can select the best reactor for their unique processing needs by being aware of the many process reactor types that are available and their diverse applications.