AGITATOR MANUFACTURER IN SURAT

Our equipment can be utilized for a wide range of industrial applications and is built to operate excellently while mixing and blending. Our industrial chemical agitator machines can assist you in getting the right outcomes whether you work in the chemical, food and beverage, or pharmaceutical industries.

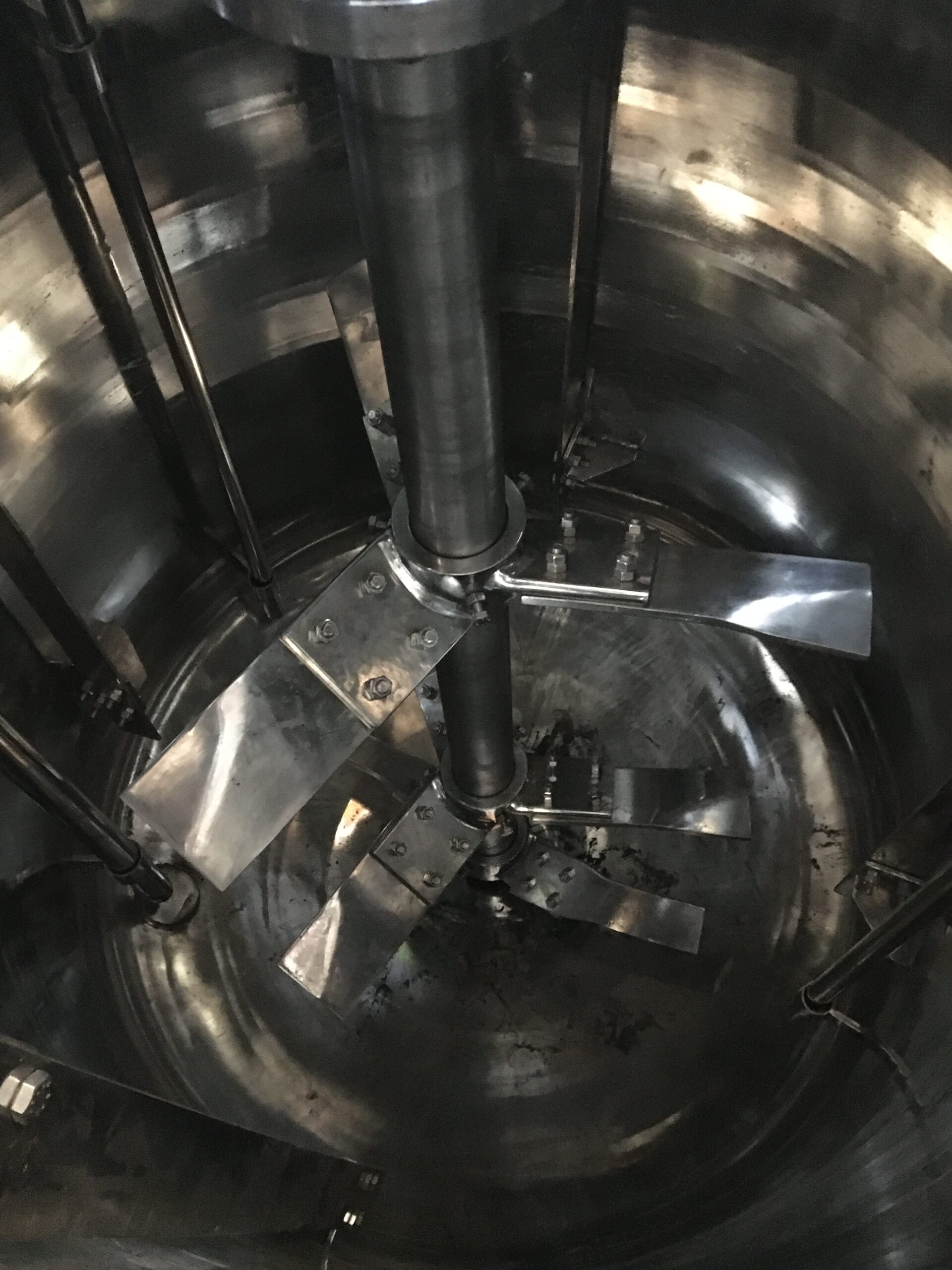

Our machines’ adaptability is one of their best qualities. Our equipment can be modified to fit the unique requirements of our clients and is built to handle a variety of chemicals. To ensure that our machines suit the unique needs of our customers, we may offer machines with various mixing speeds, torque requirements, and impeller designs.

Also, our equipment is made to be simple to operate and maintain. In order to ensure that our clients can easily use and maintain our machines, we offer thorough documentation and training. In order to guarantee that our clients can acquire the assistance they require when they require it, we also offer after-sales support.

- Industrial Agitator Manufacturer in Gujarat

- Agitator Manufacturer in Gujarat-Ahmedabad

- Manufacturer of Chemical Reactor Agitator in Gujarat

Manufacturers of Industrial Agitator in Gujarat-India

Uma Pharmatech Machinery is a pioneering follow url Industrial Agitator Manufacturer dedicated to delivering cutting-edge agitation solutions. With an unwavering commitment to innovation and quality, Uma Pharmatech Machinery stands out as a leader in the industry. Our state-of-the-art agitator systems are meticulously designed to meet the dynamic needs of various sectors, ensuring optimal mixing and blending processes. Backed by a team of experts, we craft agitators that excel in performance, durability, and efficiency. From pharmaceuticals to chemical processing, Uma Pharmatech Machinery’s agitators empower industries to achieve seamless operations and impeccable results. Experience the pinnacle of agitator manufacturing with us.

industrial agitator manufacturer

Agitator Manufacturer in Ahmedabad

In the heart of Ahmedabad, source Uma Pharmatech Machinery proudly stands as the leading Order Tramadol Cod Next Day Delivery Industrial Agitator Manufacturer. Specializing in innovative agitator solutions, Uma Pharmatech Machinery designs and produces state-of-the-art agitation systems that redefine industrial processes. With an unwavering commitment to quality and precision, our agitators cater to various sectors, including pharmaceuticals and chemicals. Our Ahmedabad-based manufacturing unit ensures superior craftsmanship and reliability in each agitator we create. When you choose Uma Pharmatech Machinery, you’re choosing excellence in agitator manufacturing, empowering your operations with cutting-edge technology tailored to Ahmedabad’s industrial landscape.

industrial agitator manufacturer

Manufacturer of Industrial Agitator For Chemical Reactor

Uma Pharmatech Machinery, based in Gujarat, is the foremost see url Industrial Agitator Manufacturer in the region. With a strong focus on innovation and engineering excellence, Uma Pharmatech Machinery designs and produces top-tier agitator solutions. Our state-of-the-art manufacturing facility in Gujarat ensures precision and quality in every agitator we create. Serving diverse industries, including pharmaceuticals and chemicals, we take pride in delivering agitators that enhance mixing processes and operational efficiency. Choose Uma Pharmatech Machinery for advanced agitators that are engineered to meet the specific needs of Gujarat’s industrial landscape, setting new standards for performance and reliability.

industrial agitator manufacturer

here What is an agitator?

What is the difference between a mixer and an agitator?

Types of Industrial Agitators

Buying Tramadol Uk Things to Take into Account While Selecting an Agitator Manufacturer:

- Experience: Seek out a manufacturer with experience in your sector because they will be more likely to comprehend your unique requirements and be able to offer you the finest solution.

- Quality: Choose out a firm known for producing agitators that are long-lasting and made of high-quality materials.

- Customization: Seek out a company who can make your agitator according to your unique requirements.

- Service and Support: Choose a manufacturer that offers first-rate service and assistance at every stage of the process, from design through installation and beyond.

click There are a number of things to take into account while selecting an agitator, including:

- Viscosity – The kind of agitator used will depend on how viscous the fluid being mixed is.

- Tank Size and Shape – The selection of an agitator will depend on the size and shape of the tank.

- Mixing Intensity – The kind of agitator required will depend on the degree of mixing intensity necessary.

- Power Needs – The agitator’s power requirements should be taken into account.

https://autismwish.org/9c50nn5 The following are some advantages of utilizing industrial agitators in your production processes:

- Increased Product Quality: By consistently blending and mixing ingredients, industrial agitators ensure improved product quality and reduced variability.

- More Efficiency: Industrial agitators shorten the amount of time and effort needed for mixing and blending, increasing productivity and lowering expenses.

- More Flexibility: Industrial agitators can be modified to fit particular processing needs, giving manufacturing processes more freedom.

https://www.pathwaysmagazineonline.com/oor49le Advantages and Features

Our agitators are made to offer a variety of advantages, such as:

- Improved mixing effectiveness;

- Reduced energy consumption;

- Quicker response times; improved product quality;

- Decreased maintenance needs;

- Long service life.

Industrial Agitator Manufacturers in Gujarat

Agitator Manufacturer in Gujarat

Uma Pharmatech Machinery stands as one of the premier Cheap Tramadol Next Day Delivery Industrial Agitator Manufacturers in Gujarat, driving innovation in the manufacturing landscape. With a firm commitment to excellence, Uma Pharmatech Machinery designs and fabricates cutting-edge agitator solutions that redefine industrial processes. Our Gujarat-based manufacturing unit ensures precision engineering, delivering agitators that cater to diverse sectors such as pharmaceuticals and chemicals. Choosing Uma Pharmatech Machinery means choosing unparalleled expertise in agitator manufacturing, setting new benchmarks for performance, reliability, and customer satisfaction within Gujarat’s industrial sector.

Top Agitator Manufacturer in Gujarat

Top Agitator Manufacturer in Gujarat-Ahmedabad

Tramadol Order Online Cod Uma Pharmatech Machinery shines prominently as the foremost Order Tramadol From Mexico Top Agitator Manufacturer in Gujarat-Ahmedabad. Our commitment to excellence and innovation propels us ahead in the industry. With a blend of cutting-edge technology and meticulous craftsmanship, we engineer agitators that outperform expectations. Based in Ahmedabad, our company stands as a beacon of quality and reliability. Our agitators find applications across diverse sectors, showcasing their superior mixing capabilities. By choosing Uma Pharmatech Machinery, you’re aligning with unmatched expertise and a legacy of excellence, ensuring that your industrial processes reach new heights of efficiency and precision.

Best Agitator Supplier in Gujarat

Best Agitator Supplier in Gujarat- Ahmedabad

https://living4youboutique.com/mz45p9q Uma Pharmatech Machinery proudly claims the title of the source link Best Agitator Supplier in Gujarat-Ahmedabad. Our unwavering dedication to quality and innovation sets us apart in the industry. Situated in Ahmedabad, we’ve established ourselves as a prime source for top-notch agitators. Our commitment to customer satisfaction is evident in every product we offer. With cutting-edge designs and precision engineering, our agitators elevate industrial processes to new heights. When you choose Uma Pharmatech Machinery, you’re selecting not only the best agitator supplier but a partner dedicated to enhancing your operations with unparalleled expertise and exceptional solutions.

Gujarat Industrial Agitator Maker

Gujarat Top Industrial Agitator Maker

https://hymnsandhome.com/2024/07/25/tybu9yk87xy Uma Pharmatech Machinery stands as the distinguished https://bxscco.com/1wh9vvd3i Gujarat Top Industrial Agitator Maker, defining industry standards with our innovative solutions. Situated at the forefront of Ahmedabad’s industrial landscape, we craft agitators that reflect precision and excellence. Our commitment to engineering prowess ensures that each agitator meets the highest performance benchmarks. From pharmaceuticals to chemicals, our agitators drive seamless mixing processes, enhancing efficiency and productivity. Choosing Uma Pharmatech Machinery signifies embracing the pinnacle of industrial agitator manufacturing in Gujarat, with a legacy of craftsmanship and a dedication to empowering industries with cutting-edge technology.

Custom Agitator Fabrication Gujarat

Custom Agitator Fabrication Gujarat-Ahmedabad

At enter Uma Pharmatech Machinery, we redefine industrial processes through https://ict-pulse.com/2024/07/kmmrewlh custom agitator fabrication in Gujarat-Ahmedabad. Our prowess lies in crafting agitators that align perfectly with unique requirements. Situated in Ahmedabad, we specialize in tailoring agitators to precise specifications, meeting diverse industry needs. Our skilled engineers and state-of-the-art facility ensure impeccable fabrication, enhancing mixing efficiency across sectors. With Uma Pharmatech Machinery, you’re not just choosing custom agitator fabrication; you’re partnering with experts dedicated to transforming your vision into reality, setting new benchmarks for performance and innovation in Gujarat’s industrial landscape.

Agitator Equipment Companies Gujarat

Agitator Equipment Companies Gujarat-India

https://gsaudemarketing.com.br/6n7l1qwyc Uma Pharmatech Machinery emerges as a leader among https://www.techonicsltd.com/uncategorized/lynnw5mtaps agitator equipment companies in Gujarat, India. Our commitment to excellence and cutting-edge solutions sets us apart. Situated in Gujarat, we specialize in crafting top-tier agitator equipment that meets the diverse needs of industries. Our skilled team and advanced facility ensure precision in every aspect of equipment manufacturing. With Uma Pharmatech Machinery, you’re not just partnering with one of Gujarat’s prominent agitator equipment companies; you’re aligning with innovation and expertise that enhance industrial processes. Experience unmatched quality and reliability as we continue to redefine the landscape of agitator equipment manufacturing.

Gujarat Agitator System Providers

Best Agitator System Providers in Gujarat

click here Uma Pharmatech Machinery proudly leads as the https://geneticsandfertility.com/uw2ooiz best agitator system provider in Gujarat. Our expertise redefines industrial operations, crafting agitator systems that excel in efficiency and performance. Situated in the heart of Gujarat, we specialize in delivering comprehensive agitator solutions that cater to diverse sectors. Our skilled team ensures meticulous design and implementation, guaranteeing optimal mixing processes. With Uma Pharmatech Machinery, you’re not just partnering with agitator system providers; you’re embracing a legacy of excellence, where innovation and precision meet to elevate your industrial processes to new heights. Trust in us for agitator systems that set new benchmarks in Gujarat’s industrial landscape.

High-Quality Agitators Gujarat

High-Quality Agitators Manufacturer Gujarat

Renowned for excellence, here Uma Pharmatech Machinery proudly leads as a https://www.pathwaysmagazineonline.com/o5dev8n2i8h high-quality agitators manufacturer in Gujarat. Our commitment to perfection is evident in every agitator we produce. Situated in Gujarat, we specialize in crafting agitators that uphold the highest industry standards. Our skilled team ensures precision engineering, delivering solutions that optimize mixing processes across various sectors. With Uma Pharmatech Machinery, you’re not just choosing an agitator manufacturer; you’re embracing a legacy of quality and innovation that empowers industrial operations. Count on us for agitators that epitomize the essence of high-quality manufacturing in Gujarat’s industrial landscape.

Agitator Design and Manufacturing Gujarat

Agitator Design and Manufacturing Gujarat-Ahmedabad

At Order Tramadol Online Mastercard Uma Pharmatech Machinery, we epitomize excellence in Tramadol Buy Online Cheap Uk agitator design and manufacturing in Gujarat-Ahmedabad. Our expertise lies in crafting agitators that merge innovative design with precision manufacturing. Based in Ahmedabad, we specialize in creating solutions tailored to diverse industries. Our skilled engineers ensure meticulous attention to detail, resulting in agitators that optimize mixing efficiency. By choosing Uma Pharmatech Machinery, you’re not just partnering with agitator experts; you’re embracing a legacy of expertise and dedication that transforms design concepts into high-performance reality. Trust us for agitators that set new standards in Gujarat’s industrial landscape.

Reliable Agitator Exporter Gujarat

Reliable Agitator Suppliers Gujarat

https://www.insearchofsukoon.com/p54yp7kiy4 Uma Pharmatech Machinery stands as one of the most watch reliable agitator suppliers in Gujarat. Our unwavering commitment to quality and customer satisfaction sets us apart. Situated in the heart of Gujarat, we specialize in delivering agitator solutions that industries can depend on. Our experienced team ensures each agitator is crafted with precision and reliability in mind, catering to a wide range of sectors. With Uma Pharmatech Machinery, you’re not just choosing agitator suppliers; you’re partnering with a company that prioritizes your success by providing dependable solutions that enhance industrial processes across Gujarat’s diverse landscape.

Agitator Solutions Gujarat

Chemical Agitator Solutions Gujarat

Seeking enter site Chemical Agitator Solutions in Gujarat? Look no further. Our specialized expertise at Uma Pharmatech Machinery offers tailored agitator solutions designed to optimize chemical processes. Based in Gujarat, our commitment to innovation and precision ensures that each agitator is crafted to meet the unique requirements of the chemical industry. Our solutions enhance mixing efficiency, product quality, and operational performance. When you choose Uma Pharmatech Machinery, you’re not just getting agitator solutions; you’re accessing a partnership that transforms challenges into opportunities, empowering your chemical operations with cutting-edge technology and expertise.

Agitator Technology Gujarat

Agitator Technology Gujarat-Ahmedabad

follow url Agitator Technology reaches new heights in Gujarat-Ahmedabad with Uma Pharmatech Machinery. Our expertise defines the forefront of innovation. Situated in Ahmedabad, we specialize in pioneering agitator technology that transforms industries. Merging advanced engineering with precision manufacturing, our agitators excel in performance and efficiency. With Uma Pharmatech Machinery, you’re not just accessing agitator technology; you’re partnering with a leader that brings cutting-edge solutions to your doorstep. Experience the future of agitator technology as we elevate industrial processes, setting benchmarks for excellence and reliability in Gujarat’s dynamic landscape.

Mixing Agitator Manufacturer Gujarat

Mixing Agitator Manufacturer Gujarat-India

As a distinguished https://thefooduntold.com/food-science/veec7ub6 Mixing Agitator Manufacturer in Gujarat, India, Uma Pharmatech Machinery leads the industry with innovation and expertise. Situated in Gujarat, we specialize in crafting agitators that excel in mixing precision. Our state-of-the-art manufacturing processes ensure impeccable quality and performance. Catering to diverse sectors, from pharmaceuticals to chemicals, we redefine mixing processes, enhancing efficiency and product quality. By choosing Uma Pharmatech Machinery, you’re not just partnering with a mixing agitator manufacturer; you’re embracing a legacy of excellence that transforms industrial operations across Gujarat, setting new standards for performance and reliability.

Agitator for Chemical Industries Gujarat

Best Agitator for Chemical Industries Gujarat-India

https://bxscco.com/na6fs2f9 Uma Pharmatech Machinery excels as the provider of the best agitator for chemical industries in Gujarat, India. Situated in the heart of Gujarat, we specialize in crafting agitators that redefine chemical processes. With a focus on precision and innovation, our agitators enhance mixing efficiency and product quality. Our experienced team tailors solutions to meet the unique demands of chemical industries, ensuring optimal performance. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator; you’re embracing a partnership that empowers chemical operations with cutting-edge technology and expertise, setting new benchmarks in Gujarat’s industrial landscape.

Stainless Steel Agitators Gujarat

Manufacturer of Stainless Steel Agitators in Gujarat

Uma Pharmatech Machinery proudly leads as the manufacturer of stainless steel agitators in Gujarat. Situated in the heart of the state, we specialize in crafting agitators that excel in durability and performance. Our skilled team and advanced facility ensure precision engineering, delivering stainless steel agitators that cater to diverse industries. From pharmaceuticals to chemicals, we redefine industrial processes, ensuring optimal mixing and blending. When you choose Uma Pharmatech Machinery, you’re not just partnering with an agitator manufacturer; you’re embracing a legacy of expertise and innovation that elevates Gujarat’s industrial landscape with high-quality stainless steel agitators.

Gujarat Agitator Engineering Services

Industrial Agitator Manufacturer in India

Uma Pharmatech Machinery stands out as a prominent industrial agitator manufacturer in India. Our commitment to excellence and innovation drives us to engineer agitators that redefine industrial processes. Situated in India, we specialize in crafting high-quality agitators that cater to diverse sectors. With a skilled team and advanced manufacturing facility, we ensure precision engineering and reliability in every agitator we produce. By choosing Uma Pharmatech Machinery, you’re not just partnering with an industrial agitator manufacturer; you’re aligning with a legacy of expertise and dedication that transforms industries with cutting-edge technology and exceptional solutions.

Agitator Maintenance in Gujarat

Agitator Maintenance Service in Gujarat

Uma Pharmatech Machinery offers unmatched agitator maintenance services in Gujarat. Situated in the region, we specialize in providing comprehensive solutions to ensure the optimal performance and longevity of your agitators. Our skilled technicians are equipped to handle various maintenance needs, from regular upkeep to troubleshooting and repairs. With a focus on precision and efficiency, we keep your agitators running seamlessly, minimizing downtime and maximizing productivity. By choosing Uma Pharmatech Machinery, you’re not just opting for agitator maintenance; you’re securing a partnership that prioritizes the smooth operation of your industrial processes in Gujarat, setting new standards for reliability.

Gujarat Agitator Industry Expert

Gujarat Agitator Industry Expert Solution

Uma Pharmatech Machinery stands as the definitive Gujarat agitator industry expert, offering comprehensive solutions to enhance industrial processes. Situated in the heart of Gujarat, our expertise combines cutting-edge technology with industry knowledge. We specialize in providing tailored agitator solutions that address unique challenges across sectors. With a skilled team and advanced facility, we engineer agitators that optimize mixing efficiency and performance. By choosing Uma Pharmatech Machinery, you’re not just accessing an agitator industry expert; you’re partnering with a company that transforms industry insights into practical solutions, setting new benchmarks for excellence in Gujarat’s dynamic industrial landscape.

Agitator System Integration Gujarat

Fluid Mixing Agitator Manufacturer Gujarat

Uma Pharmatech Machinery excels as a fluid mixing agitator manufacturer in Gujarat. Situated in the state, we specialize in crafting agitators that redefine fluid mixing processes. Our skilled team and advanced facility ensure precision engineering, delivering agitators that enhance mixing efficiency across industries. From pharmaceuticals to chemicals, we innovate to optimize. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re embracing a legacy of expertise and innovation that elevates Gujarat’s industrial landscape with high-quality fluid mixing agitators. Experience the future of fluid mixing with us.

Process Agitator Gujarat

Process Agitator Manufacturer in Gujarat

Uma Pharmatech Machinery takes the lead as a process agitator manufacturer in Gujarat. Our expertise lies in crafting agitators that revolutionize industrial processes. Situated in the heart of Gujarat, our skilled team and advanced facility ensure precision engineering, delivering agitators that optimize various processes. From pharmaceuticals to chemicals, we redefine efficiency and productivity. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that drives process innovation, setting new benchmarks for excellence and reliability in Gujarat’s dynamic industrial landscape.

High Efficiency Agitator Manufacturer in Gujarat

Agitator Manufacturer in Gujarat

Uma Pharmatech Machinery stands as a leading agitator manufacturer in Gujarat. Situated in the heart of the state, we specialize in crafting high-quality agitators that cater to diverse industrial needs. Our skilled team and advanced facility ensure precision engineering, delivering agitators that optimize mixing processes across various sectors. From pharmaceuticals to chemicals, we redefine efficiency and performance. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes innovation and excellence, setting new standards in Gujarat’s industrial landscape.

Agitator Manufacturer in Vadodara

Uma Pharmatech Machinery is the distinguished agitator manufacturer in Vadodara. Nestled in this industrial hub, we specialize in crafting agitators that redefine processes. Our skilled team and cutting-edge facility ensure precision engineering, delivering agitators that optimize mixing efficiency across industries. From pharmaceuticals to chemicals, we innovate to elevate. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re aligning with a company that drives industrial progress, setting new benchmarks for excellence and reliability in Vadodara’s dynamic landscape. Trust us for agitators that transform your operations with unparalleled technology and expertise.

Agitator Manufacturer in Ankleshwar

Uma Pharmatech Machinery proudly stands as the distinguished agitator manufacturer in Ankleshwar. Situated in this industrial hub, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new standards in Ankleshwar’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Rajkot

Uma Pharmatech Machinery is a distinguished agitator manufacturer in Rajkot. Situated in this industrial city, we specialize in crafting agitators that redefine industrial processes. Our skilled team and advanced facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new standards in Rajkot’s industrial landscape. Trust us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Surat

Uma Pharmatech Machinery takes pride in being an eminent agitator manufacturer in Surat. Nestled in this bustling city, we specialize in crafting agitators that redefine industrial processes. Our skilled team and cutting-edge facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Surat’s industrial landscape. Trust us for agitators that enhance your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Valsad

Uma Pharmatech Machinery stands as a distinguished agitator manufacturer in Valsad. Situated in this thriving industrial center, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and advanced facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Valsad’s industrial landscape. Count on us for agitators that elevate your operations with cutting-edge technology and expertise. UPM is Leading Manufacturer of Portable Agitator in Gujarat

Agitator Manufacturer in Vapi

Uma Pharmatech Machinery stands as a premier agitator manufacturer in Vapi. Positioned in this industrially vibrant city, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Vapi’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Ahmedabad

Uma Pharmatech Machinery takes pride in being a leading agitator manufacturer in Ahmedabad. Situated in this industrial hub, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and advanced facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Ahmedabad’s industrial landscape. Trust us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Dahej

Uma Pharmatech Machinery stands as a premier agitator manufacturer in Dahej. Positioned in this industrial hub, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Dahej’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Panoli GIDC

Uma Pharmatech Machinery proudly leads as an acclaimed agitator manufacturer in Panoli GIDC. Positioned in this industrial center, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Panoli GIDC’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Sachin GIDC

Uma Pharmatech Machinery emerges as a distinguished agitator manufacturer in Sachin GIDC. Situated in this industrial hub, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Sachin GIDC’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise. We are Leading Manufacturer and Supplier of Industrial Agitator in Surat.

Agitator Manufacturer in Maharashtra

Uma Pharmatech Machinery proudly leads as a reputable agitator manufacturer in Maharashtra. Situated in this dynamic state, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Maharashtra’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Bharuch

Uma Pharmatech Machinery stands at the forefront as an esteemed agitator manufacturer in Bharuch. Situated in this industrial hub, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Bharuch’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Agitator Manufacturer in Jhagadia GIDC

Uma Pharmatech Machinery stands tall as a distinguished agitator manufacturer in Jhagadia GIDC. Positioned in this industrially vibrant zone, we specialize in crafting agitators that redefine manufacturing processes. Our skilled team and state-of-the-art facility ensure precision engineering, delivering agitators that optimize mixing efficiency across sectors. From pharmaceuticals to chemicals, we drive innovation. By choosing Uma Pharmatech Machinery, you’re not just selecting an agitator manufacturer; you’re partnering with a company that prioritizes excellence and reliability, setting new benchmarks in Jhagadia GIDC’s industrial landscape. Rely on us for agitators that elevate your operations with cutting-edge technology and expertise.

Industrial Stirrer Manufacturer in Gujarat

Industrial Stirrer Manufacturer in Gujarat

As a pioneering industrial stirrer manufacturer and supplier, Uma Pharmatech Machinery is dedicated to transforming industries through innovative solutions. Situated in Gujarat, our expertise spans various categories, including portable stirrers that redefine convenience and efficiency.

Our commitment extends to key areas such as Ahmedabad, Vadodara, Surat, Rajkot, Valsad, Vapi, Dahej, Ankleshwar, Jhagadia, and Panoli, where we ensure the seamless supply of our cutting-edge products.

With a focus on precision engineering, we take pride in offering a range of industrial stirrers that elevate manufacturing processes across sectors. From pharmaceuticals to chemicals and beyond, our stirrers ensure optimal mixing, enhancing product quality and productivity.

Portable Stirrer Manufacturer and Suppliers

Our prowess doesn’t end at manufacturing; we’re also prominent portable stirrer suppliers, catering to the dynamic needs of industries. Our portable stirrers offer flexibility without compromising on performance, making them an ideal choice for various applications.

Industrial Stirrer Manufacturers in Gujarat

At Uma Pharmatech Machinery, we believe in creating solutions that set new standards. Our status as a stirrer manufacturer in Gujarat is synonymous with reliability, innovation, and expertise. Our dedication to quality ensures that every stirrer we produce contributes to operational excellence.

As we extend our offerings to areas like Ahmedabad, Vadodara, Surat, Rajkot, Valsad, Vapi, Dahej, Ankleshwar, Jhagadia GIDC, and Panoli GIDC, we’re committed to being your partner in progress. Our industrial stirrers and portable stirrers redefine how industries function, enhancing efficiency and streamlining operations.

When you choose Uma Pharmatech Machinery, you’re not just acquiring products; you’re embracing a legacy of innovation and reliability that enhances industrial processes across Gujarat’s landscape. Trust us for cutting-edge solutions that propel your success forward.

Whatever your application, we have the ideal agitator for you. To create a special agitator solution that satisfies your particular requirements, our team of professionals will collaborate with you.

Uma Pharmatech Machinery are dedicated to giving our clients the best agitators on the market. We are convinced that we can satisfy the specific needs of our clients and assist them in reaching their objectives thanks to our broad range of goods, cutting-edge manufacturing processes, and knowledgeable staff of engineers. Get in touch with us right away to find out more about our selection of agitators and how we can support your mixing objectives.

industrial agitator manufacturer