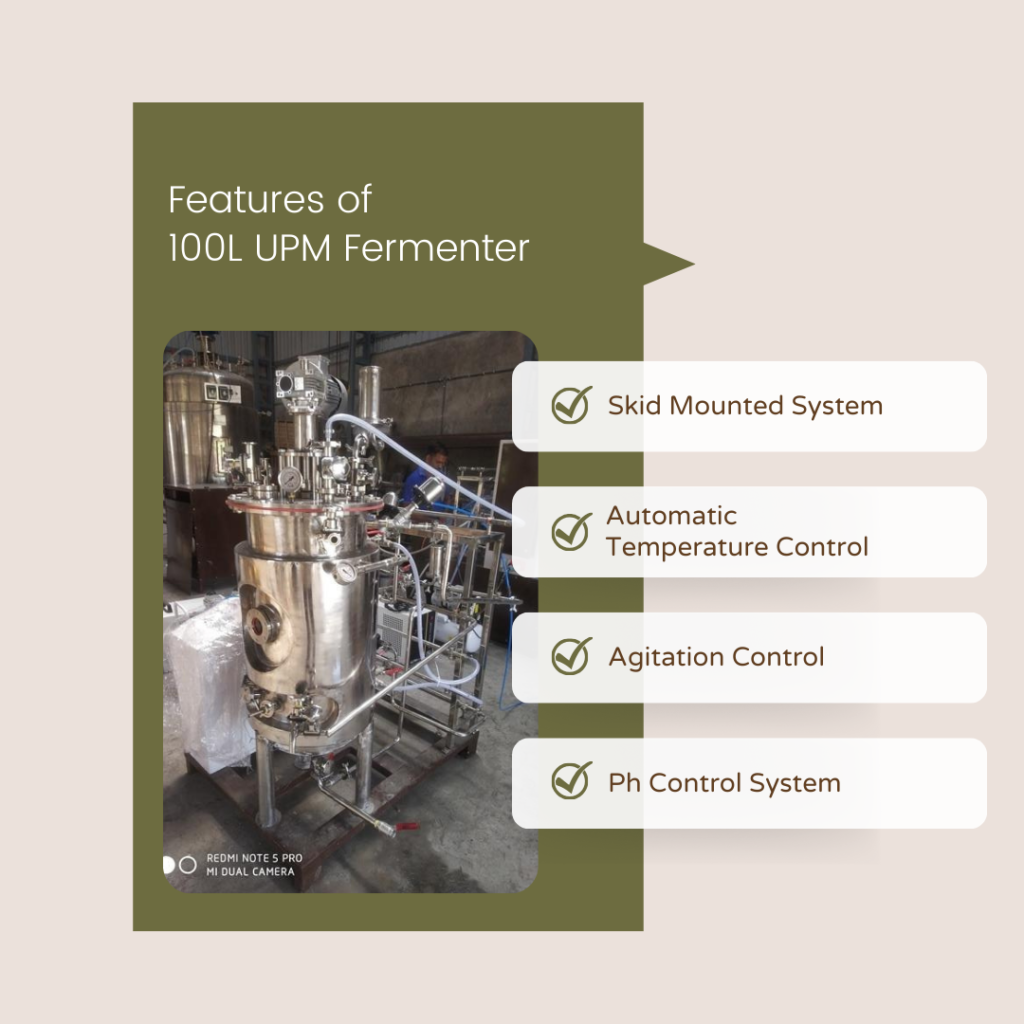

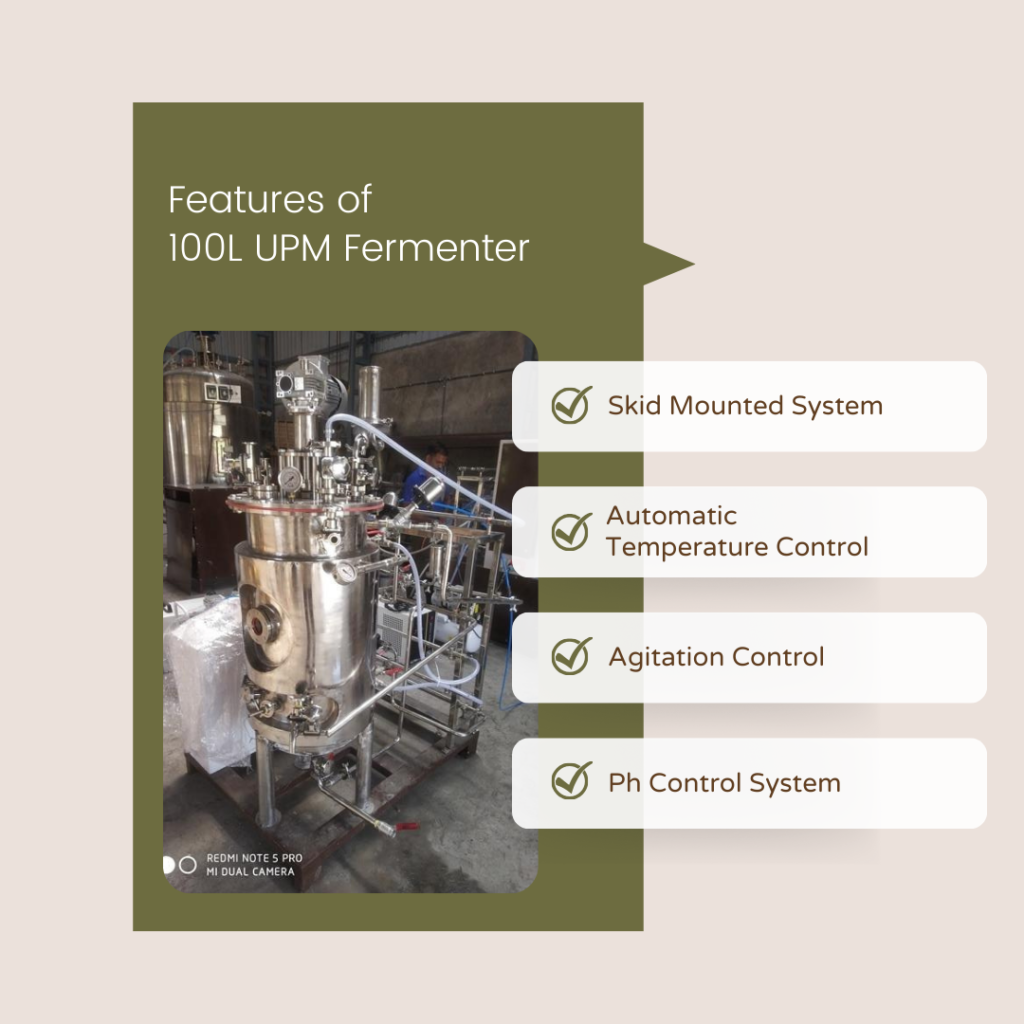

Advanced Features Of UPM Fermenter Bioreactors

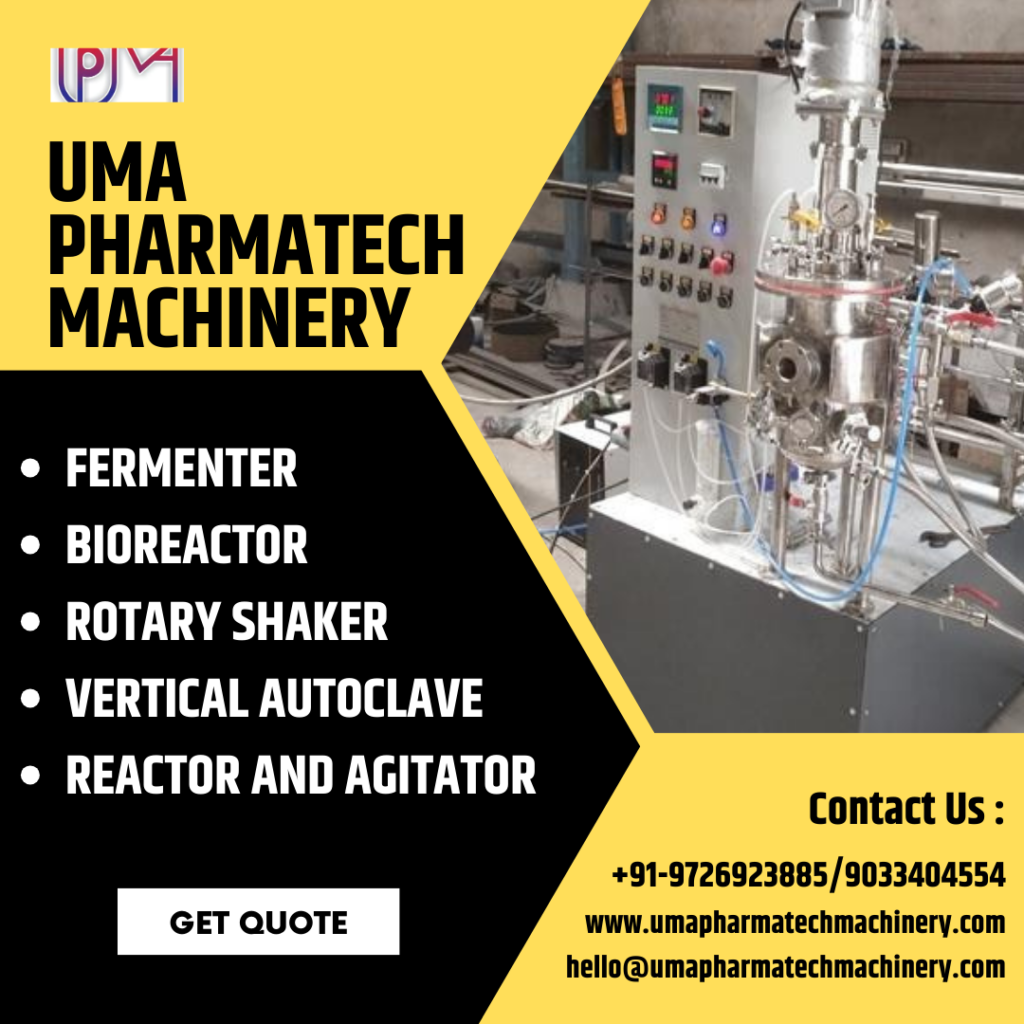

Working Volume( Liter): 70% Of Total Volumes

What material is used for fermenter?

Generally SS316L Material Is Used In Fermenter For Contact Part. SS304 or Mild Steel Material Is Used In Jacket and Non Contact Parts.

Wetted parts are SS316L/ Toughen or Borosilicate Glass, and others is SS304

Surface Finish inside surface is Matt finish

Agitation Bioreactor use Elmech decelerator

top mechanical agitator with six blade Ruston Turbines, one Top Space Mechanical Foam Breaker Or Liquid Palm Oil Deformer and four baffles(Vessel Día/12).

Single Dry mechanical seal (single or double mechanical seal With Heat Trap For High Temperature With Cooling Facilities)

speed range 0-300rpm (it depends on the size and Critical speed and pumping rate of the Agitators and baffles)

Top Entry With Shaft Jointed With Flexible Removal Couple agitator with speed variation from 100 to 1000 RPM

Using alcohol flame inoculation

Aseptic sampling and Zero Dead Flush bottom valve

CIP & SIP system inbuilt Cleaning and Sterilization.

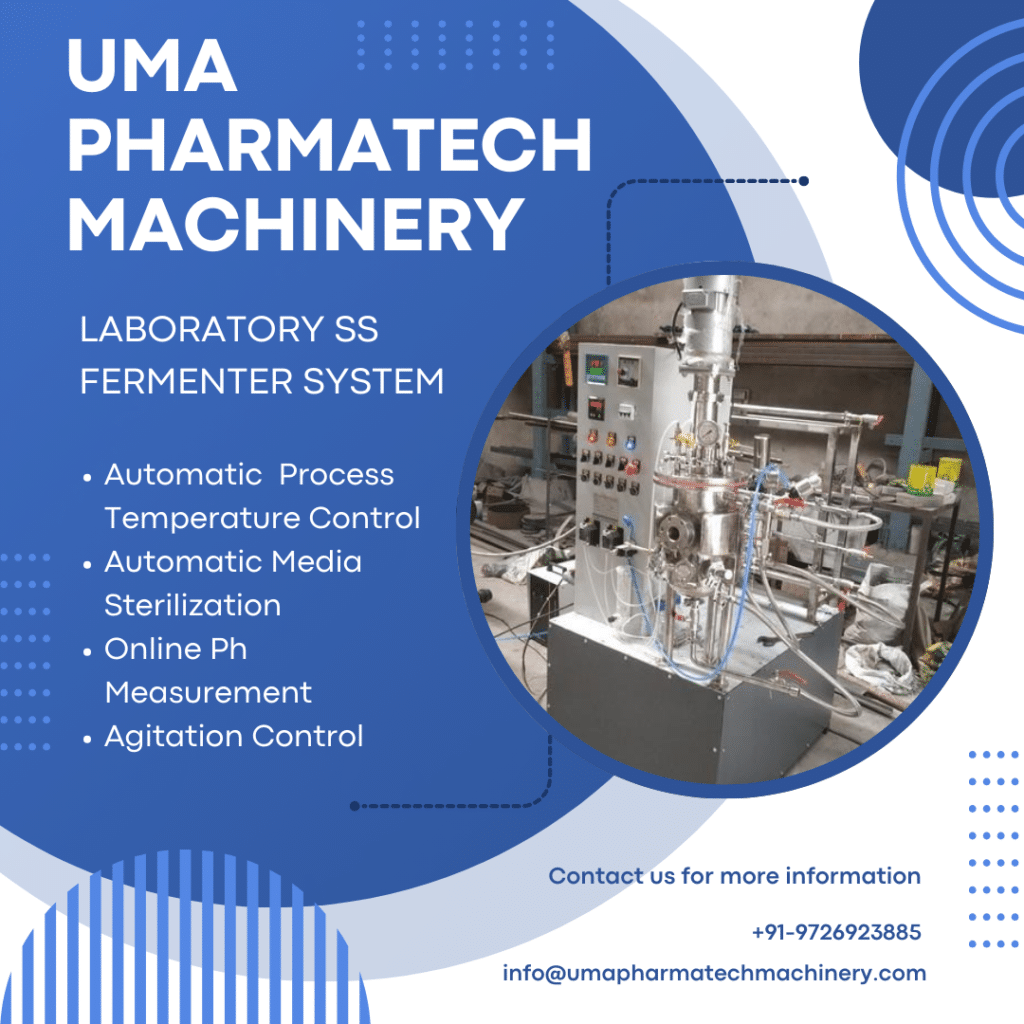

In Line PH, Inline DO, In Line temperature Measurement sensor on lower side, site glass, top with foam and Media level Electrode or Sensors.

Leg/ Lug Support Type Bioreactor vessel with Common control Panel

Capacity 10

0L to 40000L

Max Temperature (degree Celsius)250

Our Products For Biotech:

Uma Pharma provides a comprehensive range of laboratory equipment and supplies. Among our offerings are:

Autoclaves for laboratories: Our autoclaves for laboratories are designed to meet the needs of modern laboratories. They are dependable, efficient, and simple to use.

Laboratory Shakers: Our laboratory shakers are built to deliver precise and dependable results. They are ideal for a variety of laboratory applications.

UPM laboratory Bioreactors are designed to provide precise temperature control and uniform heating. They are ideal for a variety of laboratory applications.

Laboratory Incubators: Our laboratory incubators are built to provide precise temperature control and a stable environment for microorganism growth. They are ideal for a variety of laboratory applications.

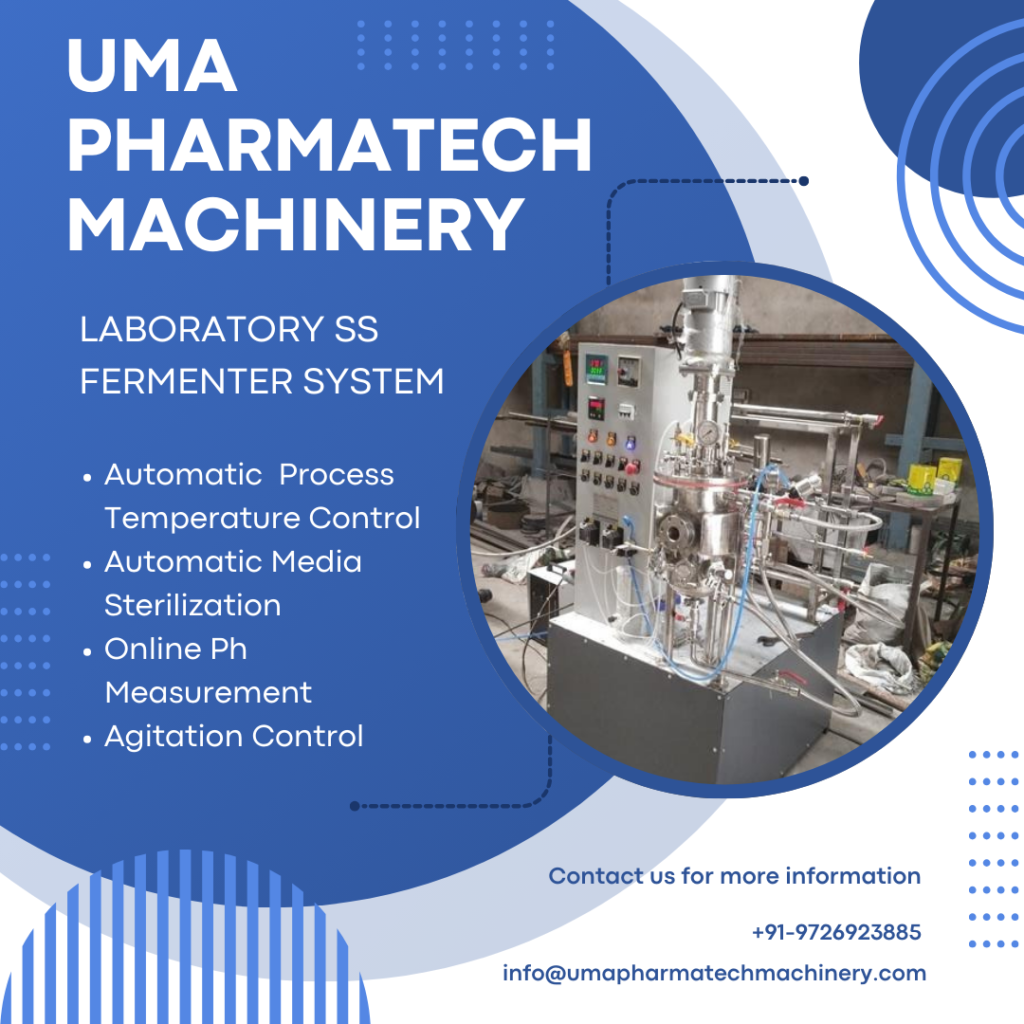

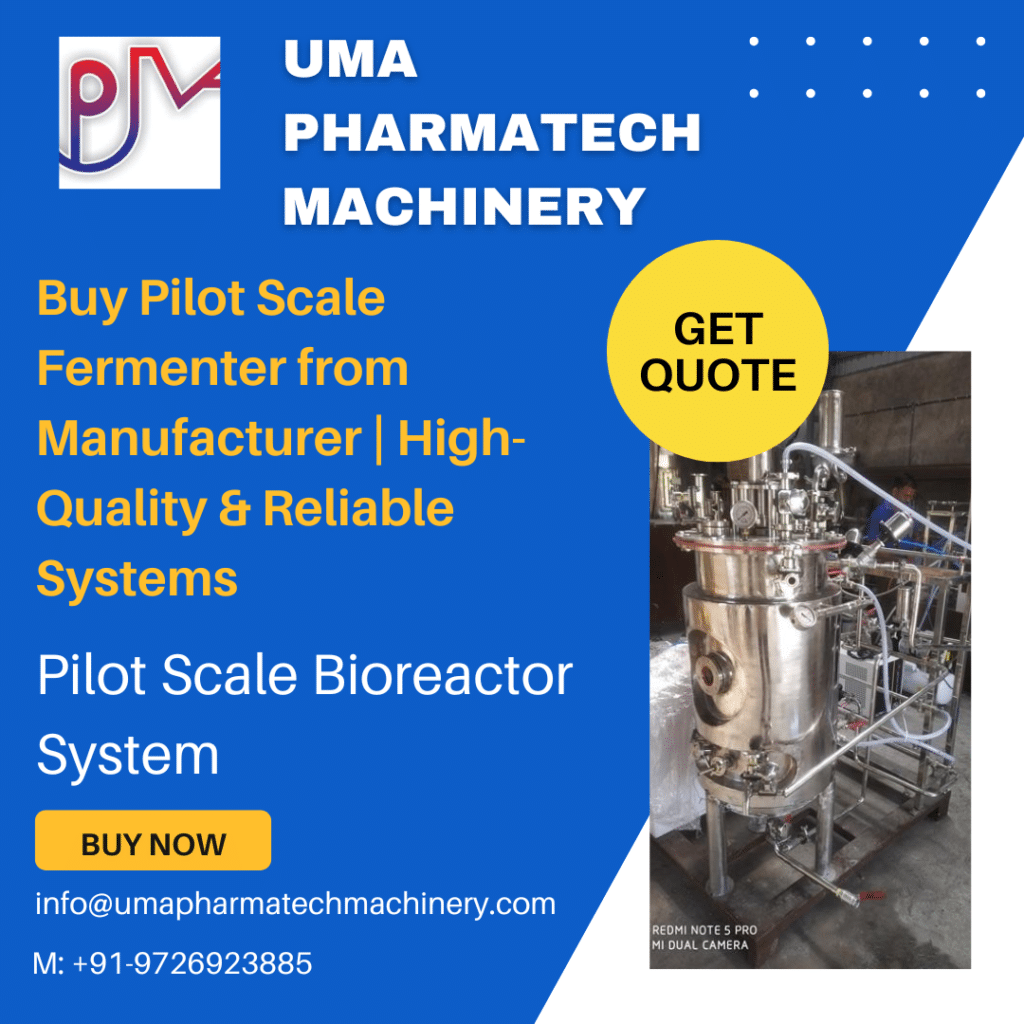

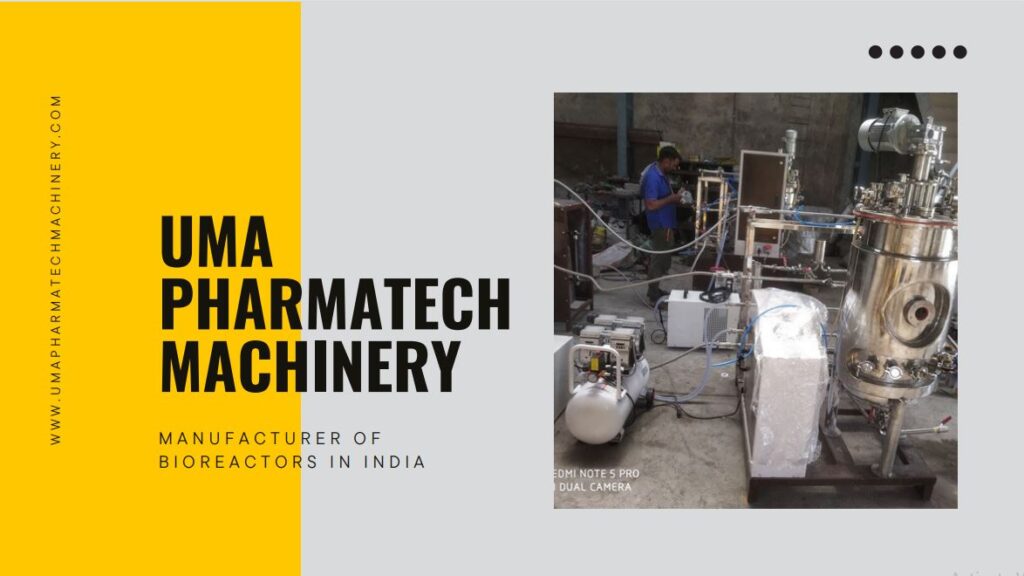

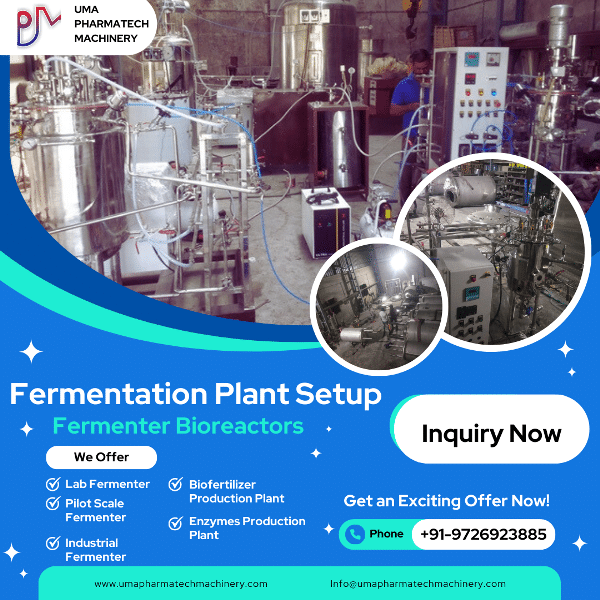

FERMENTER MANUFACTURER IN AHMEDABAD

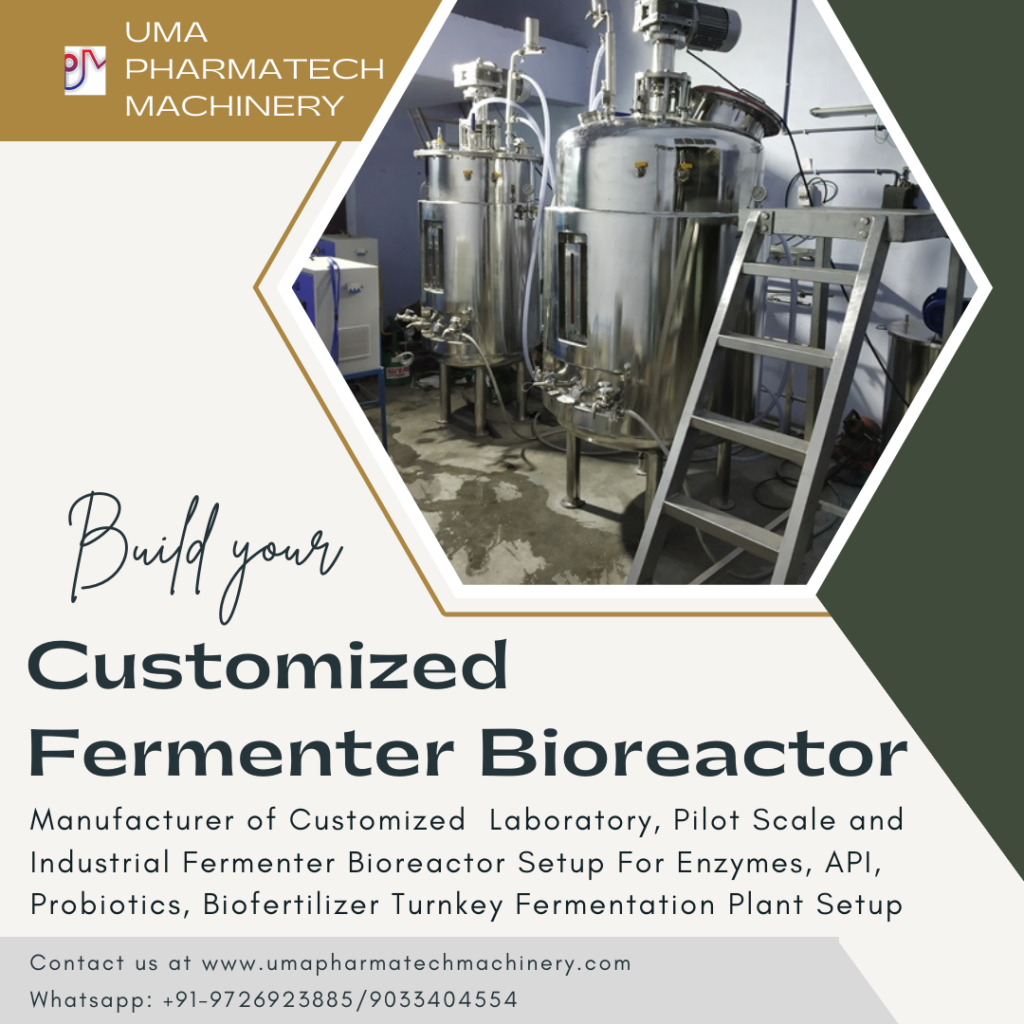

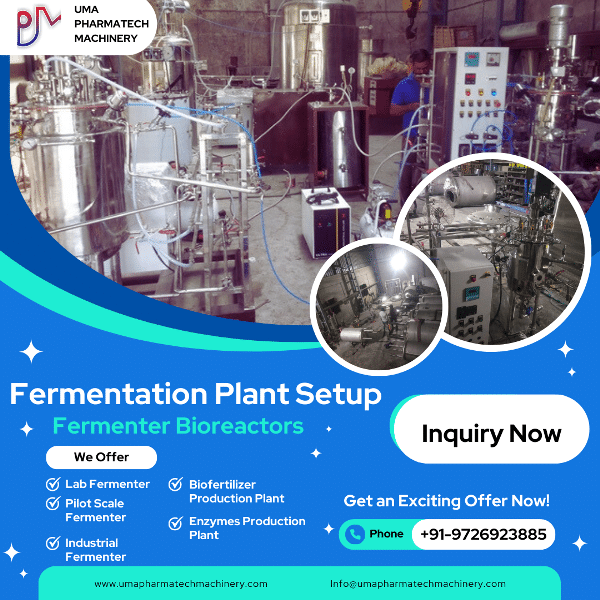

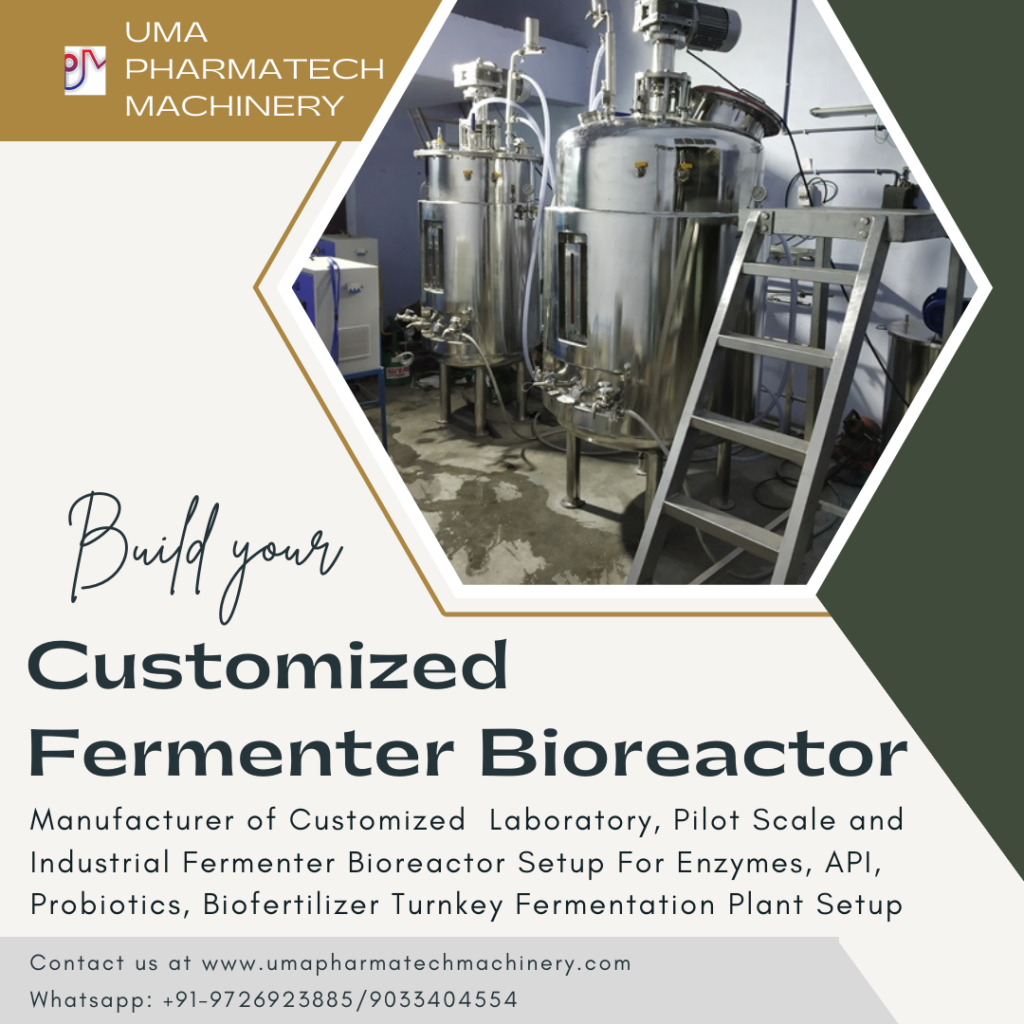

UMA PHARMATECH MACHINERY IS Leading Fermenter manufacturer in Ahmedabad. We Manufacture and Export stainless steel Fermenter From Laboratory scale to Industrial scale. which are suitable for cultivation of microbial culture & bacterial derived Enzymes.

Uma Pharmatech Machinery is your reliable source for high-quality laboratory equipment and supplies. We are a leading laboratory equipment manufacturer and supplier, offering dependable and innovative solutions to customers all over the world. UPM’s mission is to provide the highest quality products and services to our customers.

Specific characteristics of these fermenters is Attached below:

- Automatic Media preparation System

- Automatic Media Sterilization System

- Proper Mixing

- High Pumping Capacity

- Sterile Harvesting System

- Collection and tank holding system

- Precipitation Controlling

- in line pH Measurement and controlling

- in line Media and Inoculation feeding

- in line Foam control using Mechanical Deformer

Uma Pharmatech Machinery Bioreactor Construction is Very Compact Because industrial Instruments and parts of Own makes for easy Maintenance and Replace into any production facility. UPM Fermenter design Specification come with the following advantages:

Standard Aspect Ratio design (L: D ratio 2:1 optimization)

Low space Cover

Range: 10L – 40000L

Automatic and Semi Automatic in configuration to meet the Customer Requirements.

difference between bioreactor and fermentor?

What are the two types of bioreactors?

Generally Two Types Of Bioreactor Available as Per Sterilization Method

1) Insitu Serializable Bioreactors

2) Autoclavable Bioreactors

Insitu Bioreactors Made Of Stainless Steel Material. For Sterilize this Bioreactor Require Steam Generator Or Boiler. In This Bioreactor In Place Sterilization Is Possible

Where as Autoclavable Bioreactors are Made Of Borosilicate Glass Material. Autoclave Is Require To Sterile This Fermenter Bioreactor. In This Bioreactor IN place SIP(Sterilize in Place) Not Possible. Motor and Other Accessory Is to Remove From Bioreactor To Sterile Before Place In to The Bioreactor.

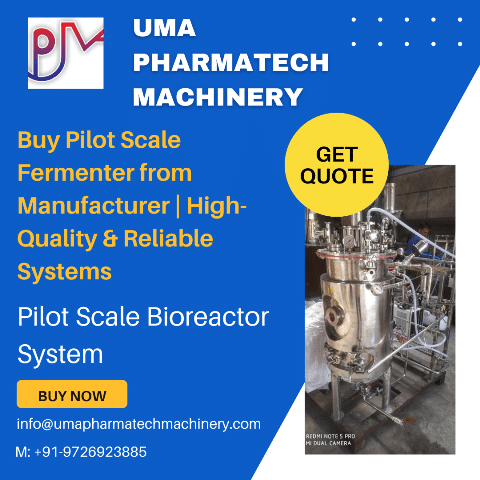

Bioreactor Is Special Designed System To Manufacture Bio Product and Biostudy With Absence Of Environment Condition. For Cell Culture and Mammalian Cell Development Bioreactor Is Require With Automatic Control Parameter Like ph., Temperature, Pressure, Agitation Control. In Pilot Scale Bioreactor Also Called as Fermenter

There are Many Types Of Bioreactors

1) Cell Culture Bioreactors

2) Photo Bioreactors

3) Single Use Bioreactors

4) Bacterial Bioreactors

5) Glass Bioreactors

6) Stainless Steel Bioreactors

7) Pilot Scale Fermenter Bioreactors

8) Lab Scale Fermenter Bioreactors

9) Industrial Fermenter Bioreactors

Basic Bio Engineering

Basic Bio Engineering is the foundation for any industrial project, ensuring the seamless integration of various processes and systems. When designing a fermentation plant, the basic engineering phase involves detailed planning and analysis to ensure that all components work together efficiently. This phase includes the creation of process flow diagrams, material and energy balances, and preliminary equipment sizing. Effective basic engineering helps in minimizing costs and maximizing efficiency, making it an essential step in the development of any fermentation facility.

Cost Analysis for Process Plant Equipment

Conducting a Cost Analysis for Process Plant Equipment is crucial for budget management and financial planning. This analysis involves estimating the capital and operating costs associated with the equipment used in the fermentation process. By understanding the costs involved, businesses can make informed decisions on equipment purchases, maintenance, and upgrades. Accurate cost analysis also helps in identifying potential cost-saving opportunities and ensuring the economic viability of the project.

Turnkey Solutions

Turnkey Solutions in the fermentation industry refer to comprehensive services provided by manufacturers and suppliers, covering everything from design and engineering to installation and commissioning. These solutions ensure that the entire project is managed efficiently and delivered on time. Turnkey solutions are particularly beneficial for businesses looking to establish new fermentation plants or upgrade existing ones, as they provide a hassle-free experience with a single point of contact for all project needs.

Revamping Old Fermenter

Revamping old fermenter systems can significantly improve their performance and extend their lifespan. Upgrading outdated fermenters with modern technology and components can enhance efficiency, reduce energy consumption, and improve product quality. This process may involve replacing worn-out parts, integrating advanced control systems, and optimizing fermentation conditions. Revamping is a cost-effective alternative to purchasing new equipment and helps in maintaining competitive production capabilities.

Solaris Biotech Applications

Solaris Biotech Applications encompass a wide range of solutions for the biotechnology industry, including fermenters, bioreactors, and other processing equipment. Solaris Biotech offers innovative and customized solutions to meet the specific needs of various applications, such as pharmaceuticals, food and beverage production, and biofuels. Their state-of-the-art equipment ensures high performance, reliability, and scalability, making them a preferred choice for biotech companies worldwide.

Beer Fermenters

Beer Fermenters are specialized tanks used in the brewing process to convert wort into beer through fermentation. These fermenters are designed to maintain optimal conditions for yeast activity, ensuring consistent and high-quality beer production. Various types of beer fermenters are available, including conical fermenters, cylindrical fermenters, and unitanks, each offering unique advantages depending on the brewing requirements.

Brewing Fermenter Types

There are several Brewing Fermenter Types used in the beer industry, each with specific features and benefits. Conical fermenters, for example, allow for easy yeast harvesting and sediment removal, while cylindrical fermenters are ideal for large-scale production due to their simple design and ease of cleaning. Choosing the right type of fermenter is crucial for achieving the desired beer quality and production efficiency.

Dairy-Processing

Dairy-Processing involves the transformation of raw milk into various dairy products, such as cheese, yogurt, and butter. This process requires specialized equipment to ensure the safe and efficient handling of milk and other ingredients. Fermenters play a key role in dairy processing by facilitating the fermentation of milk into products like yogurt and kefir. Ensuring the proper design and operation of dairy-processing equipment is essential for maintaining product quality and safety.

Processing Equipment Installation

Processing Equipment Installation is a critical phase in setting up a fermentation plant. Proper installation ensures that all equipment operates correctly and safely. This phase includes site preparation, equipment positioning, piping and electrical connections, and initial testing. Professional installation services ensure that the equipment meets industry standards and regulations, reducing the risk of operational issues and downtime.

Equipment Transportation

Equipment Transportation involves the safe and efficient movement of fermentation equipment from the manufacturer to the installation site. This process requires careful planning and coordination to prevent damage and ensure timely delivery. Specialized transportation services may be needed for large or sensitive equipment, such as fermenters and bioreactors, to ensure they arrive in optimal condition and are ready for installation.

Tank Modifications and Alterations

Tank Modifications and Alterations are often necessary to adapt existing tanks for new processes or improve their performance. Modifications can include changes to tank size, shape, or configuration, as well as the addition of new features like agitation systems or temperature control. These alterations can enhance the efficiency and versatility of the tanks, making them suitable for a wider range of applications.

Fermenter Manufacturer, Fermenter Manufacturer in India - UPM

As a leading Fermenter Manufacturer, Fermenter Manufacturer in India – UPM (Uma Pharmatech Machinery) specializes in producing high-quality fermenters and bioreactors for various industries. UPM’s products are known for their durability, efficiency, and advanced technology. Their comprehensive range of fermenters caters to the needs of pharmaceutical, biotech, and food and beverage industries, ensuring optimal fermentation performance and product quality.

Salient Features of Biotree Fermenter Manufacturers

The Salient Features of Biotree Fermenter Manufacturers include advanced design, robust construction, and user-friendly operation. Biotree fermenters are equipped with state-of-the-art control systems, ensuring precise monitoring and control of fermentation parameters. Their fermenters are designed for scalability, making them suitable for both laboratory and industrial-scale production. The use of high-quality materials and components ensures long-term reliability and minimal maintenance requirements.

Industrial Fermenter Manufacturers & Suppliers in India

Industrial Fermenter Manufacturers & Suppliers in India provide a wide range of fermenters and bioreactors for various applications. These manufacturers offer customized solutions to meet the specific needs of their clients, ensuring optimal performance and efficiency. By choosing reputable manufacturers and suppliers, businesses can benefit from high-quality equipment, excellent customer support, and competitive pricing.

Find here Industrial Fermenter, Industrial Bioreactor manufacturers & OEM manufacturers in India. Get Contact details & address of companies manufacturing and supplying Industrial Fermenter, Industrial Bioreactor across India.

To Find here Industrial Fermenter, Industrial Bioreactor manufacturers & OEM manufacturers in India, businesses can explore various directories and industry platforms. These resources provide detailed information on manufacturers and suppliers, including contact details, product offerings, and customer reviews. Utilizing these platforms can help businesses make informed decisions and find reliable partners for their fermentation equipment needs.

Industrial Fermenter

An Industrial Fermenter is a large-scale fermentation vessel used for the production of pharmaceuticals, biofuels, food products, and other biotechnological products. These fermenters are designed to handle large volumes of culture media and provide precise control over fermentation conditions. Industrial fermenters are essential for scaling up laboratory processes to commercial production levels.

Gas Liquid Fermenter

A Gas Liquid Fermenter is designed to facilitate the efficient mixing and dispersion of gases into the liquid culture medium. This type of fermenter is commonly used in processes that require the introduction of gases, such as oxygen or carbon dioxide, to support microbial growth and metabolism. Gas-liquid fermenters are widely used in the production of biofuels, pharmaceuticals, and other biotechnological products.

Industrial Fermenter Or Bioreactor, Size: 100 L To 1000 L, Capacity: 500 Liters

Industrial Fermenter Or Bioreactor, Size: 100 L To 1000 L, Capacity: 500 Liters refers to a range of fermenters and bioreactors designed for medium-scale production. These units are suitable for pilot-scale studies and small-scale industrial production. They offer precise control over fermentation conditions and are equipped with advanced monitoring and control systems to ensure optimal performance.

5Ltrs Laboratory Fermenter- South Africa, For Industrial

The 5Ltrs Laboratory Fermenter- South Africa, For Industrial is a small-scale fermenter designed for laboratory use. It is ideal for research and development, process optimization, and small-scale production. This fermenter offers precise control over fermentation conditions and is equipped with features that facilitate easy operation and maintenance.

SS 316 Stainless Steel Fermenter

An SS 316 Stainless Steel Fermenter is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion. SS 316 is commonly used in the construction of fermenters due to its excellent chemical resistance and mechanical properties. These fermenters are suitable for a wide range of applications, including pharmaceutical, food, and beverage production.

Autoclavable Glass Fermenter, Bangalore - 1L To 7L, For Industrial

An Autoclavable Glass Fermenter, Bangalore – 1L To 7L, For Industrial is designed for small-scale fermentation processes. The use of glass allows for easy observation of the fermentation process, and the autoclaving capability ensures sterility. These fermenters are commonly used in research and development, process optimization, and small-scale production.

Bio Fermenter, Size: 100 MM Dia To 2000 MM Diameter, Capacity: 1-5000 Ltrs

A Bio Fermenter, Size: 100 MM Dia To 2000 MM Diameter, Capacity: 1-5000 Ltrs is a versatile fermentation vessel designed for various biotechnological applications. These fermenters offer a wide range of sizes and capacities, making them suitable for both laboratory and industrial-scale production. They are equipped with advanced control systems to ensure optimal fermentation conditions.

Bio Fermenter, Size: 100 MM Dia To 2000 MM Diameter, Capacity: 1-5000 Ltrs

A Bio Fermenter, Size: 100 MM Dia To 2000 MM Diameter, Capacity: 1-5000 Ltrs is a versatile fermentation vessel designed for various biotechnological applications. These fermenters offer a wide range of sizes and capacities,

Borosilicate Single Column Bubble Photobioreactor (100 Ltr)

A Borosilicate Single Column Bubble Photobioreactor (100 Ltr) is designed for the cultivation of photosynthetic microorganisms. The use of borosilicate glass ensures high transparency and chemical resistance. This type of photobioreactor is ideal for research and development, as well as small-scale production.

30l Conicial Fermenter - C6675

The 30l Conicial Fermenter – C6675 is designed for small to medium-scale production. The conical shape allows for easy yeast harvesting and sediment removal. This fermenter is equipped with advanced control systems to ensure precise monitoring and control of fermentation conditions.

SS Bio Fermenter, Capacity: 100 Liters

An SS Bio Fermenter, Capacity: 100 Liters is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion. These fermenters offer advanced monitoring and control systems to ensure optimal fermentation conditions. They are suitable for various applications, including pharmaceuticals, biofuels, and food production.

Plant Capacity: 2000 m3 Commercial Biogas Plant

A Plant Capacity: 2000 m3 Commercial Biogas Plant is designed for the large-scale production of biogas. This plant utilizes advanced fermentation technology to convert organic waste into biogas, providing a sustainable and renewable energy source. The plant is equipped with monitoring and control systems to ensure efficient and safe operation.

Automatic Fermentation Machine, For LAB EXPERIMENT

An Automatic Fermentation Machine, For LAB EXPERIMENT is designed for laboratory use. This machine offers precise control over fermentation conditions and is equipped with advanced monitoring and control systems. It is ideal for research and development, process optimization, and small-scale production.

Industrial And Laboratory Fermenter

Industrial And Laboratory Fermenter systems are designed to meet the needs of both large-scale production and research and development. These fermenters offer advanced monitoring and control systems to ensure optimal fermentation conditions. They are suitable for various applications, including pharmaceuticals, biofuels, and food production.

Conical Fermenters

Conical Fermenters are designed for easy yeast harvesting and sediment removal. The conical shape allows for efficient separation of solids from the liquid culture medium. These fermenters are widely used in the brewing industry, as well as in the production of other biotechnological products.

Laboratory Equipment

Laboratory Equipment includes a wide range of tools and devices used in research and development. In the context of fermentation, laboratory equipment includes fermenters, bioreactors, and monitoring systems. Ensuring the proper selection and use of laboratory equipment is essential for achieving accurate and reliable results.

Bio Fertilizer Plant

A Bio Fertilizer Plant is designed for the production of biofertilizers. These plants utilize advanced fermentation technology to convert organic waste into biofertilizers, providing a sustainable and eco-friendly alternative to chemical fertilizers. The plant is equipped with monitoring and control systems to ensure efficient and safe operation.

Fermentation Equipment

Fermentation Equipment includes a wide range of tools and devices used in the fermentation process. This equipment includes fermenters, bioreactors, agitation systems, temperature control systems, and monitoring devices. Ensuring the proper selection and use of fermentation equipment is essential for achieving optimal fermentation conditions and high-quality products.

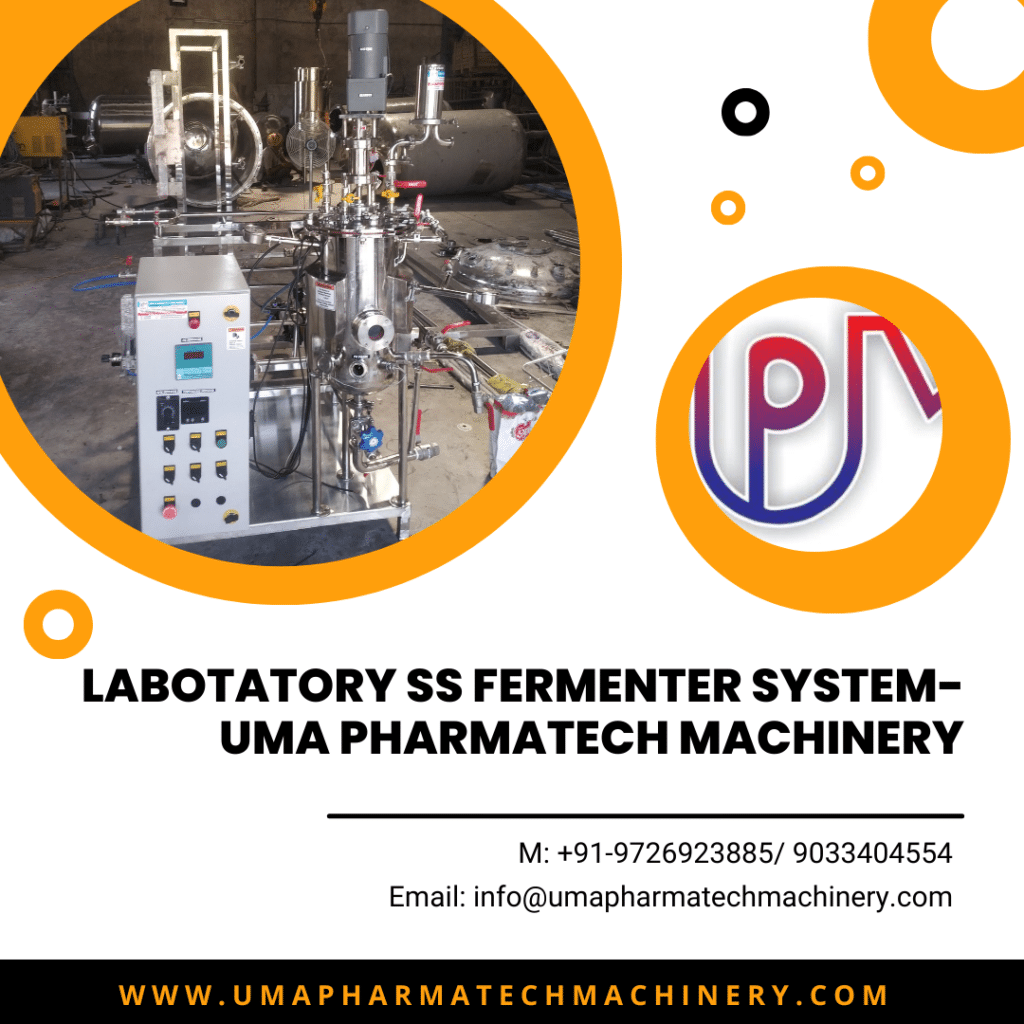

Laboratory Fermenter

A Laboratory Fermenter is designed for research and development, process optimization, and small-scale production. These fermenters offer precise control over fermentation conditions and are equipped with advanced monitoring and control systems. They are suitable for various applications, including pharmaceuticals, biofuels, and food production.

In conclusion, the integration of advanced fermentation technologies and equipment is essential for the efficient and sustainable production of biotechnological products. Whether you are looking for small-scale laboratory fermenters or large-scale industrial fermenters, the selection of high-quality equipment from reputable manufacturers and suppliers is crucial for achieving optimal results and maintaining competitive production capabilities.

- Fermenter Manufacturers in Ahmedabad

- Fermenter Suppliers in Ahmedabad

- Fermenter and Bioreactor manufacturers in Ahmedabad

Manufacturer of Fermenter in Ahmedabad

Fermenter manufacturers in Ahmedabad play a pivotal role in supporting the region’s biotechnology and pharmaceutical sectors, and Uma Pharmatech Machinery is a notable name in this domain. Located in Ahmedabad, Uma Pharmatech Machinery has gained recognition for its expertise in crafting high-quality fermenters.

Their fermenters are precision-engineered to meet the specific requirements of biotech and pharmaceutical industries, ensuring optimal conditions for the growth of microorganisms. Uma Pharmatech Machinery’s unwavering commitment to excellence is evident in their state-of-the-art equipment, which facilitates processes like fermentation, enzyme production, and more. When it comes to fermenter manufacturing in Ahmedabad, Uma Pharmatech Machinery stands as a trusted choice, offering innovative and reliable solutions that elevate industrial processes in the region.

Supplier of Bioreactor in Ahmedabad

As prominent fermenter suppliers in Ahmedabad and a leading supplier of bioreactors in Ahmedabad, Uma Pharmatech Machinery plays a pivotal role in supporting the thriving biotechnology and pharmaceutical industries in the region. Situated in Ahmedabad, Uma Pharmatech Machinery has garnered acclaim for its unwavering commitment to providing high-quality fermenters and bioreactors.

Their equipment is meticulously engineered to cater to the specific requirements of biotech and pharmaceutical sectors, ensuring precise control over fermentation processes and the growth of microorganisms. Uma Pharmatech Machinery’s dedication to excellence is evident in their state-of-the-art solutions, making them the trusted choice among fermenter and bioreactor suppliers in Ahmedabad. Their innovative and reliable equipment enhances industrial processes, contributing significantly to the region’s growth and success.

Indian City Where We Supply Our Fermenter and Equipment’s

- Ahmedabad

- Surat

- Vadodara

- Rajkot

- Bhavnagar

- Jamnagar

- Gandhinagar

- Junagadh

- Anand

- Navsari

- Morbi

- Surendranagar

- Vapi

- Bharuch

- Porbandar

- Godhra

- Nadiad

- Mehsana

- Patan

- Ankleshwar

Fermenter and Bioreactor manufacturers in Ahmedabad

Fermenter and bioreactor manufacturers in Ahmedabad are integral to the success of the burgeoning biotechnology and pharmaceutical industries, and Uma Pharmatech Machinery stands tall in this field. Located in Ahmedabad, Uma Pharmatech Machinery is renowned for its precision-engineered fermenters and bioreactors.

Their equipment is tailored to meet the exacting standards of these industries, ensuring precise control over fermentation and microbial growth processes. Uma Pharmatech Machinery’s unwavering commitment to quality shines through their state-of-the-art solutions, making them the preferred choice among fermenter and bioreactor manufacturers in Ahmedabad. With their innovative and reliable equipment, Uma Pharmatech Machinery plays a pivotal role in advancing industrial processes and contributing to the region’s growth and development.

Bioreactor Manufacturer In Ahmedabad- Gujarat

UPM Projects is design and Research advanced manufacturing or Production facilities for a Wide range of Fermenter Manufacturing Company in Ahmedabad including Bio Chemical, pharmaceutical API.

Most Of Microorganism are Applicable in Pilot Scale Production in Biotech Lab to produce a More range of chemical Fertilizer and Biochemicals, enzymes and drugs is Manufactured In Fermenter in Ahmedabad With Automatic Controlling System.

- growth Bacteria and Fungai economically in fermenters on either solid/ liquid media

- Micro Organisms fast growth rate and so can produce large Fermenter yields in less time

- They can be genetically Designed with relative Sense to synthesize natural product.

- It Can able to Migrate Fair growth condition Like Temperature , Ph and Pressure Etc. (Examples:. extremophiles is growing in high temperature and pressure With Aerobic and Acidic Atmosphere)

Fermenter Manufacturing Companies in India

Pilot scale Fermenter used in pharmaceuticals or biotech & agriculture industries for Many bio Enzymes and API Bulk Drug product manufacturing in Ahmedabad.

We are manufacturing Pilot Scale Bioreactor For Fermentation plant as per Client requirement

We are manufacturing Industrial Bioreactors up to 50000Liter Growth Volume capacity.

Industrial Fermenter Vessels manufactured by Uma Pharmatech Machinery is the most Complicated designed product to meet the Need of the Pharma and Biotech Research Lab & Companies In Ahmedabad.

SEND INQUIRY

UMA PHARMATECH MACHINERY

Why Should You Use Uma Pharmatech Machinery Fermenter?

Uma Pharmatech Machinery is dedicated to providing the best laboratory equipment and supplies to our customers. Here are some of the reasons why you should work with us:

Quality Products: Uma Pharma products are made with cutting-edge technology and high-quality materials. To ensure that our products meet the highest standards, we only use the best raw materials and components.

Price of Fermenter In Gujarat

UPM offers competitive pricing on all of our products, allowing you to get the best value for your money.

UPM expert team has years of experience in the laboratory equipment industry. They are always available to offer you the best advice and support.

Customization: We provide tailored solutions to meet our customers’ specific requirements. We can assist you whether you require a standard product or a customized solution.

After-Sales Service: To ensure that our customers are completely satisfied with their purchases, we provide excellent after-sales service. When you require technical support or assistance, our team is always available.

Top fermenter bioreactor Manufacturers in Ahmedabad-Gujarat

Being an Top 10 organization in the Fermenter Manufacturing industry in Ahmedabad, we are Dealing in providing a Superior quality range of Pilot Scale and Laboratory Bioreactors and Fermenter For Production. Specifications: • Scada control with touch screen module Features: • Computer compatible control system with PLC• Limpet Coil pressure Reactors made of stainless steel 304 Grade with standard ports • Data Acquisition and Data Logging system is provided to Graph and Report Batch parameter( Process/ Sterilization) Dual set point failures • Single Dry mechanical shaft seal with Heat Trap Cooling Systems.

Price of Bioreactors in Ahmedabad-India

Uma Pharmatech is dedicated to providing the best laboratory equipment and supplies to our customers. We provide high-quality products at competitive prices, as well as expertise, customization, and excellent after-sales service For Fermenter and Bioreactor In Ahmedabad-Gujarat. Uma Pharmatech is the place to go for dependable and innovative laboratory equipment and supplies. To learn more about our products and services, please contact us today.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.