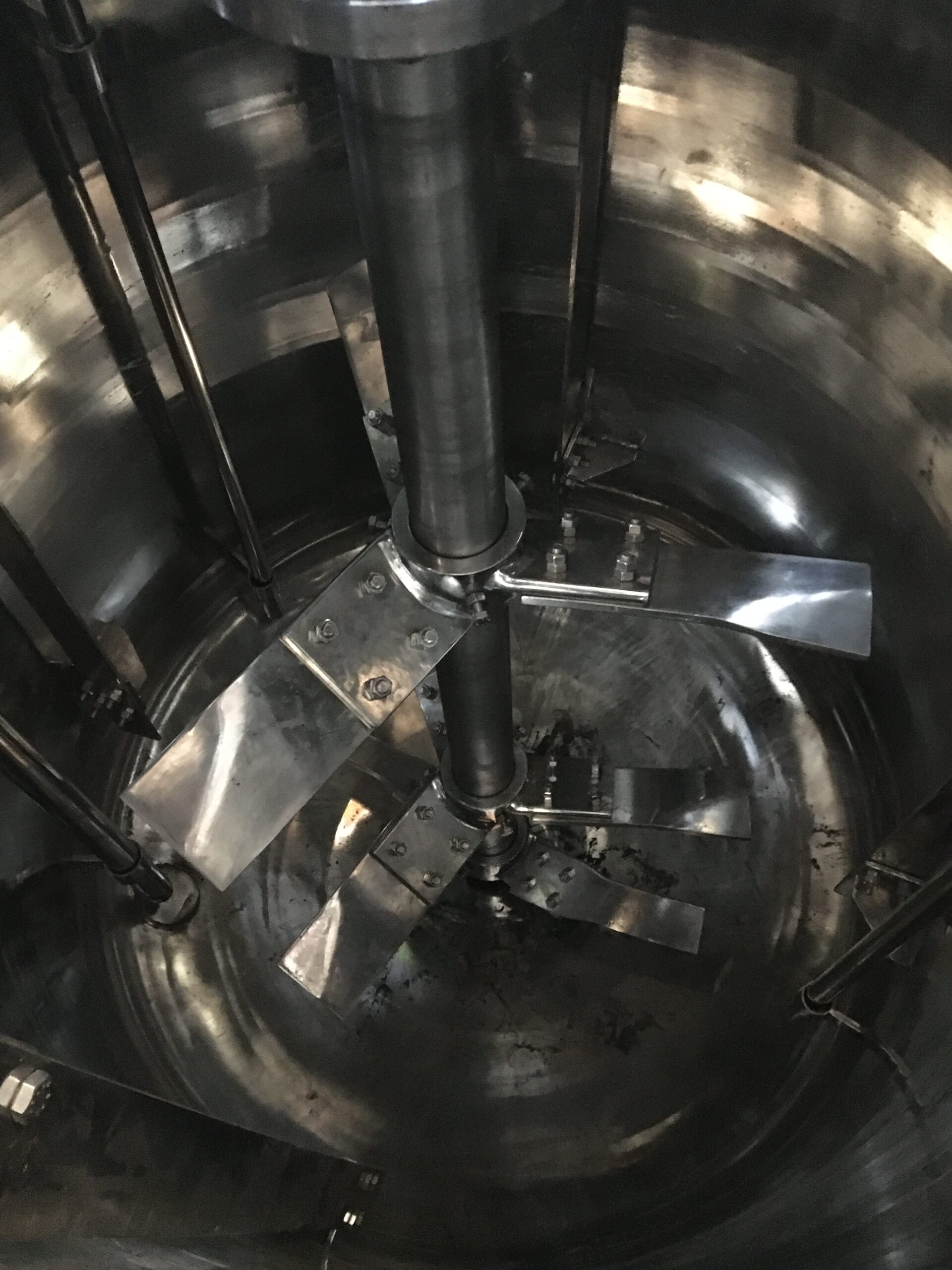

Food Grade Agitator Manufacturer

Best Food Grade Agitator Manufacturer in India – UMA PHARMATECH MACHINERY

When it comes to hygienic and efficient mixing solutions, industries in Ahmedabad, Vadodara, and Surat trust UMA PHARMATECH MACHINERY as their go-to food grade agitator manufacturer. Our agitators are designed for food processing plants, dairy production, beverage manufacturing, and condiment mixing applications, ensuring compliance with strict hygiene and safety standards.

Our machines are crafted from stainless steel SS316L and SS304, meeting international food grade agitator requirements while delivering consistent mixing results. Whether you are producing dairy products in Anand, spices in Rajkot, or bakery fillings in Gandhinagar, our agitators are engineered for reliability, durability, and performance.

Best Food Grade Agitator Manufacturer in India – UMA PHARMATECH MACHINERY

Food producers in Bhavnagar, Bharuch, and Navsari prefer our solutions because we combine affordability with top-notch engineering. Key features include:

Corrosion-Resistant Stainless Steel for long life and hygienic operation

Variable Speed Control for different product viscosities

Sanitary Shaft and Blade Design for easy cleaning and maintenance

Custom Capacity Options from small-batch mixing to large production runs

Energy-Efficient Motors to reduce operational costs

We understand that food manufacturers need both high-quality mixing and competitive pricing, and our designs are built with both in mind.

Mixing Volume vs Mixing Intensity Chart

| Mixing Volume (Liters) | Low Intensity (RPM) | Medium Intensity (RPM) | High Intensity (RPM) |

|---|---|---|---|

| 50 – 100 | 30 – 50 | 60 – 100 | 120 – 180 |

| 100 – 300 | 25 – 45 | 50 – 90 | 100 – 160 |

| 300 – 500 | 20 – 40 | 40 – 80 | 80 – 140 |

| 500 – 1000 | 18 – 35 | 35 – 70 | 70 – 120 |

Applications of Food Grade Agitators Across Gujarat

Dairy Processing in Anand – milk blending, yogurt mixing, butter churning

Beverage Production in Surat – juice homogenization, flavor infusion

Spice and Condiment Units in Rajkot – sauce blending, paste mixing

Bakery Ingredient Mixing in Vadodara – creams, fillings, and icings

Oil and Fat Processing in Bharuch – margarine, edible oils

Comparison Table – UMA PHARMATECH MACHINERY vs Market Standard

| Feature | UMA PHARMATECH MACHINERY | Market Standard |

|---|---|---|

| Material Grade | SS316L / SS304 | SS304 |

| Speed Variability | Wide Range (Custom) | Limited |

| Cleaning System | CIP Compatible | Manual Only |

| Blade Types | Multiple Options | Single Type |

| Warranty | 12 Months | 6 Months |

Trusted in Gujarat’s Top Industrial Cities

From Palanpur to Junagadh and Amreli, our food grade agitators have earned a reputation for precision and long-lasting performance. The ability to deliver custom-built agitators that meet the hygiene standards of the F&B industry makes UMA PHARMATECH MACHINERY the preferred choice for both small manufacturers and large-scale processing plants.

Our design and fabrication process ensures every part that touches food is polished, crevice-free, and fully compliant with sanitary regulations, reducing the risk of contamination while maintaining product quality.

What to Consider Before Purchasing a Food Grade Agitator

When buying a food grade agitator in Gujarat’s manufacturing hubs like Navsari or Gandhinagar, consider:

Capacity and Batch Size – match the agitator size to your production needs

Type of Product – viscosity, temperature, and shear sensitivity matter

Cleaning and Maintenance Requirements – opt for CIP-friendly designs

Energy Efficiency – saves costs in the long run

Price vs Lifespan – higher initial quality often means lower lifetime cost

UMA PHARMATECH MACHINERY ensures that buyers get the right balance between price, performance, and hygiene compliance.

Frequently Asked Questions

Q1: What is the price range for a food grade agitator suitable for dairy production?

A1: Our food grade agitators for dairy start from cost-effective models for small batches and go up based on capacity, speed options, and customization.

Q2: Can I get a custom agitator for high-viscosity food products like peanut butter or chocolate?

A2: Yes, we manufacture customized high-torque, variable-speed agitators designed for thick and semi-solid food products while maintaining hygiene standards.