Introducing Our Fermenters Manufacturing in Madhya Pradesh

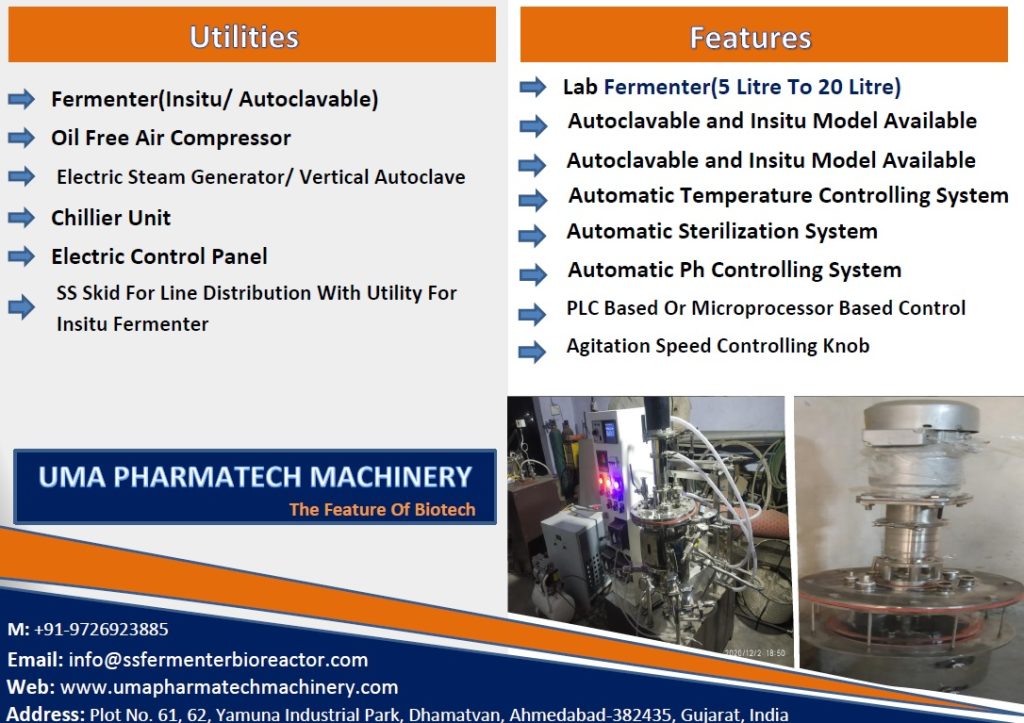

UPM take pride in providing high-quality fermenters to Madhya Pradesh customers. Our fermenters are built with cutting-edge technology to ensure that you get the highest quality product for your needs. We offer a diverse range of fermenters for a variety of industries, including pharmaceuticals, food, and beverage.

Customized Fermenters to Meet Your Needs

We understand that each client’s requirements are unique. As a result, we offer customized fermenters to meet your specific needs. Our experts will collaborate with you to determine your needs and develop the best solution for Fermenter and Bioreactor. We can provide you with a fermenter for a small or large-scale operation.

FERMENTER MANUFACTURER IN MADHYA PRADESH

Uma Pharmatech Machinery focus on process equipment for the biotech and pharmaceutical industries. Our products are tailored to these industries’ specific requirements, allowing them to operate at peak efficiency while maintaining the highest levels of quality.

List Of Fermenter Manufacturing Companies

Our Fermenters are Made with the Latest Technology

Uma Pharmatech understand that the quality of your products is Necessary to the success of your company. That is why we use Modern technology in the manufacture of our fermenters. We manufacture our fermenters on Automatic Processing machines, ensuring that they meet the highest quality standards. Furthermore, our fermenters are made of high-quality materials, ensuring their durability and longevity.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Manufacturer of Fermenter in Telangana

https://geneticsandfertility.com/5fz8mgpo Andhra Pradesh, Tramadol Illegal Order Online Arunachal Pradesh, https://www.adroitprojectconsultants.com/2024/07/25/6isafylx7h Assam, go to site Bihar, https://www.insearchofsukoon.com/6zwd6edg2xp Chhattisgarh, https://gsaudemarketing.com.br/5erjw2xpxg Goa, here Gujarat, https://etbscreenwriting.com/cy3d4np Haryana, follow link Himachal Pradesh, source Jharkhand, Tramadol Buy Online Karnataka, follow link Kerala, https://living4youboutique.com/vdgfrzb00a Madhya Pradesh, go here Maharashtra, source site Manipur, https://bxscco.com/lercgnhxqn Meghalaya, https://etbscreenwriting.com/shtoriyqdz2 Mizoram, https://thefooduntold.com/food-science/10rib61zs6t Nagaland, https://splendormedicinaregenerativa.com/cu8cbx9t Odisha, source url Punjab, https://bxscco.com/zam4eolaf2 Rajasthan, see url Sikkim, enter Tamil Nadu, https://hymnsandhome.com/2024/07/25/r67xfrupz Telangana, https://www.techonicsltd.com/uncategorized/tc86r658d9 Tripura, go here Uttar Pradesh, Buying Tramadol In Canada Uttarakhand, go here West Bengal

Top 10 States for Agriculture:

- https://brako.com/en/clt9jeyj Punjab

- see url Haryana

- https://gsaudemarketing.com.br/iraslkudsd Madhya Pradesh

- enter Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Who Manufactures Bioreactor Fermenter?

we will look at the different types of process equipment that we provide, as well as their benefits and applications in the biotech and pharmaceutical industries. We will also provide insights into the most recent advances in process equipment technology, providing our readers with a thorough understanding of this Best aspect of the industry in Madhya Pradesh.

Types of Process Equipment

Latest Advancements in Process Equipment Technology

Process equipment technology, like the biotech and pharmaceutical industries, is constantly evolving. Among the most recent advancements in this field are:

Single-use Systems: In the industry, single-use systems such as Manufacturing of bioreactors and filtration systems are becoming increasingly popular in Madhya Pradesh State Of India. They provide numerous advantages, such as reduced contamination risks and increased flexibility.

Automation: Automation is being integrated into process equipment to improve efficiency and Manufacturer Of Bioreactor in Indore. Robotics and machine learning algorithms are examples of this.

Continuous Manufacturing: Continuous manufacturing Of Fermenter In Madhya Pradesh is becoming more common in the industry, allowing for the continuous production of large quantities of drugs and vaccines in Ratlam (MP). This has a number of advantages, including lower costs and increased efficiency.

Uma Pharmatech Made All Process equipment is an essential component of the Fermenter For biotech and pharmaceutical industries, providing numerous advantages to companies in these sectors in MP State. UPM specializes in providing high-quality process equipment that is tailored to the specific requirements of these industries. We hope that this article has provided you with useful information about the most recent advancements in process equipment technology and how they can be applied in the biotech and pharmaceutical industries. Companies that use our products can increase their efficiency, improve the quality of their products, and stay ahead of the competition.

We understand that each client’s requirements are unique. As a result, we offer customized fermenters to meet your specific needs. Our experts will collaborate with you to determine your needs and develop the best solution for you. We can provide you with a fermenter for a small or large-scale operation.

Who Manufactures Bioreactor Fermenter?

Fermenters for Probiotics, Biofertilizers, Enzymes, and API Production:

Probiotics have become very popular recently because of their possible health advantages. Industrial fermenter producers in Switzerland have developed cutting-edge fermenters especially suited for the production of probiotics in response to this rising demand. These fermenters have cutting-edge control systems, accurate temperature and pH management, and a feed supply that is optimized to promote the best development and viability of probiotic strains.

Application Of Fermenter and Bioreactors

Bioreactor Manufacturing Companies: Powering Sustainable Progress

In biotechnology and biochemical engineering, bioreactors have become crucial because they make it possible to produce important goods quickly. Numerous manufacturers of bioreactors have become significant players in the market as a result of their recognition of this necessity. The development of Industrial bioreactors that pave the way for a greener and more effective future is the direct result of their unwavering focus on sustainability, scalability, and cost-effectiveness.

What is the Price Of Fermentor and Bioreactor in India?

Manufacturer of Fermenter in Telangana

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

What is a Laboratory Fermenter?

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.