What are the two types of bioreactors?

Generally Two Types Of Bioreactor Available as Per Sterilization Method

1) Insitu Serializable Bioreactors

2) Autoclavable Bioreactors

Insitu Bioreactors Made Of Stainless Steel Material. For Sterilize this Bioreactor Require Steam Generator Or Boiler. In This Bioreactor In Place Sterilization Is Possible

Where as Autoclavable Bioreactors are Made Of Borosilicate Glass Material. Autoclave Is Require To Sterile This Fermenter Bioreactor. In This Bioreactor IN place SIP(Sterilize in Place) Not Possible. Motor and Other Accessory Is to Remove From Bioreactor To Sterile Before Place In to The Bioreactor.

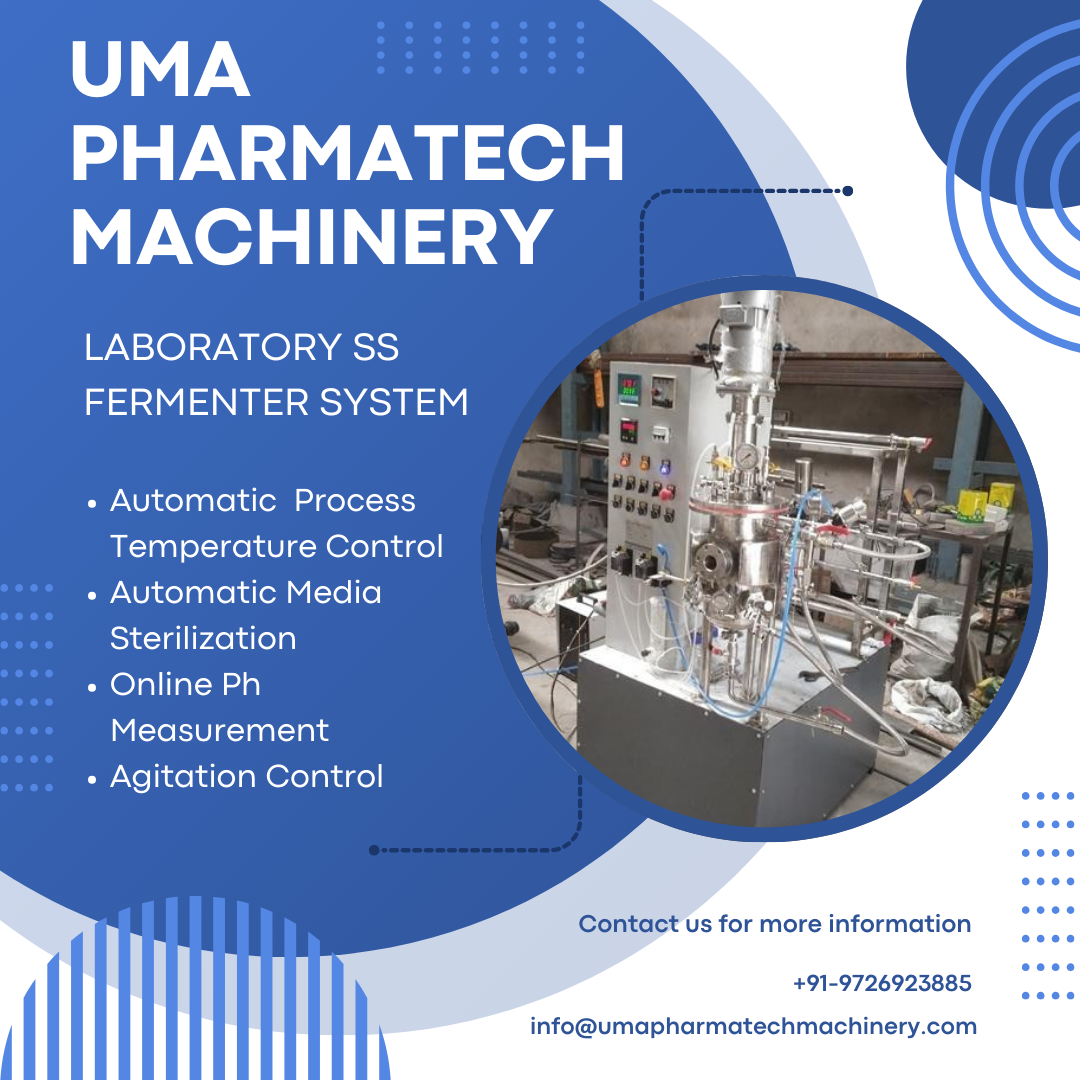

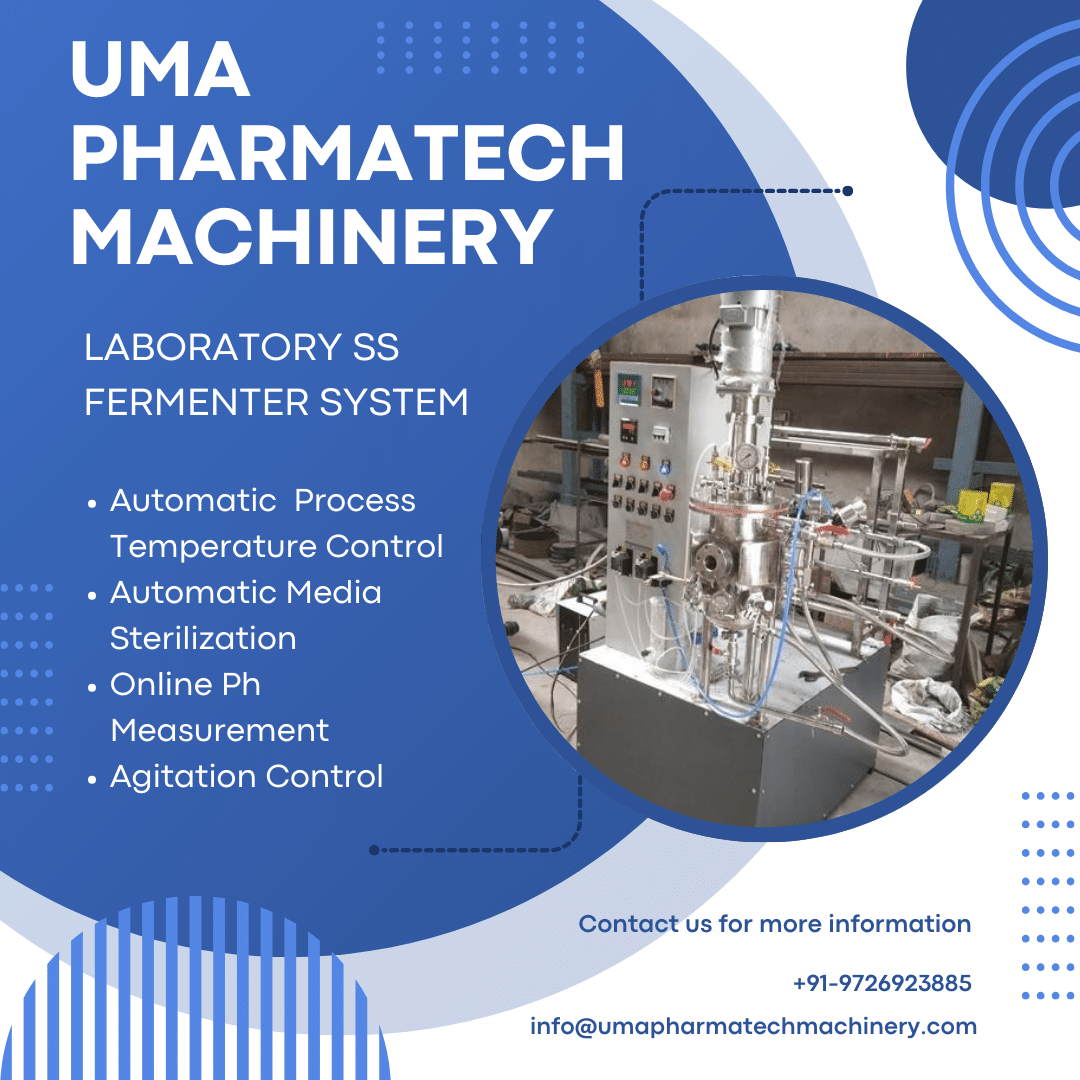

Bioreactor Is Special Designed System To Manufacture Bio Product and Biostudy With Absence Of Environment Condition. For Cell Culture and Mammalian Cell Development Bioreactor Is Require With Automatic Control Parameter Like ph., Temperature, Pressure, Agitation Control. In Pilot Scale Bioreactor Also Called as Fermenter

There are Many Types Of Bioreactors

1) Cell Culture Bioreactors

2) Photo Bioreactors

3) Single Use Bioreactors

4) Bacterial Bioreactors

5) Glass Bioreactors

6) Stainless Steel Bioreactors

7) Pilot Scale Fermenter Bioreactors

8) Lab Scale Fermenter Bioreactors

9) Industrial Fermenter Bioreactors

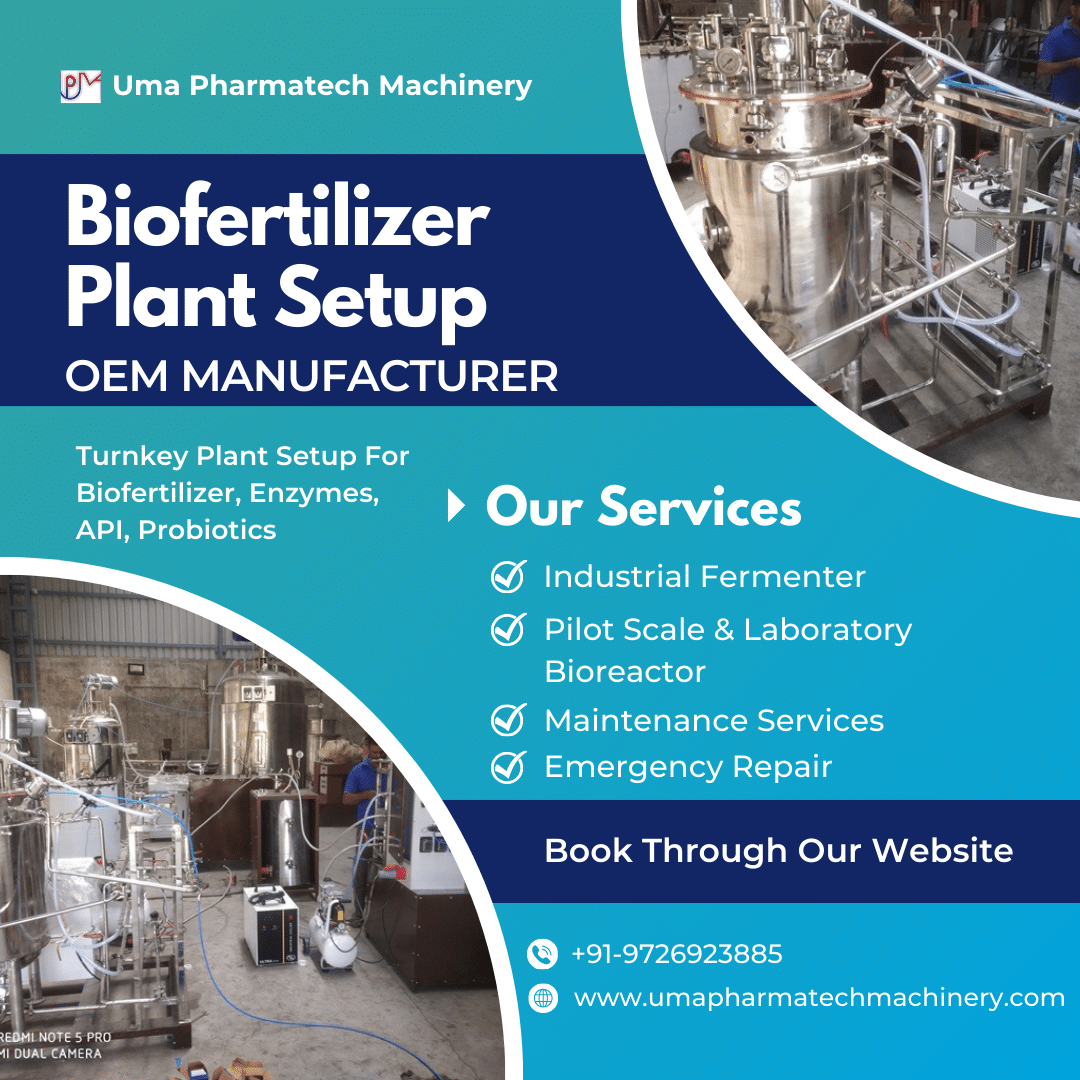

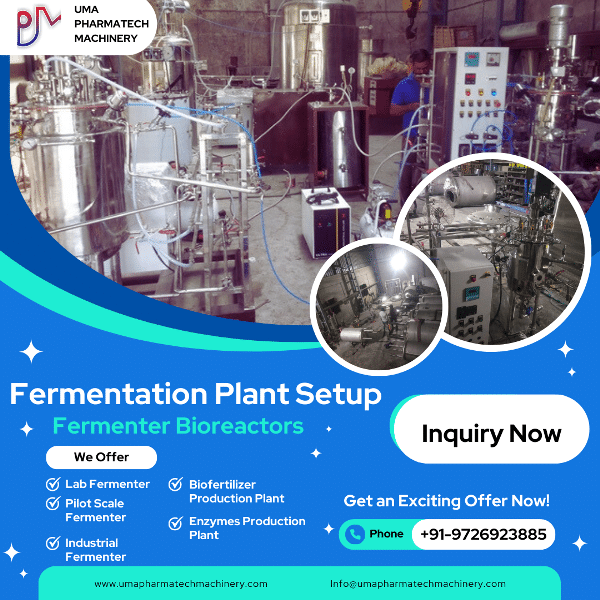

In the ever-evolving landscape of biotechnology, fermenters and bioreactors play a pivotal role in driving innovation and progress. These essential pieces of equipment are the backbone of numerous industries, from pharmaceuticals and biofertilizers to enzymes production and API manufacturing. As the biotech industry in India continues to soar, the demand for top-tier fermenter manufacturers and bioreactor suppliers has never been more critical. In this article, we will explore the dynamic market of fermenters and bioreactors in India, focusing on the states of Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, and Chhattisgarh.

Bioreactor Manufacturer Jharkhand

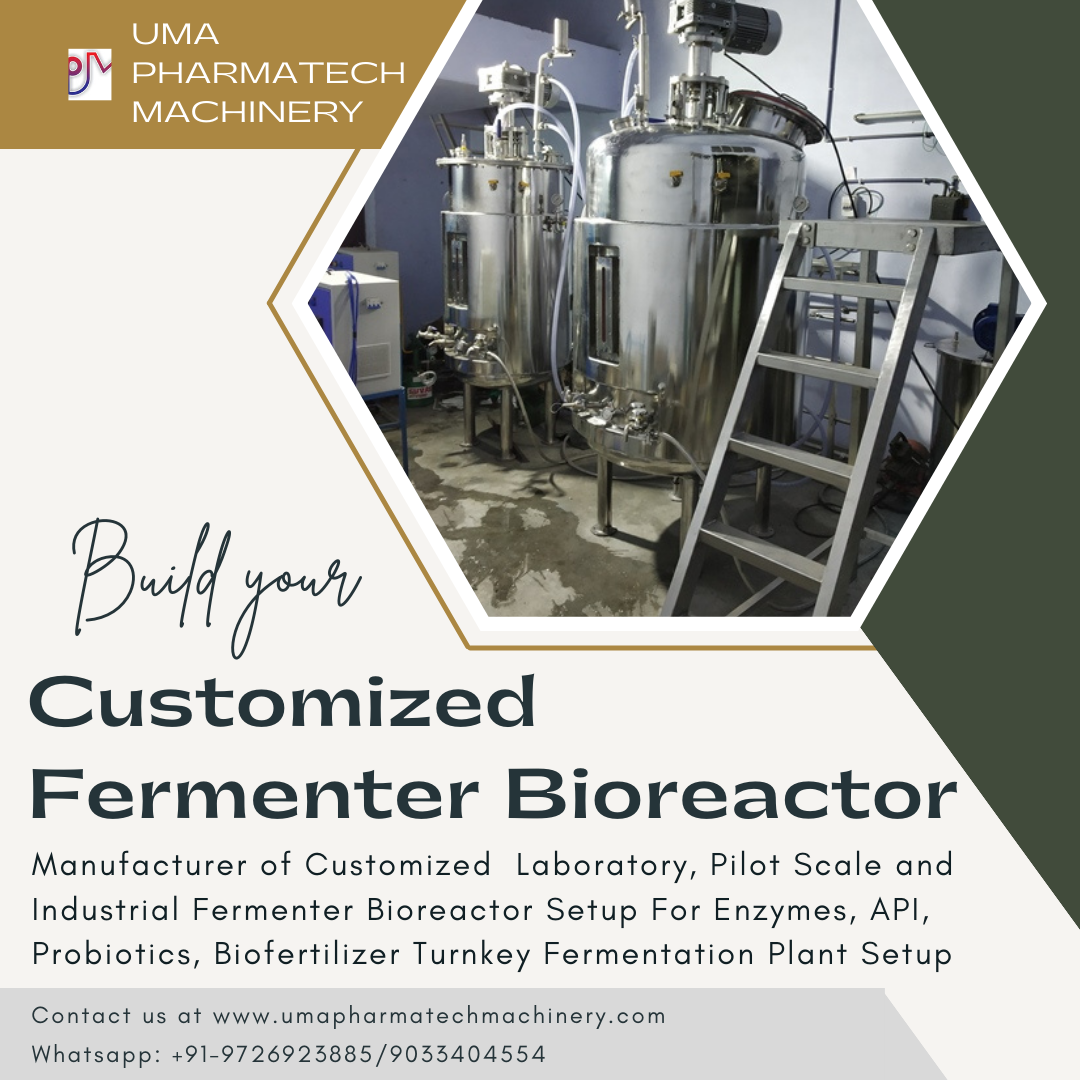

When it comes to specialized fermenter solutions, our Fermenter Customization & Consulting Services are designed to meet the unique requirements of each client. Whether you are scaling up production, optimizing specific processes, or needing a bespoke fermenter setup, our team provides tailored designs, engineering solutions, and expert consulting to guide you through every stage.

Who Manufactures Bioreactor Fermenter?

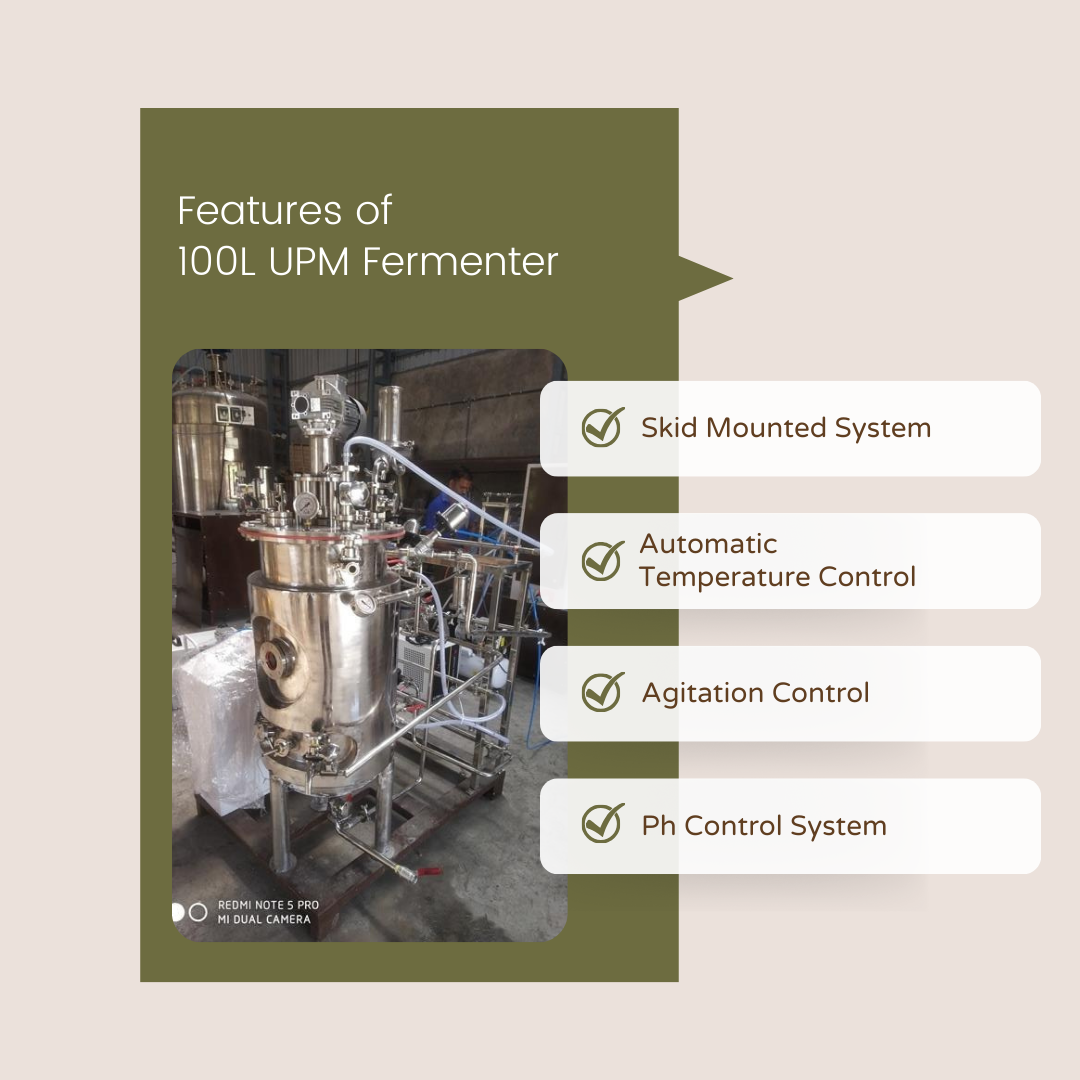

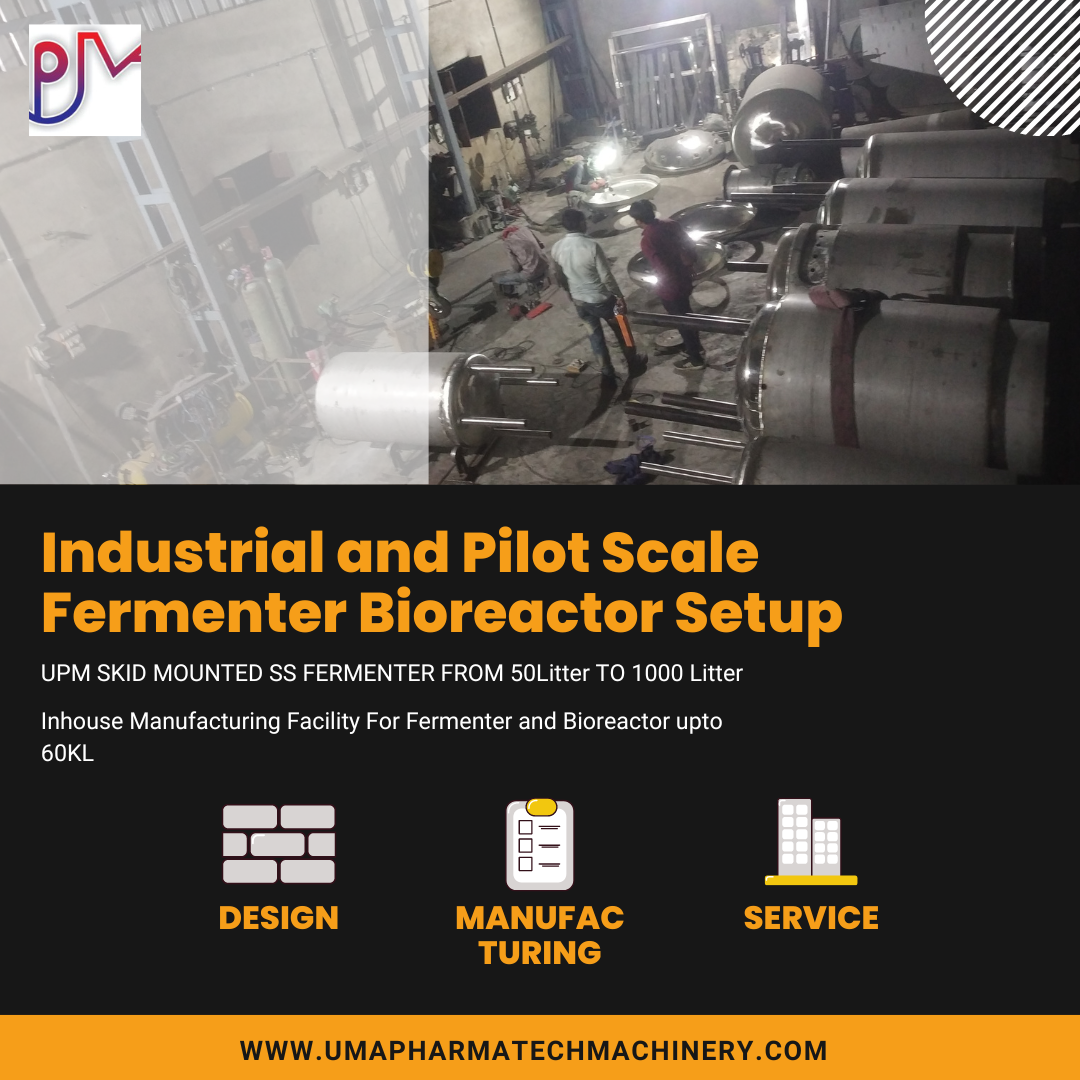

Many Company are available In Indian Market For Laboratory Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Trusted Brand For Manufacturing Of Pilot Scale Fermenter and Industrial Bioreactors. UPM Provide Best Quality and Automatic Bioreactor Manufacturer in India. Uma Pharmatech Present Low Cost Industrial Fermenter Bioreactor With All Necessary Equipments Like Compressor, Chiller, Steam Boiler, Cooling Tower, Pipeline, Skid Erc..

Lab Model Of Microbial Bioreactor Price Start From 500000/- Per Fermentation Plant Setup.

Pilot Scale Model Of Microbial Bioreactor Price Start From 1500000/- Per Fermentation Plant Setup.

Lab Model Of Microbial Bioreactor Price Start From 2500000/- Per Fermentation Plant Setup.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

- Industrial Fermenter Manufacturers in Pune

- Laboratory Fermenter Manufacturer in Jharkhand

- Pilot Scale Fermenter Manufacturer in Jharkhand

Industrial Fermenter Manufacturers in Jharkhand

We offer customization options for a variety of fermenters, including:

- Laboratory and Pilot-Scale Fermenters – Customize vessel sizes, temperature controls, and agitation systems for research or small-scale production.

- Industrial Fermenters – Optimize for large-scale production with options in stainless steel design, automatic controls, and advanced monitoring.

- In-situ Sterilization Systems – Integrate in-situ sterilization for easier maintenance and enhanced safety standards.

Laboratory Fermenter Manufacturer in Jharkhand

With our consulting services, you gain access to years of industry expertise in fermentation technology. Our consulting support includes:

- Process Design & Optimization – Guidance on how to design efficient fermentation processes, considering factors like temperature, pH, and aeration for optimal yield.

- Quality Assurance & Compliance – Ensure your systems meet industry regulations and quality standards, from installation to daily operation.

- Scale-Up Strategies – Moving from lab-scale to industrial production can be challenging, and our team helps facilitate smooth scaling to meet production targets.

Pilot Scale Fermenter Manufacturer in Jharkhand

- Tailored Solutions – We develop fermenters that match your operational needs, whether you’re looking for small-batch customization or a large-scale fermenter setup.

- End-to-End Support – From design to post-installation maintenance, we offer comprehensive support throughout the lifecycle of your fermenter.

Our commitment to high-quality craftsmanship and extensive consulting makes us a trusted partner for customized fermenter systems.

Cost Efficiency: Affordability is a key consideration for many businesses, especially startups and small enterprises. A reliable manufacturer offers competitive pricing without sacrificing quality, allowing companies to invest in essential equipment without straining their budgets.

Quality Assurance: Reliability in manufacturing means that the fermenters are built to last and meet industry standards. A reputable manufacturer employs strict quality control measures to ensure that every unit performs efficiently and consistently, reducing the risk of downtime and maintenance costs.

Customization Options: An ideal manufacturer provides customizable fermenters tailored to specific production needs. This flexibility enables businesses to design systems that suit their unique processes, whether for laboratory research or large-scale production.

Comprehensive Support: A reliable manufacturer often offers excellent customer support, from pre-purchase consultations to post-installation services. This support is vital for troubleshooting issues and ensuring that the fermenters operate smoothly.

Key Features of Affordable and Reliable Fermenters

- Durable Materials: Affordable fermenters made from high-quality materials, such as stainless steel, ensure long-lasting performance and resistance to corrosion and wear.

- User-Friendly Design: Simplified controls and interfaces make it easier for operators to monitor and manage fermentation processes, improving efficiency and reducing the likelihood of errors.

- Energy Efficiency: Many reliable manufacturers focus on energy-efficient designs, helping businesses save on operational costs while supporting sustainable practices.

Fermenter Manufacturers in Jharkhand-India

Investing in trusted fermenters for biopharma applications is crucial for companies aiming to produce high-quality biopharmaceuticals efficiently and reliably. With features designed to meet stringent regulatory standards, enhance process control, and reduce contamination risks, these fermenters play a vital role in advancing biopharmaceutical manufacturing. By choosing reliable fermentation systems, biopharma companies can ensure the success of their products in a highly competitive market.

Indian Exporter Of Fermenters and Bioreactors

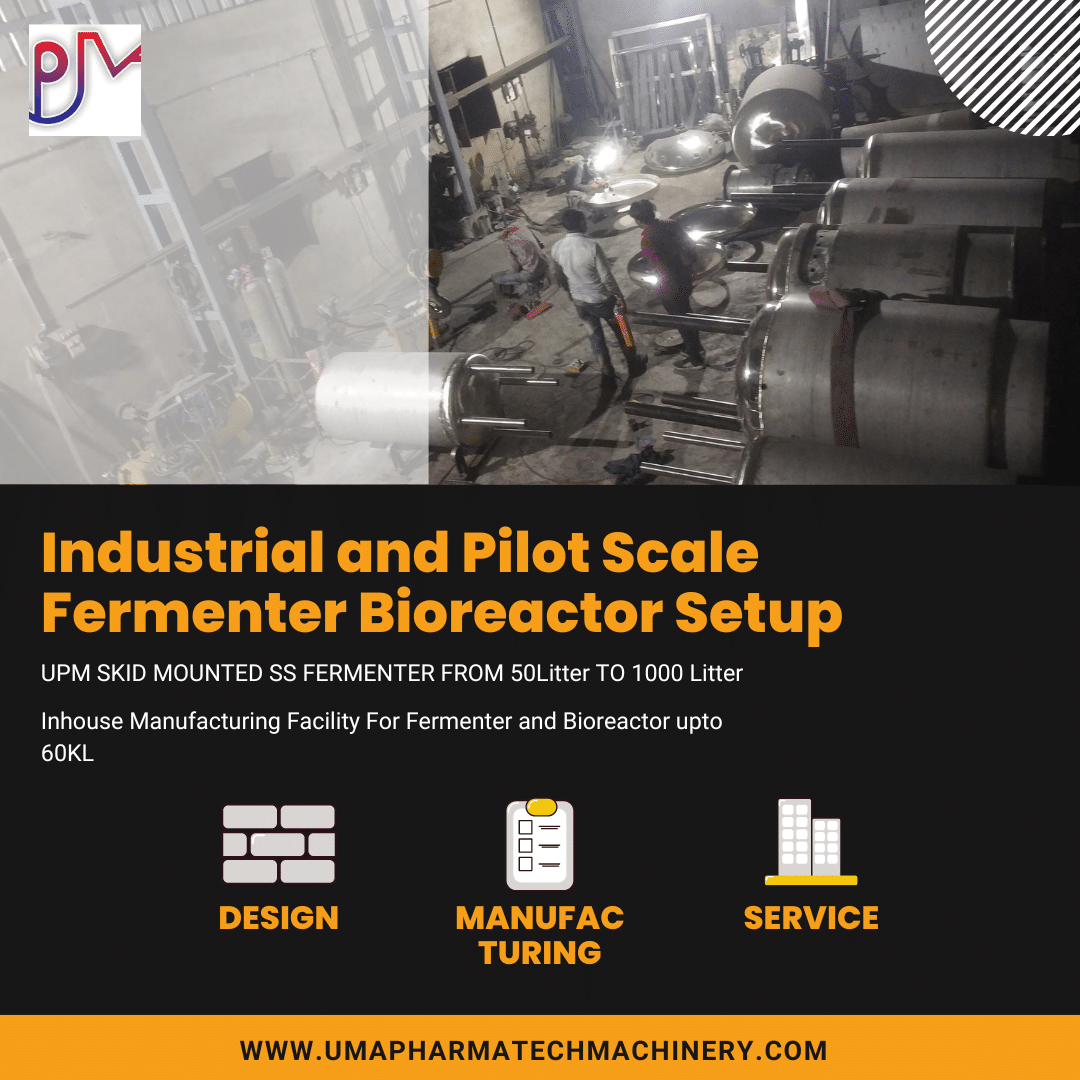

UPM 500LTR Fermenter Exporter From Pune is a Sturdy Construction With Easy To Move Castor Wheel Mounted Design. UPM fermenters are Specially Design for Automatic System development & Laboratory scale Research &Manufacturing. The Very Unique design and Numbers of standard and Non Standard parts for the flexibility to customize the system to Get your Desired process & Sterilization requirement in Maharashtra.

Total Volume Of Pilot Scale Fermenters and Bioreactors

- 10 Liter To 100 Liter

- 100 Liter To 500 Liter

Oxygen and Co2 Measurement and Control flow Using Rotameter

- O2 gas

- Co2 gas

- Other (Optional)

Exhaust Gas line

- Exhaust condenser

- Automatic pressure control

As industries expand and demand for high-quality fermentation processes grows, the need for export-grade fermenters has never been more critical. These fermenters are designed to meet international standards and are suitable for a wide range of applications, making them an ideal choice for companies looking to enhance their production capabilities while targeting global markets.

Key Features of Export-Grade Fermenters

Compliance with International Standards: Export-grade fermenters are built to adhere to stringent international quality and safety standards, such as ISO, GMP, and FDA regulations. This compliance ensures that products manufactured using these systems meet the highest quality benchmarks.

Durable Construction: These fermenters are made from high-quality materials such as stainless steel, ensuring longevity and resistance to corrosion and wear. This durability is crucial for maintaining performance over extended operational periods.

Scalability and Flexibility: Designed to accommodate various production scales, export-grade fermenters can be easily scaled up or down according to production needs. This flexibility allows manufacturers to adapt to changing market demands efficiently.

Advanced Technology Integration: Export-grade fermenters often feature the latest technology in automation, control systems, and digital monitoring, enhancing process efficiency and providing real-time insights into fermentation parameters.

Customizable Configurations: These fermenters can be customized to fit specific production processes and requirements, including options for mixing, heating, cooling, and sterilization. This adaptability is vital for companies operating in diverse industries.

Uma Pharmatech Machinery Provide Advanced Quality Insitu Lab Fermenter and Pilot Scale Fermenter and Bioreactor Set up Plant. UPM Provide 100% contamination free finish Superior functioning Computer compatible control system with SCADA PLC controlled with large color touch panel display Agitation, Aeration, Temperature, pH, O2, Total Bio Mass and pCO2, pressure and level as an option Glass and SS316 material

Reduced Operational Costs – By minimizing energy consumption, these fermenters help cut down on utility bills, leading to more profitable operations in the long term.

Enhanced Process Efficiency – Advanced designs and smart control systems ensure that energy is used effectively, reducing waste and ensuring consistent fermenting conditions.

Lower Carbon Footprint – Energy-efficient fermenters support greener practices by decreasing carbon emissions, helping businesses meet environmental regulations and sustainability goals.

Extended Equipment Life – Efficient energy use reduces wear and tear on fermenter components, extending the equipment’s life and reducing maintenance costs.

Energy-Saving Features in Modern Fermenters

- Variable Speed Drives – These allow motor speeds to adjust based on process needs, lowering energy consumption during low-demand periods.

- Improved Insulation – Enhanced insulation reduces heat loss, maintaining temperature stability and reducing energy required for heating and cooling.

- Automated Control Systems – Smart sensors and automation can optimize energy usage by regulating parameters like temperature, aeration, and agitation based on real-time data.

- Improved Process Control: Continuous monitoring ensures that fermentation conditions remain within optimal ranges, enhancing product quality and yield.

- Increased Operational Efficiency: By automating routine tasks and providing immediate feedback, digital monitoring systems minimize downtime and streamline operations.

- Data-Driven Decisions: Access to real-time data empowers operators to make informed decisions quickly, leading to improved responsiveness and process adjustments.

- Regulatory Compliance: Digital monitoring aids in maintaining compliance with industry standards and regulations by ensuring that all critical parameters are tracked and documented.

Fermenter Manufacturers in Assam: Empowering Biotech Innovations

Assam, with its lush tea gardens and rich cultural heritage, is carving a niche for itself in the biotech domain. The state’s fermenter manufacturers have earned a reputation for delivering top-quality equipment, supporting research and development in both traditional and emerging biotech sectors. These manufacturers collaborate with research institutions and industries, fostering a collaborative ecosystem for biotech innovations that benefit not only Assam but also the entire nation.

As India marches confidently into the future of biotechnology, the roles played by fermenter manufacturers and bioreactor suppliers become ever more crucial. The states of Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, and Chhattisgarh are at the forefront of this progress, each contributing uniquely to the nation’s scientific growth and economic prosperity. By embracing cutting-edge technology, fostering sustainable solutions, and expanding their global reach, these states are leaving an indelible mark on India’s biotech landscape.

In this journey of advancement, collaboration, and innovation, the concerted efforts of fermenter manufacturers and bioreactor suppliers have set the stage for India to stand tall in the global biotech arena, leaving other nations behind and making its mark as a biotechnology powerhouse.