What is the Size Of Small Fermenter?

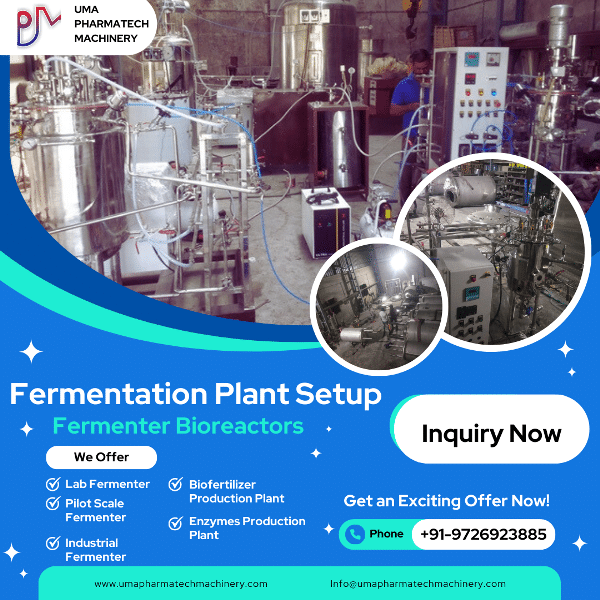

FERMENTER MANUFACTURER IN SURAT

In Surat, India, Uma Pharmatech Machinery is a leading Supplier & manufacturer of fermenters. Uma Pharmatech specialize in the design and manufacture of high-quality fermenters for industries such as biotechnology, pharmaceuticals, and food & beverage. Our skilled staff has years of experience in the bioprocessing business and is dedicated to providing our clients with the best solutions For Pilot Scale Fermenter.

Fermenter Bioreactor Manufacturers in Surat

UPM Fermenter Quality

UPM provide a diverse selection of Pilot Scale fermenters for a variety of applications, including microbial fermentation, animal cell culture, and plant cell culture. Our items are composed of high-quality materials, which ensures their durability and lifespan. We use innovative production technology to ensure that our products are of the highest quality Industrial Fermenters and Bioreactors.

UPM also provide customization choices for our clients in order to satisfy their individual requirements. Our skilled staff collaborates closely with our clients to understand their needs and create customized solutions. Uma Pharma also offer after-sales service to ensure that our clients’ equipment is in good working order.

Comprehensive Guide to Laboratory Fermenters and Bioreactors

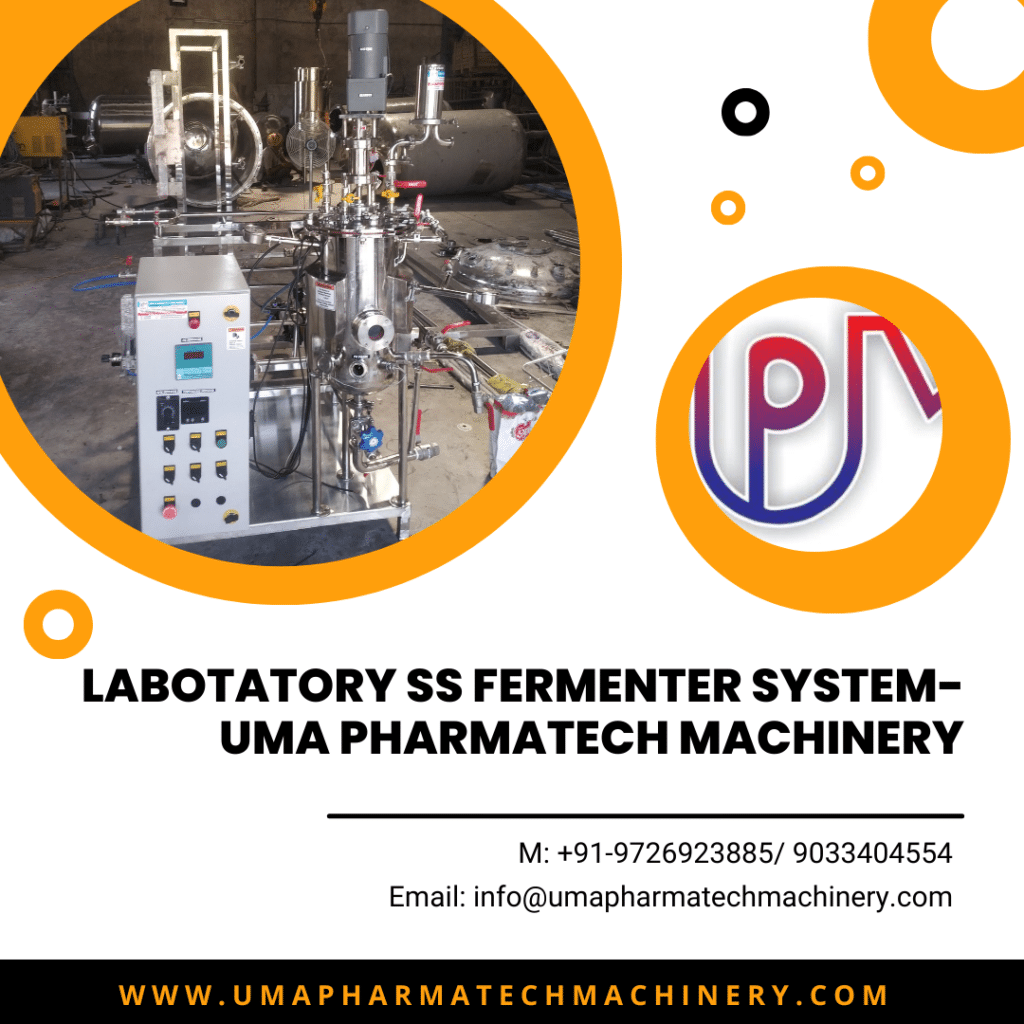

Introduction to Laboratory Fermenters

Laboratory fermenters are essential tools in the field of biotechnology and microbiology. These sophisticated devices provide an environment conducive to the growth of microorganisms and cells, allowing for controlled fermentation processes. At Uma Pharmatech Machinery, we specialize in manufacturing top-tier laboratory fermenters designed to meet the diverse needs of researchers and scientists.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

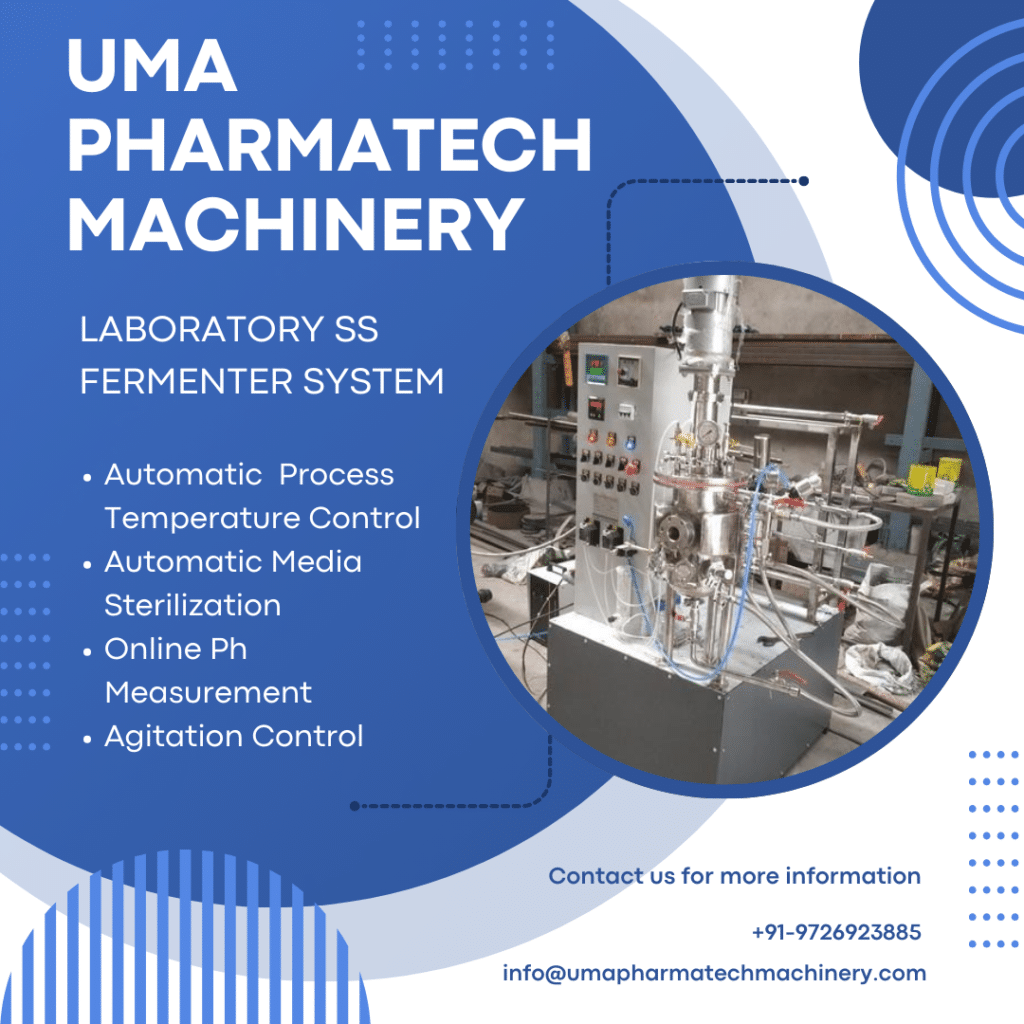

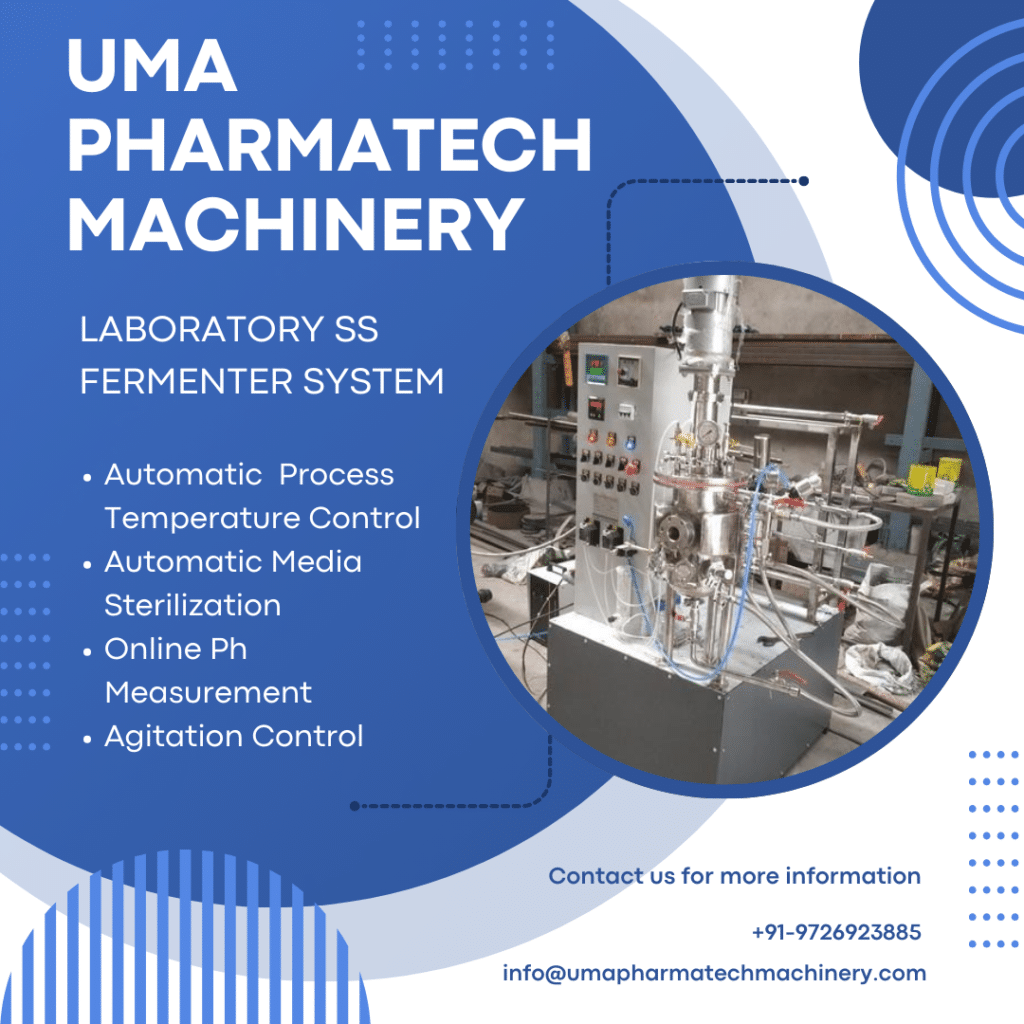

Key Features of Our Laboratory Fermenters

Advanced Temperature Control

Maintaining the optimal temperature is crucial for successful fermentation. Our laboratory fermenters are equipped with advanced temperature control systems that ensure precise and consistent temperature management, crucial for various microbial growth phases.

Automated pH Monitoring

pH levels significantly impact the fermentation process. Our fermenters include automated pH monitoring and control systems, allowing for real-time adjustments and ensuring the ideal environment for microbial activity.

Sterility and Contamination Prevention

Sterility is paramount in fermentation processes. Our fermenters are designed with state-of-the-art sterilization features, including SIP (Sterilize-In-Place) and CIP (Clean-In-Place) systems. These features minimize the risk of contamination and ensure reliable, reproducible results.

Scalability

Uma Pharmatech Machinery offers fermenters that cater to various scales of operations. Whether you’re conducting small-scale laboratory research or large-scale production, our fermenters are scalable to meet your requirements.

Cost-Effectiveness

Investing in our high-quality fermenters ensures long-term cost savings. The durability and reliability of our equipment reduce maintenance costs and downtime, providing a cost-effective solution for your fermentation needs.

Applications of Laboratory Fermenters

Laboratory fermenters find applications in numerous fields, including:

- Pharmaceuticals: For the production of antibiotics, vaccines, and other bio-pharmaceutical products.

- Food and Beverage Industry: In the production of fermented foods and beverages like yogurt, beer, and wine.

- Agriculture: For developing bio-fertilizers and bio-pesticides.

- Environmental Biotechnology: In the treatment of waste and wastewater through microbial degradation processes.

Benefits of Using Our Laboratory Fermenters

Enhanced Productivity

Our fermenters are designed to optimize the fermentation process, significantly enhancing productivity. The automated controls and monitoring systems reduce the need for manual intervention, allowing researchers to focus on analysis and development.

manufacturer of fermenter bioreactor in surat- Gujarat

In Surat, Gujarat, India, are you trying to find a reputable and excellent fermenter and bioreactor manufacturer? You’ve found it! We are a well-known business that Manufacture and Supply high-quality fermenters and bioreactors for a range of industries. With our state-of-the-art technology, flawless craftsmanship, and dedication to client satisfaction, we have made a name for ourselves as Surat’s go-to manufacturer. Whether you require a bioreactor, lab fermenter, or pilot scale fermenter, we have you covered.

In Surat UPM leading bioreactor manufacturer with 20 years of expertise designing and manufacturing high-quality bioreactors. UPM bioprocessing expertise has enabled us to serve a variety of industries, including biotech, pharmaceuticals, and food & beverage. We are dedicated to offering the greatest solutions for our clients, and our skilled staff is committed to delivering excellence in all aspects of our business in Lab Fermenter .

Application Of Fermenters in Various Industries

UPM provides a variety of bioreactors and Fermenters for a variety of purposes, including microbial fermentation, mammalian cell culture, and stem cell culture. We use innovative production technology to ensure that our products are of the highest quality. Our bioreactors are constructed using high-quality materials to ensure durability and lifespan.

We also provide customization choices for our clients in order to satisfy their individual requirements. Our skilled staff collaborates closely with our clients to understand their needs and create customized solutions. We also offer after-sales service to ensure that our clients’ equipment is in good working order.

Pilot Scale Fermenter Manufacturer in Surat, India:

We are your dependable partner if you need a pilot scale fermenter for research and development or small-scale manufacturing needs. Our pilot scale fermenters are designed to mimic industrial-scale conditions, enabling you to streamline the scaling up process and optimize your processes. We offer dependable and affordable solutions for Fermenter that satisfy your unique needs thanks to our expertise in the manufacture of pilot scale fermenters.

What is an Industrial Fermenter?

UPM Manufacturing Methodology For Fermenter Manufacturing:

Uma Pharmatech adheres to a strict production procedure to produce the finest quality bioreactors. UMA begin by gaining an understanding of our clients’ goals and requirements, allowing us to create tailored solutions. The Industrial bioreactors are then designed using innovative technologies and high-quality materials to ensure that they satisfy our clients’ requirements.

The manufacturing step begins once the design is complete. Our skilled team manufactures and Indian Exporters the bioreactors using latest technologies to ensure the finest quality. We use a comprehensive quality control method to ensure that each product is thoroughly inspected before it is dispatched to our Valuable clients.

Laboratory Fermenter Manufacturer in Surat:

Precision and dependability are crucial in scientific research. We created our lab fermenters with these ideas in mind. We are aware of the special requirements of laboratories and provide fermenters that enable carefully monitored research and precise data collecting. Our laboratory fermenters offer the perfect platform for your studies, whether you’re researching microbial growth, carrying out enzymatic reactions, or creating new goods.

Who Manufactures Bioreactor Fermenter?

Fermenter Manufacturer in Surat:

We distinguish ourselves from the competition in Surat when it comes to Pilot Scale fermenter production. Our cutting-edge facility is outfitted with Automatic equipment and run by a knowledgeable staff of professionals. To guarantee that every fermenter leaving our plant satisfies the highest industry requirements, we follow strict quality control procedures. Our fermenters are built for dependable, effective fermentation operations that promote microbial development and the growth of finished products.

Bioreactor Manufacturer in Surat:

We provide a broad selection of bioreactors designed to fulfil the unique requirements of diverse sectors as a renowned bioreactor manufacturer in Surat. Our bioreactors are made to aid in the biotechnological processes of cell culture, microbial fermentation, and others. Our bioreactors offer a controlled environment for maximum production and yield thanks to features like accurate temperature control, agitation systems, and strong monitoring capabilities. We give safety, scalability, and simplicity of use top priority while designing bioreactors.

Achieving superior outcomes in bioprocessing applications requires optimizing Industrial fermenter performance. You may increase the effectiveness and output of your fermentation processes by concentrating on elements like oxygen supply and mixing, temperature control, pH management, and nutrient input. We at Uma Pharmatech Machinery (India, Gujarat) recognize the significance of these elements and provide premium Laboratory fermenters with cutting-edge features to assist you dominate your sector.

Keep in mind that your fermentation processes’ performance depends not only on the hardware but also on process improvement, microbial strain choice, and other elements particular to your application. Consult with industry professionals who can offer customized solutions to fit your particular needs if you want to get a competitive edge.

What is the principle of fermenter?

The main vessel used to store the culture media and microorganisms is called a fermentor vessel.

An agitator makes sure that the culture media, nutrients, and oxygen are properly mixed to encourage optimum growth.

Aeration System: Maintains appropriate dissolved oxygen levels and provides oxygen to promote aerobic fermentation.

The temperature is controlled and maintained during the fermentation process by the temperature control system.

pH Control System: Tracks and modifies pH levels to provide the best conditions for bacteria.

Feed and sample Ports: Allow for periodic sample and nutrient supply without disturbing the culture.

Factors Influencing Fermentor Performance

1. Mixing and supplying and Control oxygen in Fermenter

For boosting cell growth and increasing the yield of desired products, an adequate oxygen supply is essential. Take into account the following to maximize oxygen transport and mixing:

Choose an agitator with an effective mixing system that reduces shear stress on the cells.

Aeration Rate and Strategy: Based on the unique requirements of the microorganisms and the method being used, choose the best aeration rate and strategy.

Select the best sparger design to ensure that oxygen is distributed effectively throughout the culture media.

2. Temperature Management and Controlling in Fermenter

The right temperature must be maintained for microorganisms to develop and carry out their metabolic functions. If you want to control the temperature effectively, take into account:

Using a powerful heating and cooling system that can react fast to temperature changes is recommended.

Install precise temperature sensors at key areas inside the fermentor to properly monitor and control the temperature.

Determine the ideal temperature range for the particular microorganisms and modify the setpoints as necessary.

3. Automatic Control of pH in Bioreactor

Microorganism development and viability in the fermentor depend on maintaining an ideal pH level. To effectively manage pH, take into consideration the following steps:

Placement of the pH Probe: Set the pH probe up so that it gives accurate measurements of the culture media.

pH Adjustments: To modify and maintain the required pH level, use the proper pH control solutions or automated systems.

Continuous Monitoring: Establish a reliable pH monitoring system to identify any deviations and allow prompt corrective action.

4. Aseptic Addition and sampling of nutrients in Bioreactor

The performance of the fermentor must be maximized by supplying an adequate supply of nutrients and by performing routine sampling. Think about the following techniques:

Feeding Plan: Create a thorough feeding plan that assures a steady supply of nutrients during the fermentation process.

Establish standardized sampling procedures to keep track of important variables like biomass concentration, product yield, and contaminant concentrations.

Automation and Integration: To streamline the adding and sampling of nutrients, use automation and integration capabilities. This will decrease human error and increase efficiency.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.

We are the company that businesses and researchers alike turn to for fermenter and bioreactor manufacture in Surat, Gujarat, India. We stand out from the competition thanks to our dedication to providing high-quality goods, personalized solutions, and first-rate customer support. All of our fermenters and bioreactors are scalable, durable, and deliver reliable performance. To discuss your needs and take the first step towards improving your fermentation and biotechnology operations, get in touch with us right away.