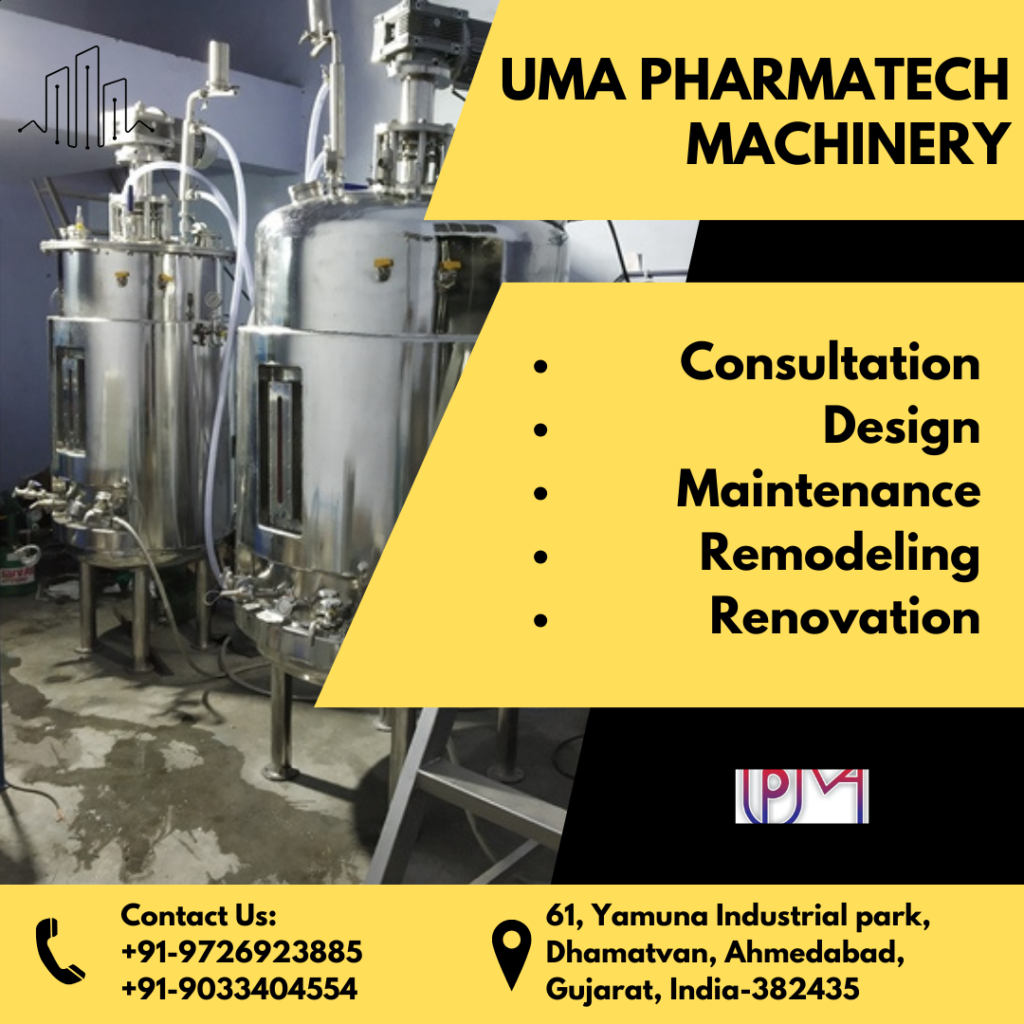

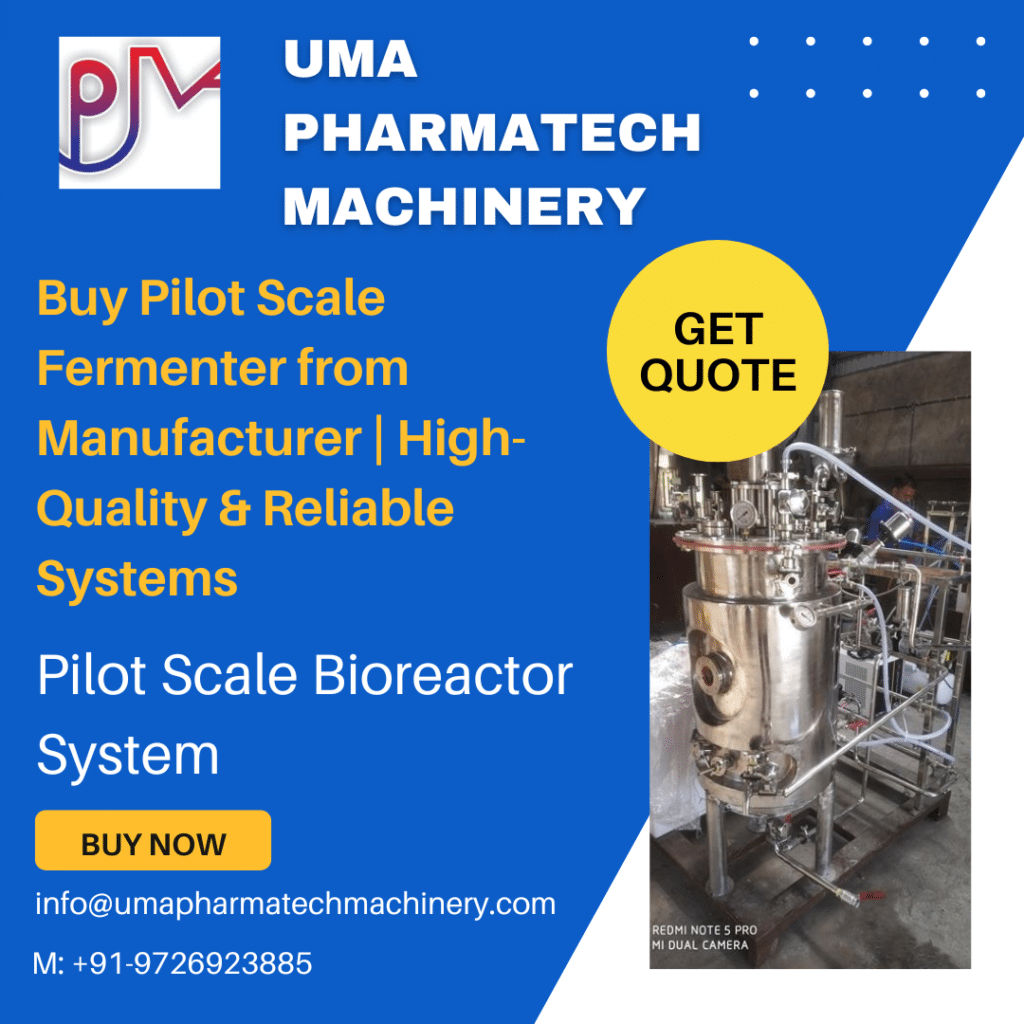

Fermenter and Bioreactor Suppliers and Exporter From India

Our firm is dedicated to supplying our clients with the finest quality industrial fermenters. UPM fermenters are intended to serve a wide range of sectors, including pharmaceuticals, biotechnology, food & beverage, and chemical processing.

Fermenters, also known as bioreactors, are pieces of biotech equipment used to manufacture biopharmaceuticals, food, and drinks, among other things. They are intended to create a regulated environment for the development of microorganisms that generate the desired output. In this post, we will look at the many types of fermenters and their uses.

Our fermenters are composed of high-quality materials and are designed to last. We employ cutting-edge technology to guarantee that our fermenters are both efficient and effective, delivering the greatest outcomes to our clients.

Uma Made industrial fermenters are available in a variety of sizes, from small laboratory fermenters to huge industrial fermenters. We may also custom design and manufacture fermenters to match our clients’ particular demands.

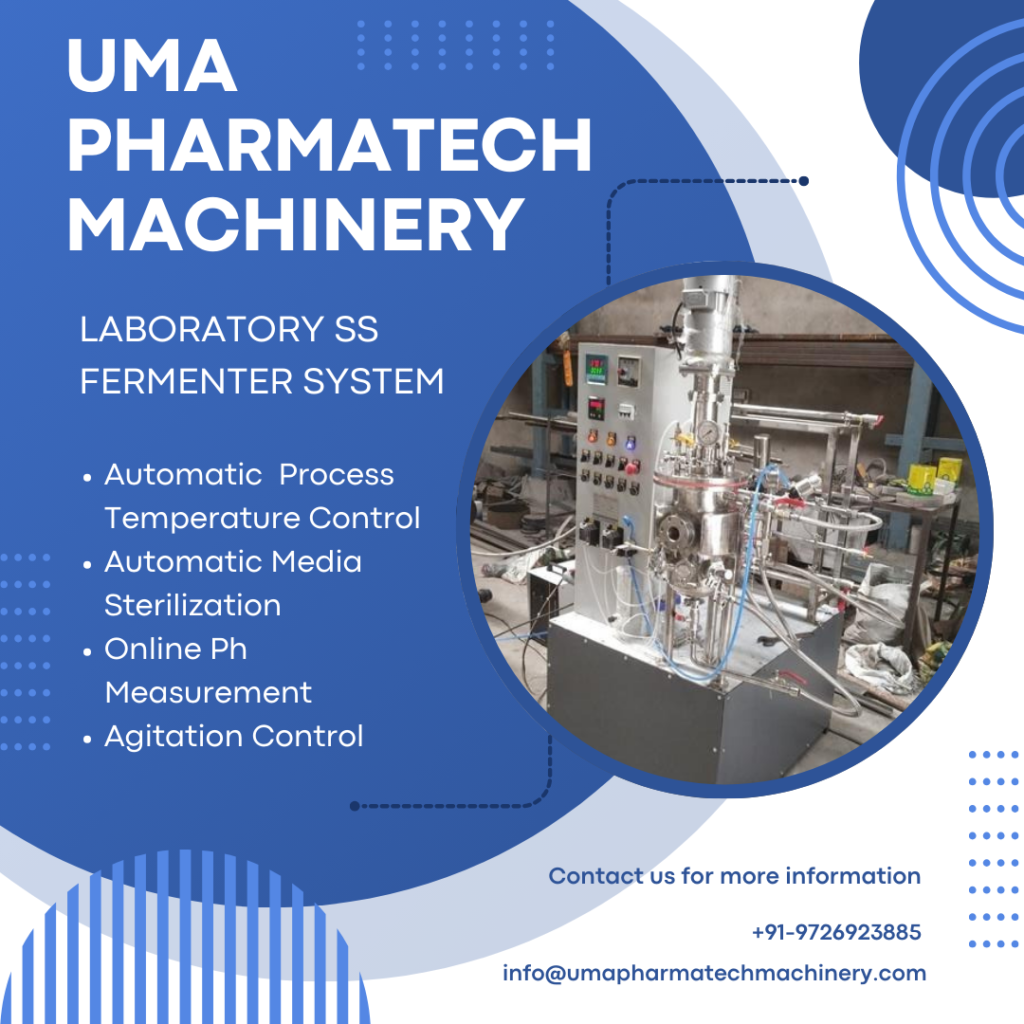

Our industrial fermenters are built to provide you complete control over the fermenting process. We employ modern software to monitor and regulate the fermentation process temperature, pH, and other essential factors. This guarantees that our clients receive the most consistent and dependable outcomes.

We recognize that each sector has its own set of requirements and obstacles. That is why we collaborate extensively with our clients to understand their individual demands and design tailored solutions to suit them.

Our organization is dedicated to offering the greatest quality of service and support to our clients. To guarantee that our clients get the most out of their fermenters, we provide extensive training and technical assistance. We also provide continuous maintenance and repair services.

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Fermenter Bioreactor Suppliers: Get Quote

In the rapidly evolving field of biotechnology, the demand for high-quality fermenter bioreactor suppliers has never been greater. These sophisticated systems are essential for various applications, including pharmaceuticals, biofuels, and research. This guide will explore the latest offerings, innovations, and key considerations when selecting the best fermenter bioreactor suppliers.

Understanding Fermenters and Bioreactors

Fermenters and bioreactors are crucial in creating controlled environments for cultivating microorganisms or cells. These systems facilitate the production of a wide range of products, from enzymes and antibodies to biofuels and biopharmaceuticals.

Types of Bioreactors and Fermenters

Stainless Steel Bioreactor Fermentor: Known for their durability and ease of cleaning, these are ideal for industrial applications. Stainless Steel SS 316 & 304 Industrial Fermenter 1KL To 50 KL – Anand Kheda is a popular choice, offering high capacity and polished finishing.

Benchtop Mini Bioreactors Fermenters: These are perfect for laboratory-scale experiments and small-batch productions. They provide a controlled environment for precise bioprocessing.

Algae Bioreactor With Electronic Control Panel, Capacity: 6-20 Liters: Designed for cultivating algae, these bioreactors come with advanced electronic controls for optimizing growth conditions.

Parallel Fermenter, Hyderabad, 20kw, Capacity: 250L: Ideal for conducting parallel experiments, this bioreactor offers robust performance and versatility.

Borosilicate Glass Napro Laboratory Fermentor (Autoclavable), Model Name/Number: Ns-laf-3-e, Capacity: 3-10 Litres: These glass fermentors are perfect for laboratory settings, offering transparency and ease of sterilization.

Key Features and Specifications

When selecting fermenter bioreactor suppliers, it’s essential to consider the specific features and specifications of the equipment:

- Capacity: Ranges from small 5-liter bioreactors to large 50,000-liter systems. For example, the Bioreactor Fermenter System, For Industrial, Capacity: 1000 Litre/Hour caters to large-scale production needs.

- Material: Stainless Steel Bio-Reactor Vessels are highly preferred for their durability and resistance to corrosion. SS 316 and 304 are common grades used in industrial fermenters.

- Control Systems: Advanced electronic control panels, such as those found in Algae Bioreactor With Electronic Control Panel, are crucial for maintaining optimal conditions.

- Sterilization: In-situ sterilizable options, like the In Place Sterilization Fermenter, Capacity: 3-300 L, ensure aseptic conditions and ease of maintenance.

- Finishing: Polished finishes, as seen in the 340 V 240 RPM SS Fermenters & Bioreactors for Pharmaceutical, Capacity: 5000 Lph, Finishing: Polished, provide ease of cleaning and reduced contamination risk.

Applications of Bioreactors

Bioreactors and fermenters find applications across various industries:

- Pharmaceuticals: Used for producing antibiotics, vaccines, and other critical drugs. Bioreactors, For Pharma are designed to meet stringent regulatory standards.

- Biofuels: Essential for the fermentation processes that produce bioethanol and biodiesel.

- Research: Lab-scale bioreactors and fermenters are crucial for R&D in biotechnological advancements.

- Waste Treatment: Used in the biological treatment of industrial and municipal wastewater.

Finding the Right Suppliers for fermenter bioreactor purchase

When looking for fermenter bioreactor suppliers, it’s important to consider the following:

- Reputation and Experience: Look for suppliers with a proven track record in the industry.

- Customization: The ability to customize bioreactors and fermenters to meet specific needs is crucial.

- Support and Maintenance: Reliable after-sales support and maintenance services are essential for the longevity and performance of the equipment.

Latest Offerings in the Market for bio fermenter

Bioreactor – Bioreactor for Cell Culture Latest Price, Manufacturers & Suppliers: This category includes the latest advancements in bioreactors designed for cell culture applications. The focus is on optimizing conditions for cell growth and product yield.

5Ltrs Bioreactors- Delhi: Ideal for smaller scale experiments and production, these bioreactors offer flexibility and ease of use.

Stainless Steel Bio-Reactor Vessels: Known for their robustness and hygiene, these vessels are suitable for a wide range of industrial applications.

200 Liter Insitu Fermenter Bioreactor: This medium-sized fermenter is perfect for medium-scale production, offering in-situ sterilization for convenience and safety.

Fermentors And Bioreactors, Capacity: 2-3 KL, Size: 5 Liter: These versatile systems cater to various scales of operation, providing flexibility for different production needs.

Fermenter Bioreactor Suppliers: Get Quote

Selecting the right fermenter bioreactor suppliers is crucial for the success of biotechnological processes. Whether you need a small benchtop bioreactor for research or a large industrial fermenter for mass production, there are numerous options available to meet your needs. By considering factors such as capacity, material, control systems, and supplier reputation, you can ensure that you choose the best equipment for your specific applications.

For more information on fermenter bioreactor suppliers, you can find contact details and addresses of companies manufacturing and supplying bioreactors and fermenters across India. Whether you are looking for a Bioreactor for Cell Culture or a large-scale Stainless Steel Bioreactor Fermentor, there are suppliers ready to meet your requirements.

This comprehensive guide aims to assist you in navigating the complex landscape of fermenter bioreactor suppliers. By staying informed about the latest products and innovations, you can make informed decisions that will enhance the efficiency and effectiveness of your biotechnological processes.

Fermenter Bioreactor Suppliers: Get Quote

In the rapidly evolving field of biotechnology, the demand for high-quality fermenter bioreactor suppliers has never been greater. These sophisticated systems are essential for various applications, including pharmaceuticals, biofuels, and research. This guide will explore the latest offerings, innovations, and key considerations when selecting the best fermenter bioreactor suppliers.

suppliers of fermenter in india

When seeking top-notch fermenter suppliers in India, it’s essential to consider various factors such as quality, customization, and support services. India boasts a range of suppliers offering advanced fermenters for diverse applications, from pharmaceuticals to biofuels. Suppliers provide a variety of options, including Stainless Steel Bio-Reactor Vessels and Benchtop Mini Bioreactors Fermenters, catering to different scales and specifications. Renowned for their robust construction and cutting-edge technology, these suppliers ensure efficient and reliable fermentation processes. For detailed contact information and product offerings, explore the extensive network of fermenter suppliers in India committed to excellence in bioprocessing solutions.

suppliers of bioreactors in India

India is home to a diverse array of bioreactor suppliers that cater to various sectors, including pharmaceuticals, biotechnology, and industrial fermentation. These suppliers offer a wide range of bioreactors such as Stainless Steel Bio-Reactor Vessels and Benchtop Mini Bioreactors Fermenters, ensuring high-quality and efficient bioprocessing solutions. Known for their advanced technology and robust construction, these bioreactor suppliers in India provide customized solutions to meet specific requirements. With options like In Place Sterilization Fermenters and Algae Bioreactors, these suppliers are equipped to support innovative research and large-scale production, contributing significantly to the bioprocessing industry.

Manufacturer of Fermenter in Telangana

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Applications of Fermenters For Biotech

Fermenters are used in a variety of biotech applications. These are some of the most prevalent uses:

Biopharmaceutical Production – Fermenters are extensively employed in the manufacturing of biopharmaceuticals such as vaccines, hormones, and enzymes. Fermenters’ regulated atmosphere ensures the creation of high-quality goods.

Fermenters are used in the manufacturing of a variety of food and beverage items, including cheese, beer, and yoghurt. Fermenters’ regulated atmosphere ensures the manufacture of consistent and high-quality goods.

Fermenters are frequently used in the manufacture of biofuels such as ethanol and biodiesel. Fermenters’ regulated atmosphere ensures the generation of high-quality biofuels.

Manufacturers of Pilot Scale Fermenter in India

Fermentor bioreactors must include various components, including:

The primary body of the bioreactor that houses the medium and microorganisms is known as the vessel.

The agitation system ensures the proper mixing and aeration for maximum growth and product development.

The control system regulates the temperature, pH, and dissolved oxygen levels in the bioreactor.

Sampling System: Enables sample collecting during the fermentation process.

Sterilization System: Ensures that the vessel and its components are sterile before beginning the fermentation process.

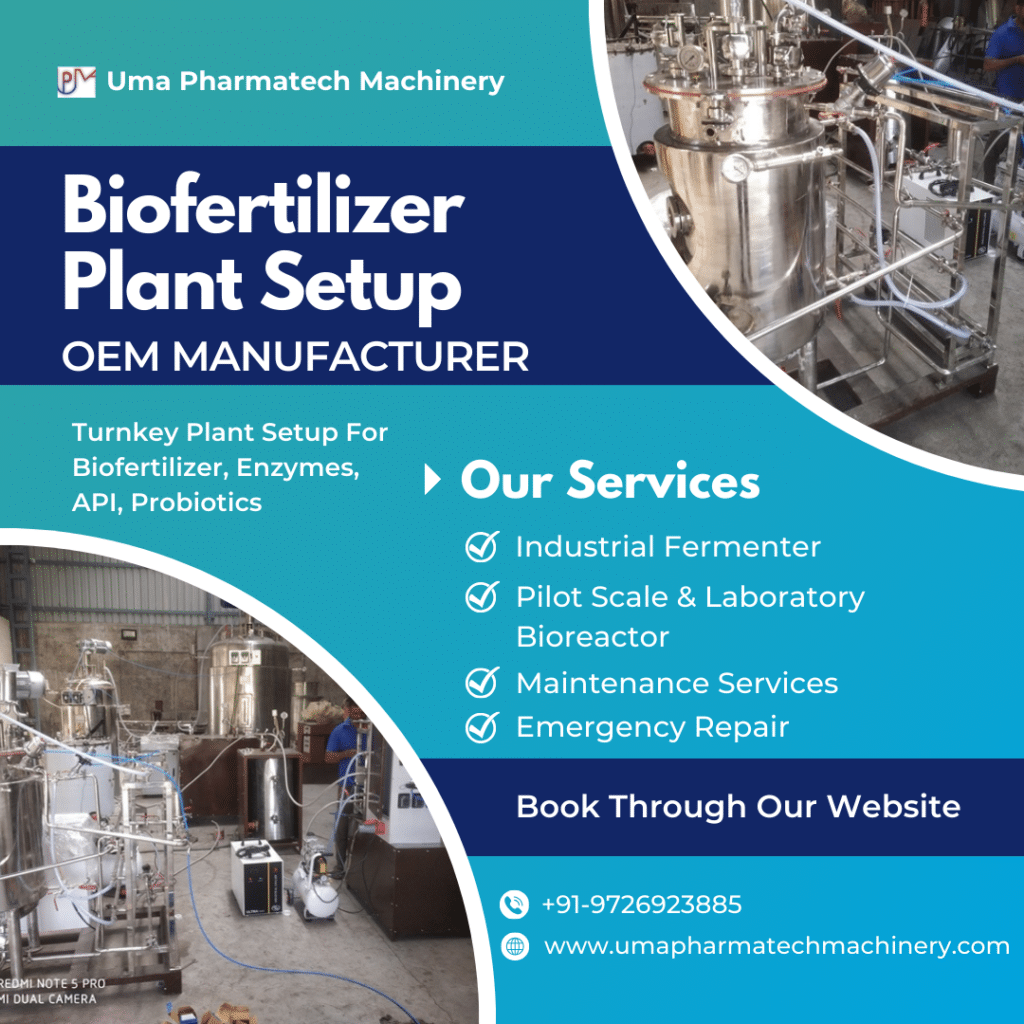

Applications of Fermentor Bioreactors For Biofertilizer

Fermentor bioreactors are used in a variety of industries. They are utilized in the pharmaceutical sector to make vaccines, antibiotics, and other biopharmaceuticals. They are utilized in the biotechnology sector to make enzymes, biofuels, and genetically engineered organisms (GMOs). Lastly, they are utilized in the food sector to make fermented foods such as cheese, yoghurt, and beer.

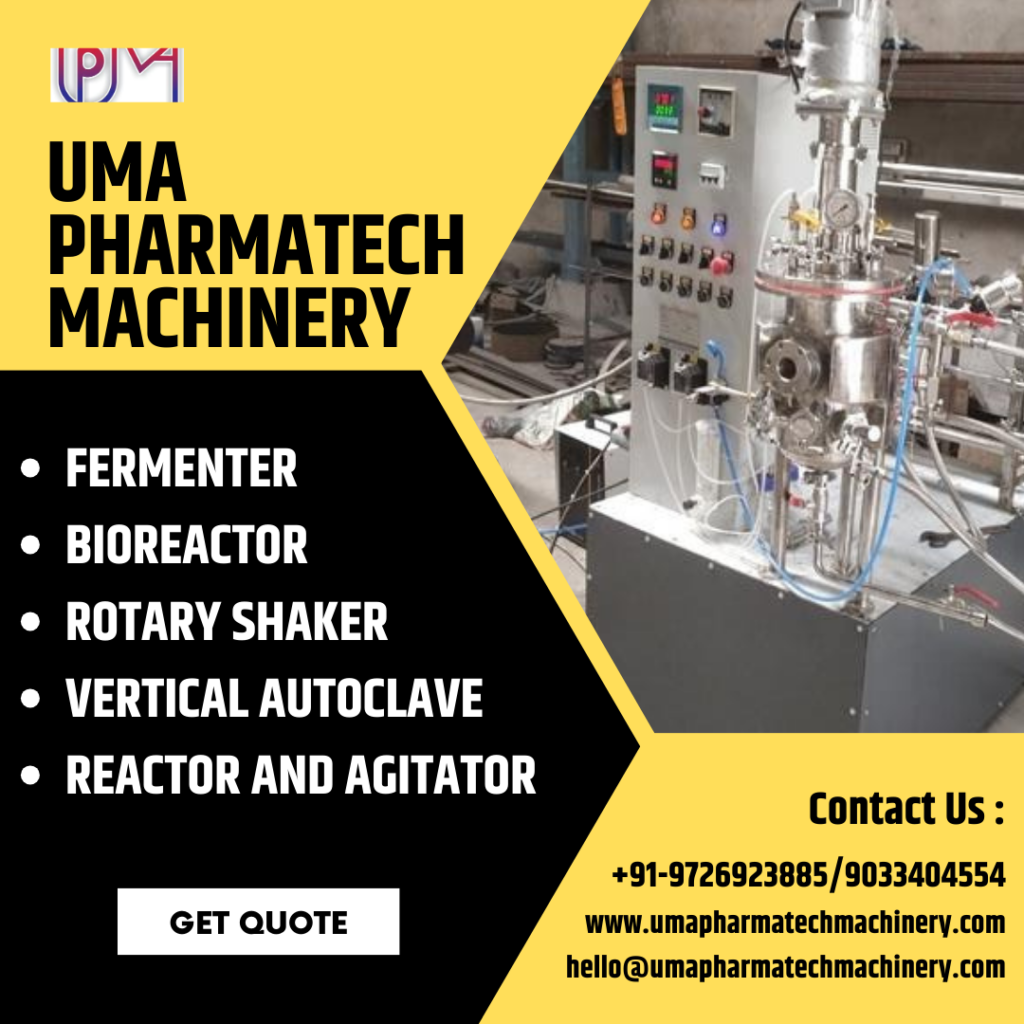

Why Choose UPM Fermenter for Your Fermentation Needs?

We specialize in delivering high-quality fermentation equipment for both business and domestic usage at Uma Pharmatech. Our equipment is built with Advanced technology to make your fermentation process as efficient and successful as possible. We provide a wide selection of fermentation systems to suit the demands of every brewer, from novice to expert.

UPM Fermentation Systems

We provide a wide range of fermentation systems to meet the demands of every brewer. Our systems include anything from tiny homebrewing installations to huge commercial systems for professional brewers. Among our most popular fermentation systems are:

Conical Fermenters: Our conical fermenters are intended to enhance fermentation efficiency. These fermenters facilitate yeast harvesting and sediment removal, which can improve the quality and flavor of your beer.

Jacketed Fermenters: Our jacketed fermenters are designed to keep your fermentation temperature stable. This can assist to minimize off-flavors and maintain the consistency of your beer’s taste and quality.

At Uma Pharmatech, we take pleasure in providing high-quality industrial fermenters that are tailored to our clients’ individual requirements. Our industrial fermenters are built to handle a variety of fermentation activities, such as microbial fermentation, enzyme synthesis, and cell culture.

In this post, we will go over the characteristics and benefits of our industrial fermenters, as well as how they may help you improve your fermentation process. We will also emphasize the essential features that set our fermenters apart from those given by other firms, such as the website: www.umapharmatechmachinery.com

Types of Fermenters

Fermenters vary in type, size, and configuration depending on the application and industry requirements. In Rajasthan, the following fermenters are commonly used:

Batch fermenters: The most basic type of fermenter, in which the entire batch of material is inoculated at once and allowed to ferment until finished. They are appropriate for small-scale productions and are relatively easy to operate and maintain.

Continuous fermenters are designed to operate continuously, with fresh substrate added and product harvested on a continuous basis. They are frequently employed in large-scale industrial applications.

Aerobic fermenters are intended to aid in the growth of microorganisms that require oxygen to respire. Antibiotics, enzymes, and other biologically active substances are frequently produced using them.

Anaerobic fermenters are designed to aid in the growth of microorganisms that do not require oxygen to respire. They’re commonly used to make organic acids, alcohols, and other biochemicals.

Fermenters have varying features depending on the application and industry requirements. Some of the common characteristics of Rajasthan fermenters include:

Most fermenters in Rajasthan are made of stainless steel, which is corrosion-resistant, long-lasting, and easy to clean.

Temperature and pH Control: Fermenters have temperature and pH sensors to monitor and control the fermentation process.

Fermenters have an agitation system that is used to mix the substrate and microorganisms and to increase the mass transfer of nutrients and oxygen.

Fermenters are outfitted with a sterilization system, which is used to sterilize the equipment before and after each batch to prevent contamination.

What are Fermentor Bioreactors?

Fermentor bioreactors are containers used in bioprocessing, which is a way of producing goods such as enzymes, antibiotics, and vaccines by employing living cells or organisms. These bioreactors provide a regulated environment for microbe development, making them an important tool in sectors such as pharmaceuticals, biotechnology, and food processing.

Types of Fermentor Bioreactors

Fermentor bioreactors are classified as batch, fed-batch, continuous, and perfusion bioreactors. Depending on the product being produced and the industry’s requirements, each kind has distinct advantages and drawbacks.

Batch bioreactors are the most basic and widely used form of fermentor bioreactor, in which a predetermined volume of medium is supplied to the vessel housing the microorganisms. Let the fermentation process to continue until the desired result is created. Fed-batch bioreactors are similar to batch bioreactors in that extra nutrients or substrate are fed during the fermentation process to boost output.

Continuous bioreactors are designed to provide a continual supply of nutrients and microbes, allowing for continuous production. Lastly, perfusion bioreactors are designed to produce mammalian cell cultures by continuously supplying new medium while eliminating trash.

What is Fermentation?

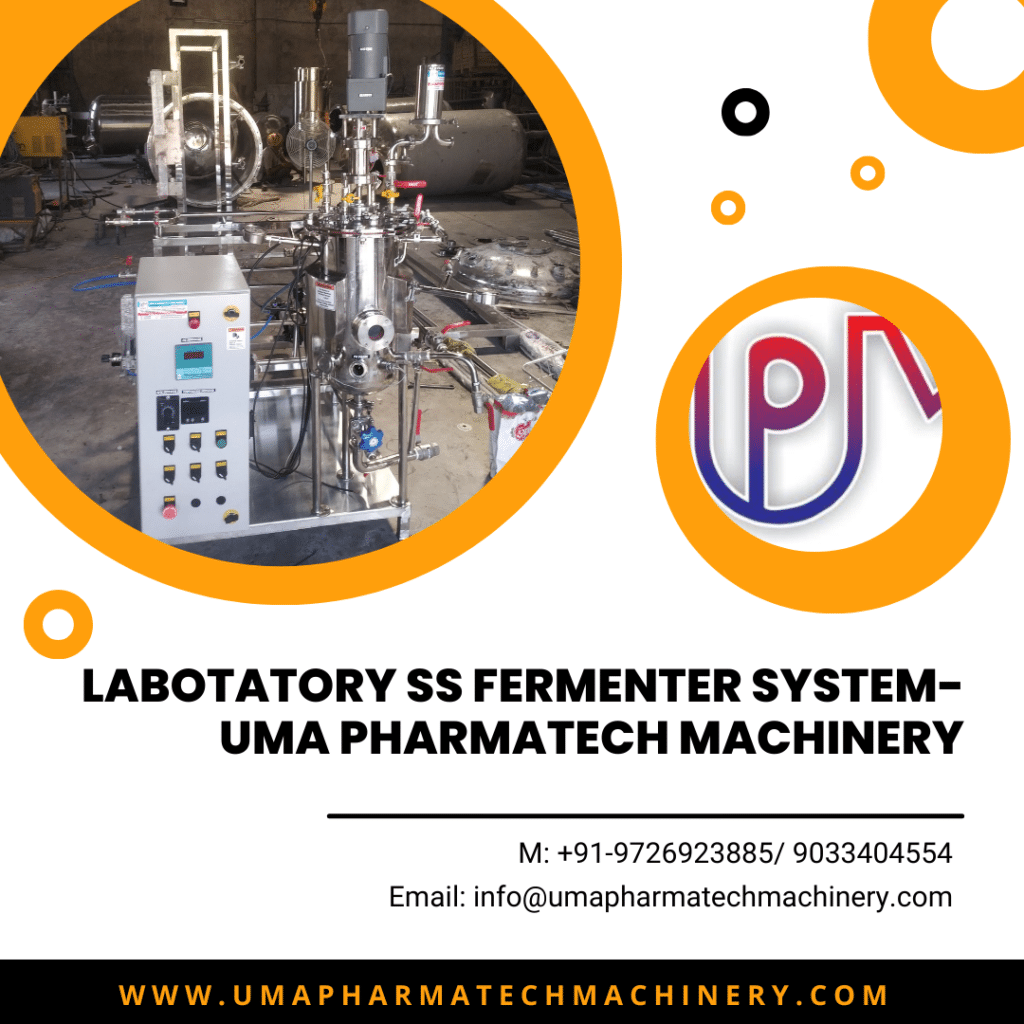

Applications of Laboratory Fermentors

Laboratory fermentors are used in a variety of disciplines, including biotechnology, pharmaceuticals, and food processing. Following are a few of the most typical uses for laboratory fermentors:

Development of Bioprocesses

Laboratory fermentors are extensively employed in the development of bioprocesses because they allow researchers to control numerous factors such as pH, temperature, and aeration to maximize production.

Biopharmaceutical Manufacturing

Laboratory fermentors are Necessary components in the manufacture of biopharmaceuticals such as insulin and monoclonal antibodies. These systems offer a controlled environment for microbial cultivation, providing constant and high-quality output.

Fermentation of Food

Laboratory fermentors are also used to make fermented foods including cheese, yoghurt, and sauerkraut. These systems enable the controlled development of lactic acid bacteria.

Who Manufactures Bioreactor Fermenter?

Many Company are available In Indian Market For Laboratory Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Trusted Brand For Manufacturing Of Pilot Scale Fermenter and Industrial Bioreactors. UPM Provide Best Quality and Automatic Bioreactor Manufacturer in India. Uma Pharmatech Present Low Cost Industrial Fermenter Bioreactor With All Necessary Equipments Like Compressor, Chiller, Steam Boiler, Cooling Tower, Pipeline, Skid Erc..

Lab Model Of Microbial Bioreactor Price Start From 500000/- Per Fermentation Plant Setup.

Pilot Scale Model Of Microbial Bioreactor Price Start From 1500000/- Per Fermentation Plant Setup.

Lab Model Of Microbial Bioreactor Price Start From 2500000/- Per Fermentation Plant Setup.

Features and Benefits of Our Industrial Fermenters:

Our industrial fermenters are built with Latest technology and technical know-how to provide exceptional performance and durability. Here are some of our fermenters’ important features and benefits:

Our industrial fermenters come in a variety of sizes and configurations and Cost to accommodate varied fermentation processes. We can also tailor our fermenters to our clients’ exact requirements, assuring optimal efficiency and output.

High-Quality Materials: Our fermenters are built of high-quality stainless steel, assuring long-term durability and corrosion resistance. To ensure precise and dependable performance, we also employ high-quality components such as agitators, sensors, and control systems.

User-Friendly Interface: Our fermenters include user-friendly interfaces that allow operators to easily monitor and manage the fermentation process. The interface displays critical metrics such as temperature, pH, and dissolved oxygen, as well as warnings and notifications if any of the values are exceeded.

Effective Heat Transfer: Our fermenters are built with efficient heat transfer mechanisms including jacketed walls and heat exchangers to provide optimal temperature control throughout the fermentation process. This helps to cut energy usage and running expenses.

Simple Maintenance: Our fermenters include easy-to-clean surfaces and components, resulting in less downtime for maintenance and cleaning. In order to maintain optimum uptime and productivity, we also provide complete maintenance and support services to our clients.

Why Quality Fermentation Equipment Matters in Enzymes Production

Any brewer who wants to get the finest possible results must invest in high-quality fermenting equipment. The proper equipment may aid in the efficiency, effectiveness, and consistency of your fermentation process. This can result in better-tasting beer and more customer satisfaction.

Uma Pharmatech Biofertilizer and Enzymes Manufacturing Plants is dedicated to supplying our clients with high-quality fermentation equipment. We think that the appropriate equipment can make or break the brewing process, and we are committed to assisting our clients in achieving the greatest outcomes possible.

Fermenter Suppliers For API in India

Finally, we take pleasure in supplying the finest quality industrial fermenters as well as the greatest service and support to our clients. We are convinced that our fermenters will suit the demands of a variety of sectors and will assist our clients in achieving the best possible outcomes in their fermentation operations. If you require an industrial fermenter, please contact us to learn more about our products and services.

Fermenter bioreactors are Important instruments for enterprises that rely on bioprocessing to manufacture a variety of goods. With various varieties available, each with its own set of benefits, selecting the suitable bioreactor for the intended product and business is essential. We hope that this tutorial has given you a thorough grasp of Pilot Scale fermenter bioreactors and their uses. Please do not hesitate to contact us if you have any queries or would like further information.

Uma Pharmatech Made Enzyme Manufacturing Plants provides the appropriate fermentation system for you, whether you’re an experienced brewer or just starting out. Our cutting-edge technology is designed to help you obtain the finest possible outcomes every time. We have something to satisfy the demands of each brewer thanks to our extensive selection of fermentation systems. Invest in high-quality fermenting equipment today to begin making the greatest beer imaginable.

Laboratory fermenters are important instruments in biotechnology because they allow researchers to examine and optimize diverse microbial activities. We have gone over the principles of laboratory fermenters, their kinds, and their uses in depth in this post. We hope that this text has given you a thorough grasp of laboratory fermenters and their applications.

Top Suppliers of Bioreactor in India:

While other businesses Manufacture and Supply industrial fermenters, the following major qualities distinguish our fermenters from those provided by others:

Customization: We provide a high level of customization for our fermenters, ensuring that they match our clients’ individual demands and specifications. This aids in the optimization of the fermentation process and increases production.

Quality Control: We have a strict quality control mechanism in place for our fermenters to ensure that they satisfy the highest quality and reliability requirements. We employ high-quality materials and components, and our fermenters are thoroughly tested and inspected before delivery.

Technical Expertise: Our fermenters are designed and manufactured by a team of highly trained and experienced engineers and technicians.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.