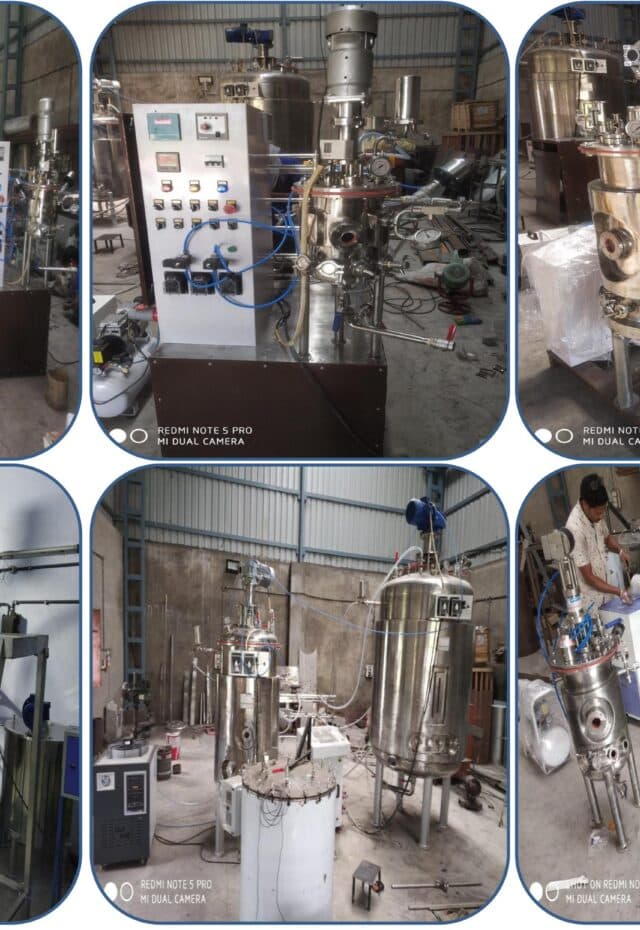

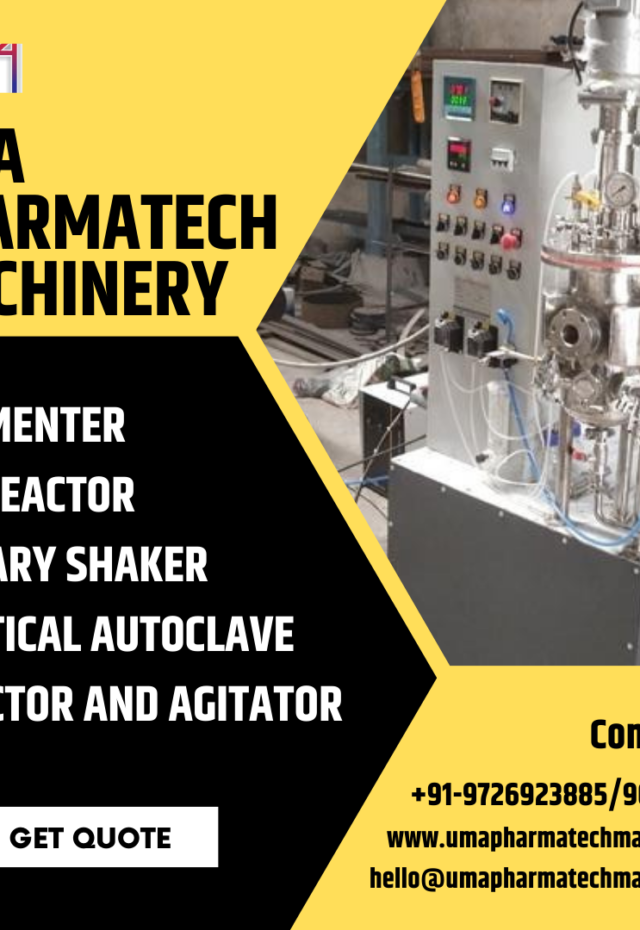

Pilot Scale Fermentor Manufacturer in India

Uma Pharmatech Machinery Is One Of The Pioneer Manufacturer and Suppliers Of Pilot Scale Fermenter and Pilot Scale Bioreactors In India. We Cover Indian Most Of Agriculture States For Fermenter and Bioreactor Supply In India:

- Gujarat

- Maharashtra

- Punjab

- Haryana

- Telangana

- Tamilnadu

- Andhra Pradesh

- Karnataka

- Assam

- Sikkim

- West Bengal

- Madhya Pradesh.

Manufacturer Of Pilot Scale Fermenter

What are Fermenters and Bioreactors?

Vessels used to culture and regulate the development of microorganisms include fermenters and bioreactors. These containers offer a setting that enables microorganisms to develop and proliferate in a controlled manner, making them perfect for the manufacturing of a variety of goods.

Since the early days of handcrafted goods, manufacturing has advanced significantly. To produce high-quality products quickly and effectively, contemporary manufacturing relies on a variety of specialized tools and machinery. The fermenter or bioreactor is one such device that is essential to many contemporary production processes.

Applications of Laboratory Fermenters

Laboratory fermenters are used in a variety of industries, including biotechnology, chemistry, and pharmaceuticals.

Enzyme, protein, and antibiotic production.

Biofuel and bioplastics production.

New product and process research and development.

Existing manufacturing processes should be optimised.

Leading Manufacturers of Pilot Scale Fermenter

In the field of biotechnology, pilot size fermenters and bioreactors are essential equipment that allow researchers and scientists to scale up laboratory procedures for larger-scale manufacturing. These adaptable containers are essential in a number of sectors, including the pharmaceutical, food & beverage, biofuel, and other industries. In this article, we will examine the essential elements and characteristics of pilot scale fermenters and bioreactors, illuminating their importance and demonstrating how they promote bioprocessing.

The need for high-quality fermenters and bioreactors is always growing in the vibrant field of biotechnology. Finding trustworthy manufacturers and suppliers of laboratory fermenters, industrial fermenters, and bioreactors is essential for your bioprocessing whether you are in Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab. This in-depth study seeks to offer insightful information on the top vendors of bioreactors and fermenters in these particular areas.

Who Manufactures Bioreactor Fermenter?

Many Company are available In Indian Market For Laboratory Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Trusted Brand For Manufacturing Of Pilot Scale Fermenter and Industrial Bioreactors. UPM Provide Best Quality and Automatic Bioreactor Manufacturer in India. Uma Pharmatech Present Low Cost Industrial Fermenter Bioreactor With All Necessary Equipments Like Compressor, Chiller, Steam Boiler, Cooling Tower, Pipeline, Skid Erc..

Lab Model Of Microbial Bioreactor Price Start From 500000/- Per Fermentation Plant Setup.

Pilot Scale Model Of Microbial Bioreactor Price Start From 1500000/- Per Fermentation Plant Setup.

Lab Model Of Microbial Bioreactor Price Start From 2500000/- Per Fermentation Plant Setup.

Uma Pharmatech Export Laboratory Fermenter From India In Following Developing Biotech Companies In The World Like:

- Us

- UAE

- Malaysia

- Russia

- Argentina

- Belgium

- Denmark and Many More.

What are the Benefits of Fermenters and Bioreactors?

For contemporary production processes, fermenters and bioreactors have many advantages. The following are some of the most important advantages:

Enhanced Effectiveness

The fermentation process may be precisely controlled in fermenters and bioreactors, which can boost productivity and decrease waste. Manufacturers can optimize the growth of microorganisms and increase yields by managing variables including temperature, pH, and nutrition levels.

Product Quality Improvement

Fermenters and bioreactors can assist producers in achieving higher levels of consistency and quality in their goods by offering a controlled environment for the development of microorganisms. This is crucial in sectors like the pharmaceutical industry, where product uniformity and purity are essential.

Types of Industrial Fermenters

Batch fermenters, continuous fermenters, fed-batch fermenters, and airlift fermenters are only a few of the several types of industrial fermenters. The choice of fermenter is based on the particular application and each type has pros and cons.

Fermenters in Batch

The simplest and most popular kind of fermenter is the batch fermenter. They are perfect for producing goods on a small scale that are simple to extract from the liquid culture. Moreover, batch fermenters are employed in the manufacturing of high-value goods like pharmaceuticals and enzymes.

Permanent Fermenters

Large-scale manufacture of products that are challenging to separate from the liquid culture is accomplished using continuous fermenters. They are also employed in the manufacturing of goods that need a steady supply of nutrients.

Flow-through Fermenters

Fed-batch fermenters are a type of continuous/batch fermenter. They are employed in the production of goods that need a lot of nutrients. Fed-batch fermenters are also used to make goods that need a steady stream of oxygen.

Lift Fermenters by Air

Products that need a steady supply of oxygen are produced in airlift fermenters. Also, they are employed in the production of goods that need a lot of nutrients.

What are the Key Features of Pilot Scale Fermenters and Bioreactors?

To meet the unique requirements of various production processes, fermenters and bioreactors are available with a variety of features and options. When choosing a fermenter or bioreactor, some important characteristics to consider are as follows:

Capacity Of Fermenter Bioreactor

A variety of sizes are available for fermenters and bioreactors to accommodate various production capacities. Based on the particular requirements of the production process, the size of the vessel should be chosen.

Control Parameter and Automation Of Fermenter System

To optimize the fermentation process, manufacturers can track and modify important variables like temperature, pH, and nutrient levels using control systems. Look for a fermenter or bioreactor with a user-friendly control system that provides a number of customizable options.

Sterilization

To prevent contamination and guarantee the purity of the finished product, fermenters and bioreactors must be adequately sterilized. A vessel that enables simple and efficient sterilization processes, such as autoclaving or in-place sterilization, is what you should be looking for.

Agitation and Aeration.

Many fermentation processes depend on aeration and agitation to keep microbes in suspension and disperse nutrients. Find a fermenter or bioreactor that has efficient aeration and agitation systems that are simple to modify to match the unique requirements of the operation.

What is an Industrial Fermenter?

An industrial fermenter is a large vessel used to produce microorganisms, enzymes, and other biological products on a large scale. These vessels are typically made of stainless steel and have a capacity of several thousand liters. Industrial fermenters can be used for batch or continuous processes and are designed to provide optimal conditions for the growth and reproduction of microorganisms.

Uma Pharmatech Machinery is Leading Industrial Fermenter Manufacturer In India.

Industrial fermenters are classified into three types: batch fermenters, continuous fermenters, and fed-batch fermenters.

Batch Fermenters: A batch fermenter produces a single batch of a product at a time. Because these fermenters are emptied and cleaned between batches, they are ideal for producing small amounts of a product.

Continuous fermenters are designed to produce a consistent supply of product over an extended period of time. These fermenters are not emptied between batches, and the product is harvested continuously as it is manufactured.

Fed-Batch Fermenters: Fed-batch fermenters combine batch and continuous fermentation. These vessels are initially filled with a nutrient-rich broth, which is then supplemented with nutrients during the fermentation process.

Uma Pharmatech Machinery is Leading Industrial Fermenter Manufacturer In India.

Pilot Scale Fermenter: Scaling Up the Fermentation Process

A pilot scale fermenter acts as a link between small-scale production and laboratory-scale research. Before moving to large-scale manufacturing, it enables scientists to improve and fine-tune the conditions for fermentation. We will concentrate on the core characteristics and elements of these systems, despite the fact that numerous manufacturers produce pilot scale fermenters.

The tank itself is an important part of a pilot scale fermenter. It offers a sterile and controlled environment for microbial or cell culture growth and is made from premium materials like stainless steel. The vessel’s volume ranges from a few liters to several hundred liters, depending on the use and production needs.

Pilot scale fermenters also need agitation and aeration systems. These ensure the best possible oxygen transport and mixing, which is essential for the development and metabolism of cells or microorganisms. To preserve homogeneity and improve mass transfer, a variety of techniques are used, including mechanical stirring, sparging, or impeller systems.

The fermenter’s intended environment must be maintained at all times, which requires temperature and pH control devices. The growth and sustainability of the cultures are guaranteed by careful management of these factors. Automated control systems allow for real-time monitoring and modification, which increases the consistency and dependability of the operation.

Pilot Scale Bioreactor: Bridging the Gap Between Lab and Production

Pilot scale bioreactors offer a way to move from small-scale production to large-scale manufacturing, much like pilot size fermenters do. In order to meet various bioprocessing requirements, such as cell culture, enzyme manufacturing, biofuel generation, and others, these systems also have extra functions.

A pilot scale bioreactor has a vessel design of fermenter, made of materials like stainless steel or other biocompatible materials. Depending on the application and production size, the volume capacity ranges from tens to hundreds of liters.

Pilot size bioreactor agitation systems are made to provide effective mixing without harming fragile cells or enzymes. Different impeller designs and combinations are used, taking into account things like mass transfer restrictions, oxygen transfer, and shear stress.

Temperature, pH, dissolved oxygen, and other Basic parameters may be precisely regulated thanks to sophisticated monitoring and control systems. Real-time data from in-situ sensors enables process optimization and guarantees constant product quality throughout the manufacturing cycle.

Modern manufacturing processes depend heavily on fermenters and bioreactors because they enable precise control over the cultivation and growth of microorganisms. These vessels have a number of advantages, such as higher productivity, enhanced product quality, and cost savings. It is Vital to take into account aspects like capacity, control systems, building material, sterilization choices, and aeration and agitation systems when choosing a fermenter or bioreactor. Manufacturers may achieve the best outcomes and maintain their competitiveness in the market today by selecting the appropriate fermenter or bioreactor and Manufacturers.

In the fields of bioprocessing, pilot-scale fermenters and bioreactors are essential Equipment’s that help researchers and scientists bridge the gap between small-scale manufacturing and laboratory-scale study. The parts and functions covered in this article give readers a view of these systems’ fundamental components. Pilot scale fermenters and bioreactors are available from a variety of manufacturers, but knowing the basic parts will enable you to choose the best equipment for your particular needs.

Manufacturers of bioreactors in Kenya concentrate on creating small, portable devices to help farmers in outlying locations overcome their difficulties. Manufacturers in Japan are experts in cutting-edge automation and control systems, providing optimal performance and yield in the production of biofertilizers. Due to the restricted space available for agriculture, Singapore’s bioreactor manufacturers excel at designing small, energy-efficient systems. Italian producers integrate conventional agricultural methods with cutting-edge bioreactor technology, fostering a seamless fusion of history and progress. Large-scale bioreactors are given top priority by Brazilian manufacturers to suit the needs of the enormous agriculture sector of the nation. German manufacturers produce dependable and effective biofertilizer manufacturing systems by placing a strong emphasis on precision engineering and stringent quality control.

Manufacturers of Fermenters in Particular Regions in India

Many reputable fermenter manufacturers with cutting-edge products for numerous sectors may be found in Andhra Pradesh. These producers place a high value on dependability, quality, and client happiness. In order to suit the various demands of bioprocessing applications, their fermenters are built with cutting-edge characteristics.

Pradesh, Arunachal

Despite being in the northeast, Arunachal Pradesh has reputable fermenter Suppliers. These producers make sure that their fermenters comply with global quality standards with an emphasis on delivering high-performance goods. They offer ground-breaking solutions to meet the demands of biotechnology research and manufacturing facilities.

Assam

Since Assam has a thriving biotechnology sector, it is crucial that there are top-tier fermenter manufacturers there. These manufacturers provide a wide range of fermenters that facilitate effective microbial culture development, fermentation, and bioconversion because they recognize the value of precision and control in bioprocessing.

Bihar

Expect nothing less than the best from the fermenter manufacturers in Bihar. These producers provide fermenters that excel in performance, durability, and usability using cutting-edge technology and engineering know-how. They serve a wide range of sectors, including the pharmaceutical, biopharmaceutical, and biofuel industries.

Chhattisgarh

Although Chhattisgarh is well recognized for its mineral-rich resources, it also has reputable fermenter manufacturers in its home state. These producers make use of their knowledge to manufacture fermenters that adhere to exacting quality standards. They offer dependable solutions for bioprocess optimization and scale-up with an emphasis on ongoing innovation.

Goa

Goa, a beautiful state, is home to fermenter manufacturers renowned for their technological expertise, in addition to its stunning beaches. These firms create fermenters that guarantee maximum microbial growth and product yield by fusing their engineering prowess with a thorough understanding of bioprocessing requirements.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.