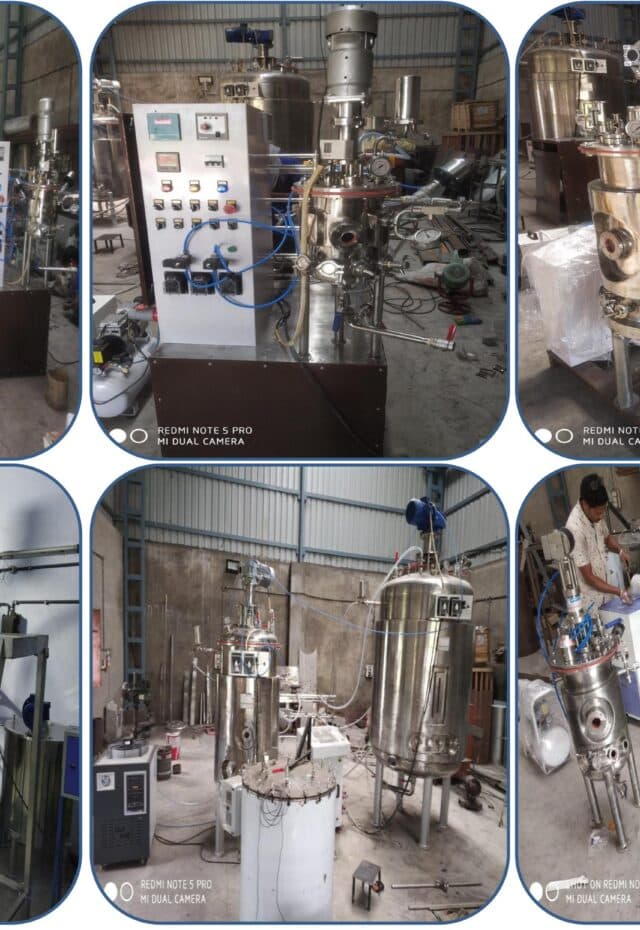

Enzymes Fermentation Plant Suppliers in India

UPM Provide Turnkey Solution For Enzymes Fermentation Plant For Industrial Enzymes Production. UPM 500L-50L Capacity Fermentation Plant Comes With Below Specification.

500L-50L Enzymes Manufacturing Pilot Scale Plant

| OFFER NUMBER | upm-23-24-4062-500-50-E | Date | 01-08-23 | ||

| Description | Technical Specification | Qty | Prize | ||

| 350L Fermenter working volume(Total Volume 500L)( With Inbuilt Heating System-12kw)-2 hp motor | Annexture 1 | 1 Nos | |||

| 35L Fermenter working volume(Total Volume 50L)-0.5 hp motor | Annexture 2 | 1 Nos | |||

| Automatic Ph Monitoring System (Ph Sensor(Imported)+Cable+Transmitter) | 2 Set | ||||

| SS Filter Housing Set With 0.2 Microne PP Plated Filter Cartridge | 4 set | ||||

| Automatic Pressure Control System In Vessel | |||||

| Automatic Ph Controlling System (2 Nos Fixed Speed Peristaltic Pump+ 2 Nos Glass Bottle+ 2 Nos Air Vent 0.2 Microne Filter) | |||||

| Automatic Media Sterilization System | |||||

| Automatic Temperature Controlling System in Process Mode | |||||

| Data Logging Facility For Time, Temperature, Ph, Pressure | |||||

| Oil Free Air Compressor(5 hp) | Annexture 3 | 1 Nos | |||

| Chiller(1 tr) With Inbuilt 70L SS Tank | Annexture 4 | 1 Nos | |||

| Electric Steam Generator(24kw)(Automatic Feed Water) | Annexture 5 | 1 Nos | |||

| SS Skid For Connecting 2 Fermenter With Utilities and valves and clamp and fittings | 1sets | ||||

| Common Control Panel BOX ( 500L & 50L) with PLC Processing Programming 7 inch HMI Control System with Automatic Media Sterilization and VFD For Agitation Speed Control | 1 Nos | ||||

| Commercial Terms and Condition | |||||

| Prize Basis | Ex Factory Ahmedabad | ||||

| Packing | 1%Extra | ||||

| Freight & Insurance | By Purchase | ||||

| GST | Eatra as applicable at the time of dispatch, preseently GST 18% | ||||

| Installation | By customer at their site( Extra By Us ) | ||||

| Payment | 60% Advance and Balance Against Proforma Invoice Before Dispatch | ||||

| Annexture 1 | |||||

| Fermenter Vessel Details | |||||

| Total Volume(Litter) | 500L | ||||

| Diameter(mm) | 650 | ||||

| Straight Height(mm) | 1500 | ||||

| shell(cylindrical) | 3mm thk ss 316 | ||||

| Jacket | 3mmthk SS 304 | ||||

| Top | Dished end with body flanged ( 10% torispherical) | ||||

| Bottom | Dished end( 10% torispherical) | ||||

| leg | mild steel | ||||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | ||||

| manhole | no | ||||

| Inner Finish | Mirror Finish | ||||

| Outer finish | Matt Finish | ||||

| Nozzles-Standard suitable Tc Ferrule or Nipple | |||||

| Total Height | to be confirmed | ||||

| Design Criteria | |||||

| Viscosity | 100 cP | SG | 1.1 | ||

| Pressure | FV to 3kg/cm2 | Temp | 130 deg C | ||

| Mechanical Detail | |||||

| Sealing | Stuffing Bod With PTFE Gland Packing | ||||

| Gearbox (Elmech) | Worm Gearbox/inline helical | ||||

| Motor HP (Elmech) | 2 | NFLP, 4 Pole, Flanged, 3 Ph, 415 V, 50 Hz, | |||

| Impeller Type (From bottom) | Ruston Turbine | Ruston Turbine | |||

| Impeller Blade | 6 Blade | 6 Blade | |||

| Agitator Details | |||||

| MOC Contact Parts | SS 316 | Shaft Diameter | 50 mm | ||

| MOC Non-CP | MS/CS | Shaft Speed(RPM) | 144 | ||

| Air Flow Control | Rotameter(150 LPM) | Speed Controlling | Variable Frequency Drive | ||

| Scope of Supply | Design, manufactur, supply of UPM make agitator assembly. Which includes impeller blades with hub, shaft, lantern assembly with bearing housing etc. | ||||

| Scope of Buyer | Installation in scope of buyer Electricity, Water, Drain Line,Cooling Tower, Valves and Fittings and Clamp In Buyer Scope | ||||

| Annexture 2 | |||||

| Fermenter Vessel Details | |||||

| Total Volume(Litter) | 50L | ||||

| Diameter(mm) | 330 | ||||

| Straight Height(mm) | 580 | ||||

| shell(cylindrical) | 3mm thk ss 316 | ||||

| Jacket | 3mmthk SS 304 | ||||

| Top | Flat body flanged | ||||

| Bottom | Dished end( 10% torispherical) | ||||

| leg | SS 304 | ||||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | ||||

| manhole | no | ||||

| Inner Finish | Mirror Finish | ||||

| Outer finish | Matt Finish | ||||

| Nozzles-Standard suitable Tc Ferrule or Nipple | |||||

| Total Height | to be confirmed | ||||

| Design Criteria | |||||

| Viscosity | 100 cP | SG | 1.1 | ||

| Pressure | FV to 3kg/cm2 | Temp | 130 deg C | ||

| Mechanical Detail | |||||

| Sealing | Stuffing Bod With PTFE Gland Packing | ||||

| Gearbox (Elmech) | Worm Gearbox | ||||

| Motor HP (Elmech) | 0.5 | NFLP, 4 Pole, Flanged, 3 Ph, 415 V, 50 Hz, | |||

| Impeller Type (From bottom) | Ruston Turbine | Ruston Turbine | |||

| Impeller Blade | 6 Blade | 6 Blade | |||

| Agitator Details | |||||

| MOC Contact Parts | SS 316 | Shaft Diameter | 25mm | ||

| MOC Non-CP | MS/CS | Shaft Speed(RPM) | 190 | ||

| Air Flow Control | Rotameter(150 LPM) | Speed Controlling | Variable Frequency Drive | ||

| Scope of Supply | Design, manufactur, supply of UPM make agitator assembly. Which includes impeller blades with hub, shaft, lantern assembly with bearing housing etc. | ||||

| Scope of Buyer | Installation in scope of buyer Electricity, Water, Drain Line,Cooling Tower, Valves and Fittings and Clamp In Buyer Scope | ||||

| Annexture 3 | |||||

| MODEL | PE 5 T NL | Working Pressure (KG/CM2) | 8 | ||

| Working Pressure (KG/CM2) | 8 | Piston Displacement (CFM) | 15.6 | ||

| Free Air Delivery (CFM) | 11 | Air Receiver (LTRS.) | 200 | ||

| Motor (H.P) | 5 | Electrical Condition | 415 Volts / 3 Phase / 50 Hz | ||

| Annexture 4 | |||||

| Capacity | 1 Tr | Medium To Be Cool | Water | ||

| Tank | 40L | inlet Tempetature In Chiller | 35 Degree Celcius | ||

| Power Consumption | 3 kw | Outlet Temperature From Chiller | 15 Degree Celcius | ||

| Refrigerent | R-22 | Water Pump | 0.5HP | ||

| Annexture-5 | |||||

| Electric Steam Generator | |||||

| Capacity | 24kw | Capacity(steam output) | 32 kg/hr | ||

| Design Pressure:4kg/cm2 | 6 kg/cm2 | Maximum Operating Pressure: | 4kg/cm2 | ||

| Power Supply: | 440V/50Hz/Ac | SS Safety Valve(Mechanical Spring Type) | Adjustable | ||

| Base Structurex | MS | Material of construction of Shell(Chamber-30L): | SS304 | ||

| Insulation | Glass Wool | Temperature Sensor | PT100 | ||

| Pressure Switch | Den Force kp 36 | Pressure Guage | Jel Filled Dial Type | ||

| Controlling | Micro Processor Based Temperature Control With Digital Display | ||||

| Water Level | Automatic Feed Water | ||||

Industrial Enzymes and Their Applications

Industrial enzymes find applications in diverse industries, such as:

1. Food and Beverage Industry

Enzymes are widely used in the food and beverage industry for various purposes, including:

Brewing

: Enzymes aid in the conversion of starches into fermentable sugars, which is essential in brewing beer.Bakery

: Enzymes improve dough handling, texture, and shelf life of baked goods.Dairy

: Enzymes enhance cheese production and improve milk processing.Fruit Juice

: Enzymes assist in fruit juice clarification and filtration.

2. Pharmaceutical Industry

In the pharmaceutical industry, enzymes are employed in the synthesis of drugs, such as antibiotics and anti-cancer agents. They are also used in diagnostics and drug testing.

3. Biofuels and Renewable Energy

Enzymes are crucial in converting biomass into biofuels, such as ethanol and biodiesel. They contribute to the development of sustainable and renewable energy sources.

4. Textile and Leather Industry

Enzymes play a role in the processing of textiles and leather, assisting in tasks such as desizing, scouring, and biopolishing.

5. Environmental Remediation

Enzymes are used in environmental applications, like wastewater treatment and bioremediation, to break down pollutants and contaminants.

Economic Fermentation Plant For Biofertilizer and Biopesticide Production

Manufacturer of Fermenter in Telangana

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.