100L SS Pilot Scale Fermenter

Bioreactor Fermenter Manufacturer in Maharashtra

When it comes to bioreactor fermenter manufacturers in Maharashtra, one name stands out in the industrial fermentation landscape. This article explores the different aspects of industrial fermenters and bioreactors available in Maharashtra, focusing on their applications, benefits, and why they are the preferred choice for many businesses in the state, especially in Mumbai.

Industrial Fermenter in Mumbai

Industrial fermenters are crucial for the large-scale production of various biological products. In Mumbai, the demand for high-quality industrial fermenters is on the rise. Manufacturers in Maharashtra meet this demand by offering a range of fermenters tailored to different industrial needs. Whether it’s for pharmaceutical production or food processing, their industrial fermenters ensure efficiency and reliability.

Manufacturer of Fermenter and Bioreactors

Fermenter 5KL to 50KL Bangalore

While Mumbai is a significant hub for industrial fermenters, the availability of fermenters ranging from 5KL to 50KL in nearby Bangalore also serves the needs of Maharashtra-based industries. These large-capacity fermenters are ideal for extensive industrial applications, providing the necessary scale for significant production.

Industrial Bioreactor in Mumbai

Industrial bioreactors play a vital role in various industrial processes, including the production of pharmaceuticals, enzymes, and biofuels. In Mumbai, suppliers and manufacturers provide a range of bioreactors that cater to these diverse needs. The key to choosing the right bioreactor lies in understanding the specific requirements of the production process and selecting a bioreactor that offers optimal performance and scalability.

Borosilicate Single Column Bubble Photobioreactor (100 Ltr)

One of the specialized types of bioreactors available is the Borosilicate Single Column Bubble Photobioreactor. With a capacity of 100 liters, this bioreactor is perfect for specific applications that require precise control over the fermentation process. Its borosilicate construction ensures durability and resistance to chemical reactions, making it a reliable choice for high-precision fermentation.

Industrial Scale Fermenter

For large-scale industrial applications, industrial scale fermenters are indispensable. These fermenters are designed to handle substantial volumes and provide consistent results. They are equipped with advanced features that allow for precise control of fermentation conditions, ensuring the highest quality output for industrial processes.

State-of-the-art bioreactor by Uma Pharmatech Machinery – Leading Bioreactor Manufacturer.

SS Bio Fermenter, Size: Standard, Capacity: 5000

Standard-sized SS bio fermenters with a capacity of 5000 liters are commonly used in various industries. These stainless steel fermenters offer durability and resistance to corrosion, making them suitable for long-term industrial use. Their large capacity makes them ideal for processes that require significant volume handling.

Conical Fermenters

Conical fermenters are another popular choice for industrial applications. Their conical shape facilitates easy removal of sediments and simplifies the cleaning process. These fermenters are used widely in the brewing industry and other fermentation-based production processes.

Uma Pharmatech Machinery: Premier Manufacturer of Bioreactors.

Industrial Fermenter, Size: 100 Liter to 5000 Liter, Capacity: 5000 Liters

The availability of industrial fermenters in sizes ranging from 100 liters to 5000 liters provides flexibility for different production scales. Whether for small-scale experimental setups or large-scale industrial production, these fermenters cater to various needs.

Fermentation Techniques

Fermentation techniques play a critical role in the production of various biological products. Advanced fermentation techniques, coupled with state-of-the-art fermenters, ensure high efficiency and quality of the end product. These techniques include enzyme development by fermentation, which is crucial for producing enzymes used in various industrial processes.

Industrial Fermenter Or Bioreactor, Size: 100 L To 1000 L, Capacity: 500 Liters

For medium-scale production, industrial fermenters or bioreactors with capacities ranging from 100 liters to 1000 liters are ideal. These units provide the necessary flexibility and scalability for medium-sized industrial applications, ensuring efficient fermentation processes.

SS 306 Stainless Steel Fermenter

SS 306 stainless steel fermenters are known for their high durability and resistance to chemical reactions. These fermenters are widely used in the pharmaceutical and biotechnology industries, where maintaining the purity of the fermentation process is crucial.

Two Stage Fermentor Model for Biofertilizer Production, Capacity: 50 Litre Onwards

For specific applications such as biofertilizer production, two-stage fermentor models are available. These fermentors, with capacities starting from 50 liters, are designed to handle the unique requirements of biofertilizer production, ensuring efficient and high-quality output.

Uma Pharmatech Machinery: Leading Bioreactor Manufacturers in India.

Industrial Production Fermenter

Industrial production fermenters are designed for large-scale production needs. These fermenters offer advanced features that allow for precise control over fermentation conditions, ensuring consistent and high-quality production outcomes.

Benchtop Fermentors/ Industrial Fermenter

For research and development purposes, benchtop fermentors are an excellent choice. These small-scale fermenters are ideal for experimental setups and pilot studies, providing the necessary control and precision for developing new fermentation processes.

Bio Fermentor, Size: Lab, Capacity: 1 Liter – 100 Liter

Bio fermentors for laboratory use come in sizes ranging from 1 liter to 100 liters. These fermentors are perfect for small-scale experimental work and pilot production, providing the necessary flexibility and control for developing new fermentation processes.

Wine Fermentation Vessel

Wine fermentation vessels are specialized fermentors used in the winemaking process. These vessels are designed to handle the specific requirements of fermenting grape juice into wine, ensuring the best quality product.

Uma Pharmatech Machinery: Expert Automatic Laboratory Fermenter Bioreactor Manufacturer.

high-quality industrial fermenters and bioreactors in Maharashtra, especially in Mumbai, caters to the diverse needs of various industries. With a wide range of options available, from small-scale lab fermenters to large-scale industrial units, businesses can find the perfect solution for their fermentation needs. The advanced features and durability of these fermenters ensure efficient and reliable production processes, making them an essential component in the industrial fermentation landscape.

| OFFER NUMBER | upm-22-23-4052-100L-E | Date | 26-07-23 | ||

| Description | Technical Specification | Qty | Prize(Rs.) | ||

| 100L( Total Volume) Fermente-0.5 hp motor | Annexture 1 | 1 Nos | |||

| Automatic Media Sterilization | |||||

| Automatic Air Pressure Control In Vessel | |||||

| Automatic Temperature Control In Process Mode(Cooling Water Circulation & Cooling Tower is In Buyer Scope) | |||||

| Ph Measurement System(Sterilizable Ph Sensor(Indian Made)+3 Meter Cable+ Transmitter) | 1 Set | ||||

| SS Filter Housing Set With 0.2 Microne PP Plated Filter Cartridge | 2 set | ||||

| Oil Free Air Compressor(2 hp) | Annexture 2 | 1 Nos | |||

| Chiller(0.5 tr) With Inbuilt 15 L SS Tank | Annexture 3 | 1 Nos | |||

| Electric Steam Generator(18kw) | Annexture 4 | 1 Nos | |||

| Control Panel BOX with PLC based Control System With Touch Screen HMI | 1 Nos | ||||

| Optional Control | |||||

| Fixed Speed Peristaltic Pump For Addition of Acid/Base/Nutrient/Innoculation( With 1L Glass Bottle + 3 Meter Silocon Tube+ 0.2 Micron Vent Filter+ Ss Hose Attachment) | |||||

| Do Sensor Set With Cable and Transmitter | |||||

| Load Cell | 1 set | ||||

| Automatic Filter Sterilization | 1 Nos | ||||

| Automatic Ph Control System | 1 Nos | ||||

| Commercial Terms and Condition | |||||

| Prize Basis | Ex Factory Ahmedabad | ||||

| Packing | 1%Extra | ||||

| Freight & Insurance | By Purchase | ||||

| GST | Eatra as applicable at the time of dispatch, preseently GST 18% | ||||

| Pipe line | All Pipeline , Tubing and Electrical Work In Buyer Scope | ||||

| Installation | By customer at their site( Extra By Us After Completion Of Pipeline and Electric Work)(Free Video Calling Support) | ||||

| Payment | 60% Advance and Balance Against Proforma Invoice Before Dispatch | ||||

| Annexture 1 | |||||

| Fermenter Vessel Details | |||||

| Total Volume(Litter) | 100(Approx.) | ||||

| Diameter(mm) | 400 | ||||

| Straight Height(mm) | 800 | ||||

| shell(cylindrical) | 3 mm thk ss 316 | ||||

| Jacket | 3 mmthk SS 304 | ||||

| Top | Body Flange | ||||

| Bottom | Dished end( 10% torispherical) | ||||

| leg | mild steel | ||||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | ||||

| manhole | No | ||||

| Top Glass | 75mm(Vision 30mm) | ||||

| Front Glasas | 75mm(Vision 30mm) | ||||

| Inner Finish | Mirror Finish | ||||

| Outer finish | Matt Finish | ||||

| Nozzles-Standard suitable – Nipple | |||||

| Total Height | to be confirmed | ||||

| Design Criteria | |||||

| Viscosity | 100 cP | SG | 1.1 | ||

| Pressure | FV to 3kg/cm2 | Temp | 130 deg C | ||

| Mechanical Detail | |||||

| Sealing | Mech Seal | ||||

| Gearbox (Elmech) | Worm Gearbox | ||||

| Motor HP (Elmech) | 0.5 | NFLP, 4 Pole, Flanged, 3 Ph, 415 V, 50 Hz, | |||

| Impeller Type (From bottom) | Ruston Turbine | Ruston Turbine | |||

| Impeller Blade | 6 Blade | 6 Blade | |||

| Agitator Details | |||||

| MOC Contact Parts | SS 316 | Shaft Diameter | 35 mm | ||

| MOC Non-CP | MS/CS | Shaft Speed(RPM) | 144 | ||

| Air Flow Control | Rotameter(100 LPM) | Speed Controlling | Variable Frequency Drive | ||

| Scope of Supply | Design, manufactur, supply of UPM make agitator assembly. Which includes impeller blades with hub, shaft, lantern assembly with bearing housing etc. | ||||

| Scope of Buyer | Installation in scope of buyer (Electricity,Insulation, Water, Drain Line, Valves and Fittings and Clamp ) | ||||

| Annexture 2 | |||||

| Oil Free Air Compressor | |||||

| Working Pressure (KG/CM2) | 6 | ||||

| Free Air Delivery (CFM) | 6.5 | Air Receiver (LTRS.) | 50 | ||

| Motor (H.P) | 2 | Electrical Condition | 230 Volts / 1 Phase / 50 Hz | ||

| Annexture 3 | |||||

| Capacity | 0.5 Tr | Medium To Be Cool | Water | ||

| Tank | 15L | inlet Tempetature In Chiller | 35 Degree Celcius | ||

| Power Consumption | 0.5 kw | Outlet Temperature From Chiller | 15 Degree Celcius | ||

| Refrigerent | R-22 | Water Pump | 0.25HP | ||

| Annexture-4 | |||||

| Electric Steam Generator | |||||

| Capacity | 18kw | Capacity(steam output) | 22 kg/hr | ||

| Design Pressure:4kg/cm2 | 6 kg/cm2 | Maximum Operating Pressure: | 4kg/cm2 | ||

| Power Supply: | 440V/50Hz/Ac | SS Safety Valve(Mechanical Spring Type) | Adjustable | ||

| Base Structurex | MS | Material of construction of Shell(Chamber-35L): | MS | ||

| Insulation | Glass Wool | Temperature Sensor | PT100 | ||

| Pressure Switch | Den Force kp 36 | Pressure Guage | Jel Filled Dial Type | ||

| Controlling | Micro Processor Based Temperature Control With Digital Display | ||||

| Water Level | Automatic Feed Water System | ||||

UPM is ready to present its self to be one of the Largest Fermenter Manufacturer in Maharashtra. We are supported by advanced Automation and state-of-the-art Facility To Control Fermenter. WE allows to produce Different Size and Capacity Of Fermenter Manufacturer in Maharashtra? We have our own manufacturing facility To expert team working with us that plays a vital part in enhancing Our Fermenter Bioreactor product quality.

Fermenter Bioreactor Manufacturers in Maharashtra

If you`re looking to buy one of our Fermenter From Manufacturer in Maharashtra, feel free to reach us through our website/Call/Email. Uma Pharmatech Machinery suppliers in are the Biotech/Pharmaceutical/Agriculture industry-leading Manufacturer that can be offered the best price for our Pilot Scale and Production Fermenter. Contact us to learn more About Uma Pharmatech Machinery.

The growth of our company is Calculated by the level of satisfaction of our customers will receive from our Fermenter. Thus we invest 100% into improving the quality of our Bioreactor over time. Our products are sturdy Construction and have passed several quality tests.

| Total Volume | 100L |

|---|---|

| Working Volume | 70% Of Total Volume |

| Contact Part | SS 316L |

| Non Contact Part | SS304 |

| Sheet Thickness | 4 mm |

| Inner Finish | Mirror Finish |

| Outer Finish | Matt Finish |

| Motor | 1 HP |

| RPM | 144 |

| Speed Control | Using VFD(Variable Frequency Drive) |

| Design Temperature | 130 Degree Celsius |

| Temperature Sensor | PT-100 |

| Design Temperature | 121 Degree Celsius |

| Max. Operating Temperature | 121 Degree Celsius |

| Design Pressure | 6 kg/cm2 |

| Max. Operating Pressure Of Jacket | 4 kg/cm2 |

| Max. Operating Pressure Of Vessel | 1.2 kg/cm2 |

| Safety Valve | Adjustable Spring Operated |

| Pressure Indicator | Analog Type |

| Air Outlet | 0.2 Micron PP Filter With 5” SS 316L Filter Housing |

| Air Inlet | 0.2 Micron PP Filter With 5” SS 316L Filter Housing |

| Air Outlet Through | Through Shell Tube Type Condenser ( Heat Exchanger) |

| Sparger System | Ring Type Air Spurger System At Bottom |

| Sealing | Mechseal/ Stuffing Box |

| Baffle | 4 Nos( Size Vessel Dia/10) |

| Impeller | 3 Nos Of Adjustable Ruston Turbine( Six Blade) |

| Bottom End | Dish End With 50 mm Tc Drain Valve For Material Outlet |

| Sight Glass | Toughen Glass |

| Top Glass | Toughen Glass |

| Top Light Glass | Toughen Glass |

Fermenter Manufacturer In Maharashtra

MANUFACTURING FACILITY FOR FERMENTER BIOREACTOR in Maharashtra

upm have a solid foundation of Of EOT Crane for the Trusted Manufacturer Of Industrial Fermenter. Our Lab Fermenter Manufacturing , Designing and Purchasing process is equipped with Automatic that allow us create Bioreactor As Per ASME Guideline to the preferences of our Existing clients From Pune, Nashik, Nagpur, Amravati, Jalgaon, Satara, Jalna, Akola, Mumbai, Thane, Nanded, Kolhapur, Latur, Wardha, Dhule, Panvel, Bhusawal and Many Cities Of Maharashtra .

Suppliers Of Fermenter Bioreactor

Modern machinery for a variety of industries, including biotechnology, pharmaceuticals, and agriculture is provided by fermenter manufacturers in Maharashtra. A strong fermentation technology ecosystem can be found in Pune, Mumbai, Jalgaon, Akola, Nashik, Aurangabad, Amravati, Kolhapur, Solapur, Satara, Nandurbar, Jalna, Nanded, Dhule, Thane, and Navi Mumbai. These producers specialize in creating premium fermenters that are specifically designed to satisfy the demands of biofertilizer manufacturing. They guarantee the best nutrient conversion and increased crop output with their knowledge and cutting-edge designs. Similar to this, Maharashtra-based fermenter manufacturers provide cutting-edge technologies that facilitate effective enzyme synthesis, purification, and scaling up. Their ground-breaking approaches enable businesses to create enzymes for a variety of uses, from food and drink to pharmaceuticals and biofuels.

INDUSTRIAL FERMENTER MANUFACTURER

Quality is the main stay of our Fermenter in the effort to maintain Best Services and Quality. Uma Pharmatech Machinery improve and Learn processes From Large Experience. Uma Pharmatech make sure our clients get what they Deserve Bacterial and Fungus Growth for.

Maharashtra is a notable location for API manufacturing facilities, and bioreactor manufacturers are essential in this industry. They offer reliable and legal bioreactor systems for the manufacture of API, guaranteeing exact control over crucial process variables. These manufacturers are located in Maharashtra’s Pune, Mumbai, and other cities, and they serve the needs of the pharmaceutical sector. The bioreactors produced in these facilities adhere to strict rules and are made to accommodate the requirements of large-scale API production.

Industrial Fermenter For Enzymes and API Production

Laboratory Fermenter For Biotech Lab

Uma Pharmatech has been operating since 2018 and is well-known within the Biotech and Agriculture industry for being one of the leading Fermenter Manufacturer in Maharashtra located. Our managed to cover miles in a matter of Second to the leadership and guidance of our Team Manager Ankur Patel. Ankur Patel is the renowned CEO of the company and our Manager. The experience in the industry proved to be an asset to the business and its expansion.

Maharashtra’s bioreactor manufacturers are known for their technological proficiency and dedication to quality. In order to meet the various demands of various businesses, they provide a wide range of bioreactors, from lab-scale to industrial-scale. They have revolutionised the bioreactor market with their cutting-edge technology and never-ending innovation, making it possible to produce numerous bio-based goods efficiently and affordably.

fermenter manufacturer in Hyderabad

Biofertilizer Plant With Fermenter and Lab Equipment

Ankur Patel is always keeping his fingers in the air to stay him and his team up-to-date on the latest trends and changes in the market. This aids them in meeting their obligations. We are Using top-quality and advanced raw materials and advanced technology. That helps our business to establish its mark in the industry.

Top-notch fermentation equipment is available for numerous sectors from fermenter manufacturers in Maharashtra, specifically in Pune, Mumbai, Jalgaon, Akola, Nashik, Aurangabad, Amravati, Kolhapur, Solapur, Satara, Jalna, Nanded, Dhule, Thane, and Navi Mumbai. These manufacturers excel at creating premium fermenters that meet the particular requirements of biofertilizer production. They offer fermenters created to optimise the fermentation process, providing effective and reliable biofertilizer production, thanks to their cutting-edge technology and knowledge. Additionally, their innovative fermenters for producing enzymes are designed to give remarkable performance, enabling biotechnology firms to generate enzymes with the highest level of accuracy and productivity. Bioreactors are essential in API manufacturing facilities, and reputed bioreactor producers may be found in Maharashtra. These suppliers focus on delivering bioreactors that are specifically designed to meet the needs of API manufacturing facilities.

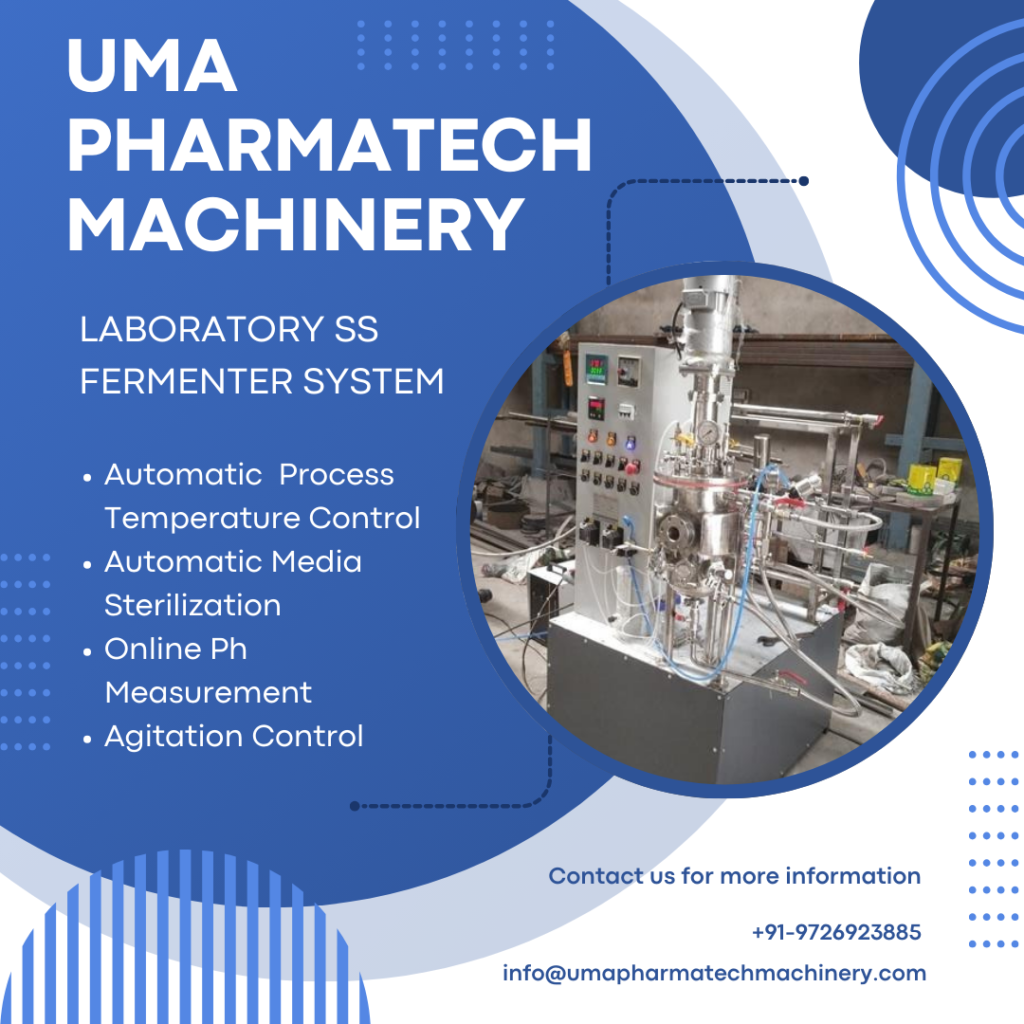

laboratory ss fermenter

Supplier Of Fermenter In India

we can Make it to you in custom designs at a competitive cost. As one of the impressive Manufacturers of Fermenter in Maharashtra located in India we also offer all-inclusive support for our customers after they have completed the sale process. Contact us today, for more information.

Additionally, Maharashtra’s bioreactor manufacturers have competence that goes beyond facilities that make APIs. Additionally, they provide a huge selection of bioreactors appropriate for a variety of applications and sectors. These Maharashtra manufacturers have the expertise and capacity to provide effective and dependable bioreactors for any industry, including pharmaceuticals, biotechnology, food and beverage, and renewable energy. They continually push the limits of bioreactor technology with their dedication to innovation and customer satisfaction.

Leading Manufacturer of Fermenter In Maharashtra

Maharashtra is home to a number of thriving cities, including Mumbai, Pune, Jalgaon, Akola, Nashik, Aurangabad, Amravati, Kolhapur, Solapur, Satara, Jalna, Nanded, Dhule, Thane, and Navi Mumbai, which are renowned for their industrial strength. Fermenter and bioreactor manufacturers have a presence in these locations, which has aided in the expansion of the state’s industrial industry. Their state-of-the-art facilities and knowledgeable team enable them to design and construct fermenters and bioreactors that adhere to the highest performance and quality standards around the world.

Manufacturers of fermenters in Maharashtra take advantage of their technological know-how and market insight to create fermenters that are not only effective but also environmentally beneficial. They put a high priority on sustainability and incorporate waste-management systems and energy-efficient designs into their fermenters, reducing the fermentation process’ negative effects on the environment. by offering green alternatives.