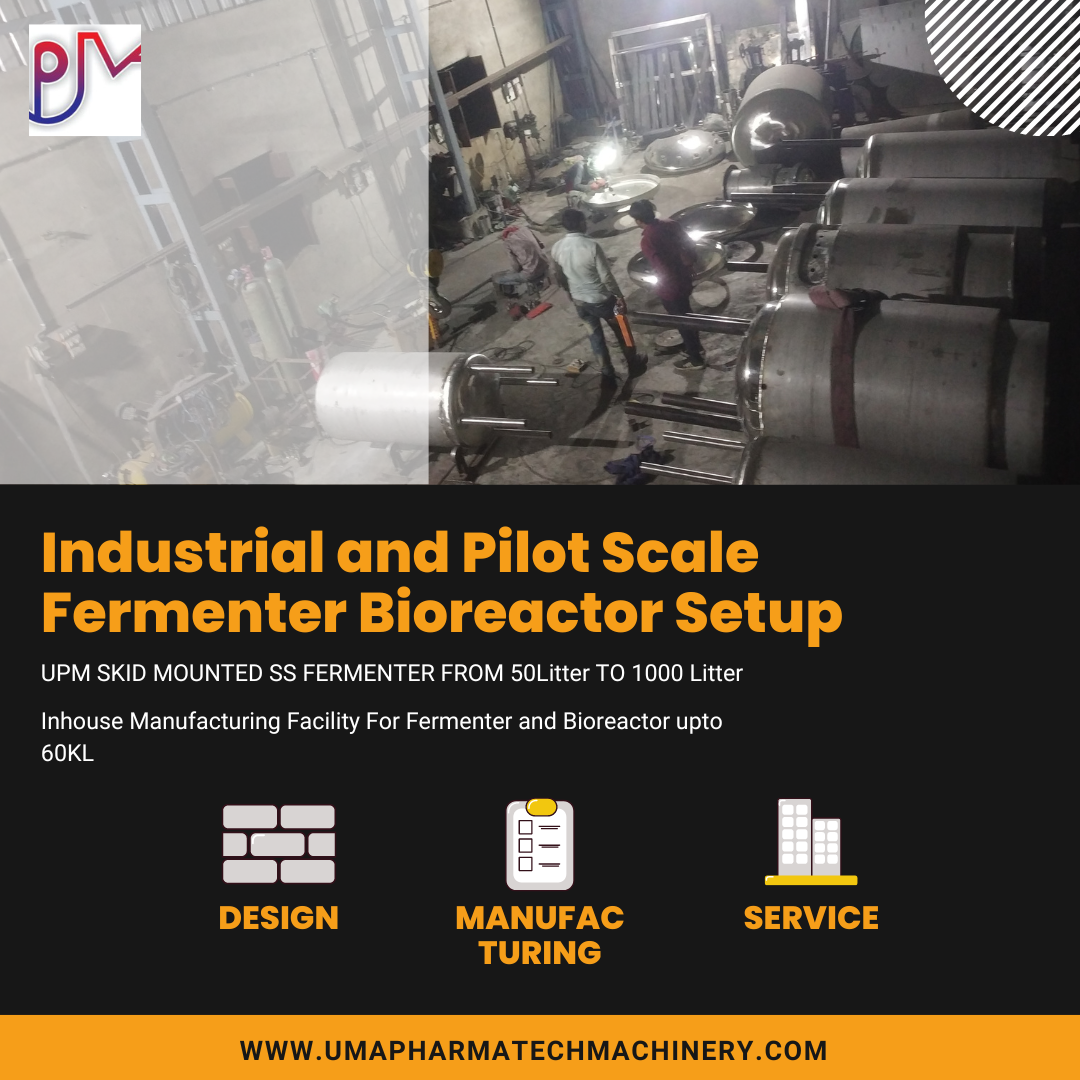

INDUSTRIAL FERMENTER MANUFACTURER IN TAMILNADU

Fermenters for industrial use are used in a variety of industries, including food, pharmaceuticals, and biofuels. These Fermentation vessels are used to produce large amounts of microorganisms, such as bacteria, yeast, and fungi, which are then used to make a variety of products. This article will provide a comprehensive overview of industrial fermenters Manufacturers, their applications, and the various types available.

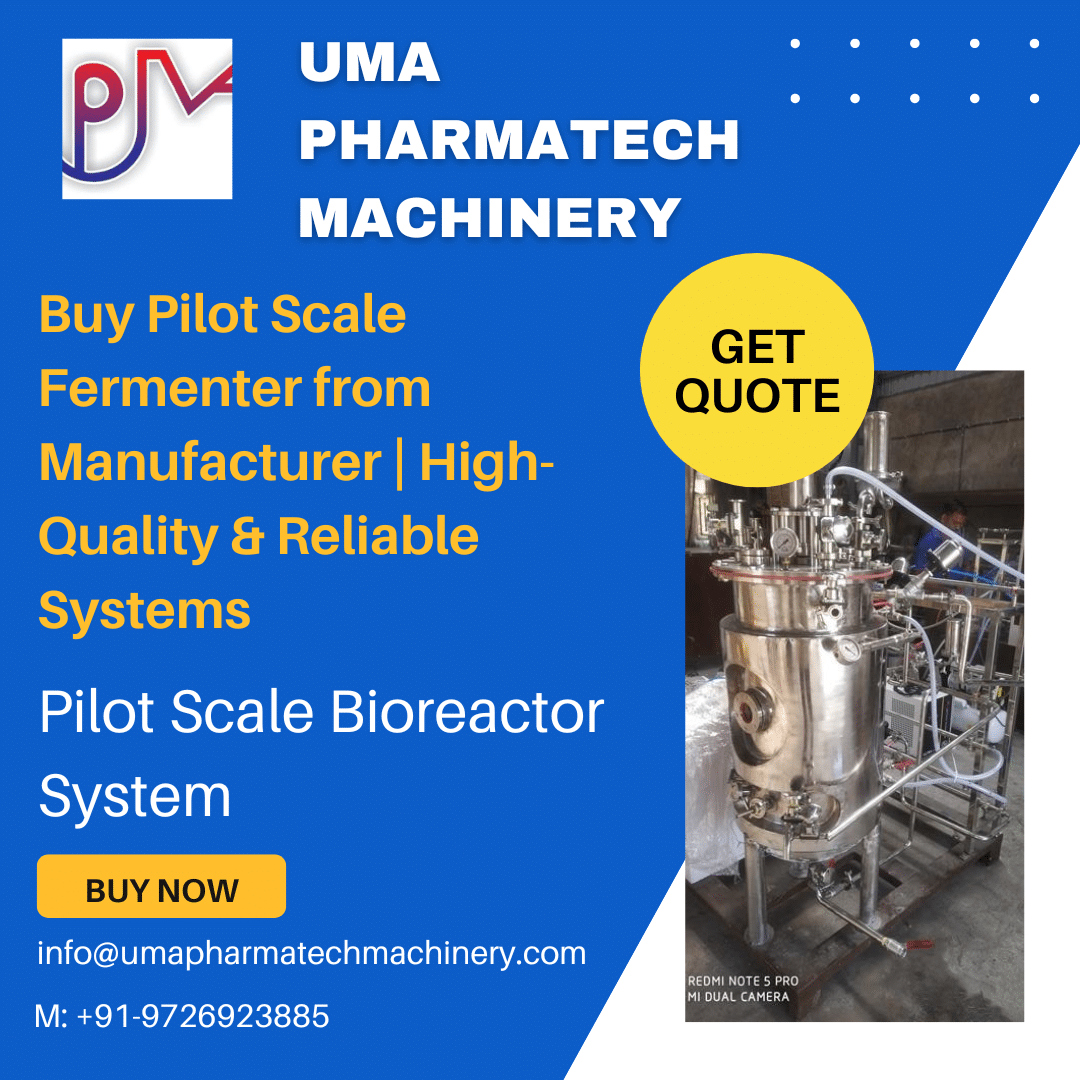

Pilot Scale Fermenter Manufacturer in Tamilnadu

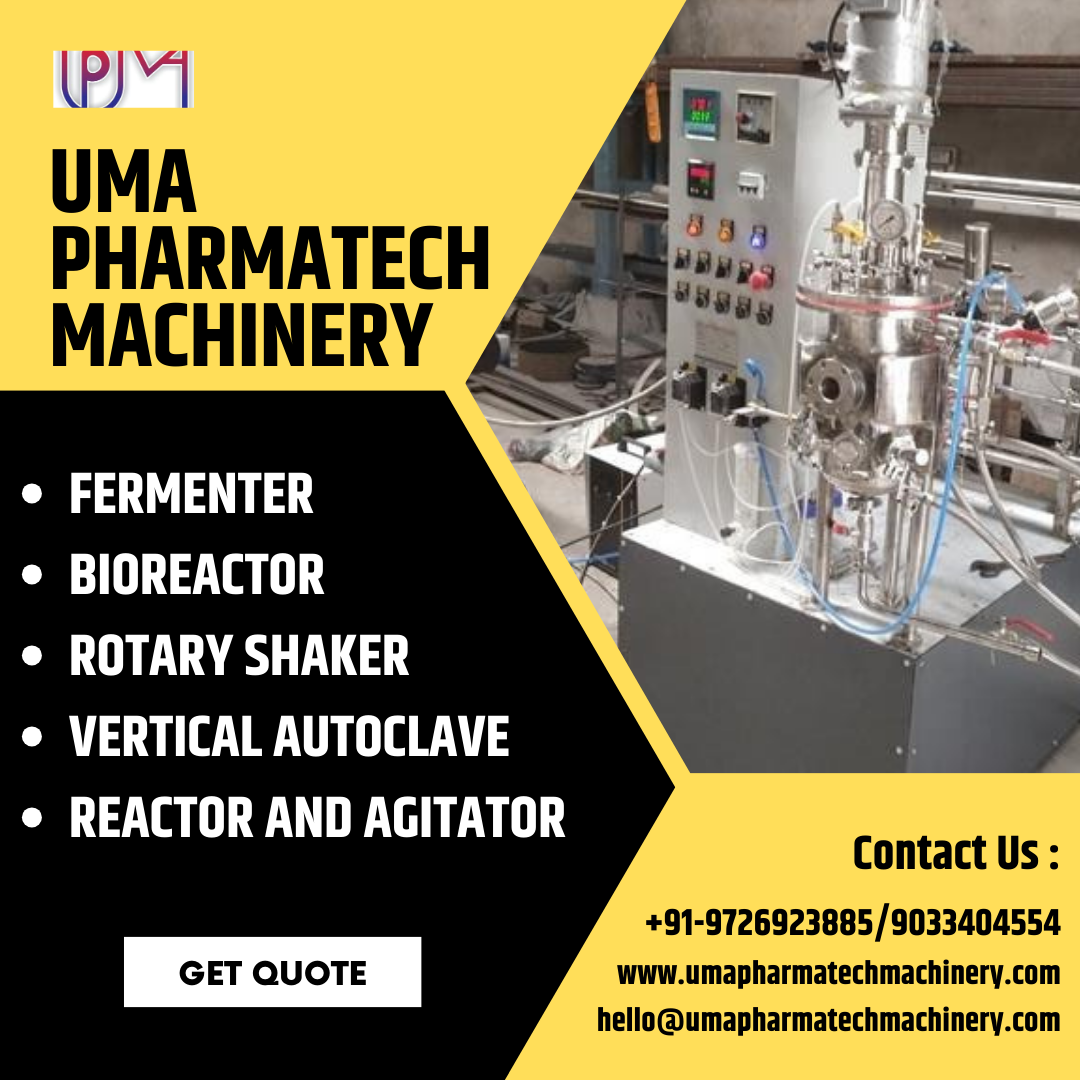

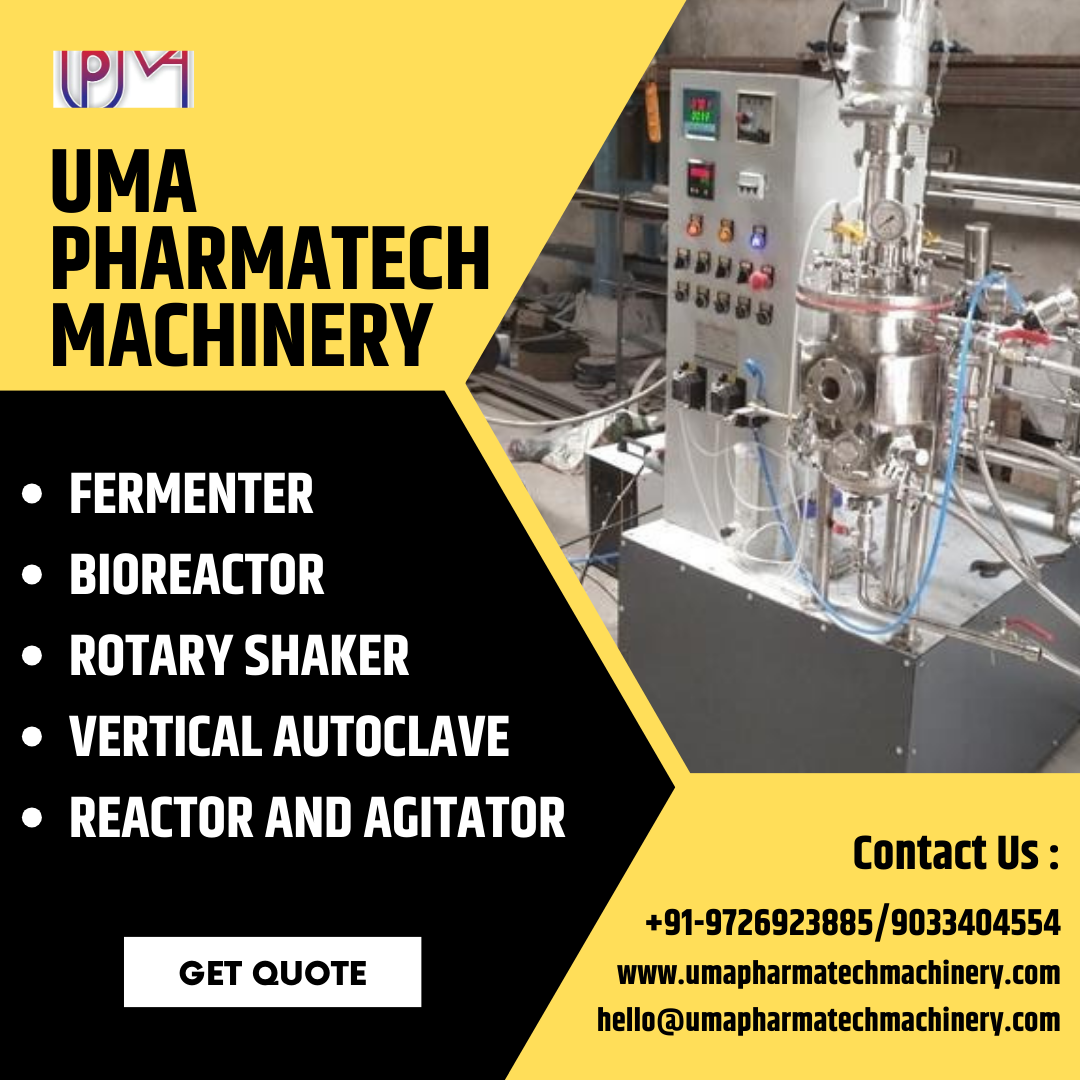

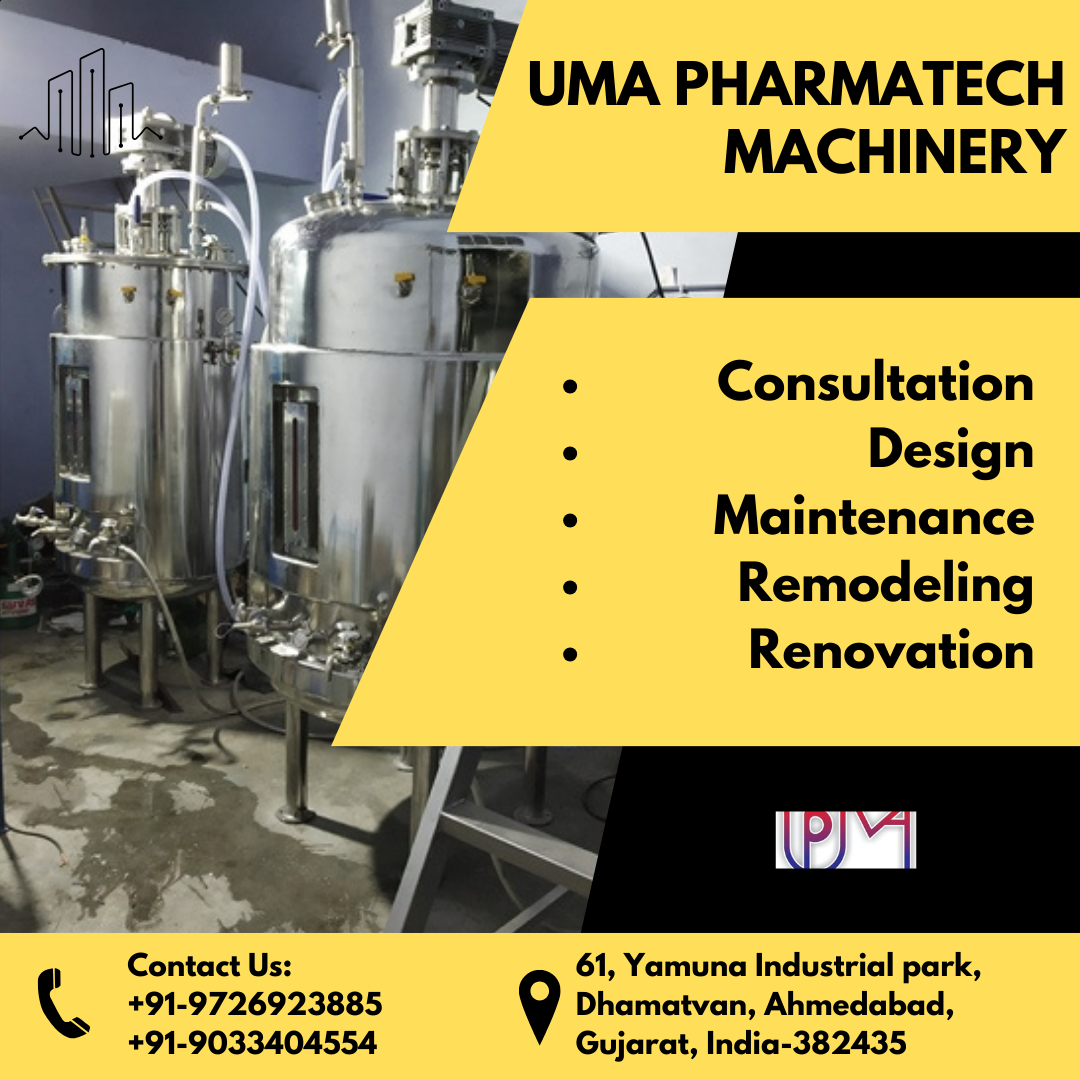

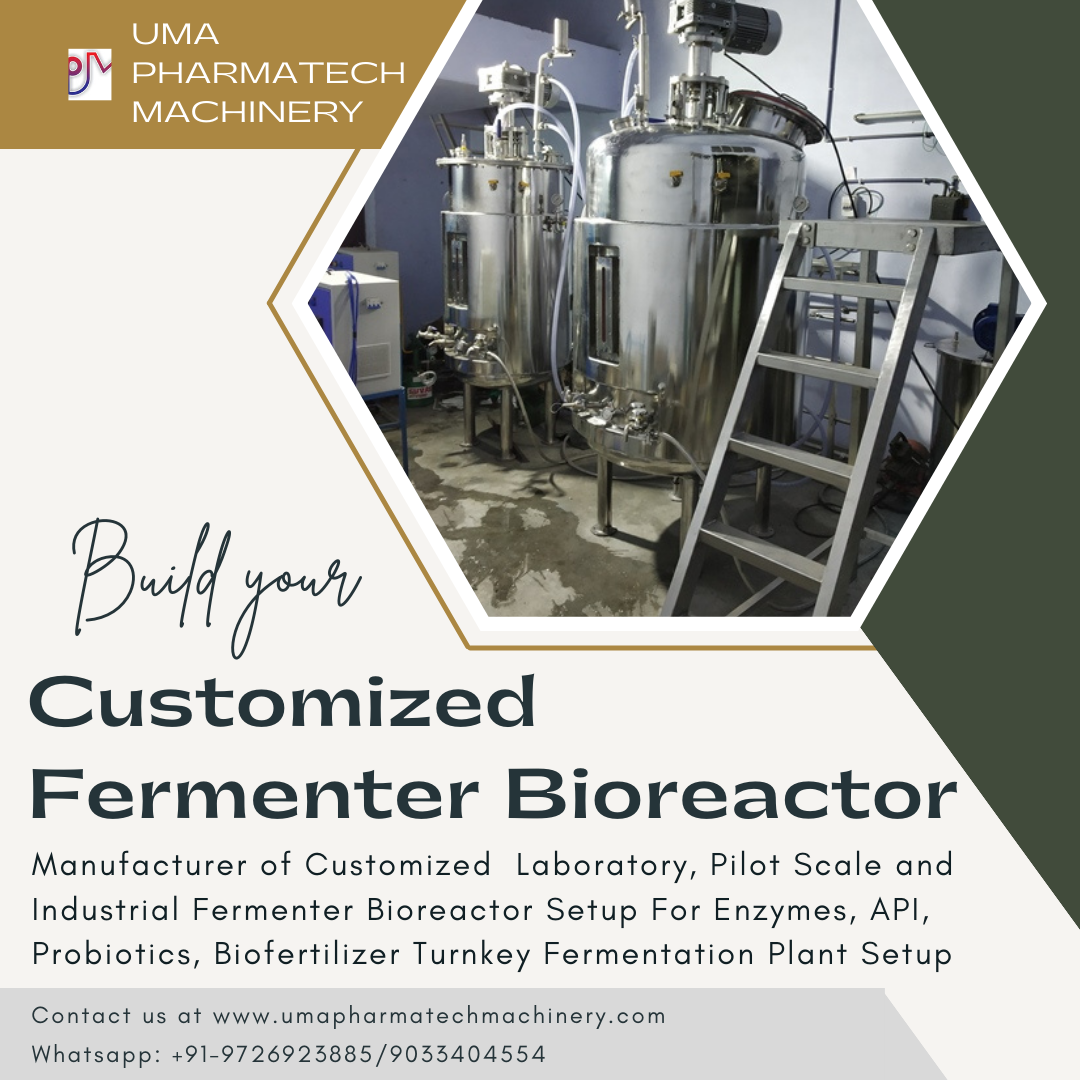

Are you searching for a trusted Bioreactors Manufacturer in Tamilnadu? Look no further than Uma Pharmatech Machinery! Our cutting-edge bioreactors, coupled with advanced Steam Sterilizer Machines, offer precision and innovation for optimal performance.

Collaborate with us and experience excellence as we lead the industry in crafting Vertical Bioreactors in Tamilnadu. Witness our expertise in action: YouTube Video.

Explore our offerings:

- Bioreactors Suppliers in Tamilnadu

- Bioreactor Manufacturers Tamilnadu

- Bioreactor Manufacturer Tamilnadu

Elevate your bioprocessing with Uma Pharmatech Machinery—your trusted partner in Tamilnadu, where cities like Chennai and others stand out as industrial hubs!

- Chennai

- Coimbatore

- Madurai

- Tiruchirappalli

- Salem

- Tirunelveli

- Erode

- Vellore

- Thoothukudi

- Thanjavur

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Manufacturer of Fermenter in Telangana

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal

Top 10 States for Agriculture:

- Punjab

- Haryana

- Madhya Pradesh

- Uttar Pradesh

- Rajasthan

- Gujarat

- Maharashtra

- Andhra Pradesh

- Telangana

- Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

Top 3 Agriculture Countries:

- United States

- China

- India

Applications of Laboratory Fermenters

Laboratory fermenters are used in a variety of industries, including biotechnology, chemistry, and pharmaceuticals.

Enzyme, protein, and antibiotic production.

Biofuel and bioplastics production.

New product and process research and development.

Existing manufacturing processes should be optimised.

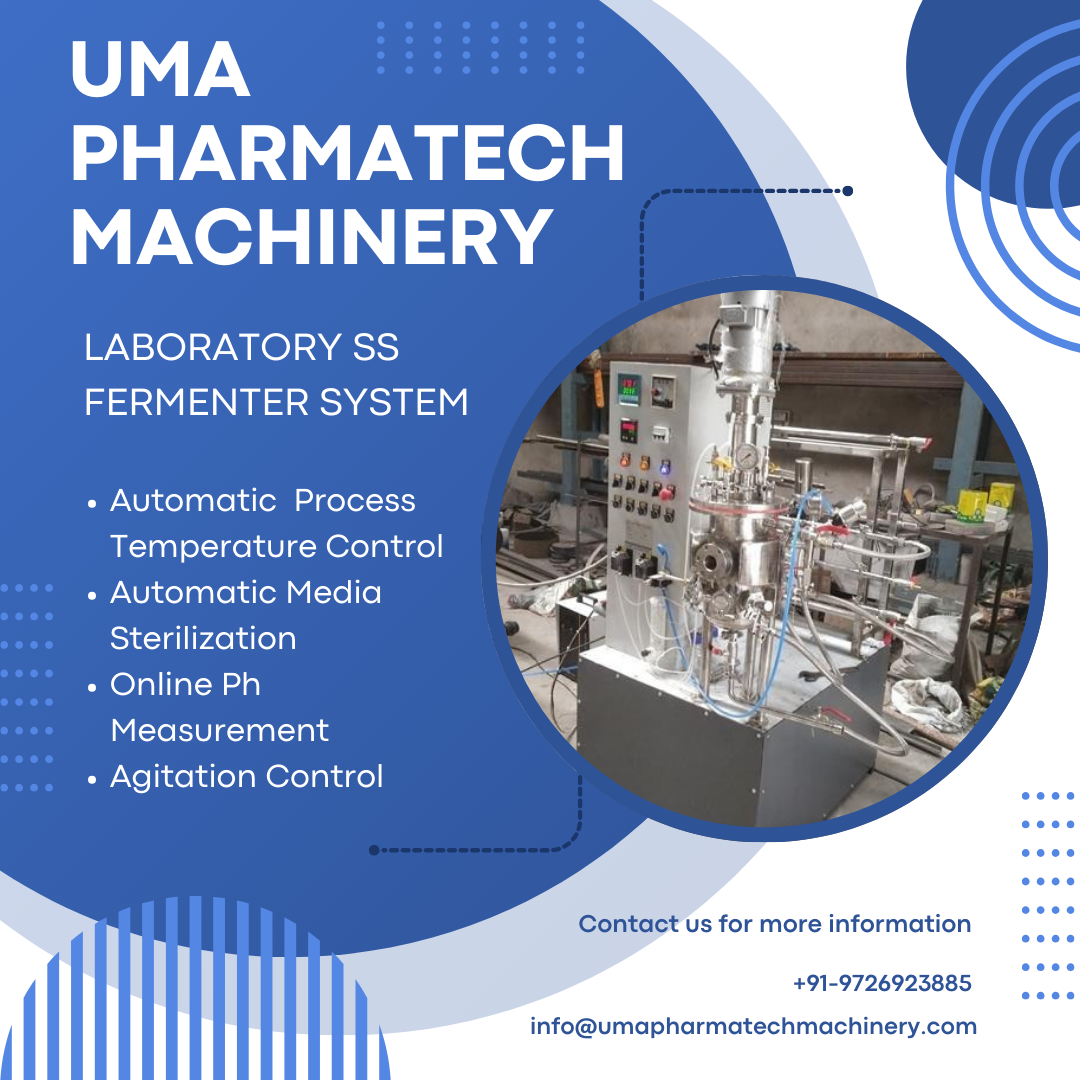

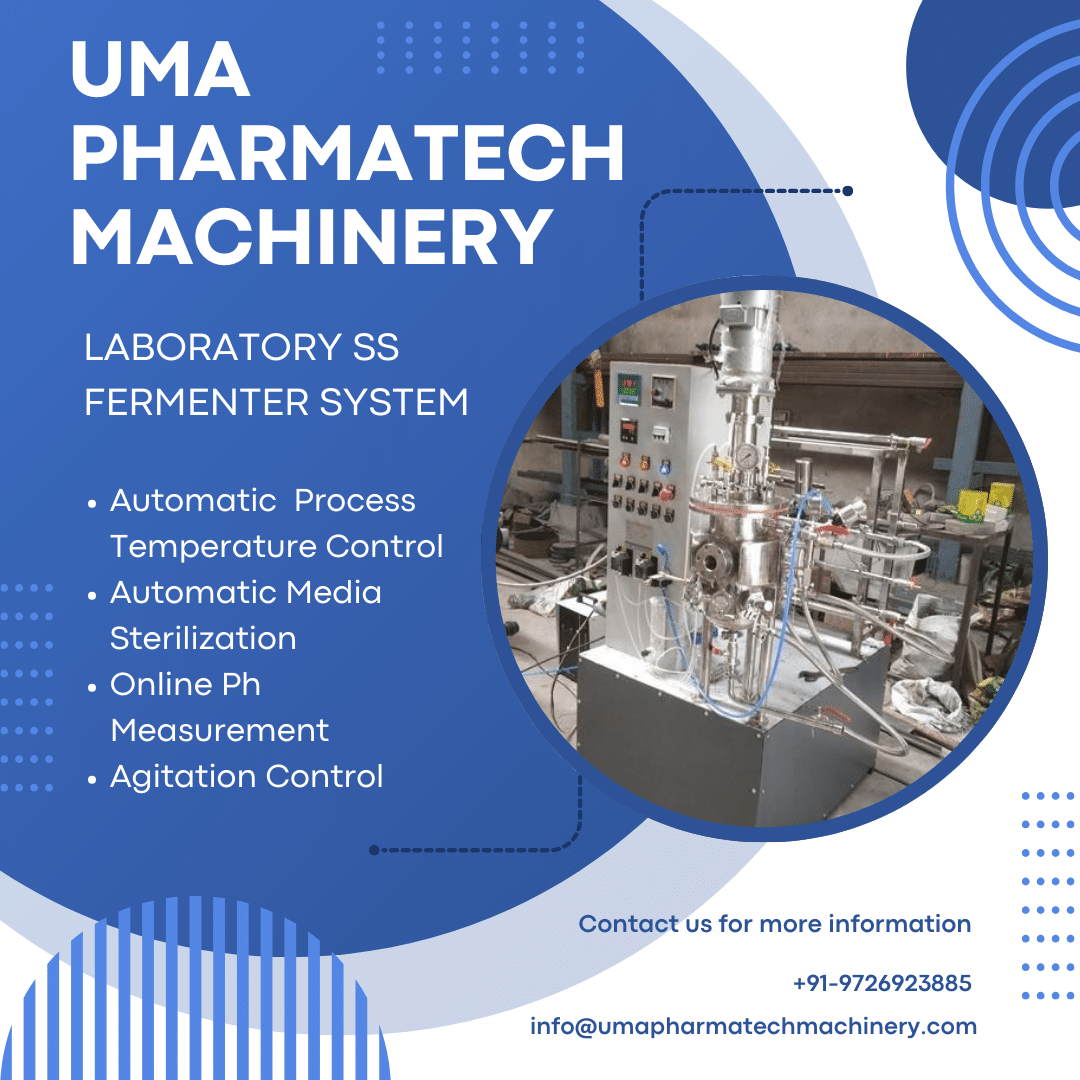

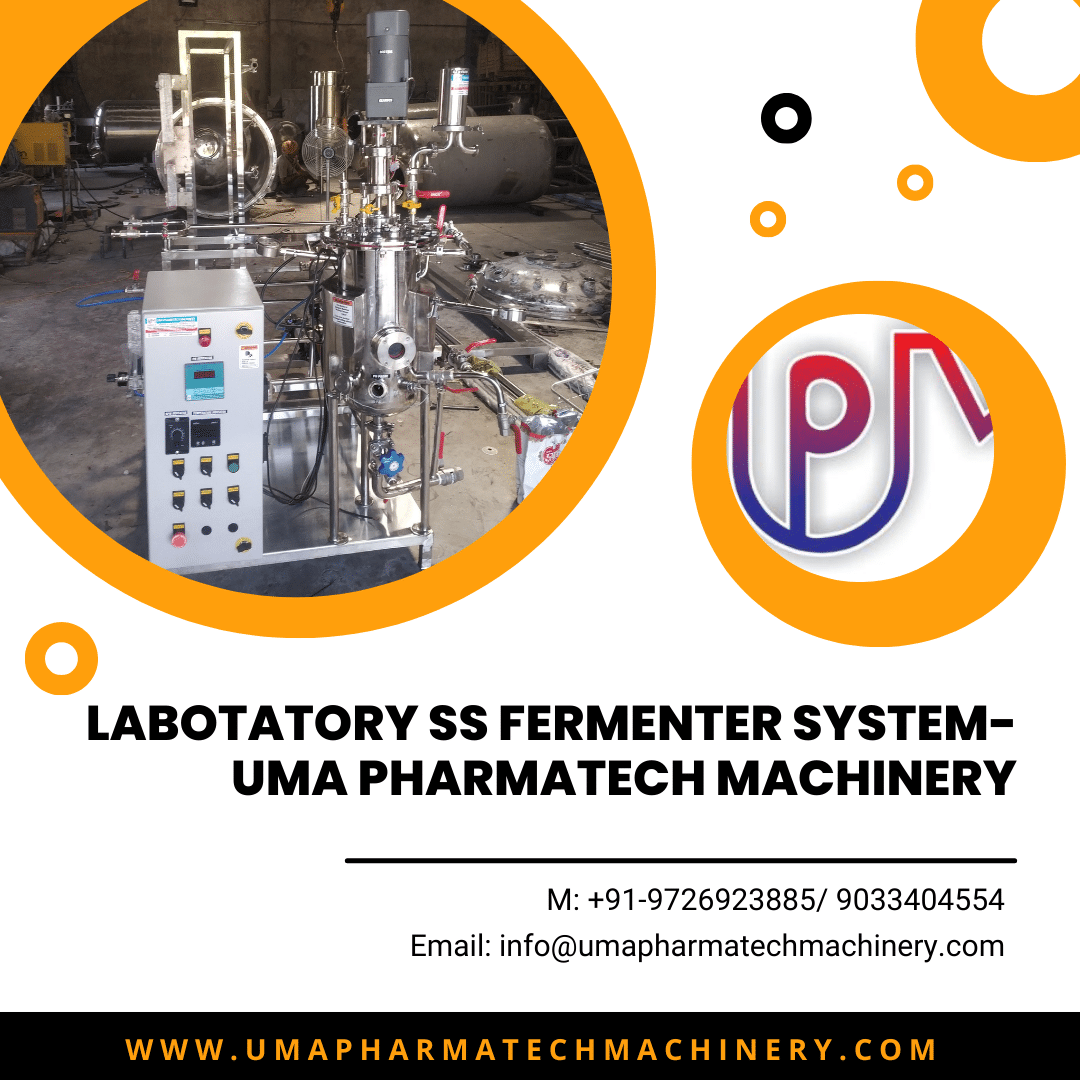

What is a Laboratory Fermenter?

A laboratory fermenter, also known as a bioreactor, is a piece of equipment used for large-scale fermentation of microorganisms in the biotechnology, chemical, and pharmaceutical industries. The fermenter provides a controlled environment in which microorganisms can grow, multiply, and produce substances such as enzymes, proteins, and antibiotics. A vessel or container, agitator, sparger, temperature control system, pH control system, and monitoring system are all part of the equipment.

There are several types of laboratory fermenters on the market, and the choice of fermenter is determined by the nature of the microorganisms and the research requirements. The following are the most common types of laboratory fermenters:

Batch fermenters are ideal for research that requires a specific product at the end of the fermentation process. The process begins with the addition of a nutrient-rich medium to the vessel, followed by microorganism inoculation. The fermentation process continues until the desired product is formed, at which point the vessel’s contents are removed.

Fed-Batch Fermenter: In this type of fermenter, nutrients are added to the vessel at regular intervals. The process is appropriate for research that requires the production of a specific product that necessitates the use of a nutrient-rich medium.

Air-Lift Fermenter: The agitator in this type of fermenter is replaced with air bubbles, which lift the nutrient-rich medium, creating a continuous flow of medium in the vessel. The method is appropriate for research that requires gentle mixing of the medium.

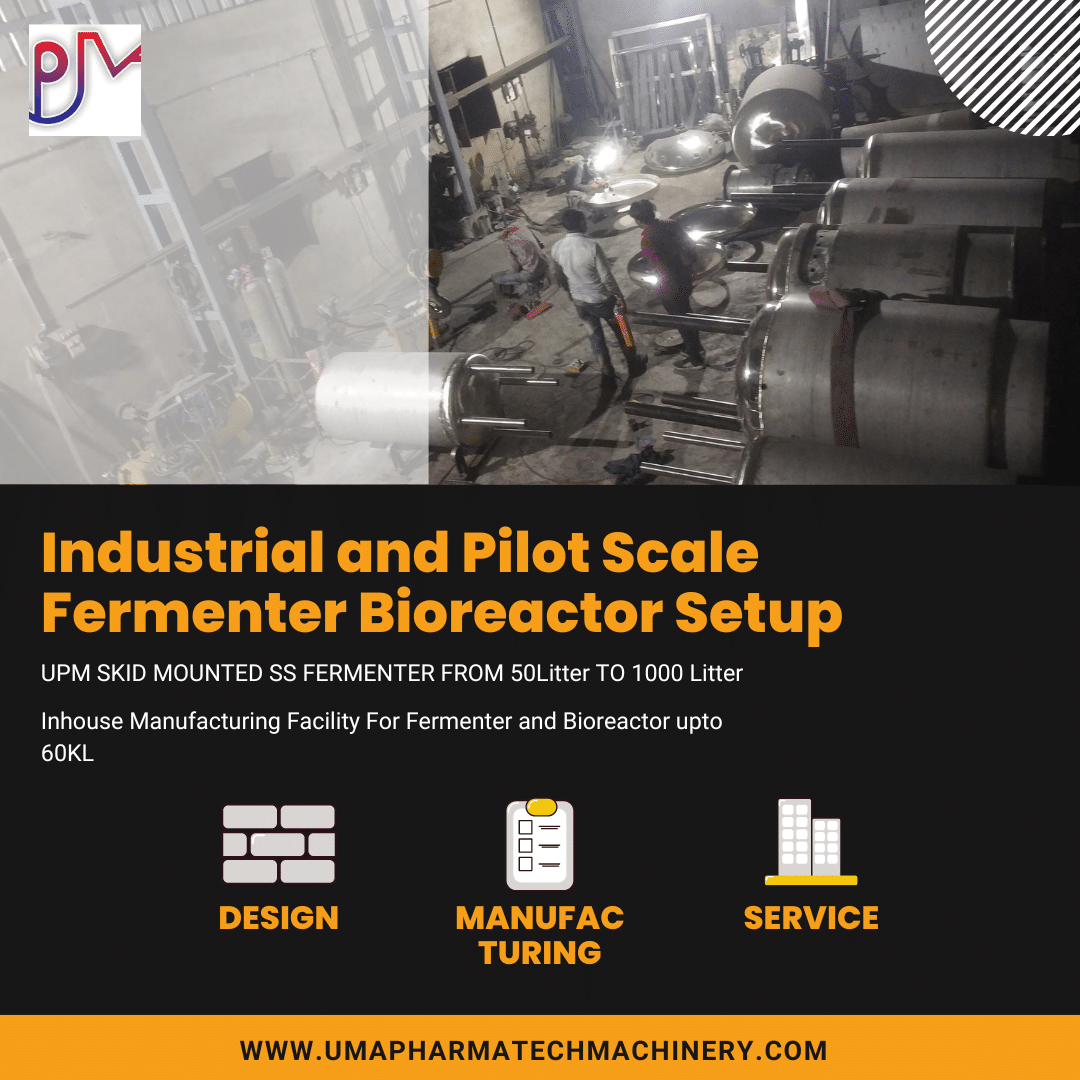

What is an Industrial Fermenter?

An industrial fermenter is a large vessel used to produce microorganisms, enzymes, and other biological products on a large scale. These vessels are typically made of stainless steel and have a capacity of several thousand liters. Industrial fermenters can be used for batch or continuous processes and are designed to provide optimal conditions for the growth and reproduction of microorganisms.

Uma Pharmatech Machinery is Leading Industrial Fermenter Manufacturer In India.

Industrial fermenters are classified into three types: batch fermenters, continuous fermenters, and fed-batch fermenters.

Batch Fermenters: A batch fermenter produces a single batch of a product at a time. Because these fermenters are emptied and cleaned between batches, they are ideal for producing small amounts of a product.

Continuous fermenters are designed to produce a consistent supply of product over an extended period of time. These fermenters are not emptied between batches, and the product is harvested continuously as it is manufactured.

Fed-Batch Fermenters: Fed-batch fermenters combine batch and continuous fermentation. These vessels are initially filled with a nutrient-rich broth, which is then supplemented with nutrients during the fermentation process.

Uma Pharmatech Machinery is Leading Industrial Fermenter Manufacturer In India.

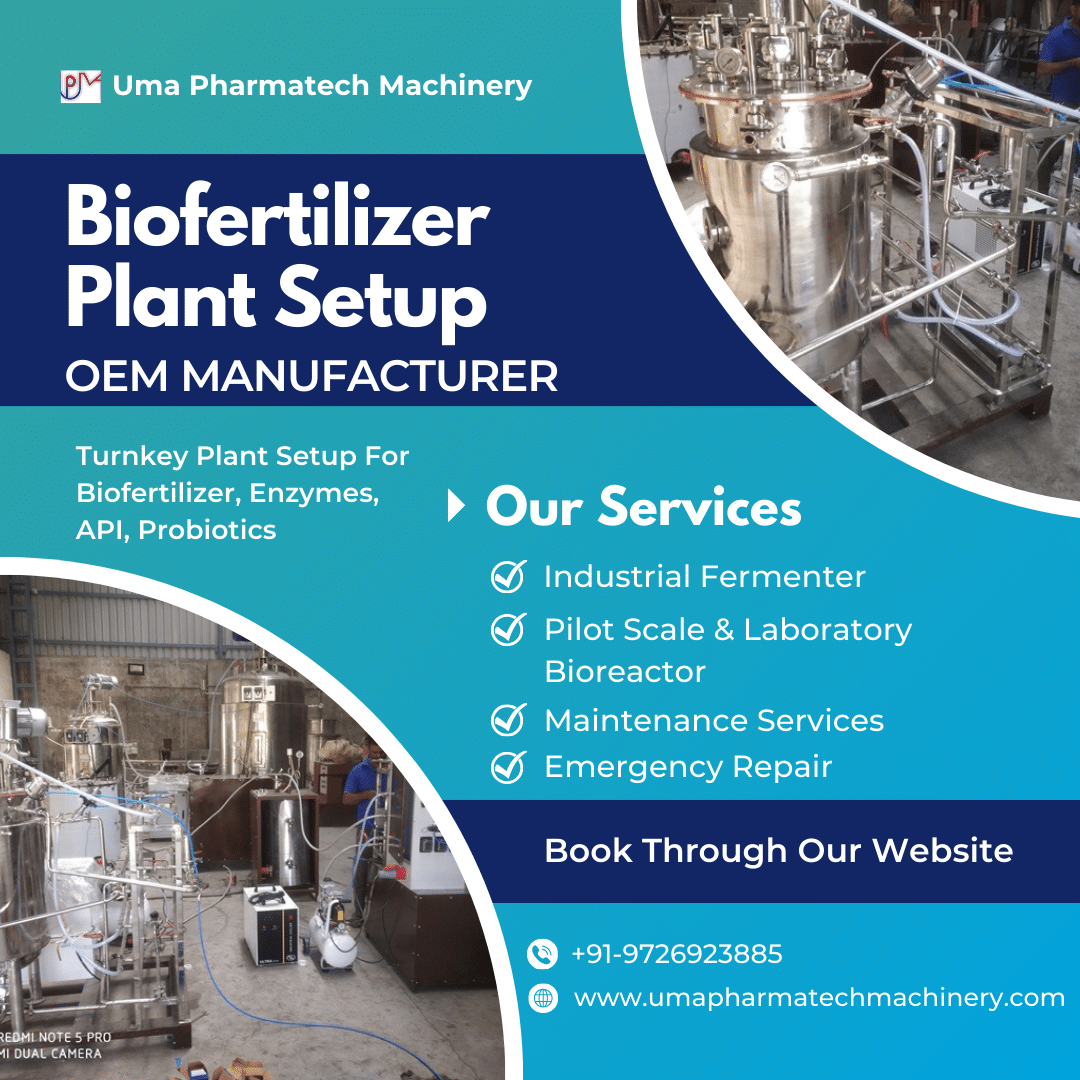

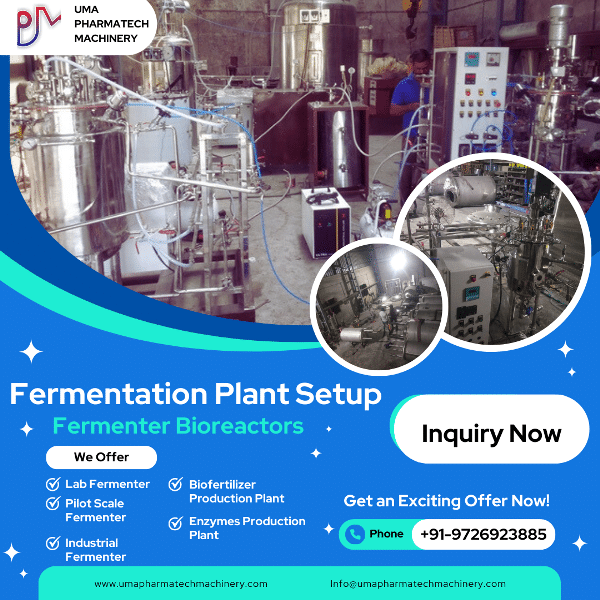

Fermenter For Biofertilizer Plant Setup

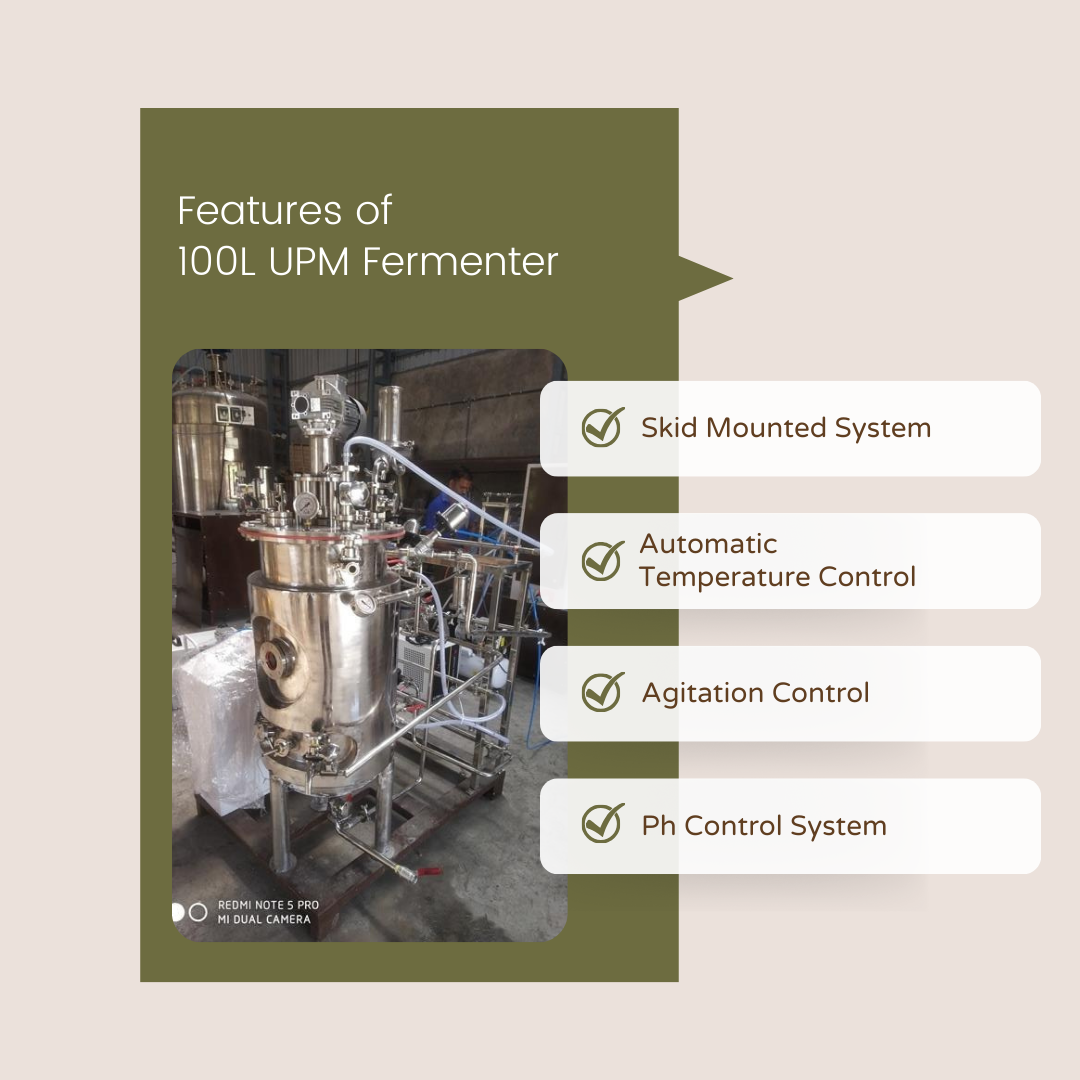

We understand the importance of having the right tools for your research as laboratory equipment experts. A Pilot Scale fermenter Supply is an essential piece of equipment for any laboratory that works with microorganisms. We will cover everything you need to know about Exporter of fermenters and Bioreactors and how they can help you with your research in this comprehensive guide.

Top Suppliers of Fermenter in Tamilnadu

Fermenters are used in a variety of industries, including:

Food industry: Industrial fermenters are used to manufacture a variety of food products such as yoghurt, cheese, and bread.

Pharmaceutical industry: Antibiotics, enzymes, and vaccines are manufactured using industrial fermenters.

Industrial fermenters are used to produce ethanol and other biofuels in the biofuels industry.

Laboratory Fermenter For Enzymes Production in Tamilnadu

There are several advantages to using a laboratory fermenter in your research, including:

Improved Control: A laboratory fermenter provides microorganisms with a controlled environment in which to grow and multiply, resulting in consistent and reproducible results.

Increased Efficiency: A laboratory fermenter can produce a large amount of product in a short period of time, reducing the amount of time and effort required for research.

Reduced Contamination: Because a laboratory fermenter is a closed system, it reduces the risk of contamination from outside sources.

Fermenter Quality is Improved: Automatic laboratory fermenter provider a controlled environment for microorganisms to produce high-quality products, resulting in higher yields and less waste.

What is the Price Of Fermentor and Bioreactor in India?

Price Of Laboratory Bioreactor Start From 6 Lac With Semiautomatic Control. 100 Litter Pilot Scale Fermenter Set With Automatic Controlling With Chiller, Steam Boiler, Compressor, Skid, Ph Control System Price Start From 15 Lac/ Set. Uma Pharmatech Machinery Provide High Quality PLC Based Automatic Fermenter as a Indian Exporter. Price Of UPM Fermenter Is Very Low Compared With Other Indian Brand. 1000 Litter Industrial Fermenter Price Stary From 23Lac/ Plant With All Utility. Because Of Inhouse Bulk Manufacturing Of Fermenter Uma Pharmatech Can Sell Low Cost Fermenter and Bioreactor For Pilot Scale and Lab Scale Plant.

Glass Fermenter Cost in India is Start From RS 500000/ Bioreactor. in 2023 Cost Of Glass Bioreactor increase to much then Expected Because Of Electronics and Raw Material Price Increase. Stainless Steel Bioreactor is best Compared With Glass Bioreactor Because Pressure Can Not Sustain By Glass. Proper Sterilization and Process Can Be Automated in Stainless Steel Insitu Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Best Indian Exporter and Fermenter Manufacturer in India.

Suppliers of Bioreactors in Tamilnadu

industrial fermenters Indian Exporter are an important Machinery in many industries because they provide a cost-effective and efficient way of producing large quantities of microorganisms and other biological products. We hope that this comprehensive guide has provided useful information about the various types of fermenters Manufacturer in India, their applications, and the various processes involved. Please do not hesitate to contact us if you have any questions or comments.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering fermenter manufacturer and bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.