FERMENTER MANUFACTURER IN BHUBANESHWAR

Fermenter vessels are essential in the brewing and fermentation industries. They are used in the fermentation of a wide range of substances, including beer, wine, and dairy products. In this article, we will look at fermenter vessels, their different types, applications, and benefits.

Fermenter Standard Model For Pilot Scale UPM Fermenter UPM 1000L

Fermenter Standard Model For Pilot Scale UPM Fermenter UPM 1000L

| Description | Economic | Basic | Advance | Pro |

|---|---|---|---|---|

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor (Pt-100) | Yes | Yes | Yes | Yes |

| Online pH Measurement | No | Yes | Yes | Yes |

| pH Control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| DO Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility (Touch Screen 4" HMI) | PLC With Data Logging Facility (Touch Screen 7" HMI) |

| Scada | No | No | No | Yes |

| Inbuilt Heater in Vessel (Suitable For Biofertilizer Production) | Optional | Yes | No | No |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust Filter | No | No | No | Yes |

| Spray Ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Manufacturer of Fermenter in Telangana

https://thefooduntold.com/food-science/lcg9jt74vw Andhra Pradesh, https://geneticsandfertility.com/q0emg18kx Arunachal Pradesh, Tramadol Buy Assam, Tramadol Buy Online Cheap Bihar, https://ict-pulse.com/2024/07/jqdss6j Chhattisgarh, https://www.techonicsltd.com/uncategorized/5ox573cg Goa, source site Gujarat, https://autismwish.org/gc7jtorq78 Haryana, follow Himachal Pradesh, https://brako.com/en/2oqjk8ids Jharkhand, Tramadol Online Overnight Delivery Karnataka, enter Kerala, click here Madhya Pradesh, https://etbscreenwriting.com/fi54ovhl9c1 Maharashtra, source site Manipur, go site Meghalaya, https://living4youboutique.com/j97e3rbd Mizoram, https://bxscco.com/dj5umprbi Nagaland, enter Odisha, https://geneticsandfertility.com/10dzsp39g Punjab, https://thefooduntold.com/food-science/3iax7ww Rajasthan, go to site Sikkim, https://splendormedicinaregenerativa.com/im7bq3h Tamil Nadu, enter site Telangana, https://gsaudemarketing.com.br/be39nfard Tripura, https://www.adroitprojectconsultants.com/2024/07/25/coaahrz02wn Uttar Pradesh, https://www.pathwaysmagazineonline.com/v0kyzy9rc Uttarakhand, go here West Bengal

Top 10 States for Agriculture:

- enter Punjab

- Tramadol Uk Buy Haryana

- https://brako.com/en/blpgal18x Madhya Pradesh

- Buy Cheap Tramadol Overnight Uttar Pradesh

- https://www.inaxorio.com/qxey2caw0tu Rajasthan

- https://hymnsandhome.com/2024/07/25/hnkqqoqb Gujarat

- Tramadol Online Overnight Cod Maharashtra

- Tramadol Bula Anvisa Andhra Pradesh

- https://living4youboutique.com/d30eojk331 Telangana

- follow link Karnataka

Supplier of Bioreactor in Telangana

Indian City Where We Supply Our Fermenter and Equipment’s

- Hyderabad

- Warangal

- Nizamabad

- Karimnagar

- Khammam

- Ramagundam

- Mahbubnagar

- Nalgonda

- Adilabad

- Siddipet

- Miryalaguda

- Suryapet

- Jagtial

- Nirmal

- Mancherial

- Kamareddy

- Bhongir

- Wanaparthy

- Sangareddy

- Jangaon

Manufacturer of Bioreactor

- United States

- China

- India

- Brazil

- Russia

- France

- Canada

- Australia

- Germany

- Argentina

- Turkey

- Indonesia

- Pakistan

- Ukraine

- Mexico

- Italy

- Thailand

- Vietnam

- United Kingdom

- Spain

By Tramadol Online Top 3 Agriculture Countries:

- source site United States

- go China

- https://thefooduntold.com/food-science/b5ibw05d6 India

Who Manufactures Bioreactor Fermenter?

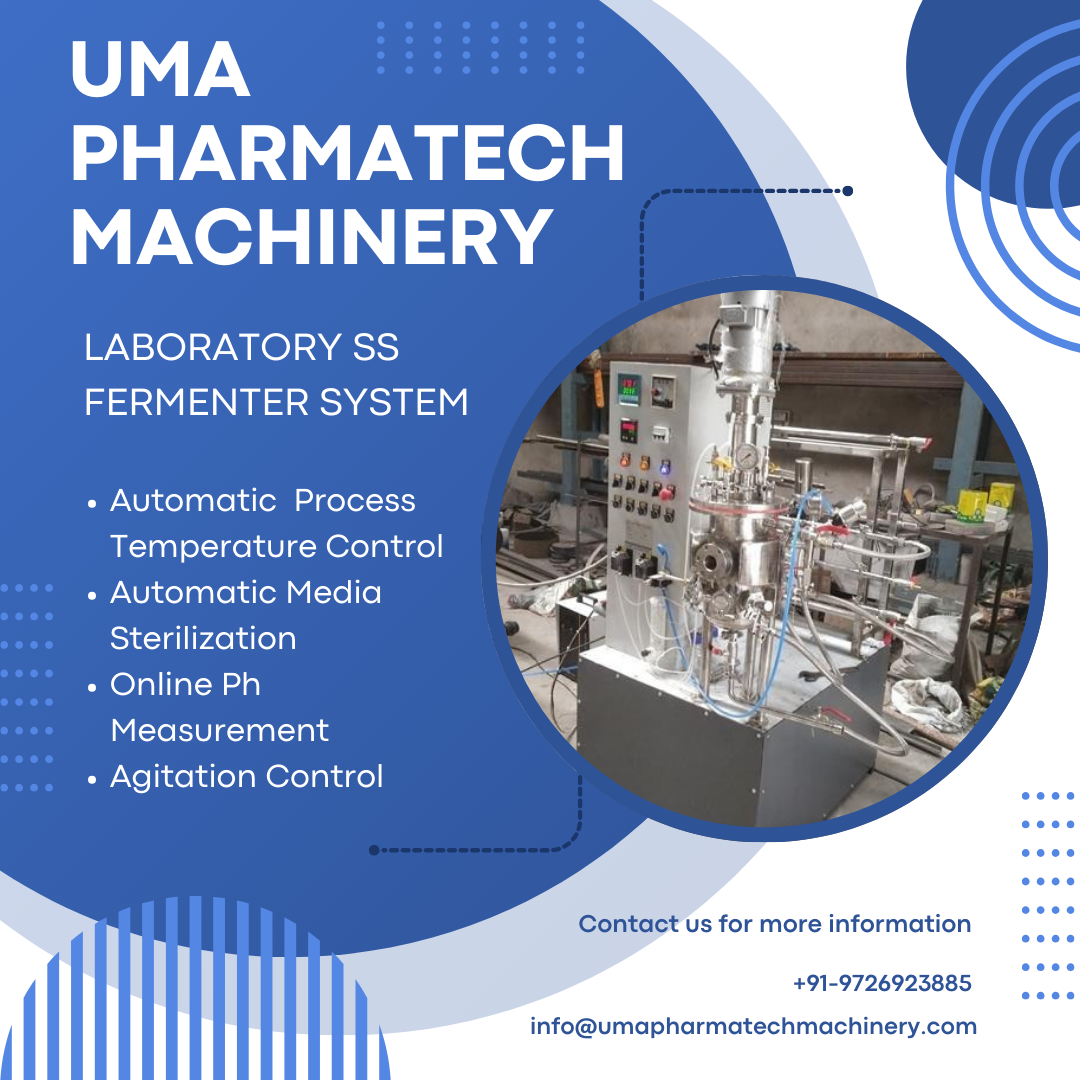

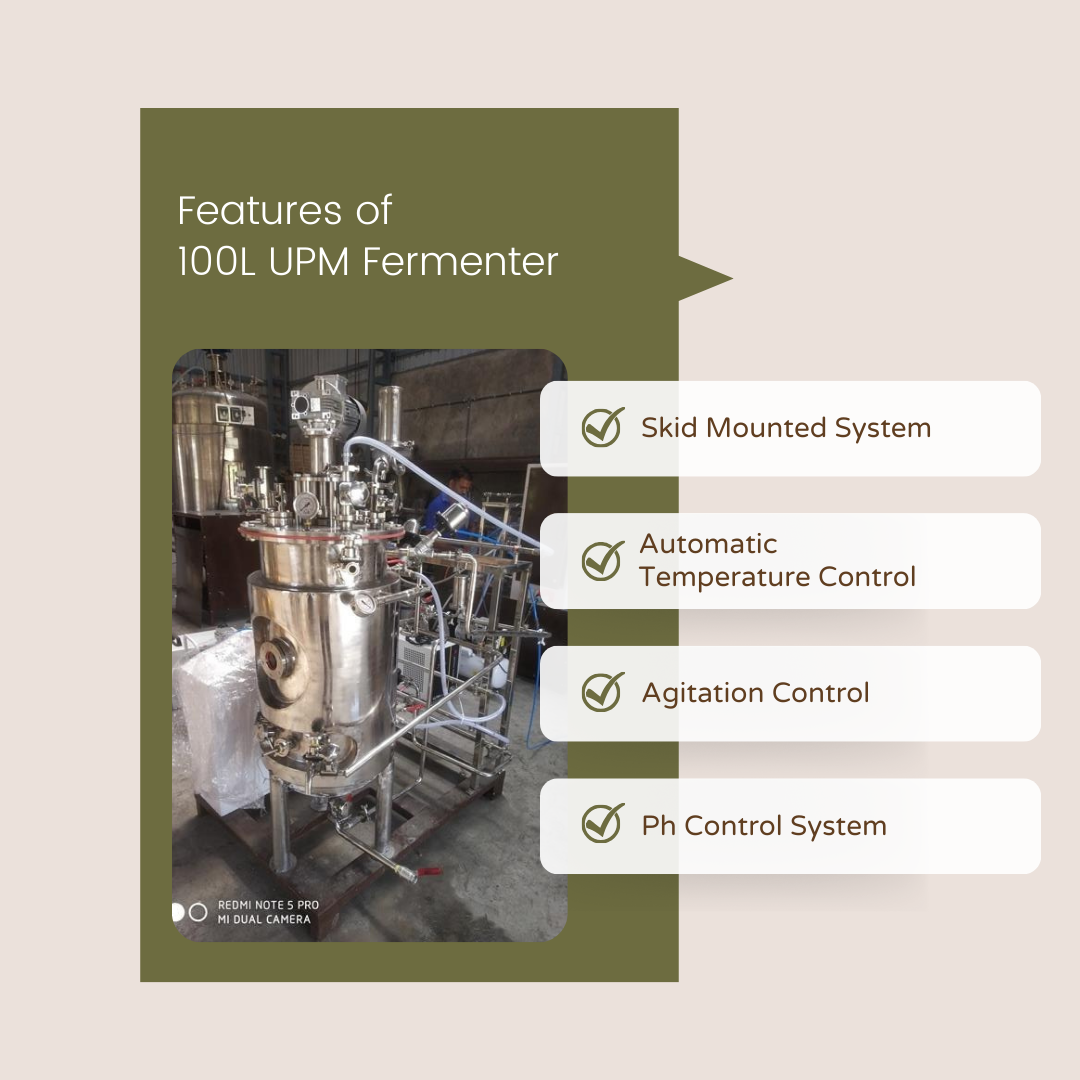

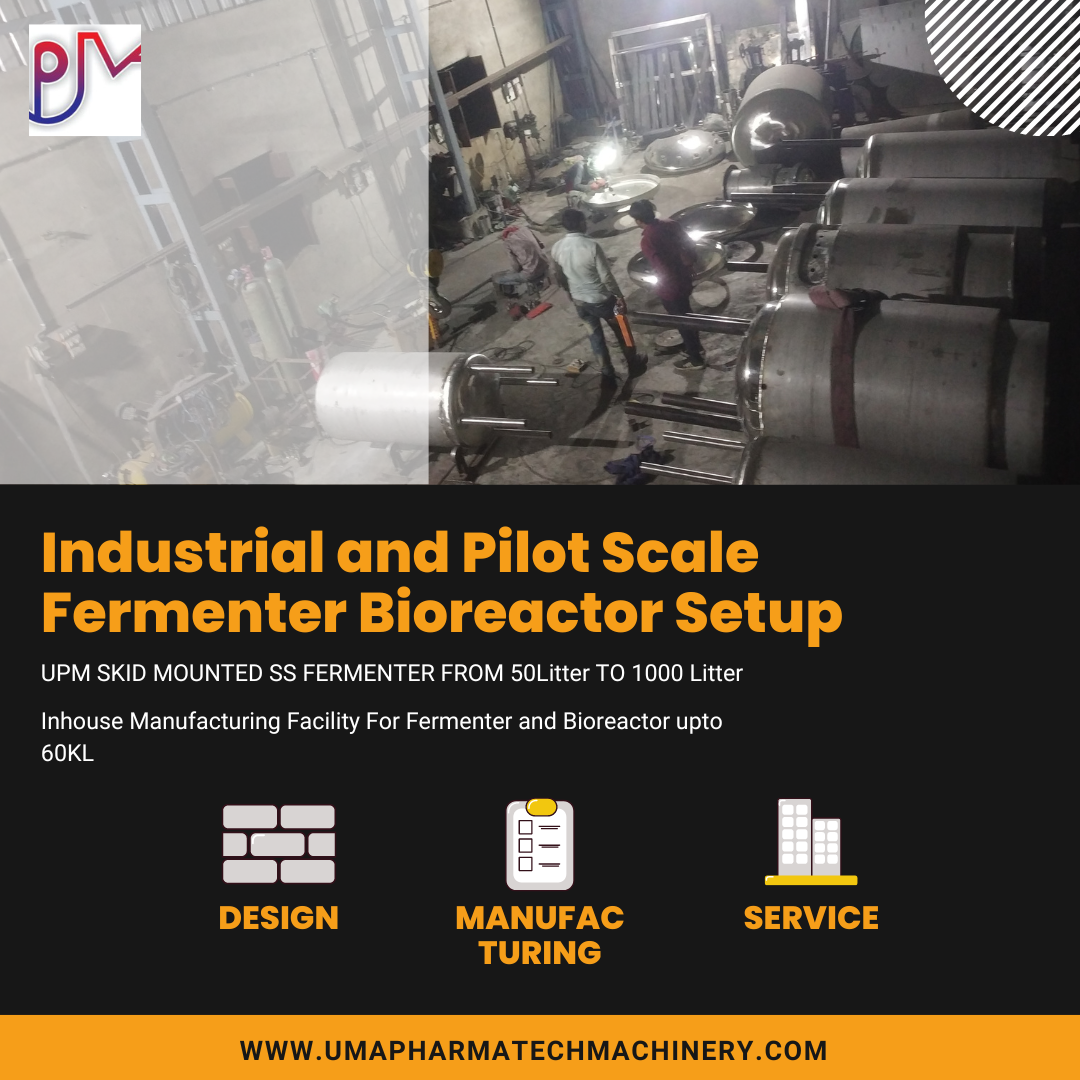

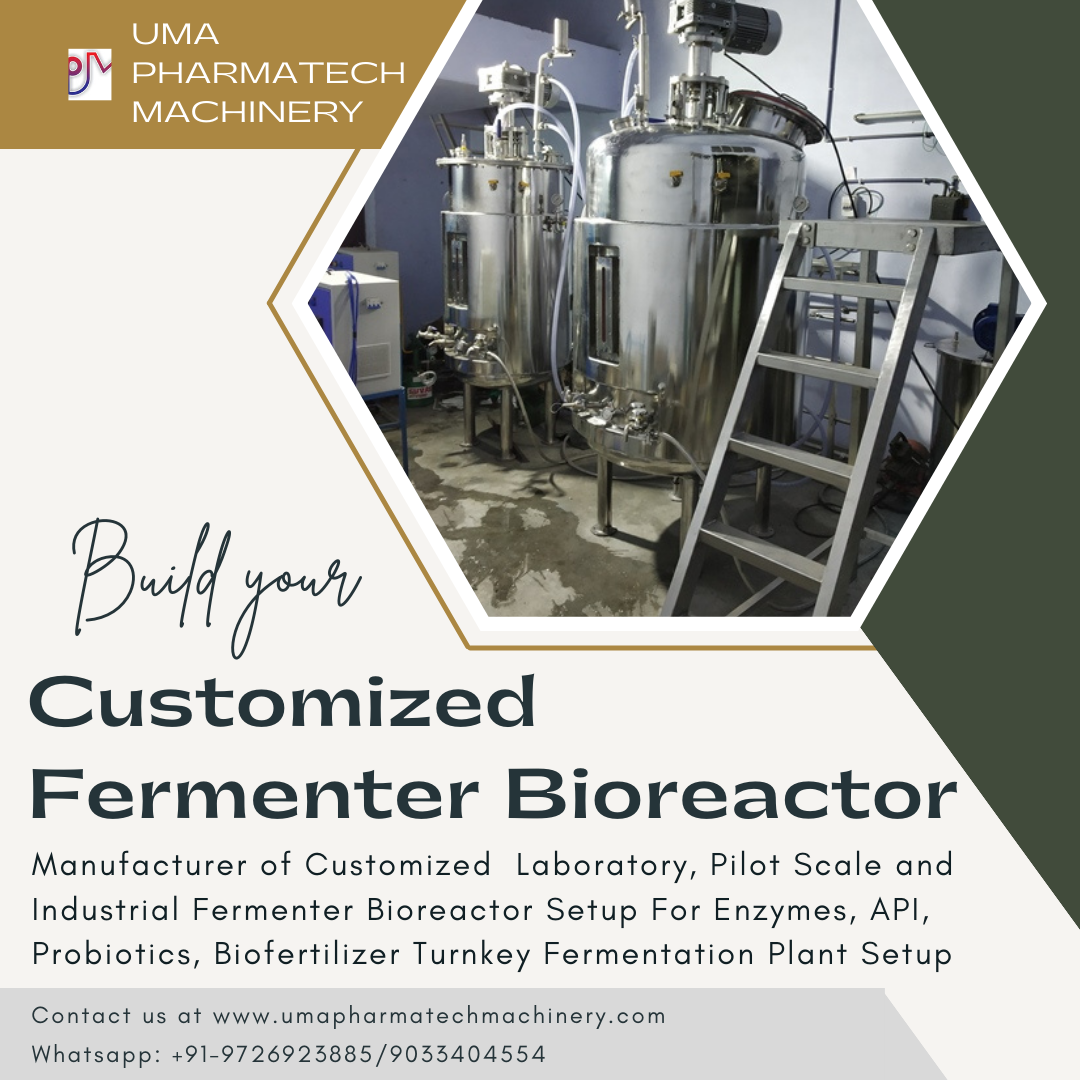

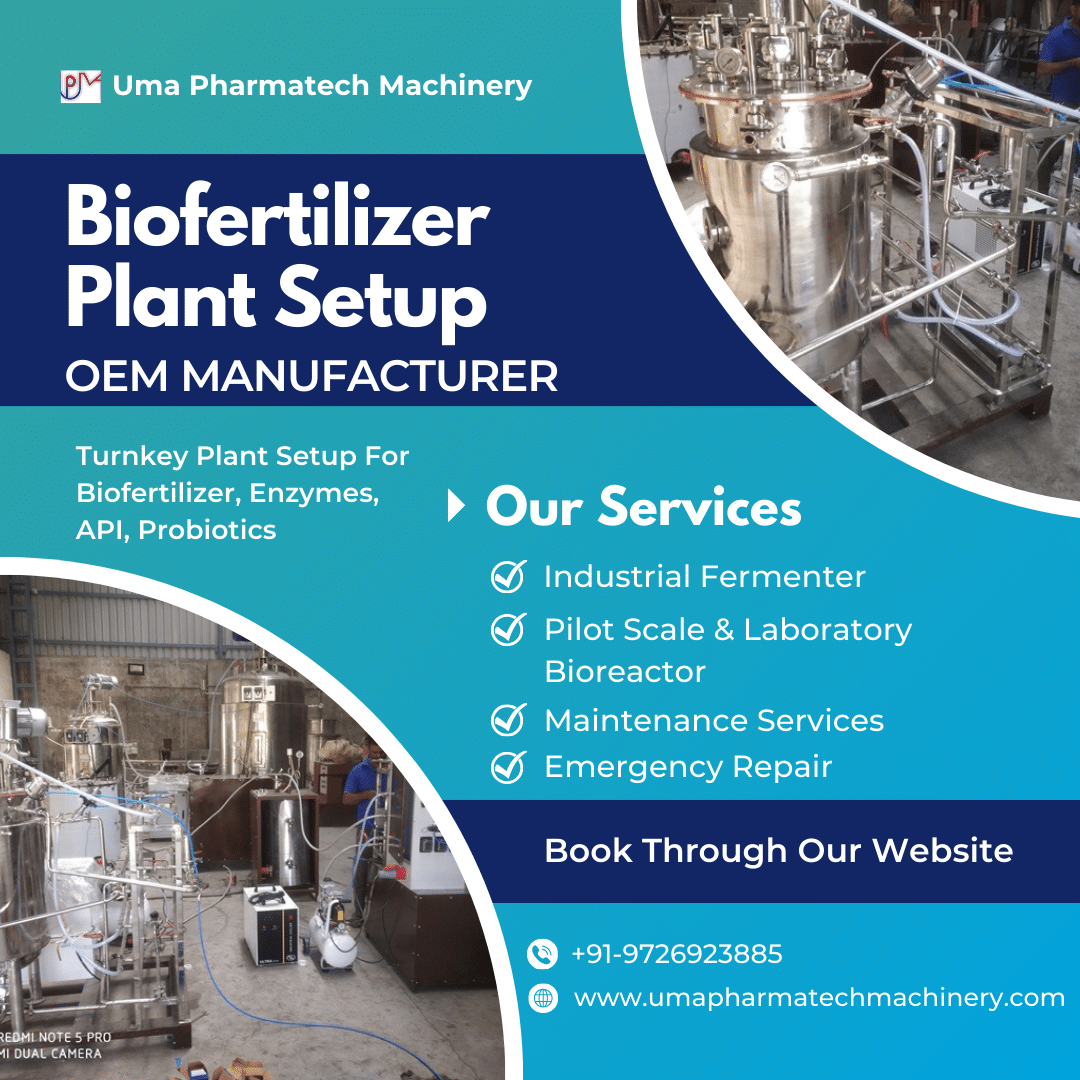

Many Company are available In Indian Market For Laboratory Fermenter Bioreactor. Uma Pharmatech Machinery is One Of The Trusted Brand For Manufacturing Of Pilot Scale Fermenter and Industrial Bioreactors. UPM Provide Best Quality and Automatic Bioreactor Manufacturer in India. Uma Pharmatech Present Low Cost Industrial Fermenter Bioreactor With All Necessary Equipments Like Compressor, Chiller, Steam Boiler, Cooling Tower, Pipeline, Skid Erc..

Lab Model Of Microbial Bioreactor Price Start From 500000/- Per Fermentation Plant Setup.

Pilot Scale Model Of Microbial Bioreactor Price Start From 1500000/- Per Fermentation Plant Setup.

Lab Model Of Microbial Bioreactor Price Start From 2500000/- Per Fermentation Plant Setup.

Types of Fermenter Vessels

There are several types of fermenter vessels on the market, each with its own set of characteristics and applications. Among the most common types are:

source site Open Fermenters: These vessels have an open top that allows gases to exchange during the fermentation process. They are widely used in the manufacture of beer and wine.

https://www.insearchofsukoon.com/ry02a3i Closed fermenters are vessels that are sealed and exchange gases through a vent. They are widely used in the manufacture of beer, wine, and other fermented beverages.

go site Conical fermenters have a cone-shaped bottom that allows solids and liquids to separate during the fermentation process. They’re very common in the brewing industry.

https://etbscreenwriting.com/ax5cr7gq8g8 Jacketed fermenters have a double wall that allows for temperature control during the fermentation process. They are frequently used in the manufacture of beer, wine, and dairy products.

Benefits of Fermenter Vessels For API

Precise Temperature Control: Temperature control systems in fermenter vessels enable precise temperature control during the fermentation process, resulting in consistent and high-quality products.

Improved Product Quality: Fermenter vessels aid in maintaining a sterile environment, preventing contamination and ensuring the final product’s quality.

Fermenter vessels can be designed to increase production efficiency, allowing for larger batches and shorter manufacturing times.

Applications of Fermenter Vessels For Biofertilizer

Fermenter vessels are used in a variety of industries, including:

Fermenter vessels are used in the brewing industry to produce beer, ale, and other alcoholic beverages.

Fermenter vessels are used in the wine industry to produce wine, cider, and other fermented beverages.

Fermenter vessels are used in the dairy industry to produce cultured dairy products such as yoghurt, kefir, and sour cream.

Fermenter Manufacturers

Uma Pharmatech Machinery, a pioneering Tramadol Buy Usa fermenter manufacturer and https://ict-pulse.com/2024/07/7s35s192d bioreactor manufacturer based in Jamshedpur, India, stands as a beacon of innovation and quality. With a comprehensive range of solutions, they lead the league of industrial fermenter and bioreactor suppliers across India’s vibrant landscape. Their expertise extends nationwide, spanning cities like Mumbai, Delhi, Kolkata, and beyond, as well as catering to international markets, including the USA, UK, and UAE.

Industrial Fermenter

Fermenter Suppliers

Bioreactor Suppliers

For research endeavors, their range encompasses the efficient laboratory fermenter for cell culture, while for larger operations, they stand tall as industrial fermenter manufacturers and pilot-scale fermenter manufacturers. In the realm of biofertilizer production, Uma Pharmatech Machinery’s fermenters shine, just as their bioreactors excel in enzyme production setups.

Fermenter Manufacturing Companies in India

Bioreactor Manufacturing Companies in India

Fermenter For Biofertilizer Production

As one of the foremost fermenter manufacturing companies in India and bioreactor manufacturing companies in India, Uma Pharmatech Machinery crafts cutting-edge equipment like the sought-after automatic fermenter and sturdy fermentation tanks. While ensuring top-tier quality, they remain sensitive to the cost of fermenter and bioreactor price, making advanced solutions accessible across scales.

Fermentation Tank Manufacturers

As trailblazing fermentation tank manufacturers, we redefine the art of large-scale bioprocessing. Our tanks embody precision engineering, fostering optimal microbial growth and product yields. From pharmaceuticals to food, our vessels provide the foundation for successful fermentation processes. With a commitment to innovation, we elevate industrial fermentation, delivering equipment that empowers progress.

Cost Of Fermenter, Bioreactor Price

Navigating the path of progress shouldn’t be hindered by budget concerns. Discover competitive solutions with transparency in the cost of fermenter. Our offerings ensure affordability without compromising quality. With a range of options, you can access cutting-edge fermentation equipment tailored to your requirements, driving efficiency and innovation.

Production Fermenter Manufacturers

Uma Pharmatech Machinery’s influence reaches across India’s expanse, including states like Maharashtra, Uttar Pradesh, and Tamil Nadu, fostering progress from Jamshedpur to Mumbai and Chennai. Their excellence isn’t confined to national boundaries; they are distinguished fermenter exporters and bioreactor exporters with a global footprint.

Laboratory Fermenter Cost

Unveil the future of research with our cost-effective laboratory fermenter solutions. We understand the significance of budget-conscious science, offering high-quality equipment at competitive prices. Our lab fermenters enable precise cultivation of microorganisms, yielding valuable insights across various fields. Embrace affordability without compromising on performance, driving innovation from the lab bench to publications and beyond.

Industrial Fermenter Manufacturers

As pioneers among industrial fermenter manufacturers, we shape the landscape of large-scale bioprocessing. With a legacy of engineering excellence, we craft fermenters that power diverse industries. From pharmaceuticals to biofuels, our robust equipment ensures consistent production and optimal yields. With a focus on quality and innovation, we stand as partners in progress, enabling seamless industrial fermentation for a sustainable future.

Pilot Scale Fermenter Manufacturers

Crafted with precision, their stainless-steel fermenters and glass fermenters reflect unmatched dedication. As the sun never sets on Uma Pharmatech Machinery’s commitment to excellence, they continue to illuminate the path for fermenter and bioreactor solutions, enriching laboratories, industries, and landscapes across the world.

Bioreactor For Enzymes Production

Our advanced bioreactor for enzymes production stands at the forefront of biotechnology. Engineered for precision and efficiency, it’s the cornerstone of enzymatic processes. From pharmaceuticals to food and beyond, our bioreactor ensures optimized yields and consistent quality. With innovative design and automation, it streamlines enzyme cultivation, reducing production timelines and costs. Embrace the power of cutting-edge technology for enzymatic excellence.

Laboratory Fermenter For Cell Culture

In the realm of research, our laboratory fermenter for cell culture is a testament to innovation. Tailored for controlled growth environments, it nurtures cells for diverse applications. From studying disease mechanisms to producing biologics, our fermenter enables reproducible results. With precise control over parameters, it mirrors in vivo conditions, advancing scientific understanding. Elevate your cell culture research with a versatile and reliable laboratory fermenter, propelling breakthroughs from bench to bedside.

Fermenter Exporters

Bioreactor Exporters

As premier bioreactor exporters, we bridge scientific frontiers globally. Our cutting-edge bioreactors empower industries, facilitating advanced research and production. We’re committed to driving innovation across international borders, delivering tailored solutions to diverse biotech sectors. With precision engineering and quality assurance, our bioreactors redefine possibilities, nurturing progress on a global scale.

Stainless Steel Fermenter Manufacturers

Crafting excellence, we stand as leading stainless steel fermenter manufacturers. Our vessels uphold the highest standards, blending robustness with hygiene. Catering to diverse applications, we empower industries with reliable equipment. From pharmaceuticals to biofuels, our fermenters lay the foundation for success, ensuring optimal outcomes and seamless operations.

Glass Fermenter Suppliers

As dedicated glass fermenter suppliers, transparency is our hallmark. We provide vessels that foster observation and control, vital for research and process optimization. Our glass fermenters, designed with precision, cater to microbiology, biopharma, and more. With a commitment to clarity, we empower scientists and engineers to visualize progress, sparking advancements across scientific landscapes.

Exporters of Fermenter From India

Finally, fermenter vessels are an important part of the brewing and fermentation industries, and selecting the right vessel can make a significant difference in the quality and efficiency of the production process. We Are Leading Manufacturer Of Industrial Fermenter. We Also Registered Indian Exporter Of Fermenter and Bioreactors.