- Laboratory Fermenter: 350000

- Glass Bioreactor: 210000

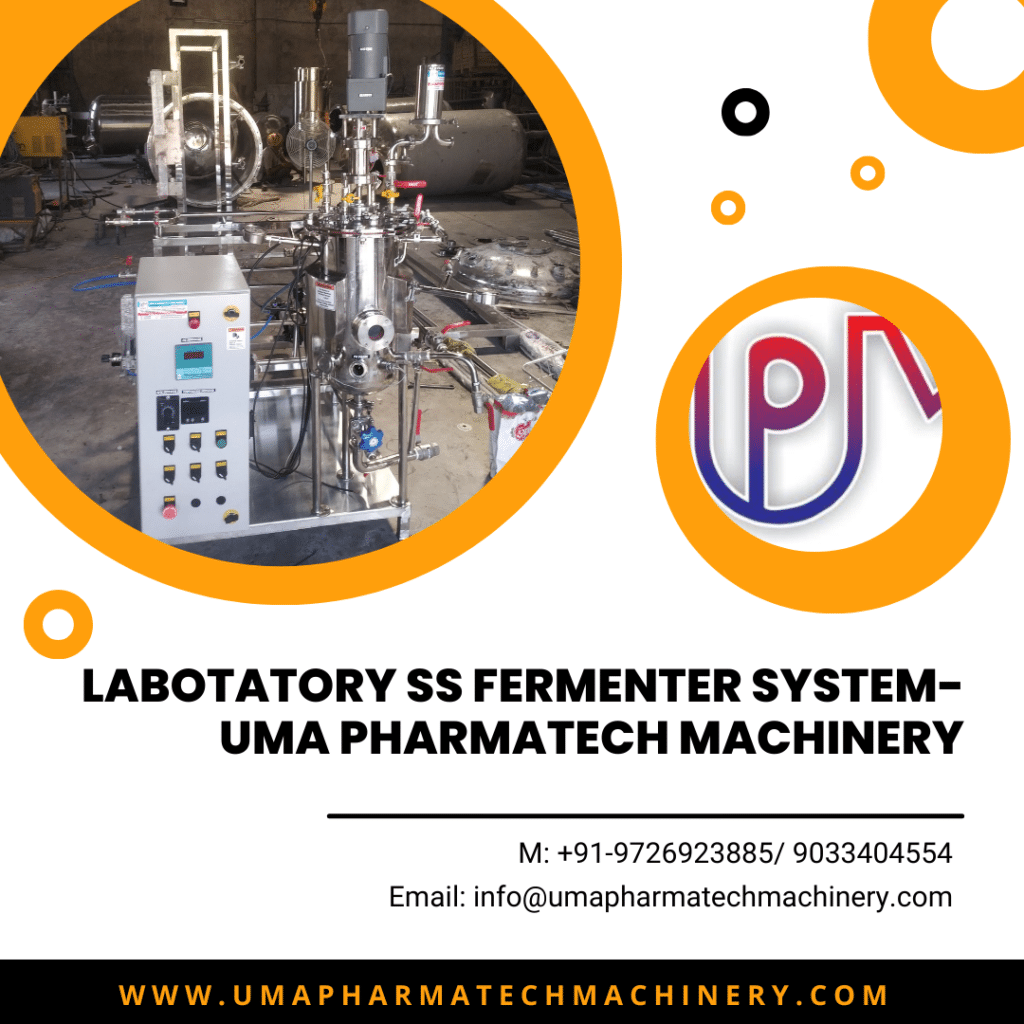

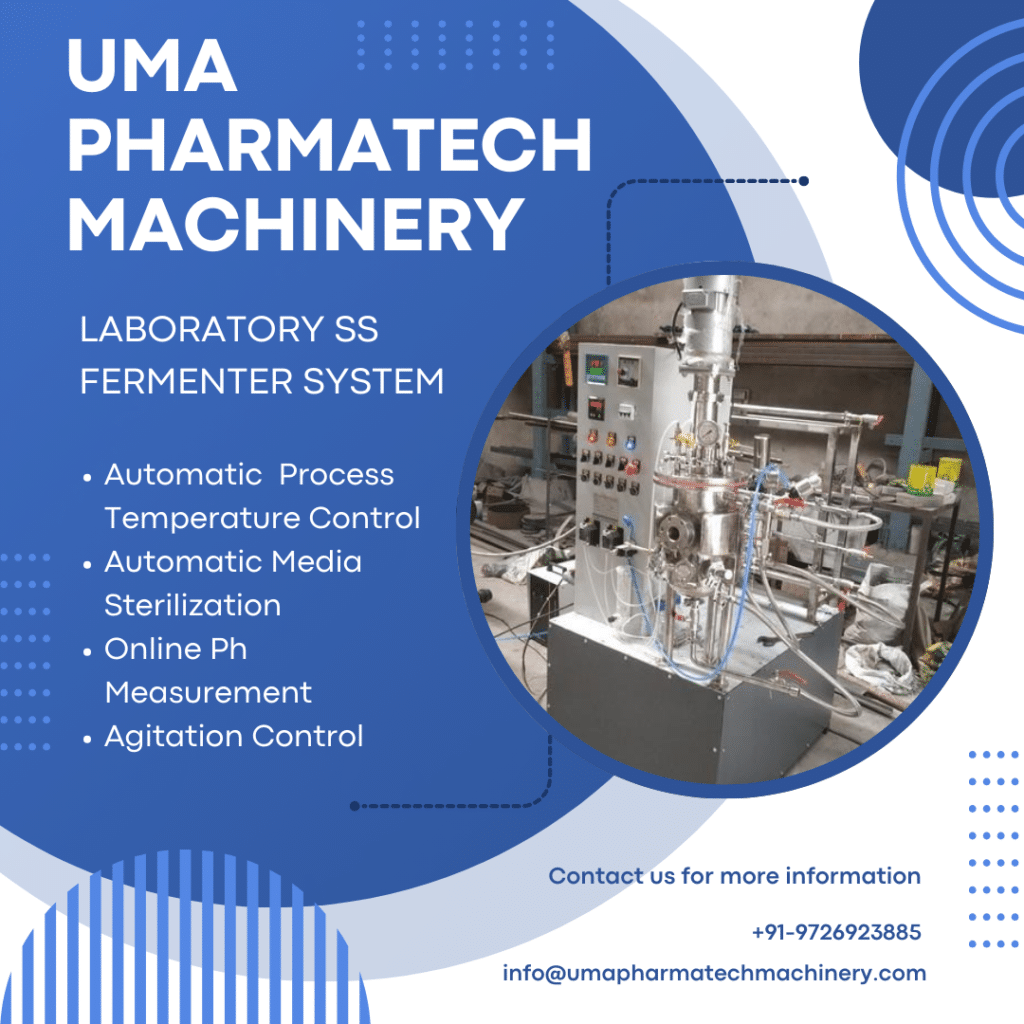

Stainless Steel Fermenter

Stainless Steel Fermenter Manufacturer In India

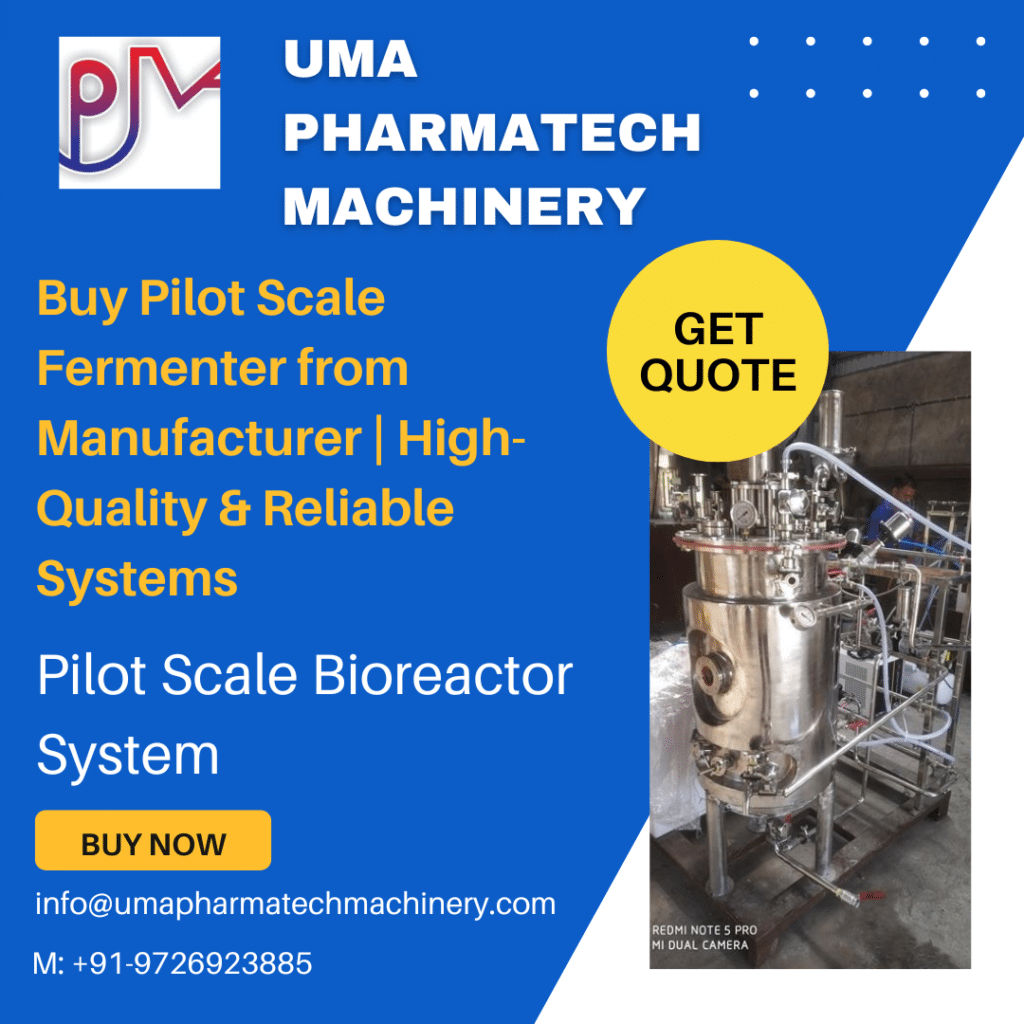

Uma Pharmatech Is Well Known Brand For Manufacturing Of Stainless Steel Fermenter and Bioreactor in India. We Have Expertise In Stainless Steel Fermenter. Because Steel Is Our Family Business. We Have Well Experienced Team For Design Of Bioreactor and Stainless Steel Fermenter Manufacture. We Have Manufacturing Facility To Make Up to 60Kl Fermenter Inhouse Production In India.

| Description | Economic | Basic | Advance | Pro |

| Fermenter With Utility | ||||

| Steam Boiler | No | No | Yes | Yes |

| Chiller | No | No | Yes | Yes |

| Compressor | Yes | Yes | Yes | Yes |

| Probe | ||||

| Temperature Sensor(Pt-100) | Yes | Yes | Yes | Yes |

| online ph measurement | No | Yes | Yes | Yes |

| ph control With 2 Nos Peristaltic Pump | No | No | Yes | Yes |

| DO Sensor With 3 Meter Cable and Transmitter | No | No | Optional | Yes |

| Do Control | No | No | No | Yes |

| Load Cell | No | No | No | Yes |

| Control | ||||

| Controlling Processor | Microprocessor | PLC Based Without Data Logging | PLC With Data Logging Facility(Touch Screen 4″ HMI) | PLC With Data Logging Facility (Touch Screen 7″ HMI) |

| Scada | No | No | No | YES |

| Inbuilt Heater in Vessel(Suitable For Biofertilizer Production) | Optional | Yes | NO | NO |

| Agitation Control | No | Yes | Yes | Yes |

| Automatic Media Sterilization | No | Yes | Yes | Yes |

| Auto Filter Sterilization | No | No | No | Yes |

| Process Temperature Control | Yes | Up To Atmospheric | Yes | Yes |

| Aeration Control By Rotameter | Yes | Yes | Yes | Yes |

| Pressure Control | Yes | Yes | Yes | Yes |

| Dual Exhaust filter | No | No | No | YES |

| Spray ball | Optional | Optional | Optional | Yes |

| Feed Control Peristaltic Pump | No | No | No | Yes |

| Antifoam Control Peristaltic Pump | No | No | No | Yes |

Introduction to Stainless Steel Fermenters

Stainless steel fermenters have revolutionized the fermentation industry, providing unmatched durability, hygiene, and efficiency. These fermenters are essential for a variety of applications, including brewing, pharmaceuticals, and biotechnology. Our cutting-edge stainless steel fermenters are designed to meet the highest industry standards, ensuring optimal performance and reliability.

Buy Fermenter From OEM Manufacturers

Key Features of Stainless Steel Fermenters

Superior Material Quality

Our stainless steel fermenters are constructed from high-grade stainless steel, ensuring excellent resistance to corrosion and wear. This material choice guarantees a long lifespan and minimal maintenance requirements.

- Corrosion Resistance: Stainless steel offers exceptional resistance to rust and chemical damage, making it ideal for fermentation processes involving acidic or alkaline substances.

- Durability: The robust nature of stainless steel ensures that our fermenters can withstand high pressure and temperature variations without compromising structural integrity.

Get Qupte Industrial-and-Laboratory-Fermenter-Manufacturers-Uma-Pharmatech

Advanced Design and Engineering

We employ state-of-the-art engineering techniques to design fermenters that maximize efficiency and productivity.

- Precision Engineering: Our fermenters are meticulously crafted to ensure uniformity in wall thickness and smooth internal surfaces, minimizing contamination risks and facilitating easy cleaning.

- Customizable Options: We offer a range of customization options, including varying capacities, configurations, and additional features to meet specific client requirements.

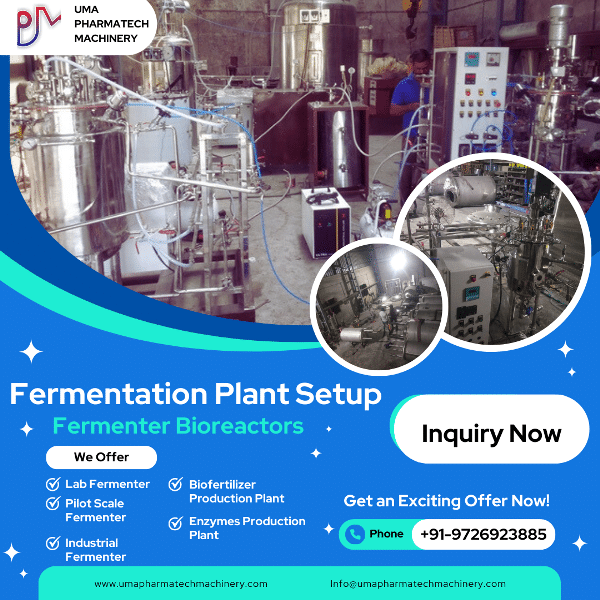

Applications of Stainless Steel Fermenters

Stainless steel fermenters are versatile tools used in multiple industries for various fermentation processes.

Brewing Industry

In the brewing industry, stainless steel fermenters are indispensable for producing high-quality beer. They provide a controlled environment that ensures consistent fermentation, leading to superior taste and quality.

Pharmaceutical Industry

For the pharmaceutical industry, stainless steel fermenters are crucial in the production of antibiotics, vaccines, and other biologics. Their sterile design and ease of sterilization make them ideal for maintaining the purity and integrity of pharmaceutical products.

Biotechnology

In biotechnology, these fermenters are used for culturing microorganisms and cells. Their precise control over environmental conditions such as temperature, pH, and oxygen levels is vital for successful biotechnological applications.

Top Biofermenter Manufacturer and Suppliers For Biofertilizer, Enzymes, API, Probiotics

Advantages of Using Stainless Steel Fermenters

Hygiene and Sanitation

Stainless steel is inherently easy to clean, reducing the risk of contamination. Our fermenters feature smooth, polished interiors that prevent microbial build-up and make thorough cleaning simple and efficient.

Temperature Control

Our fermenters are equipped with advanced temperature control systems, ensuring optimal fermentation conditions. This precise control is crucial for maintaining the quality and consistency of the final product.

Manufacturer Of Pilot Scale Fermenter Bioreactor Manufacturer

Choosing the Right Stainless Steel Fermenter

When selecting a stainless steel fermenter, consider the following factors to ensure you choose the best fit for your needs:

- Capacity: Determine the volume of production to select a fermenter with appropriate capacity.

- Configuration: Choose between vertical and horizontal configurations based on space constraints and operational preferences.

- Additional Features: Consider features such as automated control systems, agitation mechanisms, and sampling ports to enhance functionality.

Manufacturer of Industrial Fermenter andBioreactor

industrial fermenter Manufacturer

now I’m going to rinse the probes and put them into the head plate. we’re just going to insert the pH probe the temperature probe does not get disconnected. so just connect the pH probe and insert it and screw it into the head break. all right and now the protective cap on the top should be replaced back on. check that part during the autoclave all right now we’re going to attach the tubing. we have three sets of tubing with filters on it. and please note that filters have an inlet side their air filters well. gas filters I guess we should say there’s an inlet side and there’s a side that’s not marked Inlet. so we have to think about the direction of the flow of the gas air co2 or whatever is coming out of the industrial fermenter. one of the filters is going to go on the condenser port. and in that case theist’s going to be going gases from the buyer actor out through the condenser and into the room. so the flow of air there is from the industrial scale fermenter into the room.

laboratory fermenter price

so we want the gas to pass through the inlet first. so we’re going to put the inlet side facing the condenser. and it’s this top tube here. now you can see that’s not the inlet that’s the inlet so we’ll go from fermenter bioreactor through the inlet and then out into the room for the other two the co2 overlay. the Spurger the inlets are going to be going from the gas Fermentation tank through the filter. it says Inlet here can’t really see it very well into the fermentor and bioreactor. so the inlet side here should be facing away from the head plate. so here is our co2 overlay right next to the condenser. and the Spurger is on the other side. here’s this larger so this larger here’s the inlet point in to the lab scale bioreactor. and for the co2 overlay in to the buck through in first and then into the lab bioreactor.

Fermenter Manufacturer in Gujarat

laboratory scale fermenter

since we’re only going to use one opening of the three-way addition port. we want to close off the other two the easiest way to do that let’s take a piece of tubing and connect it to two of them. so that they are now closed off and won’t allow anything from the room to get in there. now for the last position on the three-way port right there. we’re going to connect our feed bottle that’s going to adjust the pH. that’s going to on the third spot. and we can just secure it with that cable tie which is already on it. now we still have one opening we have the harvest tube opening you remember that’s like a straw.

Laboratory Fermenter Manufacturers

Energy Efficiency

Designed with energy efficiency in mind, our stainless steel fermenters incorporate innovative insulation technologies that minimize energy consumption while maintaining optimal fermentation temperatures.