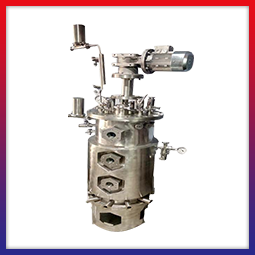

1000L SS Pilot Scale Fermenter

Pilot Scale Fermenter Manufacturer

Uma Pharmatech Manufacture Pilot Scale Fermenter In India. We Supply Up To 10kl Pilot Scale Fermenter and bioreactor For Various Application In Biotech , Pharmaceutical and Agriculture Industries.

List Of Fermenter Manufacturing Companies

| Total Volume | 1000L |

|---|---|

| Working Volume | 70% Of Total Volume |

| Contact Part | SS 316L |

| Non Contact Part | SS304 |

| Sheet Thickness | 5 mm |

| Inner Finish | Mirror Finish |

| Outer Finish | Matt Finish |

| Motor | 3 HP |

| RPM | 144 |

| Speed Control | Using VFD(Variable Frequency Drive) |

| Design Temperature | 130 Degree Celcius |

| Temperature Sensor | PT-100 |

| Design Temperature | 121 Degree Celcius |

| Max. Operating Temperature | 121 Degree Celcius |

| Design Pressure | 6 kg/cm2 |

| Max. Operating Pressure Of Jacket | 4 kg/cm2 |

| Max. Operating Pressure Of Vessel | 1.2 kg/cm2 |

| Safety Valve | Adjustable Spring Operated |

| Pressure Indicator | Analog Type |

| Air Outlet | 0.2 Micron PP Filter With 5” SS 316L Filter Housing |

| Air Inlet | 0.2 Micron PP Filter With 5” SS 316L Filter Housing |

| Air Outlet Through | Through Shell Tube Type Condenser ( Heat Exchanger) |

| Sparger System | Ring Type Air Spurger System At Bottom |

| Sealing | Mech seal/ Stuffing Box |

| Baffle | 4 Nos( Size Vessel Dia/10) |

| Impeller | 3 Nos Of Adjustable Ruston Turbine( Six Blade) |

| Bottom End | Dish End With 50 mm Tc Drain Valve For Material Outlet |

| Sight Glass | Toughen Glass |

| Top Glass | Toughen Glass |

| Top Light Glass | Toughen Glass |

UPM Is One Of The Leading and Well Known Brand For Pilot Scale Fermenter Manufacturer in India. Uma Pharmatech Machinery Manufacturer & supply ss Pilot Scale Fermenter and Bioreactor For Pharmaceutical API Bulk Drug, Bio Tech, Life Science, Probiotics, Biofertilizer and Biopesticides Manufacturing, Enzymes Manufacturing. Pilot Scale Fermenter manufacturer 1000Litter and -100Litter Set Manufacture By Us. We Manufacture and Supply Pilot Scale Fermenter With Utility Like Chiller, Oil Free Air Compressor, Steam Generator, SS Skid and Pipeline, Automation. UPM Fermenter Comes With Automatic Controlling With Advance State Of Art Techniques.

We Have Specialized Design and Manufacturing Team For Manufacture High Quality and State Of Are Technique To Manufacture Pilot Scale Fermenter and Bioreactor in India. For Fully Automatic Controlling and Data Logging We Have Best Programmed For Pilot Fermenter Manufacturer Handle Without any Manpower. This Will Help To End User Customer For Cost Cutting and Low Maintenance with Best Performance and High Quality Product Manufacturing in India.

Pilot Scale Fermenter Manufacturer in India

Pilot Scale Fermenter Is Very Useful For MSME Who Start There Business With Small Investment in India. Our Manufacturing Facility For Fermenter and Bioreactor Manufacturing In Pilot Scale Is Located In Ahmedabad-Gujarat-India. We Supply Pilot Scale Fermenter and Bioreactor In Maharashtra, Karnataka, Odisha, Punjab, Haryana, West Bengal, Gujarat, Tamilnadu, Telangana, Rajasthan, Andhra Pradesh, Gujarat, Assam, Chhattisgarh, Goa, Jharkhand, Himachal Pradesh, Kerala, Madhya Pradesh, Manipur, Meghalaya, Nagaland, Tripura, Uttarakhand etc.

fermenter manufacturer in India

We Supply Fermenter and Bioreactor in Gujarat Most Cities Like Surat, Ahmedabad, Jamnagar, Bhavnagar, Vadodara, Navsari, Rajkot, Gandhinagar, Anand, Patan, Bharuch, Ankleshwar, Gandhidham, Morbi, Palanpur, Mehsana, Vapi, Nadiad, Kutch, Mansa, Mandvi, Himmatnagar, Vyara, Rajpipla, Kheda, Dabhoi, Valsad, Bhuj, Palanpur, Dahej, Jetpur, Junagadh, Bharuch etc…

| Description | Technical Specification | Qty | Prize | ||

| 1000L Fermenter working volume(Total Volume 1300L)( With Inbuilt Heating System-24kw)-3 hp motor | Annexture 1 | 1 Nos | Contact Us On +91-9726923885

Or Email |

||

| ph Measurement System(Ph Sensor(Indian Made)+ Transmitter+ 3 meter Cable) | |||||

| Automatic Ph Controlling System With 2 Nos Peristaltic Pump+ 1 L Glass Bottle With Ph Attachment Pump Needle+ 0.2 Microne Air Vent+ Siticon Tube | |||||

| Automatic Pressure Control System In Vessel | |||||

| Automatic Temperature Control | |||||

| Automatic Media Sterilization | |||||

| Automatic Sequencing System With Automatic Solenoid Control Valve | |||||

| data Logging Facility For Temperature, Ph | |||||

| Load Cell (500 kg) For Feeding media | |||||

| SS Filter Housing Set With 0.2 Microne PP Plated Filter Cartridge | 2 set | ||||

| Oil Free Air Compressor(3 hp) | Annexture 3 | 1 Nos | |||

| Chiller(1 tr) With Inbuilt 40L SS Tank | Annexture 4 | 1 Nos | |||

| Electric Steam Generator(24 Kw) | Annexture 5 | 1 Nos | |||

| Common Control Panel BOX ( 1300L) with PLC Processing Programming with 4 inch Touch Screen HMI Control System with Fully Automatic Media Sterilization and VFD For Agitation Speed Control | 1 Nos | ||||

| Commercial Terms and Condition | |||||

| Prize Basis | Ex Factory Ahmedabad | ||||

| Packing | 1%Extra | ||||

| Freight & Insurance | By Purchase | ||||

| GST | Eatra as applicable at the time of dispatch, preseently GST 18% | ||||

| Installation | By customer at their site( Extra By Us ) | ||||

| Payment | 60% Advance and Balance Against Proforma Invoice Before Dispatch | ||||

| Annexture 1 | |||||

| Fermenter Vessel Details | |||||

| Total Volume(Litter) | 1300 | ||||

| Diameter(mm) | 1000 | ||||

| Straight Height(mm) | 1630 | ||||

| shell(cylindrical) | 5 mm thk ss 316 | ||||

| Jacket | 5 mmthk SS 304 | ||||

| Top | Dished end( 10% torispherical) | ||||

| Bottom | Dished end( 10% torispherical) | ||||

| leg | mild steel | ||||

| Baffle Recommendation(Off Wall) | 4 Nos @ 90 Degree | ||||

| manhole | Yes(Eliptical) | ||||

| Inner Finish | Mirror Finish | ||||

| Outer finish | Matt Finish | ||||

| Nozzles-Standard suitable Tc Ferrule or Nipple | |||||

| Total Height | to be confirmed | ||||

| Design Criteria | |||||

| Viscosity | 100 cP | SG | 1.1 | ||

| Pressure | FV to 3kg/cm2 | Temp | 130 deg C | ||

| Mechanical Detail | |||||

| Sealing | single dry Mech Seal | ||||

| Gearbox (Elmech) | Worm Gearbox/inline helical | ||||

| Motor HP (Elmech) | 3 | NFLP, 4 Pole, Flanged, 3 Ph, 415 V, 50 Hz, | |||

| Impeller Type (From bottom) | Ruston Turbine | Ruston Turbine | |||

| Impeller Blade | 6 Blade | 6 Blade | |||

| Agitator Details | |||||

| MOC Contact Parts | SS 316 | Shaft Diameter | 50 mm | ||

| MOC Non-CP | MS/CS | Shaft Speed(RPM) | 144 | ||

| Air Flow Control | Rotameter(150 LPM) | Speed Controlling | Variable Frequency Drive | ||

| Scope of Supply | Design, manufactur, supply of UPM make agitator assembly. Which includes impeller blades with hub, shaft, lantern assembly with bearing housing etc. | ||||

| Scope of Buyer | Installation in scope of buyer Electricity, Water,Cooling Tower+ Pump Line To Fermenter, Drain Line,Cooling Tower, Valves and Fittings and Clamp In Buyer Scope | ||||

| Annexture 3 | |||||

| MODEL | PE 3 T NL | Working Pressure (KG/CM2) | 8 | ||

| Working Pressure (KG/CM2) | 8 | Piston Displacement (CFM) | 13.6 | ||

| Free Air Delivery (CFM) | 7 | Air Receiver (LTRS.) | 150 | ||

| Motor (H.P) | 3 | Electrical Condition | 415 Volts / 3 Phase / 50 Hz |

||

| Annexture 4 | |||||

| Capacity | 1 Tr | Medium To Be Cool | Water | ||

| Tank | 40L | inlet Temperature In Chiller | 35 Degree Celsius | ||

| Power Consumption | 3 kw | Outlet Temperature From Chiller | 15 Degree Celsius | ||

| Refrigerent | R-22 | Water Pump | 0.5HP | ||

| Annexture-5 | |||||

| Electric Steam Generator | |||||

| Capacity | 24kw | Capacity(steam output) | 32 kg/hr | ||

| Design Pressure:4kg/cm2 | 6 kg/cm2 | Maximum Operating Pressure: | 4kg/cm2 | ||

| Power Supply: | 440V/50Hz/Ac | SS Safety Valve(Mechanical Spring Type) | Adjustable | ||

| Base Structurex | MS | Material of construction of Shell(Chamber-125L): | ss 304 (30L Tank) | ||

| Insulation | Glass Wool | Temperature Sensor | PT100 | ||

| Pressure Switch | Den Force kp 36 | Pressure Guage | Jel Filled Dial Type | ||

| Controlling | Micro Processor Based Temperature Control With Digital Display | ||||

| Water Level | Automatic Feed Water With Level Tube | ||||

We Distribute Fermenter and Bioreactor in Maharashtra Cities Likewise Pune, Nagpur, Akola, Sangli, Mumbai, Aurangabad, Kolhapur, Amravati, Chandrapur, Dhule, Latur, Nanded, Jalgaon, Parbhani, Solapur, Jalna, Panvel, Yavatman, Bhusawal, Thane, Gondia, Wardha, Malegaon, Satara, Navi Mumbai, Ratnagiri etc.