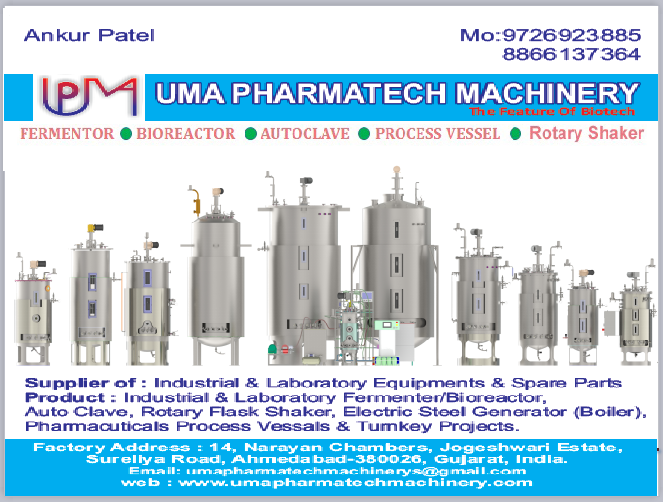

Turnkey Project

Companies from a variety of industries are continuously looking for effective and dependable solutions to improve their operations and increase their productivity in today’s cutthroat business environment. The popularity of turnkey projects has increased as a result of this pursuit of excellence. An all-inclusive solution that addresses all facet of a particular endeavor, from strategy and design through implementation and operation, is referred to as a turnkey project. We will delve into the realm of turnkey projects and their applications in the production of biofertilizers, the Manufacturing of APIs, the setup of enzyme production plants, the establishment of fermentation plants, and the setup of pilot-scale fermenters in this Website.

Turnkey Biofertilizer Project: Promoting Sustainable Agriculture

How Important Biofertilizers Are

Due to its favorable effects on agricultural practices and commitment to the environment, biofertilizers have attracted a lot of attention recently. These living-organic fertilizers assist increase soil fertility, increase nutrient availability, and encourage plant development. The demand for sustainable agriculture is increasing, and turnkey solutions for the manufacture of biofertilizer are essential.

Key Site Evaluation and Design Elements of a Turnkey Biofertilizer Project: To choose the best location for the biofertilizer production plant, a thorough investigation of the land is carried out. Considerations for the environment as well as accessibility to raw materials and transportation infrastructure are taken into account.

Bioreactor Manufacturers in Thailand-Pilot Scale Fermenter

Design, Manufacture and Installation: The turnkey project includes the purchase of the machinery and equipment required for the manufacturing of biofertilizer. All components are set up effectively and in compliance with industry standards during the installation procedure.

Process optimization: Skilled engineers and professionals raise the productivity and efficiency of the biofertilizer production process. They concentrate on elements like nutrient composition, microbial inoculants, and quality assurance procedures.

Quality Control and Regulatory Compliance: Strict quality control procedures are used to make sure that the biofertilizers meet the necessary requirements. To ensure product safety and market acceptance, compliance with pertinent standards and certifications is also crucial.

The Growth of the Biofertilizer Industry: The Impact of Turnkey Projects

The expansion and development of the biofertilizer sector are greatly aided by turnkey projects for the manufacturing of biofertilizer. These initiatives provide businesses a streamlined and affordable method for setting up biofertilizer production operations. Businesses can concentrate on their core strengths while leaving the challenges of project execution to competent hands by utilizing the experience of turnkey project providers.

Turnkey API Manufacturing Project: Strengthening Pharmaceutical Industry Knowledge Manufacturing API

The main ingredients that give pharmaceutical medications their therapeutic benefits are known as active pharmaceutical ingredients (APIs). To ensure purity, effectiveness, and safety when producing APIs, specialized facilities and exact manufacturing procedures are needed. API manufacturing turnkey projects provide end-to-end solutions that cover the whole production cycle for APIs.

A Turnkey API Manufacturing Project’s Facility Design and Construction Components include: During the design stage, a layout that maximizes safety, compliance with regulations, and workflow is created. The goal of the construction phase is to establish a cutting-edge facility with all the necessary utilities, infrastructure, and process machinery.

Installation of Equipment: Turnkey project providers aid in choosing the proper equipment for producing APIs, making sure that it is compatible with the planned manufacturing procedures. Installation is methodically done to ensure flawless functionality and integration.

Process Development and Validation: To create reliable manufacturing procedures for APIs, skilled individuals work with pharmaceutical specialists. To ensure that the production methods are consistent and reliable, extensive validation procedures are carried out.

Good Manufacturing Practices (GMP) compliance and strong quality control requirements must be followed in order to operate in the pharmaceutical sector. The establishment of systems and processes to ensure compliance and sustain high product quality is included in turnkey projects.

Fermenter Manufacturer In Bengaluru

Turnkey projects have benefits for API manufacturing.

Pharmaceutical firms can benefit from a number of advantages, including expedited project timeframes, lower costs, and decreased risks, by choosing turnkey solutions for API manufacture. Since turnkey project providers have the knowledge and skills to carry out projects effectively, APIs are always available when needed for drug production procedures.

Turnkey Enzyme Production Facility: Harnessing the Potential of Biocatalysts

Utilizing the Power of Enzymes

Biocatalysts known as enzymes are essential in many industrial processes, from the production of food to the creation of renewable energy. Establishing turnkey solutions for enzyme production facilities enables businesses to take use of biocatalyst potential and open up new avenues in a variety of industries.

Key Components of a Feasibility Study for a Turnkey Enzyme Production Project: To determine the technical and financial viability of the enzyme production facility, a thorough examination is carried out. There is an assessment of variables like market demand, raw material accessibility, and production scalability.

Plant Construction and Commissioning: The turnkey project includes building the enzyme production plant and verifying that it complies with safety regulations. Equipment and procedures are thoroughly tested and validated throughout the commissioning phase.

Automation and Control Systems: To monitor and manage the production of enzymes, cutting-edge automation and control systems are used. This improves productivity, lowers human error, and makes real-time data analysis possible.

rotary shaker

Production of Enzymes Changing Industries Complete Projects

Numerous sectors could undergo revolutions thanks to turnkey projects for enzyme production facilities. Pharmaceuticals, textiles, biofuels, food and beverage, and other industries all use enzymes. Companies can take advantage of the rising demand for eco-friendly and sustainable solutions by investing in turnkey projects, giving them a competitive advantage in the market.

Turnkey Fermentation Plant Setup Project: Facilitating Excellence in Bioprocessing

The Importance of Fermentation Facilities

The process of fermentation is essential for the creation of many different bioproducts, such as medicines, industrial enzymes, and biofuels. Companies can optimize productivity by streamlining their bioprocessing capabilities and establishing turnkey projects for fermentation plant setup.

Turnkey Fermentation Plant Project Design and Engineering Components: Fermentation plants are created by skilled engineers working with bioprocessing specialists to meet specific specifications. This entails choosing appropriate bioreactors, refining process variables, and including post-processing procedures.

Installation and Integration: Turnkey project managers supervise the installation of fermentation machinery and guarantee correct system integration. This covers services, command systems, and tools for environmental monitoring.

industrial fermenter- uma pharmatech

Process optimization and scaling up: Skilled bioprocess engineers optimize productivity, yield, and product quality by fine-tuning fermentation parameters. To enable smooth transitions from laboratory-scale to commercial-scale production, scale-up studies are carried out.

Training and technical support: Complete training program for staff members involved in fermentation plant operations are frequently included in turnkey projects. In order to handle any difficulties or problems that might emerge during the early phases of operation, technical help is also offered.

Turnkey Fermentation Projects: Unlocking the Potential of Bioprocessing

Companies can utilize turnkey projects for fermentation plant setup to fully utilize bioprocessing technologies. Businesses can increase their production capabilities, improve product quality, and investigate new potential for growth in the biomanufacturing industries by employing effective and reliable fermentation methods.

Industrial Reactor and Vessel For Fermentation Plant

Creating a Pilot-Scale Fermenter Turnkey Project: From Research and Development to Production

Pilot-Scale Fermenters’ Function

In the biotechnology and biopharmaceutical industries, pilot-scale fermenters play an essential role as a link between research and commercial production. Before ramping up to full production, these fermentation systems allow businesses to evaluate and optimize their operations at a lower scale. This crucial transition is facilitated by turnkey projects for pilot-scale fermenter setup.

Key Design and Configuration Elements for a Turnkey Pilot-Scale Fermenter Project: Pilot-scale fermenters that reproduce and simulate the appropriate production conditions are designed by skilled engineers in close collaboration with researchers and scientists. This entails picking appropriate vessel sizes, including cutting-edge control systems, and guaranteeing scalability.

In order to set up a pilot-scale fermenter, turnkey project suppliers help with the equipment procurement and installation process. They keep an eye on the installation procedure, making sure the calibration and functionality are correct.

Process Validation and Optimization: The turnkey project covers in-depth processes for process validation and optimization. This guarantees that the fermenter at the pilot-scale functions effectively, generating reliable findings that can be extrapolated to larger-scale production.

Biofertilizer Lab Equipment Manufacturers in India

Turnkey Projects for Pilot-Scale Fermenters to Speed Up Innovation

Businesses can quicken the pace of their innovation and research efforts by investing in turnkey solutions for the setup of pilot-scale fermenters. Enhancing efficiency, lowering risks, and facilitating a more seamless transition from laboratory discoveries to marketable goods are all made possible by the capacity to bridge the gap between R&D and full-scale manufacturing.

Analysis and Reporting of Data: The pilot-scale fermenter setup includes sophisticated data collecting and analysis devices. This enables scientists and researchers to gather important data, track critical performance indicators, and produce detailed reports for analysis and decision-making.

Autoclave Sterilizer For Laboratory